The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  ... and chips for my side please.

... and chips for my side please.Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

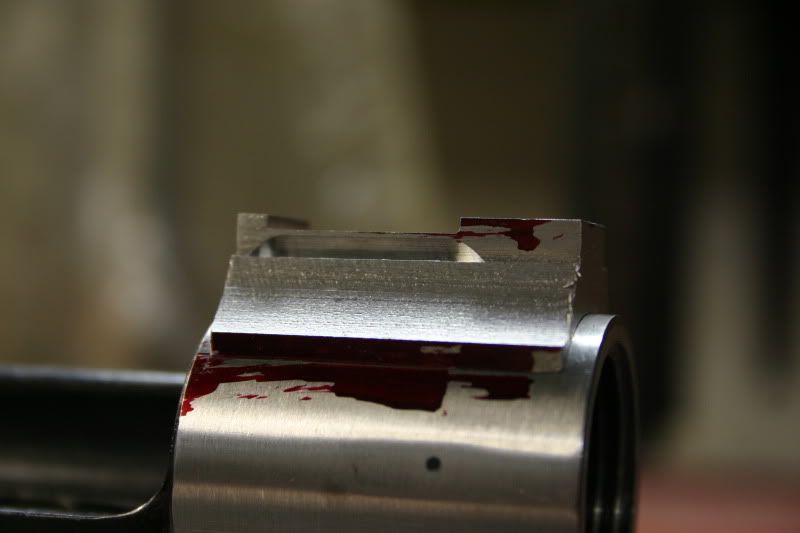

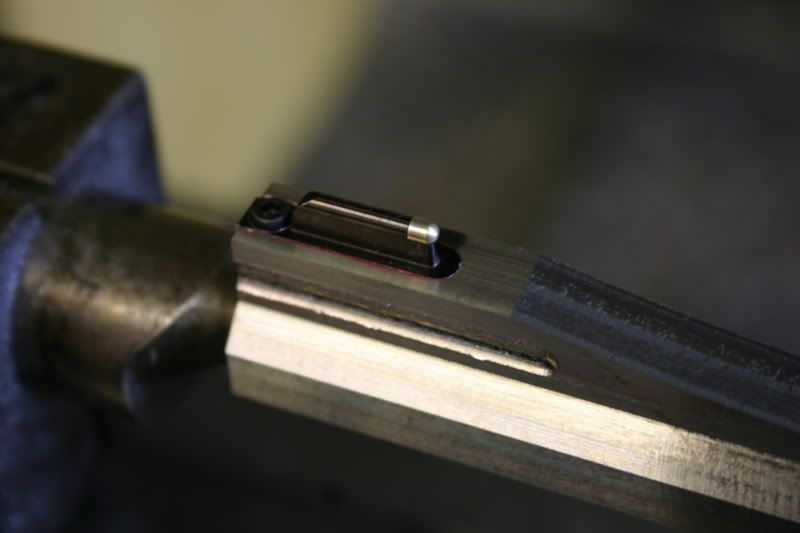

I had recently decided that purchasing scope mounts really inhibited my ability to build a nice rifle. A customer suggested I take a "whack" at making my own. So saturday morning I sawed a piece of 1"x1"x1" and a piece of 1"x1"x1 1/2" and started making a mess. I milled the radii for the bases and put the screw holes in.   Cut for the dovetails:   A functioning scope base!  I unfortunately did not take any more in process pics because I was too busy making chips! I have to say I think they turned out pretty good, I did them completely free form, no blue prints, no planning, just made them up as I went. I have some more to do (front radius)(chamfers)(polish) before I would call them done!   Milled the back angle to match the receiver:  Final product  Thought I would throw this in too. This is the integral front sight base for what will become a 7x64. Stylistically I think it looks better than a plain sided front sight base.  Let me know what you think! I am always open to improvement. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | ||

|

One of Us |

When I grow up I want to be able to make cool things... | |||

|

| One of Us |

Nate, I would say without a doubt that you have way more talent than I ever will! | |||

|

| One of Us |

Heck, make me a set while you are practicing. I need them for a 1917 DWM. | |||

|

| One of Us |

These are very nice work. If I may offer a suggestion - the "american" style of the moment seems to be for a very "angular" and "machined" look. If you look at some of the European makers they take a more "organic" or artizan approach, for example they radius each corner ear (where it touches the reciever) and generally finish with a little file work to knock some corners off etc. This is merely a matter of taste, so opinions vary. This sort of approach is very clearly illustrated in boatbuilding, sure you can produce a nicely radiused rail with a router, but an artist will use either a custom ground plane blade, or even shape entirely by eye to move beyond the look that a pure "machined" radius can give. | |||

|

one of us |

I hear ya. That is so cool. Nice work Nathaniel! Terry -------------------------------------------- Well, other than that Mrs. Lincoln, how was the play? | |||

|

one of us |

I really, really don't like the look of the rounded corners. Leave them sharp and square!!! But that's just me. Jason "You're not hard-core, unless you live hard-core." _______________________ Hunting in Africa is an adventure. The number of variables involved preclude the possibility of a perfect hunt. Some problems will arise. How you decide to handle them will determine how much you enjoy your hunt. Just tell yourself, "it's all part of the adventure." Remember, if Robert Ruark had gotten upset every time problems with Harry Selby's flat bed truck delayed the safari, Horn of the Hunter would have read like an indictment of Selby. But Ruark rolled with the punches, poured some gin, and enjoyed the adventure. -Jason Brown | |||

|

| one of us |

That's some beautiful work! The blood all over the place is a bit scary though, it looks like I've been running the machinery. (Just kidding) | |||

|

| One of Us |

I am curious about how you mill that radii (that must be plural for radius) for the bases. I would imagine that for the front ring you take a calipers and measure the circumference, an divide by half, and then use some sort of radius cutter or boring bar or something. But what about that back surface that is not a circle (or is it). How do you get that right? (doesn't that rear base look like it could have just a hair more metal taken off the sides?) | |||

|

| One of Us |

I do it about the same. Determine the radius and finish with the boring bar.  I mount them on a bar and turn radius on the lathe.  I don't do the finish cuts for the rings until they are mounted to the receiver. This makes sure they are aligned.  Butch | |||

|

| One of Us |

Sweet! They look really good I have recently seen the integral EAW mounts on the Johannsen rifles... Does anybody else do that? Only issue i can thinknof, is if they break, and they're built into the "square bridge", you're screwed?!? | |||

|

| One of Us |

JDA-CO, I too hope someday when I grow up I can make cool things. I look at some of the professional gunmakers and am amazed at their talent and abilities. My "dream" item to make is an 1/2 octagon 1/2 round barrel with integral rib, with the rib standing on the round shank. Biebs, thank you sir! I greatly appreciate your compliment. Magnum Hunter, send me an email... Tentman, thank you. I do like the european "organic" style on some rifles. I may make a more fluid set in the future. TC1, thank you sir! Jason, I will leave these sharp and square just for you. Though I am going to give the front of the front base a little draft, or a radius, or something. It just sticks out too far. boltman, thank you! Yea... that dykem is probably older than me, trust me, when it first runs it REALLY looks like blood. 22WRF, there are a number of ways to cut the radii, whether boring bar, ball endmill, or interpolated radius via CNC. The front is easy, done almost exactly how you said. The rear is a little more tricky. It is actually two flats tangent to the center radius. As for the rear base, these were just rough cut as a test run. The radius on the sides actually are exactly the same front and back. So sighting down the rifle they are level and on the same plane. Butch, those are great! I had considered mounting these on a bar on the lathe, but decided to leave them more "square". Have you ever tried HSS with a radius contour and done the same? Orvar, thank you! No I have not seen the Johannsen rifles, but I will look them up now Thank you all, I appreciate it and am glad you all like them. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

Nat, I ended up throwing them away. The set that are on the rifle in the bottom photo only had one back screw on each that the rings cover. On the front of each they fit on a tight pin that was screwed into the receiver.I soldered them to the receiver. No screws show. I don't completely understand the HSS part. Are you talking endmills? Butch | |||

|

| One of Us |

HSS, High Speed Steel, I meant a lathe bit. grind a desire radius in the lathe bit and then turn the bases on a mandrel. That or use a radius tool post. I considered doweling the bases. I might have to reconsider. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

| One of Us |

I have ground several HSS and cemented carbide lathe tools to different shapes. If I have something that is a little weird I have MCCTooling in Garland, Texas to grind it for me. If I have a drawing his wire EDM or CNC tool grinders can make it. Butch | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Custom Built Rifles

Custom Built Rifles  ... and chips for my side please.

... and chips for my side please.

Visit our on-line store for AR Memorabilia