The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Other Topics

Other Topics  Aviation

Aviation  Prop RPM

Prop RPMGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Does anyone know the prop RPM of the red Corsair with the R4350 (4360?). This aircraft was at the Tunica,MS air race two years ago. The reason I ask is she has one prop blade painted white which makes for a cool effect and was wondering if I could get similar results by painting one of my 5 blades turning at 1500. Double Rifle Shooters Society | ||

|

one of us |

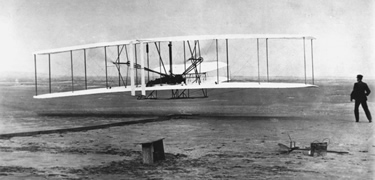

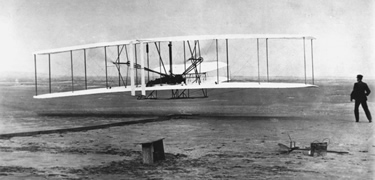

Is this the "Red Corsair" you are referring to? www.flyinghigher.net/goodyear/NX5588N.php [Pages & Images Copyrighted} I really wish you would not ask questions like this as I usually get a headache trying to remember (?) I seem to recall the R4360 had 3500HP at 1950 RPM and pulled some 42" MAP at takeoff RPM - sound right? But the R4360 was 'developed out' to something over 4000HP before its demise so I don't know which 'corncob' he is flying. Maybe someone else has a better memory or a spec sheet for the R4360. Interesting engine, recall their usage on the B36 - "Six turning and four burning" as she rattled windows and shook the ground when flying over? Lord, give me patience 'cuz if you give me strength I'll need bail money!! 'TrapperP' | |||

|

| One of Us |

Thats the one. Man! what I would do to be able to take it around the patch! Double Rifle Shooters Society | |||

|

one of us |

Hey Kelly I'll be over your way in a couple weeks I'll gladly paint one blade for ya. You been busy? Have you cycled your PF upside down lately????? God Bless http://www.davidchristmangunmaker.com/ http://i257.photobucket.com/al...wnhound/f66262d4.jpg | |||

|

| one of us |

I'd love to fly that bird. But I'd hate to be the one who had to keep it running. Or pay the Av-gas bills. | |||

|

| One of Us |

Back in 1981, there were a couple dozen of those corncobs laying around a corner of Long Beach. I'd hate to have to pay for an overhaul right now, much less the fuel bill, but I'd surely love to get my hands on that monster... | |||

|

| One of Us |

Bankers hours this time of year. Putting out some blend fertilizer and welding up a new stainless load rig. Stop by if you have a chance. Bring a large caliber rifle, we have plenty of plastic jugs that need destroyed! Double Rifle Shooters Society | |||

|

| one of us |

You should find the RPM here in the training film Get in and start your F4U This is the 3 bladed version Idle 750 RPM. Max cruise 2330 RPM Recommended cruise 2150 RPM Low RPM cruse 675 RPM Most RPMs given at about 12 min into the film. I always wanted a ceiling fan that looked like a n F4U cowling and prop complete with the starting rumble. | |||

|

| one of us |

Except a standard F4U has an R2800 CB16 for power. That will have different power settings than the R4360 version. The R4360 version was a stupid human trick as far as I can tell. | |||

|

| one of us |

O.K. I'll bite. Cruise at 675 RPM? Must need a hellofa MP setting?? | |||

|

one of us |

I cna't do the ceiling fan bit but I can give you the sound effects. Go to http://www.thecorsairexperience.com/main.htm or http://www.f4ucorsair.com/main.htm and click on "View Trailer" - watched it a couple or three times and Iwill be watching it again. And BTW, watching the plane fly and etc you can clearly see that big prop does indeed turn S-L-O-W-L-Y and the sound has to be heard, especially when they fire that R2800 off with the shotgun starter. Lord, give me patience 'cuz if you give me strength I'll need bail money!! 'TrapperP' | |||

