The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Wildcats And Their Development

Wildcats And Their Development  forming 333 okh belted from 338 win mag I guess it needs new brass

forming 333 okh belted from 338 win mag I guess it needs new brassGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I just bought one of Elmer Keiths old rifles a 333 okh I have rcbs full length dies and tried to form a case from 338 win mag once fired brass and stuck it in the dies .I guess I have to use new brass or can I anneal once fired to make it softer ? | ||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| One of Us |

As I remember it, the 333 OKH is based upon the 30/06 case much like a 338/06 except for bullet diameter (and of course throating for the long bullets he used). The 334 was base upon full length 300 H&H brass with that larger diameter. I don't know if there was a typo and you meant 334 or it's really the 333 however the bolt-face will confirm such quickly. Good luck... Edward Lundberg | |||

|

| One of Us |

334 OKH is belted, 333 OKH is not. From Donnelly's book: 334 OKH. Make from 300 H&H. Taper expand case neck to .340" dia. F/L size in OKH die. Trim to length and chamfer. Fireform. | |||

|

| One of Us |

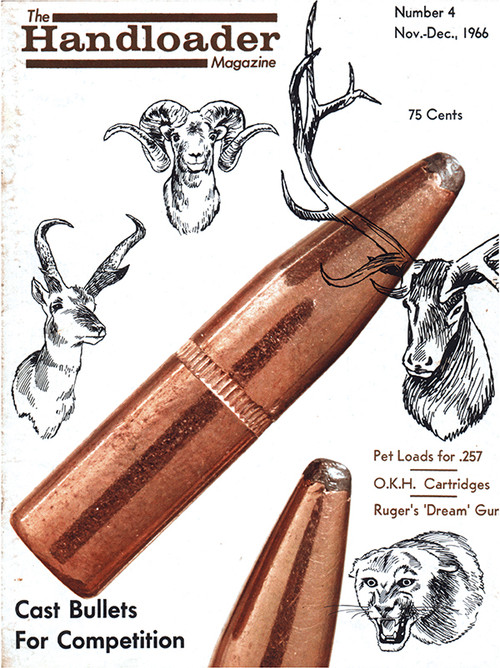

There is indeed a .333 OKH Belted (on the belted .30 short magnum case), looks like .338 Win. Mag. but with more body taper. There is an excellent early Handloader article (Nov.-Dec. 1966, Vol. 1-No.4)on all of the OKH cartridges by Bob Hagel. Hagel also states that O'Neal necked this same cartridge down to .300 and in the early 60's necked it up to .350 caliber. He states this latter was similar to the .35 Ackley short magnum, the Mashburn .350 short version and the commercial .358 Norma in performance. And similar to the .333 OKH Belted is the .333 Express (also based on the .30 short mag. case). According to the Speer Vol. No.1 Manual (1954) the .333 Express was developed by the Luft Bros. gunsmiths in Spokane, Wash. Seems there really is nothing new, they did it all back in the heyday of wildcatting. T.W. | |||

|

| One of Us |

To add to the above the article states this cartridge was called the .333 OKH Belted to distinguish it from the standard .333 cartridge based on the '06 case. The Belted case also retained the same H&H body taper of the larger .334 case. And O'Neal made yet a third case on the .333 OKH Belted when he necked it down to 6mm. And essentially you have the short Winchester Magnums! T.W. | |||

|

| One of Us |

dgr416- Your RCBS die should be stamped on top of the die body as 333B OKH . The "B" of course standing for "Belted". Hope this helps- T.W. | |||

|

| one of us |

That's what my ribs dies say ribs ,333 okh b .I have fired it a few times .I.am trying to.figure out.loads which.are about 90percent captivity of the 338 win mag.I.have ,333 bullets in 200 grain ,275 grain Elmer Keith's favorite and 300 grain.I.guess I.am.buying.a .333 bullet swagger from.Corbin to mAke bullets from .338 bullets .I need a trim length on this cartridge .It's an awesome rifle built by Charlie O'Neal for Elmer Keith and has a lot of history behind it.I don't.want to blow it up so I.am loading Very carefully for it ! | |||

|

| one of us |

Annealing would not hurt. From picture in the discussed article, the .333 OKH Belted has more body taper and a smaller diameter shoulder than the .338 Win Mag. It was made from the 300 H&H brass,shortened. I guess that trimming down some 300 H&H brass from Winchester-Western (WW) would make for an easy, one-stroke run through the .333 OKHB FL sizing die. You need to know the brass max length spec and trim the new 300 H&H brass to that length. Lube the inside of the case necks to ease the expander ball. Then run it through the .333 OKHB FL die and see if it is within -0.010" short of the max brass length spec. If you end up too short, adjust to longer initial trim length and try again. Also the uniforming of case mouth by trimming, squaring, and minimal chamfering will improve results of the forming, by FL die and fire-forming. I would use new WW 300 H&H brass, then anneal after the trim and FL size steps, before fireforming, then re-anneal after every two or three firings, and see how long they last. Lacking that, .338 WinMag from WW would be my choice. Anneal only neck and shoulder on once fired brass, though you will be working the shoulder and case body here, you do not want to anneal beyond the immediate shoulder area. Once-firing does significant hardening, and by three firings you need to anneal for sure. Maybe you just need to pump it down slowly in two or three steps, short-stroke it, brass goes into the die to point of mild resistance and back off, instead of just ramming it home in one throw of the press arm. Also careful lube, sparingly with the Redding Imperial Sizing Die Wax, finger-applied. Or RCBS Case Lube 2, cases rolled on a good, saturated pad, and any excess wiped off with paper towel, to avoid lube dents in the shoulder. Be gentle and use just enough lube. You might try some love-talk with the brass before you get started. Yes. Great article, showing the .475 OKH was done long before the 470 Capstick, and a nifty .424 OKH too. https://www.wolfeoutdoorsports...s/handloader-issues/  Riflecrank Internationale Permanente Incurable The 404 Jeffery in Nebraska, 2004, Ray Atkinson Booking Agent, Shooting the Moon and Bison:   | |||

|

| one of us |

I have to get a copy of that magazine.I.made awesome brass that fit perfect from 338 win mag brass new and once fired .I made some from 7 mm rem mag brass too which is even better I.have a ton of it .I.even made some nickel brass cases . I also got.a tapered expander from rcbs that and right club is the key to making.these cases .They look like miniature 375 h and h cases with the long neck .I.can't wait to get some real head stamped ones from quality brass.I want to write and article about this gun.It is the cartridge that the 338 win mag was developed from.I.hope to have the forming dies for bullets soon .I want to try to make some partition bullets for it. | |||

|

| one of us |

Yep, nice neck on that .333 OKHB. Hubba-hubba! That Handloader article says the .333 OKHB case is 2.500" long. Trust but verify. It kept the same sharp shoulder angle as the longer .334 OKH that came before it. The article also says that 67 grains of "4350" pushed a 250-grain Barnes Original bullet at 2769 fps MV from a "25 or 26-inch barrel, I am not sure which." So said Bob Hagel. Another load was 66 grains of "4831" with the 300-grain Kynoch at 2480 fps, from same rifle owned by O'Neil, the O of OKH, chronograph tested by Speer. Hagel said his own .333 OKHB could not handle the 67-grain load of "4350" but used 65 grains as his max load with 250-grainer. Hagel says the case holds 70 grains of "4350" when filled to base of neck. Another article of interest is "Wildcats and Wildcatters" by same author, Bob Hagel, in the 1969 GUN DIGEST 23rd ANNUAL: The excerpt below is for a review of this book. Book review: Good book.   And so, as the .334 OKH is to the .375 H&H, so too is the .410/404 Jeffery Justified to the 404 Jeffery Rimless Nitro Express. Riflecrank Internationale Permanente Incurable The 404 Jeffery in Nebraska, 2004, Ray Atkinson Booking Agent, Shooting the Moon and Bison:   | |||

|

| one of us |

Thanks for info I will trim my once fired cases back to 2.5 .I had some go as far as 2.after being.fired which made the neck look way long .My rifle has a 25 inch barrel that's pretty heavy .I gotta get the recoil pad replaces I think they screwed and glued it but it's white and Hard as a rock .I will try those powders was going to try reloader 19 and 22 which I already has a bunch for my 338 win mag.It's a awesome gun looks new was well cared for .The .333 calibers died out with the .338s .I can't wait to hunt with it next fall with a new scope on it .I don't want to get cut by that Redfield which cuts like a knife .These cartridges were ahead of their time .The 338-378 KT is almost identical to the 338 lapua in performance and I just have a extra barrel that It will work in might have one built but I already have three 338-378 weatherby rifles .These calibers are awesome just are a little extra trouble ! | |||

|

| one of us |

Cheap and easy "jacketed" and monometal copper bullet sizing: CH4D makes some great bullet sizing dies, in stock or custom order sizes. http://www.ch4d.com/products/dies/sizing/bsd "With our bullet sizing dies, you can size a bullet down a few thousandths or use a series of dies to really shrink it down. They work best if you step the bullet down .004" at a time. Available in any diameter, but they are made as needed so please allow 8-12 weeks for delivery. Price is for any diameter that will fit on a 7/8-14 die. Please call for quote on anything larger."  Lee bullet sizing dies are OK if a size you want is in stock, and I have ordered custom sizes from them too. 10 years ago these custom sizes were offerred at Lee, don't know about now. CH4D are better designed. A 1-ton arbor press from Harbor Freight with a 2-foot cheater pipe is useful for pushing bullets through the sizing dies with the provided base pusher rods that come with the bullet sizing dies. This one is $60 right now, same one I use, cheap! http://www.harborfreight.com/1...rbor-press-3552.html I use a multipostion die plate off of a Dillon press to screw the bullet sizing die(s) into and set that below the ram of the arbor press. You can remove that round, slotted, steel disc shown in the photo above. You just feed the bullets in, point down, one at a time with fingers, into the entry-hole of the upside-down sizing die. Or you can try just screwing the bullet sizing die into an RCBS AmmoMaster press, then you will be ramming the bullets upward through the die. I have not tried any of the Corbin equipment. I do not swage form homemade bullets, only size the store-bought ones down a few thou at a time with my $60 arbor press. One stroke and a smaller diameter bullet pops out the bottom into a small plastic tray set between the legs of the arbor press base. Mine is on the corner of a work bench in the garage, next to a bench vise. I think you will do well to get two sizing dies for two steps with cup & core bullets and partitions, and even monometals. .338" down to .334" then .334" down to .331" Expect the .331" to spring back to .333" and stay there after that second squeeze-down. I base this on experience sizing bullets from .400" to .395" from .416" to .411":   and even .416" to .408":   .416" to .410" will be my next project. Using STP Oil Treatment as a lube works, but it is very messy to clean up, and may be a permanent lube for the bullets. It is hard to get it all off the bullets. Probably why it works in automobile engines. RCBS Case Lube 2 is wonderful as a bullet sizing lube. You can roll the bullets on a lube pad, or dump them in a tin can or plastic tub and pour in the lube, shake them around in the container. Works great and is water soluble and easy to clean up, to get a bare bullet for use in a clean barrel of proper size. Riflecrank Internationale Permanente Incurable The 404 Jeffery in Nebraska, 2004, Ray Atkinson Booking Agent, Shooting the Moon and Bison:   | |||

|

| one of us |

I.Will check that out.I.think .333 bullets will be extinct for.good soon .Corbin told me nosler partitions could be used but accubonds could not be sized down .I have two packs of Elmer Keith's favorite the Speer 276 grain .338 bullets I.am going to size to .333 I.have one pack.of 50 275 grain.Speer .333 , bullets .I.think serria bullets might work good too .The Corbin .333 sizing die is $175 my cousin has a press but.I.like your idea .I.finally got the broken ejector changed that was a little ordeal to get the screw back.in.I am.changing.the scope and recoil pad too .I.think the.pad is glued , | |||

|

| one of us |

I.could do that for my.405 Winchester too I have tons of 416 bullets but good .411 bullets are hard to find .I.Hope to get this 333 okh rifle ready by.Hunting season..I.am getting there slowly but Hopefully this scope comes off easy it's not the original scope but is original mount.I.want to use it deer hunting.next fall and take it Alaska when I get to.go.back. . | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Wildcats And Their Development

Wildcats And Their Development  forming 333 okh belted from 338 win mag I guess it needs new brass

forming 333 okh belted from 338 win mag I guess it needs new brass

Visit our on-line store for AR Memorabilia