The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  what diameter tree for stock wood?

what diameter tree for stock wood?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

My son-in-law cut down an English walnut tree and has saved the trunk for me. It was basically cut down last year but the trunk was left standing until last week. I have no idea if it's worth toying with or not but I have 3 basic questions and my first question is: What diameter tree is needed? Second question would be: What's my first cut to check the "quality" of the wood (like I'd even know what to look for. ha) Thirdly: It's about 8' long so would I want to rip-cut it before I reduce the length... so I could see where the best wood is before whacking it in half? I hope this is the correct forum since many of you KNOW about woods. Thanks for any input, replies, direction or opinions. Zeke | ||

|

| One of Us |

Hopefully he dug up the rootball. | |||

|

| One of Us |

No but he's going to. It's no longer attached to the trunk so maybe he's already flubbed it up. (I hate after-thoughts) Please tell me more... if willing. | |||

|

| One of Us |

Please pm me. There's a couple things you said that made me cringe at the thought. It's not rocket science and ill happily show you a diagram that will help greatly | |||

|

| One of Us |

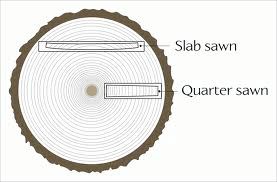

Depends how you cut it. Quarter sawn, plain sawn etc. I used to know which gave the best figure but now have forgotten it. But don't just "plank" it read a book with a chapter on how it should be cut. Best figure, as noted, is in the root. | |||

|

| One of Us |

This should give you an idea. Two slabs on the right from the root ball, split down the middle. Yep. Good stuff is in the root wad!!!!!!!! Long blank on the left is from the trunk that was split down the middle.  Two more split down the middle. Actually the long slab in the above photo cut in half. Was about a 24 inch log.  A trunk log in the sawmill. This one was about 40 inches in diameter. This mill has two blades, at 90 degrees to each other. Ideal for sawing blanks. This one was full of unbelievable grain. Knarliness on the outside is usually an indicator of nice grain inside. Once you make a cut into the log you will know how to proceed.  Air curing takes a long time. Seal the ends of the blanks with a latex sealer. Cure in a cool dry place. NO sunlight. 1/2" square "sticker wood" between the blanks for air circulation. Our curing shed had a dehumidifier in it that ran full time. The wood in the photos was cut in 1993. I am now using the blanks for stocks. | |||

|

| One of Us |

I don't know how big your log is, but here are some very basics; you can't have the center or pith in a blank ever. You want no sap wood in a blank. And you need them to be 2.5 inches thick, although some patterns will clean up less than that. They have to be dried for at least a year per inch of thickness, and you have to seal the ends so they will dry from the surface; otherwise they will crack, and they might anyway.  | |||

|

| one of us |

While it doesn't actually answer your question this has some interesting reading. http://www.oldtreegunblanks.com/sawcuts.html As usual just my $.02 Paul K | |||

|

| One of Us |

According to "Gunstock Wood and Other Fine Wood" book I bought years ago....the minimum thickness for a walnut tree is 18" in diameter. I do not remember the authors name just now. I will go find the book in my library today and give the ISBN number later today. Dennis Earl Smith Professional Member ACGG Benefactor Life NRA Life NAHC | |||

|

| One of Us |

Yep. Would be nice if he would spread some information here on AR but I suspect he is just too busy to play on forums in the manner old retired farts as I do. | |||

|

| One of Us |

Hell will freeze over before I tackle another stump!!!!!! Got about 6 black walnut stumps several years ago and had them sawed into blank size boards. Bought several blades for the man who was doing the sawing before we finally got through all the stones and nails. Didn't get a single rifle stock out of the bunch! Got some pretty good two piece blanks though. Long story short...it's cheaper to buy what you need. "Peace is that brief glorious moment in history when everybody stands around reloading". | |||

|

| one of us |

That would be my feeling. As usual just my $.02 Paul K | |||

|

| One of Us |

You guys have been very informative and helpful. I'm going to run over and look at the tree today and see if I can see any color in the end grain. I always "assumed" that quarter sawn was best but the link that Paul K. provided says either quarter or slab sawn is good for stock wood but just a different look and pattern/grain flow. I might be biting off more than I can chew but I'm learning from those who know a great deal more than me. Thank you! Zeke | |||

|

| one of us |

Hmmmm, You should have let the stump float in water for 6 months to a year before starting the drying process..Ive read about it and done a couple but what a waste of time when I can buy a real nice European blank ready to stock for $400 to $600 by the pallet, and sell them for $800 to $1200 or sell one and I have a free one..Thats what most custom gun builders do. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Oh how I wanted to stay out of this thread but find that I can't. In order to avoid any sapwood and heartwood in a blank you need a tree of minimum 24" diameter. This will yield a slab with two 8" wide blanks,4" of sapwood and 4" of heartwood (which will always crack). Dave | |||

|

| One of Us |

YOU GUYS ARE AWESOME for sharing your insight, knowledge and opinions! The wood is large enough, so it seems, but, with all the great information, I'm feeling reluctant to tackle the job. I now have just enough information to be really dangerous. haha Zeke | |||

|

| One of Us |

| |||

|

| one of us |

Cecil has some good pictures http://www.gunstockblanks.com/...ures/stump-to-stock/ As usual just my $.02 Paul K | |||

|

| One of Us |

Awesome links guys! Thanks you very much. I'm headed over to look at the thing right now. I guess I'll have to decide how badly I want to play. Zeke Side note: last year my daughter called all the lumber yards and mills that she could find in our area and none of them even wanted it for free, even if we cut it down and delivered it to them! Maybe that's the right price for the wrong product. | |||

|

| One of Us |

I don't know what it is. But a piece of heavily grained walnut just sends my heart racing. Even a blank - Just the contrast in colour and mineral streaks & swirls. A really good finished stock oil finish of course just makes my heart skip several beats! "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

Thanks again for all the help! I had some personal tutorial from AFreeman which was invaluable. Thank you sir. I know more now than I did before but I'm sure it is much less than many of you. At least I had a foundation of wood layout and grain flow before I started the project. End result is 4 rifle blanks from the trunk and 3 or 4 from the root-ball. A couple from the root are a bit shorter than the preferred 34" length but I'll be able to use them if splitting and cracking is minimal or strategic. I have 3 or 4 2-piece blanks too, depending on the above. A couple+ should be high-grade and the rest are nice mid-grade with great grain flow. An even dozen blanks total. My blank yield would have been higher if I knew more but it's way better than using it for firewood. The ends are sealed with AnchorSeal and everything looks good so far. I even ended up with a beautiful 6/4 flitch which will turn into a coffee table in my trophy room. I'm about as happy with this as I an the stock blanks! Thanks again, Zeke PS: you all were right. 4 band saw blades, 1 radial arm saw blade, 1 table saw blade and over a dozen chainsaw blades but most could just be re-sharpened. We did not ruin a blade at the sawmill so that's a big plus. | |||

|

| One of Us |

I was told by an Australian stock maker that a tree needs to be around 80 years or more to produce good stock blanks. Not sure if this is a universal rule or just a thumb rule. I know that many of the Turkish and Central Asian walnut trees are hundreds of years old. "When the wind stops....start rowing. When the wind starts, get the sail up quick." | |||

|

| One of Us |

Post some pics! ----------------------------------------- "I went to the woods because I wished to live deliberately, to front only the essential facts of life, and see if I could not learn what it had to teach, and not, when I came to die, discover that I had not lived. -Henry David Thoreau, Walden | |||

|

| One of Us |

I'm lucky to be able to post at all, let alone post pics! I'll be happy to take some good pics, before I tuck the wood away to season, but I'd need to email them to someone if they are willing to post on this thread, Sorry to be so "high-maintenance" but that's what older guys go. haha Zeke PS: My daughter counted rings at about 100 so we'll assume the tree was +/- that old. | |||

|

| One of Us |

Sent you a PM. ----------------------------------------- "I went to the woods because I wished to live deliberately, to front only the essential facts of life, and see if I could not learn what it had to teach, and not, when I came to die, discover that I had not lived. -Henry David Thoreau, Walden | |||

|

| One of Us |

Thanks Storm. I'll get some pics tonight and send them off to you. Zeke | |||

|

one of us |

Ditto. Certainly my experience trying to salvage a mesquite. NRA Life Member, Band of Bubbas Charter Member, PGCA, DRSS. Shoot & hunt with vintage classics. | |||

|

| One of Us |

Having done it ONCE, I'd be semi-inclined to agree that buying is easier and probably cheaper in the long run.... but it's done and, as they say, what's done is done. StormsGSP is going to post some pics for me (I've emailed them to him this morning). The blanks are rough-cut and the ends are sealed with Anchor Seal 2 so the pics are not as sweet as they could be but you should get the idea. I'll season the wood for at least 3 years, run it through the planer, see what I really have and if a couple are as special as I think they are, I'll be happy. I'll probably wait additional years since I won't be working on all 11 stock in 3 years! (I had to give one of the better ones to my cousin for ALL his help. I'll have to checker the damn thing for him too) Thanks, Zeke | |||

|

| One of Us |

----------------------------------------- "I went to the woods because I wished to live deliberately, to front only the essential facts of life, and see if I could not learn what it had to teach, and not, when I came to die, discover that I had not lived. -Henry David Thoreau, Walden | |||

|

| One of Us |

Thanks, StormsGSP, for posting my Pics of the process. Zeke | |||

|

| one of us |

I heard somewhere that walnut trees were worth quite a bit for veneer logs, cut in eight foot lengths. TomP Our country, right or wrong. When right, to be kept right, when wrong to be put right. Carl Schurz (1829 - 1906) | |||

|

| One of Us |

I've got some gnarly old Black walnut trees on the property, probably 35-40" diameter. You've got me thinking! | |||

|

| One of Us |

That's what I thought, what the hell! Beats the crap out of watching TV or mowing my lawn! That's about the exact diameter of the English walnut tree that I worked on and black walnut has less sap wood so the yield should be higher (or so I've been told). Zeke | |||

|

| One of Us |

Oh, and the pastry looking stuff on the wood end-grain and parts of the stock is Anchor Seal to help minimize end checking. It doesn't make for the best figure-pics but it helps protect while curing, I suppose. Zeke | |||

|

| One of Us |

All that counts is the end product :-) | |||

|

| One of Us |

Biebs, you're 100% correct but I wanted to show=off the wood a little after I worked so hard to dig it out of the tree. I think I'll give 'em 3 years and plane them all so I can enjoy the figure of them all while I'm working on one at a time. They're all plenty thick so planing won't degrade them at all. Some are almost 3.5" thick. Zeke | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  what diameter tree for stock wood?

what diameter tree for stock wood?

Visit our on-line store for AR Memorabilia