|

| one of us |

The Corsair had a 2 to 1 reduction gear driving the prop. The RPMS are given at 12 mins into the video. Check it out. 675 RPM on the prop..... Watch the video here. | |||

|

| one of us |

Have you no idea of our patheticly slow broadband speeds here. I only attempt videos of a couple of minutes. Besides, I figured all RPM's given (as far as the pilot is concerned) is for the engine only. But sure, we started off talking prop revs. My mistake. | |||

|

| one of us |

Jal, Sorry about the speed of your service. It is a pretty good video. | |||

|

| one of us |

You've nearly talked me into trying it. How long does it run? I'm still wondering about your RPM's. The little radials I had, would agreee with an ; IDLE (Engine) about 750 rpm. (So prop 375rpm)?? otherwise if prop rpm = 750 Engine idle 1500rpm? Again, Max cruise of 2330 sounds like an engine speed to me, otherwise if prop, engine 4660? don't think so. Rec cruise 2150 again sounds like the engine. Low rpm cruise, if 675 is prop, engine= only 1350? I'm wondering if all these figures are engine rpm, and low rpm cruise is actually 1675?? I'm used to a low of about 1900 RPM (engine) | |||

|

| one of us |

Low RPM cruise was 1350 on the engine according to the film and 675 on the prop. | |||

|

| One of Us |

Every radial I ever flew had the tach reading out engine RPM. Who cares what the prop is turning if the engine numbers are in the green and the jugs aren't popping off? | |||

|

| one of us |

They were, the heads were popping off. Whoops, nother story. Someone wanted to know the prop revs to paint a blade different so that it looked like it was going backwards. . . Or something. I hate that look on choppers, makes me dizzy. Didn't like night flying with a rotating beacon on either, after a while yer eyeballs go funny. | |||

|

| One of Us |

Those engines had a number of things to make a "power setting" Engine RPM, Prop Rpm, MAP and fuel flow. A "power setting" would look this way: 2150 ERPM, 1650 prop, 38"map at 51 gal/hr. The props were constant speed units. As I recall the superchargers were variable speed the props were constant speed and there was no gear reduction for prop drive. I believe the R2800 series engines ran a red line of 2400 RPM on the crank. In which case the high cruise setting of 2150 makes a ton of sense and the low cruise of 1650 the same. Roughly the 1650 figure would equate to a 60% cruise setting or best range and the 2150 a 80% best speed cruise. I also seem to recall a max boosted pressure of 50"Hg or about 28 psi/2 atmospheres. | |||

|

| one of us |

I wish you blokes would stop trying to confuse me. I thought we all agreed they did have a "reduction" (by a gear). Which is usually fixed and constant so as jetdrvr says, why include prop revs in the setting if it can't be changed anyway? | |||

|

| One of Us |

The prop RPM can be changed it's a constant speed prop just because the is no gear reducced prop drop drive does not mean prop RPM cannot be changed. Generally props that exceed 2600 RPM unless very short and fat lose efficiency because the blade tips go supersonic and the airfoil of a propeller blade is not designed for that- they also get very noisy. The massive prop- something like 100+" diameter would go supersonic quickly if the engine turned up much more than 2400 RPM. A typical gear reduced redline for an aircooled aviation engine is on the order of 3350 RPM a Continental GTSIO 520 for example a .6 to 1 reduction from a simple spur gear. There were indeed gear reduced prop drives on some radial engines, most often of the planetary type. | |||

|

| One of Us |

The prop governor controls the prop and the engine rpm on an aircraft equipped with a constant speed prop. The governor regulates oil flow through valves in the governor, which moves the geared prop hubs on a ring gear in the prop dome housing. The Hercules also has a syncrophaser, which regulates prop rpm to prevent prop tips from passing each other during the operation,thereby eliminating vibration. It keeps the blades out of phase while synching rpm by constantly, slightly changing the pitch of the blades when it senses in in-phase situation developing. Totally different than the prop on your 185. | |||

|

| one of us |

Ok, But we started off with a "geared" prop. which would ALWAYS be half engine speed. (I thought). Sure most everything over a 182 has a constant speed prop which (I thought) was a completely different thing, ie the prop governor set the blade angle to set the engine RPM, but changed prop angle when necessary to maintain engine rpm. So arn't we on two seperate things here? | |||

|

| One of Us |

The propeller gear reduction is not required to be 1/2 of engine rpm. Most piston engines are more like .6 or in the case of a turbine reduced from around 35,000 to 2000- or so. You do indeed vary propeller pitch to get a certain rpm at a certain power setting which is why I stated a "power setting" included and engine rpm, a prop rpm a manifold pressure and a fuel flow. A constant speed prop is different than a propeller reduction drive. A propeller governor controls prop rpm the throttles control engine rpm and a syncophaer adjusts slave propeller rpm to be in phase with the master prop to reduce noise and vibration harmonics there is also fan sync on jets to do the same.One can drag down engine rpm by setting a coarse prop and not increaseing throttle and vice versa. However it is incidental control not actual control. The prop governor will increase or decrease prop pitch to maintain the set rpm value when throttle is added or subtracted. It is correct to say that the prop governor controls oil pressure to the prop either the dome or a pressure chamber depending on the maker. This is accomplished by a set of flyweights in the governor that cover two ports that control flow to and from the prop actuating dome/chamber. many aircraft of all sizes have constant speed props. | |||

|

| One of Us |

We had a Herc crash in Juba, Sudan when the master dragged the other three down with it on takeoff. Guys turned around and made the runway after successfully feathering one, but overshot and ran off the side and smashed into a bunch of conex containers. No one was killed, but the airplane was a writeoff. The military has a procedure for this, pulling a couple of breakers, but Lockheed in its infinite wisdom never bothered to get it approved on the civilian version. The props on a Herc will definitely kill you. After the accident, the word went out among the capts. and FE's : screw the manual. Pull the breakers if it starts to happen again. | |||

|

| One of Us |

We've always turned it off for landing and takeoff that way maximum power can be used as one would want it. If your taking off with the sync on you're a fool to be nice about it. | |||

|

| One of Us |

Yeah, but...Lockheed, at the time, had no approved procedure for pulling the breakers. You can't do that and adhere to the operations specifications, which have the force of law. If a crewmember say, didn't like the captain and the capt. pulled the breakers, his butt would be toast with the VP Operations if he got snitched out. And that shithouse outfit was loaded with snitches. We had an FE who had done test work for Lockheed and he spread the word about the procedure after the accident, so everybody quietly agreed that they didn't want to die on a rollback because the powers that be at Marietta didn't get the procedure approved by the Feds, so if a roll back started on takeoff, the FE would quietly reach down to the essential AC bus panel and yank 'em so as not to get on the CVR. That way, we'd all live to drink beer in the bar that night and the maintenance guys would get an appropriate write-up in the book so's it would be properly repaired. Gotta play the game if you want to stay in the saddle. Now, if I'd been flying for some African outfit, we'd have just turned them off as you say. Given the state of the usual African Herc maintenance, the thing probably wouldn't be working anyway. MEL? What's a steenkin' MEL? But you don't pull that stuff on a Part 121 operation without the possibility of suffering severe consequenses. You're not supposed to fly a Herc with an inoperative syncrophaser. The thing already developes wing cracks from normal use. I've flown one bird that was on its fourth set of wings. No reason at all to aggravate an already bad situation by vibrating that wing structure an iota more than it normally experienced. If the captain who was flying that day had known about the procedure, there would likely be one more Herc still flying somewhere out there today. | |||

|

| One of Us |

I'm no fool, BTW, because I survived 39 years of flying in some of the world's most dangerous places. As bored as I am now, though, I almost wish I hadn't made it through. But nobody who ever flew with me would ever call me a fool. An asshole, maybe, but not a fool. I'm satisfied with that. | |||

