The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Optimal bullet design for Hunting

Optimal bullet design for HuntingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I now have a fully funtional Haas TL-1 and have mastered G-code to the point that I can make any shape, diameter, goove design, Hollow Point bullet imaginable and out of any non-restricted material imaginable. The question is what is an optimum bullet? The concensus seems to be a bullet made of annealed copper as the optimu material for both expansion and penetration, but what nose shape? Should the base be Flat or boat tailed. I'm not talking about a long range bullet, but one that would be optimized for close in Dangerous game where maximun penetration and expansion are the goal. What should I make?-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | ||

|

| One of Us |

Try a vld 375 for your 375-600OK. | |||

|

| one of us |

Rob, If Macifej doesn't beat you to it: You need to take that drawing of the Walterhog I posted and scale it up to .3950"-groove and .3870"-land diameters, shorten the nose by .150", add a fifth driving band, and drill the hollowpoint deeper and score it internally to fracture into 3 or 4 petals (your choice). Adjust the sub-bore diameter segment up to bore riding diameter, and add a bit to the tail segment to make its leading edge a drive band too, then taper down to a bore-riding segment then the boat tail. Make it 330 to 340 grains in .395 caliber. Heck, make it with an FN nose also. A little boattail is good there too, maybe make it identical in the nose and tail so you can shoot it forwards or backwards. Heck, start with the .375 then .395 ... make it in any conceivable caliber and just shorten/lengthen the nose or the tail as needed to make weight. No Bozo Bullet here:  | |||

|

| one of us |

I really like the idea of an FN solid that is identical on nose and tail. It should fly like a spin-stabilized football. Any slight expansion or flattening of the shoulder-stabizing FN nose would shift the CG forward and dart-stabilize it to boot. The other FN's never get dart-stabilized because their CG is so far rearward to start with. The "Football FN" starts off with CG in geometric center. Already has a headstart on getting dart stabilized. | |||

|

| One of Us |

RIP you could just get that stick of brass 3/8" allthread and chop it to the desired length!!! Since there are now a half dozen "bullet makers" here on the Big Bore forum I'm happy to get back to the big stuff and pass the reins!! | |||

|

| one of us |

Mac, I already tried that, even chucked the rod in a drill press and used a file to shape an FN flatnose. Accuracy was terrible. If I get really desperate for .395 bullets I'll go looking for 10mm metric brass allthread and use a lathe next time. 10mm = .394", might work in a .395 like all the other TSX undersize boolits. Sorry to hear you are whimping out on the Walterhog. | |||

|

| One of Us |

Not wimping out! Lots of other guys here who want to make them but don't see anyone who wants to pay for them. Like the guy in the movie says - "Show Me the Money". I'm happy to keep doing the small boutique designs. | |||

|

| one of us |

Mac, Glad to hear that. Maybe you are right about the SHark fin crimping cannelure. That is the only way I could conceive of improving on the Walterhog or GSC or North Fork design. Lack of neck tension and a poor crimp (if the reloading dies are not quite right, and a Lee Factory Crimp die is not available): skimpy driving bands = looseness Add a SHark fin/gill to the new and improved Walterhog to make a "death crimp" fool proof? Ah well here are some visual aids: S&H, SHark .395 in the middle:  310-grain SHark and and 410-grain LBT cast lead:  GSC perfection with three types in same caliber and weight, .395/340-grain, the only such trio at GSC, of all the bullets they make! More need to be made and shipped!    | |||

|

| One of Us |

Some sort of hybrid would be good I think. A Shark-Hog in copper maybe. I'll be making a few Shark FN's in my usual material in larger calibers. Right now I'm busy making new 3500 Grain FN's and that new Less Expensive reloading press for big cartridges. | |||

|

| one of us |

It's about time you saw the 2-bore to a shoot! One more very interesting and simple to program bullet would be something with the semi-bore-riding structure of the .510/705-grain AAA "Harlow" bullet. The base of the nose has a .5000" diameter bore-riding band that is about .2000" in width. The two following "wide bands" are .5100" diameter. This is another very accurate bullet that I have shot into about 0.179" for three shots at 100 yards from a 500 A-Square/.510JAB. Of course Rob knows all about this one, I am sure. Harlow on the left:  | |||

|

| One of Us |

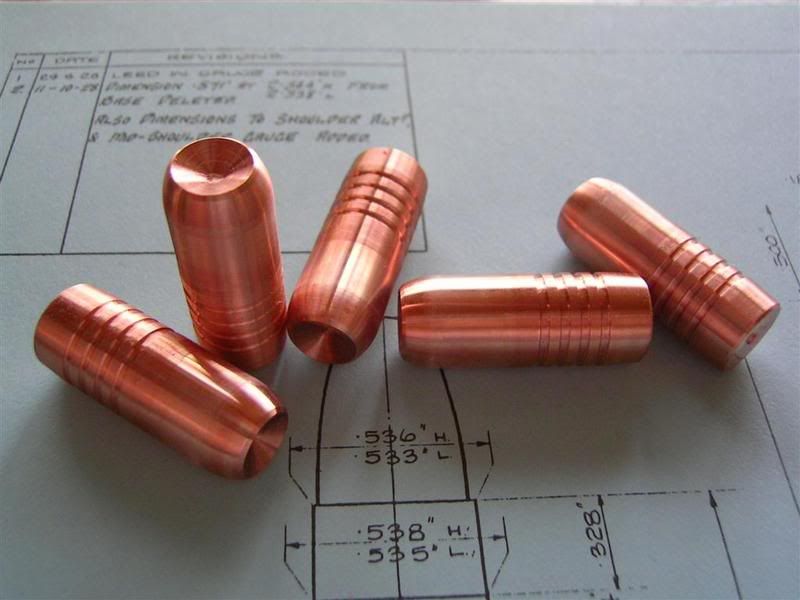

I bet you'll see something pointy like that in .395" show up in your mailbox after Christmas! Those BMG bullets are really too small for close range plinking... These are better for casual recreational shooting.  | |||

|

| one of us |

Mac, I hope you can post pictures of your new .475/475-gr S&H (Shiney&Hard) FN solid soon. Your .395/345-grain SHarlow will complete my brass "trio": three different types of bullet, all of same caliber and different weight. | |||

|

| One of Us |

Seems the Swiss Grinch came a took the Elves away on holiday until Wednsday! | |||

|

| one of us |

Bah! Humbug! X-mas without a complete set of brass .395's!!! 310-grain SHARK 330-grain S&H FN 345-grain SHarlow Nutz! | |||

|

| one of us |

Rob This is my version of the best BIG bore DG hunting bullet. Cal. .500 Jeffery 550 grn of pure copper. Cup i Ø 9mm Cheers, André  Always always use enough... GUN & KNIFE | |||

|

| one of us |

For short range hunting( out to 100 yrds) I believe a flat base bullet will be best design and minimize the loss of case capacity required by boat tails. Annealed copper is probably the material of choice too. I kinda also like Jeffery's design but would add a deeper hollow point(1/2 inch) and internal scoring so it peals back in a controlled manner. Alternatively, A steel wedge driver in the nose. I think I'll try and make a few and see how they perform. I also like Rip's paint bucket idea although I would alter the design to include a self sealing plastic target area at the base and fill them with 10% ballistic gelatin. After each shooting the buckets could be re heated to reform the gelatin over a water bath. This should provide a excellent testing media to optimize bullet expansion testing in the most realistic and reproducible media I can imagine.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Jefferydenmark, I love that bullet, dont know how well it works, but it has the "cool look" factor of 10! 505ED DRSS Member | |||

|

| one of us |

Andre', My next test will be with your .510/550-grain CCP (Copper Cup Point). What should I use? The IWB (Iron Water Buffalo, plywood and water bag sandwich) or the WBT (5-gallon Water Bucket Train)? Using the similar .423/380-grain North Fork Cup Point, and comparing it to the FP solids, and Soft points of same weight by North Fork, all at 2500 fps, the relative penetration in the IWB and Water Bucket Train (WBT) was about like this: IWB (# of 8" deep compartments, each with 1/2" wood, 7.5" water): Soft Point: 5 Cup Point: 9 Flat Point: 11 WBT (# of 5-gallon water buckets, 14.5" water each) : Soft Point: 3 Cup Point: 6 Flat Point: 9 It will be interesting to see how much your Cup Point expands at 2500 fps impact. Rob, You need to use fresh killed pigskin or cowhide as the target face of your GBT (Gelatin Bucket Train). | |||

|

| one of us |

Rob, Glad to hear that you have got that nice lathe set-up. Unfortunately, in my humble opinion Woodleigh has the market cornered for expanding bullets in big bore calibers. Best of luck with your bullet adventures however. | |||

|

| one of us |

Value of the ogived cup point versus the truncated cone cup point that North Fork makes? Is it only an aid to feeding? Will the truncated cone cup point be better at straight line penetration? Will that cup point overcome any instability introduced by the ogival shape of the round nose? The IWB will tell. Woodleigh roundnose FMJ bullets exit the sides of the IWB before going half as far as a TC-FN solid. I expect the CCP of Andre' to do way better than a Woodleigh FMJ. | |||

|

| One of Us |

Roger that!! If you like the classic cup & core design for the "antique" factor go for it! | |||

|

| one of us |

RIP Thay sounds like a good way to test them. I loo forward to the test myself. I will test some myself when the roe der season ends Jan. 15th. I can not bang away in hunting season. Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

ROB I want a solid that does ponly expand a littel to make the bullet nodse-heavy. This feature is to nose control/direct the bullet and avoid change in direction. Still at 2500 fps the bullet should expand some. I do however not want to trade expansion for pebetratio0n. I want the bullet to exit most game. Cheers, André Always always use enough... GUN & KNIFE | |||

|

| One of Us |

.........They all look very Great ....They all look like they would exit most animals up to a ton Dead weight .If it can,t be grown , its gotta be mined .... | |||

|

| one of us |

gumboot458, Yes Andre's bullet has a bore-riding nose, .500-caliber, that is how it fits in a standard 500 Jeffery throat which is only a leade, no freebore. I expect the .395/340gr SP from GSC would pencil right through a coyote chest at 2400 fps and leave only a needle hole going in and coming out. If it tumbled, half the coyote hide would be gone. Andre', Maybe we should add "Ogived" to the descriptor acronym for your bullet: Ogived Copper Cup Point .510/550gr OCCP It could be called "Universal" too since it can do the work of both softs and solids: .510/550gr OCCPU If it will stay on track, straight and true, in the IWB, it is an excellent design that will give more penetration than any "soft point" and it will deliver more bullet energy inside the animal than the FN that goes whistling out the other side. There may still be a a need for FN Solid bullets for Texas Heart Shots on elephants. A .395-caliber/330-grain OCCPU would be nice. | |||

|

| one of us |

RIP That sure is a long acronym Sounds cool, lets name it after the testing If the design is good we can make them in any caliber and weight. The first prototype I tested had a smaller cup and did not expand any! It was shoot into phonebooks. I think the expansion can be controlled by the diameter of the cup. We just need to find the right size at say 2400-2500 fps. Maybe the cup needs to be another size in a .395-caliber bullet. This it is Cheers, André  Always always use enough... GUN & KNIFE | |||

|

| one of us |

Andre', With the 10 bullets I have from you, I will be able to do the testing. My 500A2 load is 110 grains of RL-15 with 570-grain GSC giving 2405 fps in a 23" barrel. I will substitute your 550-grain bullet in that load and shoot the IWB with it. Then chronograph and expect to be 2400 to 2500 fps impact velocity verified. Simple, whenever weather and life cooperate. The IWB will ride again. Fine tuning the hollow-point or cup-point dimensions for expansion over a range of velocities is always fussy. Decent expansion in water at 2400 to 2500 fps will be a good clue. Your bullet picture above shows the slight boattail on your design. I like that. It also shows the bore riding nose section. I like that too. What is not to like about a .510/550gr OCCPU? | |||

|

| one of us |

RIP The Boat tail is to limit friction and improve accuracy. With the smaller front diameter the grooves are almost drive bands Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

Andre', Your bullet is next on my agenda for weekend shooting. It is worthy of getting the Iron Water Buffalo out of the barn and back into the pasture. I am putting the .395 aside until more rifles are built and/or I have proper reloading dies to go with the ones I have. I will be doing a drawing of a hopeful .395/350-grain OCCPU that may be made one day. Or it may turn into a .395/330-grain TCCCPU if your bullet does not stay on the straight and true in the IWB. TCCCPU: Truncated Cone Copper Cup Point Universal How's that for a long bullet designator? Looks slightly Soviet. Cold War nostalgia to boot. That bullet of yours does have "gravitas." | |||

|

| one of us |

Andre', Do you mind if I post a drawing here of a .395/330-grain OCCPU patterned after your bullet? The weight of the bullet is my estimate. Also a .395/XXX-grain Walterhog will be fun to show. It will take someone smart like Macifej to estimate the weight of the .395 Walterhog in copper. | |||

|

| One of Us |

The SHark in .395" weighs 309 grains in material "X". The SHark in .395" weighs 325 grains in material "Y" - annealed copper alloy. | |||

|

| one of us |

Thanks, Jay. The SHark in copper will do wonders if the nose is refined a bit, with a slightly smaller meplat and smaller diameter hole. Whenever I can afford it, and you have the time and energy, reprogram the Shark nose-hole to look like this ... please refer to dimensions of nose meplat and hollowpoint cavity only, below ... which might change the weight of the SHark:  The above might be called the WalterSHog. Weight and length could be adjusted by shortening or lengthening that bore-riding stern and boattail. | |||

|

| One of Us |

Already done! Four sided cavity at the meplat? | |||

|

| one of us |

Gee, you are fast! What are the dimensions on the nose cavity? Is three-sided any harder than four-sided cavity? | |||

|

| One of Us |

Ok I'm back. 3/32" x 1/2" Have to check on stock of three sided tooling. | |||

|

| one of us |

1/2" is too short. 0.6" is conservative, could go up to 0.7" deep, max, IMHO. 3/32" diameter round hole and 4-sided scoring would be good. The bottom of the cavity should be hemispherical and the scoring should stop before it gets into the hemisphere, eh? | |||

|

| one of us |

RIP I would love to see your drawing of the OCCPU .395 I sure hope that the OCCPU will fly straight in your Iron water buffalo. Merry Christmas and happy holyday to all Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

Thanks, Andre'. I wish I knew how to get the accent in the right spot over the top of the "e" in your name. Here is the .395/330-grain OCCPU, drawn more in proportion to what your bullet looks like but with specs for .395. When translated to reality it will be much more slender in appearance in the .395. It is about the same length as your bullet, but my weight should be very near 330-grains in copper:  It has a 7.0 mm cup instead of the 9.0 mm cup on your 500 Jeffery bullet. This could be the one bullet to do it all in any of the .395's used on big game. | |||

|

| one of us |

Hey Macifej! Look! It has a subtle SHark fin on the nose! | |||

|

| one of us |

RIP It sure looks great If the design works we can make a run when your rifle is done. 7mm cup sounds good to me. One of the important features is to make the bullet/cartridge feed smooth. If the cup is too big the cartridge is more likely to jam. That is why I dropped the cutting edge on the design. To make the é in my name press the key next to the "?+" key and then press the "e" key Cheers, André Always always use enough... GUN & KNIFE | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Optimal bullet design for Hunting

Optimal bullet design for Hunting

Visit our on-line store for AR Memorabilia