The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Other Topics

Other Topics  Aviation

Aviation  How does the radial engine work ?

How does the radial engine work ?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

This has been driving me nuts for a while, how do the radial engines work that the cylinders rotate around the crankshaft. As in WW1 fighters. Are they two cycle? Never rode a bull, but have shot some. NRA life member NRA LEO firearms instructor (retired) NRA Golden Eagles member | ||

|

| One of Us |

The prop's mounted to the crankcase and the crank is fixed to the airframe. An external combustion engine of sorts...throttle control on some was by means of interrupting the ignition rather than modulating the fuel flow. Lots of ways to burn fuel and most were tried 100 years or so back. | |||

|

| One of Us |

Technically, if the crankcase is bolted to the airframe and the crank shaft turns with the prop, it is called a radial. If the crank shaft is bolted to the ariframe and the crankcase and prop turn, it is called a rotary engine. When I was in tech school, we all went to see a Monosoupape fired up and running. Noisy little bastard. Although the 'blipping" of the ignition (on rotaries) was often used for landing right up to the end of the war, by mid-war, most had throttling capabilities of at least some reduction down from full throttle. The Monosoupape wasn't one of them with that capability although later ones did have the ignition ionterrupter that only cut out a certain number of cylinders allowing the remaining ones to supply a limited power source. Pluses to the design were that it cooled better since the cylinders were always turning and, due to the large turning mass, there was no need for a flywheel to soften the power inpulses. The main bad thing was that it turned like a whippet in one direction and like a cow in the other, due to the gyro effect. | |||

|

| Moderator |

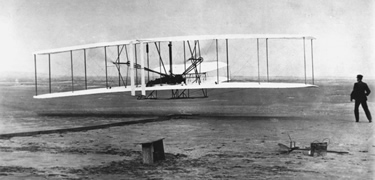

As you guessed, the rotary aircraft engines are 2 stroke, click this link to learn about it: http://www.animatedengines.com/index.shtml Here is how a radial engine works:  Radials can be either 2 stroke or 4. The interesting thing is a radial 4 stroke will almost always have an odd number of cylinders. for every hour in front of the computer you should have 3 hours outside | |||

|

| One of Us |

Can't say about all of them but some ( I believe quite a few) were 4 stroke engines. The monosoupape for certain was four cycle as it only had one valve. It would be pretty hard to have a one valve two cycle as the 2 cyc requires simultaneous exhausting of spent gases while also bringing in a new fuel air mixture. Pretty hard to do with one valve. Even though being a 4 cycle, there are many similarities to modern 2 cycs, as in the air and sometimes even the fuel mixed with air came in through the crankcase. | |||

|

| Moderator |

You're correct about that Mike, my bad! One of the hazards of posting from memory when it is too late at night/too early in the morning! for every hour in front of the computer you should have 3 hours outside | |||

|

| One of Us |

If firing order is sequential on every other cylinder, there must be an odd total number or the even numbers never fire. Engines with even numbers of cylinders fire sequentially only. | |||

|

| One of Us |

Uhhh... NOT if that one valve is an exhaust valve. Remember the old Detroit diesel truck engines? They had four valves per cylinder, all FOUR were exhaust valves. The air entered the engine via ports in the sides of the cylinders BTW, the Detroit diesels were "pressure scavenged" 2-stroke engines, there was a mechanical supercharger on the engine that blew clean air into the engine. AD If I provoke you into thinking then I've done my good deed for the day! Those who manage to provoke themselves into other activities have only themselves to blame. *We Band of 45-70er's* 35 year Life Member of the NRA NRA Life Member since 1984 | |||

|

| One of Us |

I said "pretty hard" not impossible | |||

|

| One of Us |

Two stoke engines can have any number of valves or they can have no valves at all - ala scavenging type. | |||

|

one of us |

It doesn't - simply put, a radial engine cannot work, it just ain't possible! Now, having said that, how much do you want to know about radials? I am no expert and make no claims to such but I can tell you a bit about them. Someone as already mentioned that we have both a 'rotary engine' and a 'radial engine' so I'll try and speak a bit to each type. For practical purposes let's say that the French started the whole mess with the le Rhone rotary with a progression of size and power from a 5 cylinder with I believe 30 net HP to a 7 cylinder to end with a 9 cylinder with an output of 130 Hp. The Le Rhone was a very complex engine for its day [remember, we had not been able to turn a truly round hole until a short time before WWI, supposedly the Orient Express locomotives we re the first to have round bores in the cylinders] Anyway, we also note that the radial outgrowth maintained the same basic layout as the rotary, just operated differently. Various and sundry methods were tried and mostly rejected out of hand to increase the size and output of radials until it was decided that the answer was to double bank the engine, effectively holding the line on the diameter and increasing [doubling?] the length.. The US seemed to favor the 18 cylinder design with two rows or ‘banks’ with 9 cylinders in each such as the P&W R2800 while the Japanese settled on 14 cylinder 2 banks with 7 cylinders in each as found in the Nakijima engine used on the Mitsubishi A6M ‘Zero’ which gave 925 HP up to 1210 HP with water/ethanol injection depending upon which model. The Germans likewise used a 14 cylinder engine on the Focke-Wulf 190, which used a BMW 139. Over the course of its lifespan, the radial was run in multiple configurations, some unbelievably complex and hogs for maintenance. For instance, the largest radial ever built, at least to my knowledge was the P&W R4360 which was none-to-affectionately known as the “Corncob” and several other names I can’t print here. This monster had 4 banks of cylinders with 7 cylinders in each for a total of 28 cylinders in one motor! Now this thing had dual ignitions so each engine had 56 sparkplugs giving a total of 224 sparkplugs per A/C! And the “Spruce Goose” that Howard Hughes built had six of these monsters so it had 336 sparkplugs! If you are able to visit the “Spruce Goose” museum they have a dynamic cutaway version of one of these engines slowly ticking over to give one an illustration of how they work. Also, you can go to YouTube and find a lot of examples of radials being cranked and run up, etc. A faovrite od mine is the cranking sequence video for the Russian Ant-2. What an ordeal to crank off an engine! Over the years the US had two major designers and builders of the radial engine, these being P&W and Curtiss-Wright. P&W built variants such as the R985, R1340, R1830, R1835, R2800 and the R4360 while Curtiss-Wright built engines from the Wright “Whirlwind”, the R540, R790, R1300 “Cyclone 7”, R1820 “Cyclone (“, R2600 “Twin Cyclone”, R3350 Duplex Cyclone” and the R2160 “Tornado” You can do a search on the model types to find listings of the A/C they powered and I’ll close this with one little story. We had a thread here on the “Most Beautiful Airliner” and several folks nominated the Lockheed “Constellation” I’m not going to knock the ol’ Connie but my wife had an uncle that flew these things for good old Eastern Airlines (i.e., ‘The Enemy”) and he absolutely hated Delta and the DC-7B. Both of these A/C were powered by the same basic engine, the Wright R3350 but the DC-7 engines had PRT’s (Power Recovery Turbines), three on each engine and these exhaust driven turbines gave a boost of 250HP each so the DC-7 had 3000HP more than the Connie. A favor trick of the Delta pilots was to fly up alongside the EAL Connie, match speed then just fly off and leave him as it was that much faster – the top speed on the DC-7B was slightly more than 400 MPH vs about 375 or so for the Connie - and that is stroking in a piston engined A/C . Ah, for the old days when such things happened! I miss them. Lord, give me patience 'cuz if you give me strength I'll need bail money!! 'TrapperP' | |||

|

| One of Us |

Yes the DC-7 had a more powerful version of the engine but it was faster because it was an Aircraft designed after Constellation 749's were flying (but before the first commercial examples were delivered). The improved L-1049 came somewhat later buy were in service before Douglas was riveting DC-7's together. Newer is often better, and "best airliner" is often a fleeting thing... the DC-7's career was brief. If I provoke you into thinking then I've done my good deed for the day! Those who manage to provoke themselves into other activities have only themselves to blame. *We Band of 45-70er's* 35 year Life Member of the NRA NRA Life Member since 1984 | |||

|

one of us |

And you left off a couple of things re the DC-7: Namely, it was a mtc nightmare! Those PRT's that they were so proud of would melt down in a puddle if the F/E wasn't on his toes, it was also a shakey flight and noisy. It burned fuel like a bandit - mucho dinero! I've said before and I still maintain: The day of the piston powered A/C was over the day the first commercial jet flew. The worst jet is a better ride than most any piston A/C - if we had a contest I would have to vote for the Sud Aviation 'Caravelle' as the worst jet I have ever flown on. Again, my thoughts only. Lord, give me patience 'cuz if you give me strength I'll need bail money!! 'TrapperP' | |||

|

| One of Us |

Connies had a few engines physically burn themselves off of the aircraft.... Not sure about similar things happening on a DC7, but.... I think the greatest innovation for aircraft isn't the Turbojet or the Turbofan, but the turboprop. but that's just me If I provoke you into thinking then I've done my good deed for the day! Those who manage to provoke themselves into other activities have only themselves to blame. *We Band of 45-70er's* 35 year Life Member of the NRA NRA Life Member since 1984 | |||

|

| One of Us |

The DC-7B was often termed "The Tri-motor Douglas," as it took off on four and often landed on three. The term "Three turnin' and one burnin" also applied to the 7B. | |||

|

one of us |

A lot of truth to what you say. By the time the DC-7 and the -7B came along, the radial was so badly outclassed and was performing at the very top of its envelope that it was a total disaster. Let's think about this realistically: On average I think we were getting something less than 800 Hrs MTBO – and 1000 hrs on an engine was not as common as 100 or less! Then add the PRT problems, fuel burn and the problems continue to grow and develop. Yes, I too have heard the DC-7 referred to as ‘the Douglas Tri-motor’ along with lot of other names I can't print, and seen them come out of overhaul going to the line to pickup Psgrs with three turning and one grinding – oftimes a stream of oil and fuel the size of your finger running out of the PRT shields and you knew when that heifer did light you were going to see one hell of a fireball come flying back at you. It was with the DC-7B amd the R-3350 that I first encounter the trick of pulling a sparkplug and coiling rope down into the cylinder so the prop couldn't windmill when you ferried the old girl home. And gone home on Friday afternoon with several spare engines ready and come in Monday to find a 'glider' parked in the hangar with a couple pulled off and used as spares to keep others flying. The engine itself was not entirely at fault, it was just that too much was asked of it and the range it operated at was beyond what it could deliver up on a continual basis. For instance, we flew the D-46 {our version of the C46) for years and it had two 3350’s but they were much lower rated than the compounded 3350’s on the DC-7B. Same story with the Able Dog {Douglas AD-1] – it flew with 3350’s and had one of the longest service life careers of any A/C ever in US military service, from 1946 to 1972. So, we are here looking at the end of an era, that being the demise of the piston powered A/C with radial engines – and I must admit I miss them, even with all their faults and problems. I can be in ANC or some other location where they are still flown and get a thrill just to hear one light off, much less see a DC-6 lift off again. The radial was another step in the evolution of flight but it truly carried us along long way. Lord, give me patience 'cuz if you give me strength I'll need bail money!! 'TrapperP' | |||

|

| one of us |

I've seen the oldies at Rhinebeck Aerodrome.It's very obvious that the rotaries have a torque element when you see a Fokker triplane start up. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Other Topics

Other Topics  Aviation

Aviation  How does the radial engine work ?

How does the radial engine work ?

Visit our on-line store for AR Memorabilia