|

| one of us |

Yes and plane "systems" have been killing pilots all over. I was incredulous reading about, I think it was a Russian jet freighter took of and apparently the onboard computers didn't like the quality of the fuel, so just started shutting the engines down to save damage. Trouble was the whole aircraft ended up in a building. So much for that. | |||

|

| One of Us |

That's true. Consider, however, that you're speaking about a Russian aircraft. Russia and the former Iron Curtain Countries, who primarily use Russian-built aircraft, have recently eclipsed Africa as the area of the world where the overwhelming majority of fatalities occur. I've been aboard several Russian aircraft and, given the current financial state of the above-mentioned countries and, naturally, their level of aircraft maintenance, I wouldn't get on one. That's why it is paramount to learn as much about systems as much as you possibly can in initial training. During upgrade, you have no choice, particularly in a three-seater like the 747, because the captain has to be able to operate the systems in case the Flight Engineer becomes incapacitated. The FAA Inspector who gives you the oral exam for the type rating will make sure that you know the airplane. Orals can last two or three hours, during which time you go over each of the systems, their purposes, operating limitations and operational procedures. This is becoming less of a problem now that computer automation is replacing the position of the flight engineer and the systems are less complex,(and most aircraft now only have two engines), but you'd better know them, regardless. I retired before I ever had a chance to upgrade to a fly-by-wire two-seat aircraft, but system automation or not, I'm sure that I would have missed that third set of eyes in the cockpit. In my company, the FE had to have an A&P as well. He wasn't just some junior pilot filling the third seat until he could upgrade to first officer. That knowledge served us well, as we operated in some of the world's most remote areas where company maintenance was non-existent away from base, such as Antarctica, Somalia and Papua New Guinea. I once had a break-down in Letecia, Colombia, where there is nothing but good fresh Amazon River fish and bandidos. We were hauling some trucks out of there for BP and our gas turbine compressor, a small jet engine located just ahead of the left wheel well which is used to provide electricity and compressed air for starting, broke down. The FE fixed it and signed it off in the book and we flew out of there. Had he not had an A&P and extensive systems knowledge, we could have been stuck in that hellhole for a week. And Letecia ain't a place you want to sitck around in for long. | |||

|

| One of Us |

I saw an Mi-8 with safety wire holding the PC link to the MR pitch horn, the entire hole was wrapped full of safety wire. There are rules and there is survival. | |||

|

| one of us |

Well havent you heard of fly by wire. | |||

|

| One of Us |

I gotta tell you...that MI 8 is a fine aircraft. I've seen them in Angola, Papua New Guinea, Somalia and Colombia. One taxiied by one of our Hercs on the ramp in Benguela, Angola, and chopped off about eight feet of one of Lockheed's wings without sending the main rotor blade flying off the mast. They fly and fly and fly in the most primitive conditions with third world crews flying and maybe maintaning them and they're like that EverReady bunny. They take tremendous abuse and operate in horrible conditions, and they keep on flying. A very impressive helicopter, indeed. | |||

|

| One of Us |

The Soviet style aircraft are, interesting anyway, fine aircraft I don't know about. They are heavy, crudely built, have low component life, and high fuel consumption. But they will operate with minimal knowledge and skill in crew air or ground. | |||

|

| One of Us |

They are true third-world aircraft. That MI 8 will fly in places like Angola when a Bell 212 would be grounded for lack of parts, maintenance, or plain overwork. I've seen the big Kamovs sling load stuff at Chevron's oil field in PNG that would stagger a Chinook, and they don't seem to fall out of the sky quite as often. American technical complexity is a distinct disadvatage in the third world. Soviet simplicity is equally an asset. The Mil helicopters lift heavy loads and operate in adverse conditions without sophisticated maintenance procedures or high-tech systems. I watched them do it for years and I watched them operate in PNG side by side with the American machines. If you want to build an oil field, camp, and airstrip in the center of about the most primitive place you can find, contact Heavilift and hire Russian birds. They'll be flying when the Bells and Boeings are sitting in the shop. Talk about hijacking a thread...we started off on Corsair props and ended up on fling wings. Oh, well. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia