The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Other Topics

Other Topics  Aviation

Aviation  Packard Merlins

Packard MerlinsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

The Merlin was considered to be so important to the war effort, negotiations soon started to establish an alternative production line outside the UK. Rolls-Royce had checked out a number of North American automobile manufacturers, in order to select one to build the Merlin in the USA or Canada, and Packard Motor Car Company's attention to high quality and engineering impressed the parent British company so much, Packard was selected to build the Merlin. Agreement was reached in September 1940, and the first Packard-built engine, designated V-1650-1, ran in August 1941. The first American production of the Merlin was the Packard Merlin 28 (Mark XX). This engine was a single stage, two speed supercharger. As the Merlin 28, it was used for the Lancaster bomber. The USAAF version of this engine was used in the P-40Fs. The initial Packard modifications were done on this engine by changing the main bearings from a copper lead alloy to a silver lead combination and featured indium plating. This had been developed by General Motors' Pontiac Division to prevent corrosion which was possible with lubricating oils that were used at that time. The bearing coating also improved break-in and load carrying ability of the surface. British engineering staff assigned to Packard were astonished at the suggestion but after tear down inspections on rigidly tested engines were convinced the new design offered a decided improvement. The real improvement Packard incorporated into the Merlin was adopting the Wright supercharger drive quill. This modification was designated the V-1650-3 and became known as the "high altitude" Merlin destined for the P-51. The two speed, two stage supercharger section of the -3 featured two separate impellers on the same shaft which were normally driven through a gear train at a speed of 6.391:1. A hydraulic gear change arrangement of oil operated clutches could be engaged by an electric solenoid to increase this ratio to 8.095:1 in high speed blower position. The high speed gear ratio of the impellers was not as great as the ratio used in the Allison but speed of the impeller alone was not the factor that increased the engine performance at altitude. The double staging of the compressed fuel/air mixture provided the boost pressure through a diffuser to the intake manifolds which increased the critical altitude of the power plant. The ability of the supercharger to maintain a sea level atmosphere in the induction system to the cylinders allowed the Packard Merlin to develop 1,210 horsepower at 25,800 feet. The two stage impeller created extreme heating of the fuel/air mixture during the compression process and in order to prevent detonation of the compressed charge, it was necessary to cool the mixture prior to entry into the cylinders. This cooling was accomplished by the casting of an intercooler passage into the wheelcase housing between the first and second stage impellers. Ethylene glycol coolant was circulated by a pump through this passage to carry off the excess heat generated by the impellers. Without the intercooler the temperature of the charge could be as high as 400°F (204°C). The intercooler in itself was not adequate to deal with the high temperature and an additional cooling fin and tube core was placed between the outlet of the blower and the induction manifold to the cylinders. This radiator was known as an aftercooler and served as a reservoir for the system. The glycol mixture used for the supercharger cooling was independent of the main engine cooling system and used a centrifugal pump driven by the engine to circulate the coolant through an aircraft radiator system at a rate of 30 gallons per minute. This combined system reduced the charge temperature to suitable levels. The throttle valves in the updraft carburettor throat were controlled by an automatic boost control through the pilot's linkage to maintain the selected manifold pressure during changes in altitude. These valves were only partially open during ground and low level operation to prevent overboosting of the engine. As air density decreased with an increase in altitude, the throttle valves were moved to an open position by boost pressure corresponding to aircraft altitude. This system provided full power within engine boost limitations up to the critical altitude of 26,000 feet. This was the improvement Packard brought to the Merlin. When the first of the Packard-built Merlins arrived in Britain, the engineers at Rolls-Royce stripped it down and were amazed to find the production-line built Packard engine, far from being as bad as they expected it to be for component tolerances, was actually better.[citation needed] Up until then, R-R Merlins were hand built, every face being finished off by hand, and this time-consuming process placed great strain on the production capability of the skilled workforce involved in the manufacture of these engines. The Packard engine changed many minds, although there were still some at R-R who remained unconvinced of the quality of the American engine, produced as it was by a largely unskilled and semi-skilled female workforce. In the end, the engine's performance removed any doubts about its quality and workmanship. The Packard V-1650 so outperformed the Allison V-1710 that it supplanted the Allison in the North American P-51 Mustang, which then became one of the best fighters of the war. It was also incorporated into some models of the Curtiss P-40, specifically the P-40F and P-40L. Packard Merlins powered Canadian-built Hurricane, Lancaster, and Mosquito aircraft, as well as UK-built Spitfires in the shape of the Mark XVI, otherwise the same as the Mark IX with its British-built Merlin. Although it is not commonly known, Packard greatly improved the maintainability of the engine (by allowing easier use of interchangeable parts, rather than custom finished ones), and their changes were also incorporated in subsequent British production. | ||

|

| One of Us |

That's some very interesting information. Thanks for posting it. | |||

|

| Moderator |

Yes, thanks for the interesting info.. Does anybody know if the Merlin or the complete Spitfire was ever produced in Canada? | |||

|

| one of us |

Pete I believe two Merlin (Packards) versions were built here for use in the Lanc, and Mosquito assembly. Don't think any Mustangs were built here. | |||

|

| Moderator |

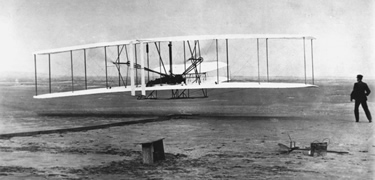

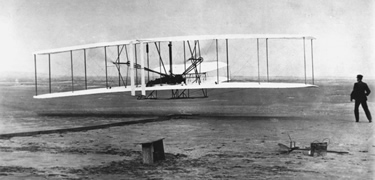

This thread needs pics!   Beautiful pieces of art! for every hour in front of the computer you should have 3 hours outside | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia