The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  glass bedding my new Ruger Lott

glass bedding my new Ruger LottGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

[URL=  ]1[/URL][URL= ]1[/URL][URL= ]2[/URL][URL= ]2[/URL][URL= ]3[/URL][URL= ]3[/URL][URL= ]4[/URL][URL= ]4[/URL][URL= ]5[/URL][URL= ]5[/URL][URL= ]5b[/URL][URL= ]5b[/URL][URL= ]6[/url] ]6[/url] | ||

|

| One of Us |

Will that be the only area of the stock that you will bed?? I have a Rigby that i want to bed. | |||

|

| one of us |

Yes.This is how I bedded both of my other Rugers.I have also bedded other rifles this way and had no issues.I had two professional jobs done this way also, one of which was a big bore. | |||

|

| One of Us |

I´ll send you my rifles and you can make bedded them I am Spanish My forum:www.armaslargasdecaza.com | |||

|

| one of us |

I have a friend who has me clean his and his hunting buddies rifles before deer hunting season,each year.Last year I got a 100 dollar tip.I told them that I didn't want the money but they insisted. | |||

|

| One of Us |

Very nice job. I see Ruger finally got around to putting a strengthening plate in. first time I got to look at a new Ruger setup. I do a similar bedding job but I also bed a couple of inches of the straight section of the chamber area at least out to the beginning of the barrel contour taper, and the tang...for strength and ALSO to index the barrel so it can be taken out and re-installed without losing it's position. I also add some alum, steel, titanium powder, etc, and colorant to the epoxy mix for added strengh. On one laminated 375 H&H Savage OEM stock I had to box in with .025" plates the bottom, sides, front and back of the blind box mag when the stock split between the mounting holes. After that little hoohaw I went with solid wood, blind mags and stiffening plates to all my heavy hitters...plus putting a steel recoil boss behind the recoil lug with a piece of all thread in it running up the forend all bedded in steel epopxy, plus a piece of all thread down the wrist. For those rifle with an open mag well I also add cross bolts on both sides of the mag well, but everyone know that. Laminated stocks might be strong and don't "wiggle" as much as tupperware or solid wood stocks, but it's only as strong as it's thinnest laminates and adhesive. Some may not like the "boxy" stock of the Ruger but if you look at the sidewalls, they are twice as thick as some other rifles which means that much MORE strength and LESS flex in the weakest part of the stock. You should go into business of bedding stocks...look at how much some 'smiths charge for such a small amount of work. I used to do bedding and accurizing just for components. Nowdays you can't hardly do that without breaking some kind of BS law. LUCK | |||

|

| One of Us |

Just what I needed to see..but I have a question please. I just picked up an older tang safety Ruger in .458 that doesn't look to have been shot much. I plan on bedding it before shooting, but, do you know if the screws that hold the action in need to be torqued to a particular poundage like a Winchester? Or in any particular order? (obviously, I am a newbie to this bedding stuff). thanks Rick DRSS | |||

|

| one of us |

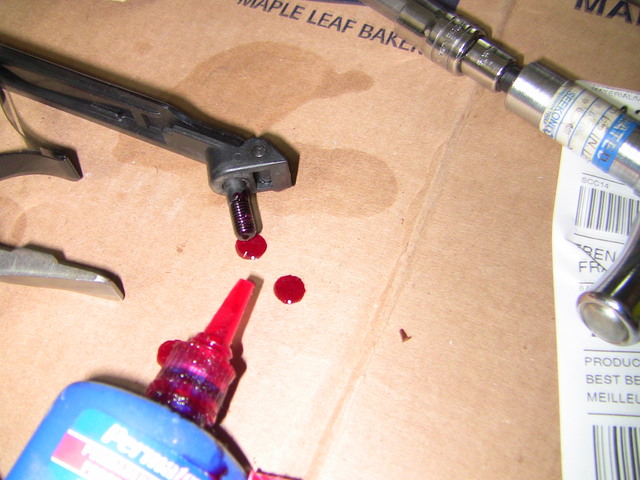

I would suggest you tighten them as tight as neccasary so that they don't undo.I would start with over 65 ft-pounds.The guard screws on my big bores only stay tight when I use red loctite and I tigten them really tight,especially the front lug screw. | |||

|

| one of us |

I have not noticed any stress or damage to the inletted stcok when I used this method.I thought about bedding other parts but that may require removing stock material.If you choose to remove wood or not you may disturbe a tight CNC fitting to begin with and cause new stress points that may crack the stock,ruin accuracy,or not allow the magazine latch to close etc... I find that the barrelled action fits best in the stock with no bedding and if I didn't detect any movement of the action or steel barrel lug piece in the stock,I would've preffered not to bed or use as little as I could. | |||

|

| One of Us |

What you say is true...the object is NOT to screwup the original bedding but to ADD to it. You don't need to take out much more than 1/32 to 1/16 material...I leave sections of original wood that I have CHECKED to see it actually fits and take out a portion around/underneath etc. The epoxy will skin and harden any wood it comes in contact with. I also use bedding blocks and pillars. Wood has a tendency to squash out over time and a CNC fit job isn't all that close anyway except in visual areas. I guarantee a barrel bedded against a piece of steel...the RIGHT way...with pillars at the mounting bolts will do the job. No matter HOW you bed wood it will "wiggle", "crawl", "torque", and "bend" an action so keeping it away from the barrel and having only two points of contact...the front and read pillars...will keep the accuracy much longer than a "CNC" fit unless you have some VERY good wood to begin with. It doesn't really matter how I do my bedding, it is YOUR shooter so you have to live with it. Take you shooter from Montreal during the wet time of year and go to Africa in the heat and I guarantee you will have a twisted/torqued barrel in some fashion...or go the other way...same thing happens. My objective is to bed for stability and strength and give enough clearance around the barrel and sides of the receiver so all that twisting is kept to a minimum...sometime you can get away with just a little clearance and sometimes not...you just have to see from wet to dry...nothing too hard or complicated and it depends on the grain and type of wood or synthetic you use. I just picked up a beautiful tiger stripe Maple stocked 1943 8mm military Mauser with original barrel that looked perfect, fitted the old fashioned way 30-40 years ago...NO gapitis...but it walked rounds up and left as it warmed up. After I took the action out of the stock there was a long black streak along the right side of the channel and a black patch at the left end of the channel...after I scraped out the patches and relieved the end a bit, shimmed up the flat behind the recoil lug and gave it some "gapitis" it started shooting nice 1" triangles with both 150 and 185 gr bullets and NO walking. It didn't take all that long and 50 odd years of experience with stocks didn't hurt either. Foxhound...I have 4 tang model Rugers pillar bedded or with an aluminum bedding block. One is my 510 Makatak...50 cal using a Rigby case shortened 0.050". I shoot mostly 535gr hard cast lead bullets but also 600-700gr. The action/stock was OEM 30-06...I did all the metal work and I made a alum bedding block to fit the action and the whole thing is bedded in steel epoxy...with the rod down the wrist and a rod up the forend. I did two OEM wood stocks with pillars, a steel plate below the flat part behind the OEM recoil lug, no rod in the forend or wrist area. And one is just epoxy bedded around the recoil lug, tang and 2" of the barrel. The pillars allow you to lock the action metal to metal and you only need about 40-50 INCH pounds of torque...without pillars you need more and YOU just have to experiment...30-50 FT lbs in some cases. I've built many a motorcycle and car/PU and BIG truck engine, trans and diff's using oil proof RTV and NO soft gaskets and torqued to the fasteners rated specs...never had one leak OR come apart...it work just as good on guns. There are lots of ways to bed...none being totally right or wrong...just different methods to arrive at the same objective. LUCK | |||

|

| one of us |

Another reason I choose not to remove any wood and keep it very simple is because of the iron or express sight factory adjustment.IMO,the rifle sights are adjusted without a bedding and if you go too far with changing the way the barrelled action fits in the stock,you will not be able to get on target.It is very difficult to get an express sight rifle to shoot bullseye at 100yds without a tight fitting setup right from the factory to begin with. | |||

|

| one of us |

I had my 338 RUM glass bedded a couple of years ago. That took away The problem. | |||

|

| one of us |

What was the problem? RUM's are problems alone. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  glass bedding my new Ruger Lott

glass bedding my new Ruger Lott

Visit our on-line store for AR Memorabilia