The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  Mauser Feed Ramp Poll

Mauser Feed Ramp PollGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Since the subject of 416 Rigbys on standard length Mauser actions comes up fairly frequently, I thought it would be interesting to get measurements of the feed ramps and the amount of cutaway into the bottom lug recess on a few Mausers to see just what we are dealing with. I will measure some of mine in std and magnum lengths and see how they shake out - just as soon as I come up with a good way of measuring! I can tell you, with my fingertip, they all feel just about the same as far as the ramp coming up to a sharp edge on the recess. Seems to me that the cartridge diameter has more of an effect on the amount of steel that needs to be removed than the OAL. | ||

|

| One of Us |

What I would love to see is measurements to exactly duplicate all Rigby's mods to a standard M-98 for the 416. I, for one, have no qualms about building and shooting one, and would love to have it just for the uniqueness. DRSS(We Band of Bubba's Div.) N.R.A (Life) T.S.R.A (Life) D.S.C. | |||

|

| One of Us |

A blueprint? That would be awesome. WOODY Everyone is allowed an opinion, even if its wrong. | |||

|

| One of Us |

Why not turn the action over and measure from the front opening to the recoil lug. That's an easy measurement and while it doesn't show the ramp it does indicate how far forward metal was removed. SCI Life Member NRA Patron Life Member DRSS | |||

|

| One of Us |

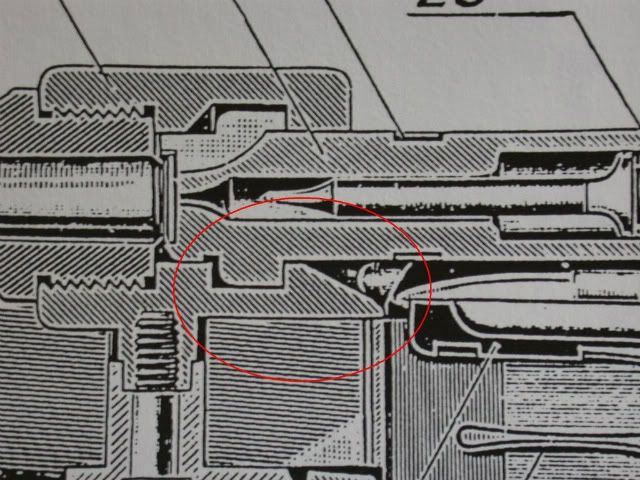

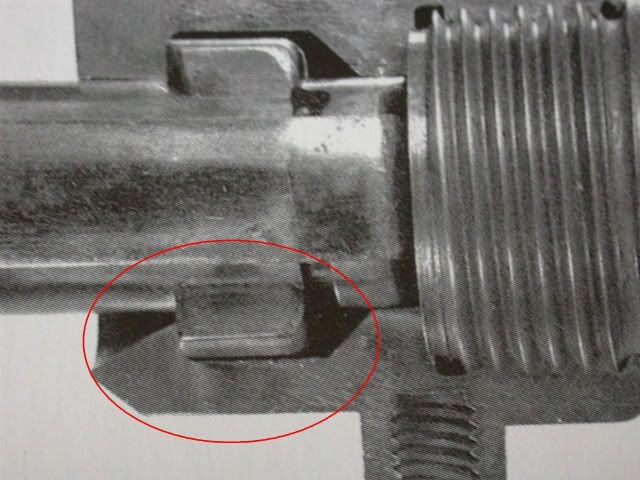

In correction of my first post here, the diameter of the case would have to be larger than the diameter of the bolt body to have any effect on the feed ramp. The bolt on a '98 Mauser is about .700" and a .500 Jeffery for example is .615" so case diameter isn't a likely culprit. I surmise that the amount of ramp modification has much to do with not only the OAL of the cartridge, but also the profile of the bullet which will be standard for the cartridge. You see in the top picture that the point of the bullet is on a plane just above the back edge of the feed ramp insuring smooth takeup. If a longer OAL cartridge is used, the ramp angle must be increased or the ramp moved forward resulting in less metal at the top of the ramp just behind the bolt lug as seen in the second picture. In any case, there is not a lot of metal behind the lug recess. Somebody here with more engineer type lurnin could tell us how the strength of the ramp area is depleted with any amount of material removal I'm sure. I don't know what these two examples are chambered in but would guess the first is in 8mm Mauser. Barrel pointing left. Notice the nice flat at the top of the feeding ramp. Nice amount of steel behind the lug recess.:  Barrel pointing to the right. Now, see that this feed ramp runs at an angle right up to the rear of the lug leaving less metal behind the lug recess. Clearly less metal behind the recess and the rear of the ramp has been taken down to the point that it is even (in a vertical line) with the rear of the receiver ring wheras the upper picture shows that the ramp protrudes farther rearward than the inside of the receiver ring. Must have been done for a longer OAL cartridge:  | |||

|

one of us |

The rear(lower part) of the ramp has very little to do with the strength of the lug recess. It is below the area the lug contacts, so it does not offer much support. But it is more important to point out that the action in the lower photo was incorrectly modified(AKA "hack job"). Note that the ramp has been cut down to the point that the "flat" immediately behind the lug recess has been completely removed. Beyond the flat being removed, the "knife-edge" at the tip of the ramp has actually been lowered. This is a huge mistake as the flat on the top of the ramp is there to center the bolt in the action. With this flat removed the bolt is not held in place(vertically) when the bolt is in battery. Using a bubba-ed hack-job to illustrate a long magnum conversion is arguing in bad faith, IMO. I'm not pointing my finger at Huvius, but rather at the author of the book that photo was pasted from. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| One of Us |

Jason, taken from none other than Speed's Mauser sporter book. This just might be an original Mauser cross sectioned action. It is from the Lester Womack collection as noted in the book. | |||

|

one of us |

To be honest, I assumed that it was from Jerry Kuhnhausen's book as he has a similar photo. But the source of the photo really makes no difference. What is important is the fact that it illustrates nothing but an incorrectly modified action. And no offense intended, but the action in the photo "just might" have been an original Mauser, but it is more likely that it was an action that was done by a "Bubba". I say that it was more likely a bubba job because it was obviously done by someone who thought that they were grinding on the "feed ramp" and did not understand that the "feed ramp" is actually is part of the locking lug recess and is responsible for more than half of the receivers locking strength. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| One of Us |

I never proposed that this is a properly modified action, in fact, I point out that "there is not a lot of metal behind the lug recess" Anyway, it is the only picture I could find of a cross sectioned Mauser action with a good shot of the feed ramp. Just happened to be a WAY cut job. | |||

|

one of us |

It would be hard to find a cross sectioned action that had been properly modified. If done by a knowledgeable smith they action is going to function properly and will be worth too much to cut-up. I wonder if there is some type of magnetic imagining that could give us a cross-section view with out destroying the action.(I have no idea id this is possible-?????) The other possibility might be to make a cast or two of the action and lug recess. BTW, I am not trying to ruin your thread. At times it seems that people claim that long magnum conversions are not safe on the M98 with the reasoning being that too much metal must be removed. Then these improperly modified actions are shown as proof. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| One of Us |

The Federal 416 Rigby ammo I have is loaded to a nominal 3.6 OAL This, being the same as 375 H&H would make the 416 Rigby conversion a no brainer..if....using that ammo or handloads keeping the OAL in consideration. Now for a commercial message:.... While back, we had a European customer wanted bottom metal for just such a project. Our 4MJ with the slight coffin floorplate filled the bill perfectly. The 416 Ruger would also be a good choice...standard length is a nice feature. Re the feed ramp: A nice long gradual slope is what dreams are made of. When openilng for longer ammo, that is not attainable. The ramp must be pretty steep to allow as much lug material as possible. Here's where the rails have to be "tuned" to allow the nose to climb that steep ramp without balk, That, along with follower configuration and extractor modification have to all work together to guarantee flawless feeding...start demanding flat nose bullets, you might have to start all over! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia