The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Double Rifles

Double Rifles  Double rifle barrel construction

Double rifle barrel constructionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Reading the post by new_guy about the new Heym and how the barrels are constructed by the shoe lump method has made me curious. How are the barrels constructed for Chapuis, VC, Merkel, and Searcy doubles? Would the shoe lump method be the best choice outside of chopper lump construction? My biggest fear is when I die my wife will sell my guns for what I told her they cost. | ||

|

| One of Us |

Searcy gives option of Monoblock or Chopperlump. | |||

|

| One of Us |

Merkel and Chpuis, VC are monobloc constructions. Two round barrels welded to the lockinglugs (part / Greener is even a thrid pard as the rail between the berrels), for the rear part is a hard welding used (around 600-700C heat), the front is a soft welding of only 450C heat. The demibloc barrel construction is more expensive. The lockinglugs are one part with the barrel (nowadays the lugs are cuted by a CNC machinery) and that two parts are then soft welded together. Some say the balance of the gun gets better using the demibloc, but as I have seen not on the Heym. I have a Spanish desigh assebled in Germany in Monobloc design. And the balance is better then on the Heym and also the same weight. So it really depends on the factroy or gunsmith who assemble the parts, if the result is good or better. For cartridges up to the 9,3 (pressure level "3400bar", therefore including 470 500 577 600 etc) it really does not make any difference. But for high pressure cartridges as the 375H+H, 458Win, 460Weath I would only go for a demi bloc. Separation of the part is a result of pressure. I have a Hubertus with a Monobloc and in even the 7mmRem after 1000 shot you can see that the barrel want to separate. That can not happen in the demibloc, it would had to crack the lockinglug. The Blaser has the Jaeger action, that holds the high pressure best because of its design. (rear bolt into the barrel end) There you never get a pressure problem that you can wear down to locking. From the accuracy the Blaser is the only which has a smale chance to compeat with other rifles caused by the barrel in tube deisgn = you get two indipendent barrels. Unfortunatly the Blaser has some other things I do not like (no ejector, is not self cocking, and the two large dia barrels look not very nice) Heym as Merkel or Blaser have a hammering machinery their barrels have withstand about 900N/mm2 or even more, A not hammered barrel is at 600-700. In the end that means to hold the pressure you need more barrel dia to hold the same pressure. In real life that makes absolutly not difference because non of the manufacturers assamble so light barrels. Merkel and Heym sell to gunsmith also unfinished parts, barrels, actions etc. Merkel also sells half finished parts as double barrel sets with unfinished luckinglugs (part), at the end most of the 470 and above came more or less or part of it from only a few companies. But for what reason should a smale company not buy in parts that they can not pruduce in that quality for that price. Heym and Merkel are the only comapnies which make all themselfes (in the mid price region). Spanish RD have Lother Walter barrels what they say. | |||

|

| One of Us |

As a clarification: Some Chapuis are monoblocked (O/U C series) and some models are shoelumped (SXS, UGEX/RGEX series) Verney-Carron, most models are available as either shoelump or monoblock depending on what the customer wants, the exception is that all 577 and 600 guns are monoblocked. Ken DRSS, PP Chapter Life NRA Life SCI Life DSC | |||

|

| one of us |

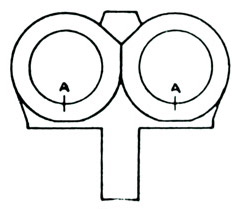

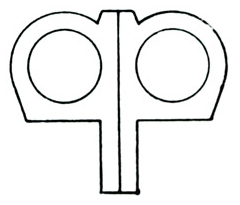

(SHOELUMP BARREL SET) Bunoushcu What you are describing above is not Mono-block but Shoelump! Merkel S/S double rifles, up until a three or four years ago were all Shoelump barrels, they are now mono-block barrel sets. The monoblock is one solid block of steel that includes the first 4 inches of the lumps, top rib, including the rib extention for the Greener corss bolt and barrel receivers! The block is drilled through for the barrels, then the block is fitted to the action. Once fitted to the action the barrels are threaded into the mono-block and trimmed off flush with the face end of the mono-block. The barrels are threaded into the mono-block exactly the same way barrels are threaded into a bolt actioned rifle! The S/S Heym Chapuis and VC are shoelump barrels!

(Chopper lump) Sorry but the German use of the word DIMI-BLOC is a misnomer! It is a French word that simply means HALF BLOC, and the word BLOC can be applied to anything that is two pieces from trigger group to a two piece stock. Even a shoe lump barrel set can be called DIMI-BLOC it doesn’t mean a CHOPPER LUMP barrel set. When Merkel doubles were made with shoelump barrels sets they advertised them as DIMI-BLOC barrels and Hallowell defined the word DIMI-BLOC as chopper-lump incorrectly! Actually the word DIMI-BLOC doesn’t mean anything definitive where double rifles are concerned. On the locking lugs you mention above, only the primary shaping is done with CNC machining! This is the case for most parts today in all makes and types of double rifles but the fitting is done by hand! The first four or so inches of all barrel sets are oven brazed together not soft soldered!

Bunoushcu , there seems to be a bit of a translation problem here! The paragraph above that you call the Blaser barrel set, is a description, , of the MONO-BLOC barrel set where the barrels are threaded into a solid block of steel like a bolt action barrel, and what you are calling a mono-block is a shoe-lump!  (PICTURE FRM HALLOWELL, Text is mine) (MONO-BLOC) Fig 3# The figure #3 above is the “MONO-BLOCK”, method of barrel joining. This is a very modern way of building a barrel set, and takes the value of the old lump locking system, and combines it with the modern bolt action technology, by fitting a solid block of steel that incorporates the breech end of the barrel set, the under-lumps, and the quarter rib butt. The barrels are then threaded into side by side holes bored through the block, similar to installing barrels into a bolt action rifle. Then trimmed off flush with breech face of the block. This is a very strong method of barrel construction. This method of barrel joining is the most maligned, by the purists, and totally without cause, in my opinion. There seems to be a factor of nostalgia involved here, and in reality makes sense, when you realize the double rifle firearm has been around for a long time, and though the mono-block is just the latest change in construction, it is the NOW step child of the purists! The other methods had their dissenters, as they came along, however we seem to forget them when something new comes off the table. This is the case with mono-block. It’s new, and not trusted by many double rifle enthusiast, especially those who are British double rifle fans.

The above is true (I think) if I read you correctly! Hammer forged barrels can be made far thinner and still hold pressure better that other ways of making barrels. The rifleing is far more precise as well because the barrels are hammered forging the barrel steel into the lands and grooves engraved on the outside of a very hard mandrill, then the mandrill is pulled from the inside of the barrel! This is superior to having the lands and grooves cut inside the barrel one at a time! It is also true that most German barrel makers sell not only barrels, but unfinished parts and whole double rifle steel parts unfinished to other makers in many countries! TE] Kebco, He seems to be confused about the different names for different barrel joinings! What he is describing as Mono-bloc is actually shoe-lump, abd what he refers to as Blaser barrels is actually mono-block! This guy knows what he is talking about but is simply using the wrong English words ! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

For rifles of the 450/400, 450 NE, and 500 NE class does it make any difference if the barrels are shoe lump or mono block? My lack of experience with either method suggests to me it is more important how well the barrels are put together over which method is used. True or false? Although it does seem to suggest to me the lack of another joint in the shoe lump method would be better. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| one of us |

Actually if done properly the MONO-BLOCK is actually stronger IMO, that either of the other mathods, but is the bastard child in the minds of purists! I believe the shoe-lump is about as good as any of them needs to be, and makes a better looking double rifle than the mono-block! As far as ballance has to do with double rifles the method of barrel joining is not what effects ballance this is done with weight distribution, not how the barrels are attached! Heyms are shoelump barrels, and I don't think you will get a better double rifle at any price as far as actual mechanical value is concerened! If I were you buying my first double rifle I would look for a good used Merkel 140E-1 chambered for 9.3X74R, or a safari grade 140-2 470NE or 500NE with extractors which are shoelump, if the little 9.3 is too small for you! Either of these two rifles can be found used for around $7K or $8K, and will serve you well. If you want to up-grade later you can get all your money back to apply to something like a Heym 88B in what ever chambering you want! It may turn out that you don't like double rifles once you get one so to be able to replace the money is important! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

Mac, As always you have a wealth of experience. But I am not looking to buy my first double as I already own three. But as we all know this is an addiction and am sure a number four will appear at some point. Then again, being left handed the Merkels would be out anyhow as they don't make a true left handed rifle. Simply trying to improve my understanding of how doubles are designed and built. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

at MacD37 The Blaser is a different design, the locking is done by third part (steel lockinglug). The part directly lock in the barrel. The shoe only hold the barrels in the possition/together but has not to hold the pressure of the round. That is the reason why they can use aluminiumalloy frames because the receiver has not to hold the pressure (only the recoil). The accuracy of a hammered barrel is not better then from an normal botom rifles one, the only difference is the fortness of the steel resulting form the method. The new rifles where the locking is directly in the barrel would not have been possible (afterward hardinging only the rear end is deforming a barrel). The min outside dia is only used in the inlay barrels for Drillingrilfes. 9,3 barrel in 16ga Shotgun barrel. Nobody buys a minimum weight DR. There is much more possible nowadays but manufactured is still designs made 100years ago. Exept the Blaser. (I do not like the Blase because its new design and it is not selfcocking nor has ejectors) | |||

|

| one of us |

I agree about the Blaser S-2 double rifle, I also do not like it for a couple reasons! I do not like aluminum on a rifle of any kind, and certainly not on a double rifle! Even if the action had been made of good steel, my main objection is the combi-cocking system the automaticlly de-cocks the rifle if opened for any reason. IMO, this is not something that should be on a double rifle that will be used on dangerous game. If you fire one or both barrels and open the rifle to re-load one or both chambers the rifle is automaticlly de-cocked, and must be re-cocked before the rifle can be fired. Thew Blaser has no facility for the barrels being opened that automaticlly re-cocks the fired barrels! Many people think the Krieghoff has the same system,but it doesn't! Once cocked, fired and opened the rifle autamaticlly re-cocks the fired barrel so that when the rifle is closed it is ready to fire! On a charge the wasn't stopped with the first two shots, I don't want to have to worry about an auto safety, anc certainly not a rifle that doesn't re-cock it's self! I can live with extractors but not a de-cocker that automaticlly de-cocks my rifle when opened for any reason! ....Mac >>>===(x)===> MacD37, ...and DUGABOY1 DRSS Charter member "If I die today, I've had a life well spent, for I've been to see the Elephant, and smelled the smoke of Africa!"~ME 1982 Hands of Old Elmer Keith  | |||

|

| One of Us |

A pair of 470 Chopper Lump Barrels in the hands of David McKay Brown, Glasgow, Scotland.  Rusty We Band of Brothers! DRSS, NRA & SCI Life Member "I am rejoiced at my fate. Do not be uneasy about me, for I am with my friends." ----- David Crockett in his last letter (to his children), January 9th, 1836 "I will never forsake Texas and her cause. I am her son." ----- Jose Antonio Navarro, from Mexican Prison in 1841 "for I have sworn upon the altar of god eternal hostility against every form of tyranny over the mind of man." Thomas Jefferson Declaration of Arbroath April 6, 1320-“. . .It is not for glory, nor riches, nor honours that we are fighting, but for freedom - for that alone, which no honest man gives up but with life itself.” | |||

|

| One of Us |

at MacD37 The Krieghoff DR is a classic design (Shoelump), it is a selfcocking DR where you have the possibility to decock, but it is selfcocking as long as you leave the safty switch in forward possition. Whey you put it on safty it is decocked. (they now also make ejectors on special order). Barrels came from Merkel (blacks). The locking is only a under barrel locking lugs. For low pressure rounds it is ok but not for more. I have from Krieghof a Hubertus sigel shotrifle in 7RemMag and the action is weak for a 4300bar round, barrels thends to separate from the lockinglug part, chamber is enlarged (too thin barrel in relation to the pressure). The Baser duo is not selfcocking rifle at all, it is a manual cocking rifle, every time you open you have separatly (again to cock), that is rubish for dangerous game. They not offer ejectors at all. But the action design is much better withstaning high pressure, because of the boltpart locking in the barrel. On the design you can go for the high pressure round, because it does not have the weak design of most DR. Unfortunatly my budget does not allow me to oder such a DR http://www.jagdwaffen-scheiring.at/index_en.html That is the state of art today. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Double Rifles

Double Rifles  Double rifle barrel construction

Double rifle barrel construction

Visit our on-line store for AR Memorabilia