The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  What's the current finish of choice?

What's the current finish of choice?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I haven't finished a stock in thirty years. Back then we used Verathane and wet sanded. What are you using now days? Still doing a lot of wet sanding? I'm probably a couple of weeks away from starting to finish "My new project" and would appreciate all the help/info I can get. Thanks, Dick Wright | ||

|

| One of Us |

Duane's site is down for maintenance right now. I'm using Daly's with alkenet root like he describes. I do not wet sand. Once it is up again you may check out his tutorial. | |||

|

| one of us |

I still like the process of wet sanding. I'm just weird that way. I use a concoction that Chic Worthing gave me years ago which is 1/3 Teak Oil, 1/3 Spar Varnish and 1/3 Mineral Spirits. If I get lazy, I just use Formby's Tung Oil finish in the non gloss version. It has some Polyurethane in it. Both allow the figure of the wood to come out without changing the color. I like the color without stains. Just personal preference. Larry "Peace is that brief glorious moment in history, when everybody stands around reloading" -- Thomas Jefferson | |||

|

| One of Us |

For about the last 20 years I have used Daly's Sea-fin Teak Oil with total satisfaction. When I was in gunsmith school we made up something I Think they called 'French Polish' which was made up of boiled linseed oil and O-Cedar Cream Floor Polish ( which I doubt still exists) and I think I think a third ingredient I have forgotten . I was looking at a well used stock I built over 50 years ago and finished with it that actually still had traces left on it. As I read below the missing component was shellac. Have no idea of the proportions just remember mixing it many times. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

The original old time French Polish finish was shellac based. The solvent was alcohol. It was fast drying and on the glossy side. It was not very durable. I learned the hard way not to get alcohol on a stock finished with French Polish when a drop of camera lens cleaning fluid ran down the side of the butt stock. It took the finish off all the way down. | |||

|

| One of Us |

Hey guys, I really appreciate this. It's been a long time since I've done this. All suggestions more than welcome. I look forward to reading everything Duane has on his site re: finishing. Thanks, Dick Wright | |||

|

| one of us |

I've been using Pro Custom stock finish, a modified tung oil. I like it as it's quite thin and penetrates very well. I thin it initially for the 'soaking' first coat then wet sand and let the muddy mess from that sanding dry on the stock. Another wet sanding/wiping off normally will have the grain filled and I rub in light coats after that to build up the finish a bit. I'm no where as experiences as Duane, but I do like the results. Shoot straight, shoot often. Matt | |||

|

| One of Us |

I'm surprised there was no mention of Tru-Oil. | |||

|

| One of Us |

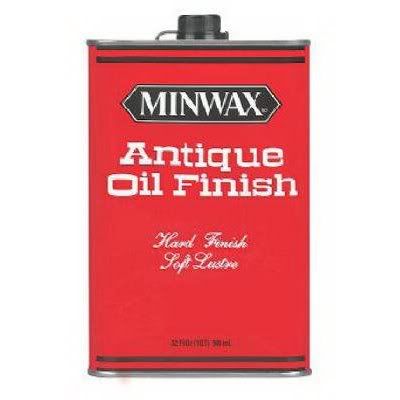

I copied this off this site years ago. I think it is Duane's recipe: Minwax Antique Oil Finish: First, do as the directions on the can specify, by applying a thin coat, allow to stand 5 to 10 minutes until it starts to get sticky, then buff off with a clean, lint-free cloth. An old linen sheet works great. Let dry 24 hours, then apply again. Put on 3 coats. After three coats as a sealer, apply a thin coat and allow to dry BONE DRY on the surface. This may take 24 hours or more. Using finer steel wool, steel wool the finish off the wood. As you steel wool, the surface coat will turn "muddy" looking so you can see it. Be careful around proof stamps and sharp edges to not round edges off or thin stamps. After steel wooling the stock down to bare wood, clean the stock with brushes or compressed air, then apply another coat, allow to dry and steel wool off. Continue this until the grain of the wood is 100% FULL, and you can see NO open grain. When held up to a light and sighted along the grain, open grain will look like tiny scratches in the surface. Usually 4 coats will fill all but the most open grain. After the last coat is steel wooled off, THOROUGHLY clean the wood. Then, apply a thin coat and allow to stand for several minutes until it starts to get sticky. Using several clean cloth pads thoroughly buff the surface until all traces of finish are off. This is a "color coat" that will give the bare wood more of a color without any build up on the surface. After buffing, allow the wood to age out and fully harden for 3 to 4 days. After aging, buy some new burlap at a fabric store, and make a small pad from several layers. Briskly buff the wood to burnish the surface and bring out the egg shell luster. The advantages of the Minwax Oil finish are: It's HARD and incredibully tough. It's water and solvent proof. It can be repaired or overhauled by adding more oil and buffing. Scratches can be filled by coating and steel wooling again. It's a REAL oil finish that looks like those seen on British double guns and American custom rifles. It's a life time finish that never has to be done over ever again. All the finish is IN the wood, not ON it so it looks like an original. Mike Ryan - Gunsmith | |||

|

| one of us |

I use Art's Gun shop filler. Comes in clear, red, and walnut. I apply it according to the instructions. Wipe across the grain and let dry. Then rub smooth. The finish I use is Hellman's spray spar varnish. Here again, it comes in satin. semi, and gloss. Most of the time I use satin. Once you learn how apply the spray, it is almost fool proof. And the finish is just beautiful and durable. I learned this form a master stock maker Bob Hisserich. Also, if you use this method and the red, it duplicates the Winchester finish of the 50's and early 60's, FYI. Jerry NRA Benefactor Life Member | |||

|

| one of us |

Another vote for Minwax Antique Oil Finish. After I get some buikd up, I wet sand with turpentine to fill the grain. After that, thin coats per the instructions bring up a hard soft luster finish.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

I used Minwax Antique Oil finish on a rifle. I like the results but I've been told it won't hold up to wet conditions. I don't care I liked the results. I took an old Whitworth stock and refinished it. Before:     After:      | |||

|

| One of Us |

I've tried a bunch of different methods to find my favorite. I've done several, but my latest (in progress) is: 1. Dry sand to 400 grit 2. Seal with 2 parts mineral spirits and 1 part Spar Urethane; I don't let it goop up or anything, I let it soak into the wood so I don't have to go back and sand, etc. 3. Wet sand with velvet oil. 400/600/800 - Get heavy mud on initial two sandings and leave on the stock to dry for 10+ days. If there is any open grain showing, repeat that grit. 4. I'm getting ready for the 800 stage right now. I plan to sand probably 2-3 times and allow to dry. I leave less mud than previous sandings on the first 1-2 times and then removes it all the last time 5. Wipe down with velvet oil and then wipe off This fills 98% of the grain pretty easily. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| One of Us |

+1 | |||

|

| one of us |

The basic question is: "what do you want it to look like?" Do you want an in-the-wood finish or a built up filled finish? In-the-wood: I prefer Tung oil or boiled linseed oil topped with Tung. Tinted per taste. Filled: tinted BLO topped with Minwax Spar Urethane, sprayed. Usually 10-15 coats. One light coat every 30 min. Urethanes can be re-applied as soon as the previous coat is tacky. The whole affair will cure through. When cured hard, wet sand then rub with rottenstone and BLO. Wax and call it a day.

| |||

|

| one of us |

Like most stock makers, I have tried them all..Basically I am sure of one thing, each of us must find the one HE uses best. Most can use one better than others..Like you I liked the Varathane finish, it is tough as nails and lasts for decades, yes it has tuanol and that causes cancer according to some, but so does white bread! I like Linseed with dryers, Linspeed, Tung oil, most of the commercial finishes are modified Urathane and they are good finishes..Brownells had them all in one form or another. All good stuff. Spar Varnish and shellac with a French rub works great..Applying any finish with a French dobber is slicker n' snot and you get no runs. I have some special finishes that I like for various reasons, one is boiled Linseed with dryers boiled with lead Oxide to darken wood, some passout at the word lead but I'm still around after using it and Varathane for many many years.. The latest finish I have used is Gun-Sav-R from Brownells, that stuff is a fantastic finish, easy to use, just spray it on and after about 5 or more coats rub it down with rotten stone and oil..However just out of habit I still wet sand it between coats. I like to wet sand, but a good rub down with rotten stone and oil sure makes using alkanet root or wood dye a lot easier. I like the alkanet root finish combined with a French rub to get a piano finish.. Lots of good options out there, I hate to use the same finish twice, its a learning process and you don't learn much just using one finish. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Well said Ray! "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  What's the current finish of choice?

What's the current finish of choice?

Visit our on-line store for AR Memorabilia