The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  500 Jeffery Bullet Launched in Denmark Captured in Kentucky

500 Jeffery Bullet Launched in Denmark Captured in KentuckyGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

More to follow. | ||

|

| One of Us |

| |||

|

| one of us |

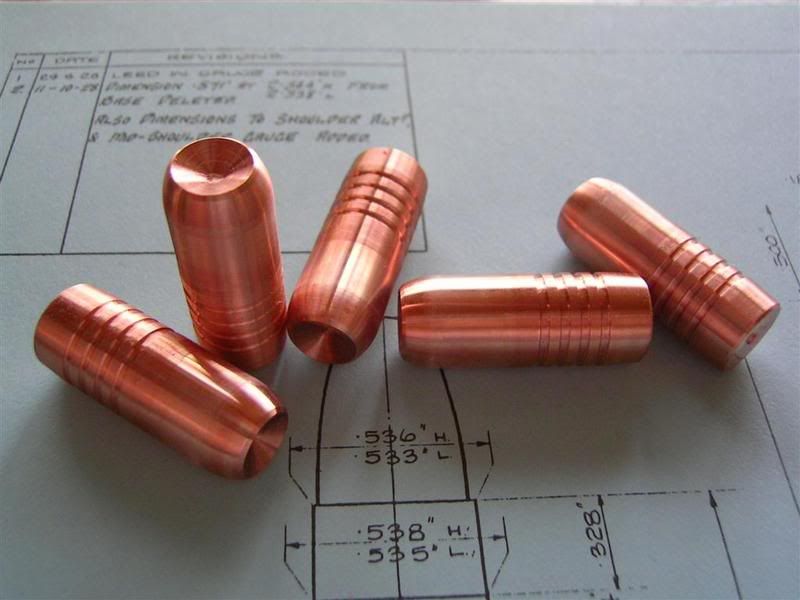

Alrighty then, Mac The Knife, you asked for it: It was a cold and sunny and slightly breezy day. 21 degrees F at Rockhill Gun Range. 16 F later at the strip pit where the IWB was reborn in a new configuration and killed dead again. The Iron Water Buffalo has more lives than a cat! BTW, it is 7 degrees F outdoors right now. High of 24, low of 7 today. This is Kentucky, down south. What happened to "global warming?" I broke 3 inches of ice on the pond with a bright orange deadblow hammer and dipped water with a bright orange 5-gallon bucket. How's that for local color? By the time I had retrieved a "Danish Cup Point" from the gutpile of the IWB, a skim of ice had formed on the unperforated water baskets, and my rubber booted toes were numb. Boy did they hurt when they came back to warmth later! Should have worn more than one pair of socks! The rifle, .510 JAB, with Wisner rear sight and safety on a BRNO ZKK 602, Zeiss 4X with German Post reticle, McMillan stock, stainless 1:10" TWIST McGowen barrel 23" long:    The loads and comparative chronograph and accuracy, three different bullets, everything else the same. To be fair, one of the XLC shots was the initial fouling shot. I had the XLC's seated and crimped on the cannelure for the firing, instead of as shown here, though the COL of Andre's CUP POINT and the GSC FN were fired as shown here:   I was just yanking the trigger with numb fingers to get three shots of three loads chronographed for ballpark velocity. This is not "best" accuracy testing. Andre's CUP POINT weighed 554.9 grains recovered. Unfired weights varied betwee 552 and 555 grains on the small sample I had. The expanded nose diameter was 0.527", before expansion in the IWB it was 0.500". Bullet diameter at driving bands varied from 0.508" to 0.509". This under-bore-size diameter along with the weight variance may explain the lesser accuracy versus the GSC FN. However my 10" twist stabilized it well, or it had incredible shoulder stabilization. It is also made of a perfect copper for a Cup Point. No signs of any cracks. Just smooth and uniform expansion. The 9 mm cup expanded to about 11.2 mm in diameter. This Danish Cup Point tracked true and ended up stopping nose forward. Dart-stabilized, nose heavy for sure after expansion. Shoulder-stabilized too. No worries. Any improvement in this bullet would be in making the driving bands a uniform 0.510" and maybe getting the weight variance less. Otherwise perfect I would say. The lesser velocity than with the GSC and XLC of heavier weight with the same powder charge: The Danish CUP point had about 5% of the case empty of powder, as seated. seating it deeper might make it faster. The GSC was about 100% full as seated. The XLC had powder charge compressed slightly as seated. Also, the undersized diameter, and diminished but adequate bearing surface of the grooved/banded shank, make for lower pressures and hence velocities. The IWB:  The Entry Port board (Equivalent to the rump of a cape buffalo if this is a Texas Heart Shot):  All that remained of the first water basket in the first compartment of the IWB, was a fragment of the offside, exit side with exit wound in it. Another tiny fragment, showing part of the entry "wound" on the target entry side, landed at my feet 20 yards uprange from the IWB, where I kneeled to shoot. It was found while I was picking up my trash. Maybe 16 F makes the water baskets brittle? (See below with the other bucket fragments.)  And the entry sides of the boards, stack of three boards per compartment, at the backside of each of the 5 out of 10 water baskets shattered:      The bullet came to rest after punching a piece of plastic into the boards backing the fifth compartment, nose first, like a cookie cutter. The bullet then fell down into the split bottom of the basket and ws found on the ground beneath the IWB, amidship. And now, the backs of the boards, from entry to stop:       The Sterilite brand 9-quart/8.5-liter waste baskets that cost $1.37 each (USD), at Wal-Mart:   All of the bucket fragments from compartments #1 through #5, again that is the biggest fragment left of bucket #1:        BTW, I also had a 12" wide, 1" thick, 6' long pine board lying on top of the IWB, just incase the bullet should tumble or veer upward in the terminal compartments. This did not happen. The splash of impact knocked this plank off the top of the IWB, flinging it to the right side. Had enough yet, Mac? Teminal end of bullet trap, the nose of the IWB:  Side of the front of the trap, IWB rumproast:  Front of the trap, Texas Heart Shot view again:  Underside of the front end of the trap, or testicle view of the IWB:  See any little icicles or frozen water drips on the above? Fifth compartment stop for Andre's great bullet. From my previous testing of GSC FN's and North Fork FP's and CUP Points of smaller than .510 caliber, I would guess the GSC FN of .510 caliber and 570-grains would get to the 7th compartment if loaded to 2300 to 2400 fps. I know it passed through 8 feet of bison from rump to neck, and exited. Two shots, one on a standing bison of over 1830 lbs, and one on the same bison dead on the ground, both exited, in at south end and out at north end, on a north-facing bison. The IWB is probably tougher than any cape buffalo or bison that has ever walked, as well as being a lot more consistent from shot to shot. I would guess that Andre's CUP Point would penetrate about 50 inches of elephant skull, about like the 50 inches out of 102" of the IWB. Great buffalo bullet. | |||

|

one of us |

A very detailed report. ------------------------------- Some Pictures from Namibia Some Pictures from Zimbabwe An Elephant Story | |||

|

| one of us |

Charles, Welcome. Mac wanted more so I unloaded. One shot. No worries about whether this bullet from Andre' for 500 Jeffery will stay on track. It is dart-stabilized and shoulder-stabilized just as he intended. Making the bands full groove diameter and better tolerances will perfect it. I think the cup on the nose is perfect. Driving it a little faster than 2306 fps MV whether in 500 Jeffery or 500A2 might expand it a little more, and that would not be bad. Andre's good photography of the current bullet:  Andre's prototype with a smaller CUP. He was wise to make it bigger. The current one, above, is just right, IMHO:  | |||

|

| one of us |

I think I would have to load a GSC .510/570-grain FN up to 3000 fps in a 50BMG to try to get to the end of the IWB, but maybe not even that would do it. The water gets harder with higher velocity, greater drag, bigger splash. An AP spitzer in 50BMG would probably just go out the side of the IBW. Maybe an 800-grain .510-caliber FN solid at 2100 to 2500 fps is the only hope for getting to the end of the IWB in its current configuration. Would that long bullet (.510/800-grain) be stable enough with the GSC-style FN nose? .510/750-grain? .510/700-grain? I do not believe any existing sporting rifle solid will get to the end of this configuration of the IWB. I stopped trying round nose solids because they always veer out the sides of the IWB at about 1/2 the distance that a same weight and caliber FN will travel in a straight path. Andre's Cup Point does not suffer this round nose trait, but does have the feeding ease of a round nose, and probably even better stability than an FN, and probably 75% of the penetration of an FN. Cup Point Universal. | |||

|

one of us |

Sounds great -- but for Eles maybe a flat (i.e. non-cupped) front would be better. It sounds like they would feed better than the GSCs in some rifles. Looking at the recvoered bullet, maybe not... We need some field tests on real big game. ------------------------------- Some Pictures from Namibia Some Pictures from Zimbabwe An Elephant Story | |||

|

| one of us |

But if you make it an ogived FN, you lose the greater dart and shoulder stabilization created by the Cup Point expansion. Of course, field tests on buffalo are in order. This is not an elephant bullet by Andre's design, but it would probably do the job. I think he wanted to deliver more energy in target and trade off the extra, unneeded penetration of the FN for a general purpose DGR 500 Jeffery. If you had to do everything with one bullet, this would be a good one. It is an expanding "hollowpoint," a "soft-solid." The North Fork Cup Point was a truncated cone, not rounded-ogived nose. | |||

|

one of us |

I do not want to make it something it is not. It seems it would do a great job on buffalo. I know the geometry of the North Fork and GSC -- for some folks they can create feeding problems. I have seen similar rounded-ogive flat points (no cup) but they do not seem as well-received as the NF and GSC design. ------------------------------- Some Pictures from Namibia Some Pictures from Zimbabwe An Elephant Story | |||

|

| One of Us |

Rip, Got any "DIY" or "IWB for dummies" instructions available... I'd like to try to build one for my range... Matt V. ______________________ Sometimes there is no spring... Just the wind that smells fresh before the storm... | |||

|

| one of us |

Matt, I'll bet you want to build one so you can see if a 600 Overkill will take it apart, eh? The long members are telescoping stainless steel square tube, 3 foot sections that go from 1.5" square at the impact end , 1.25"square tube middle section, and 1" square tube far end/low velocity section. These are 14-guage pre-drilled stock that I got at Lowe's/Home Depot/hardware store. The angle-iron is galvanized steel 18-guage. I just started building as if I had Leggo/Tinker Toy/Erector Set. The predrilled holes are 1" apart. Get some nuts and bolts and a hacksaw and go to town. The wood boards are nominal "1/2" plywood. about 7/16" thick actually. On centers, the long members make an 11" square cross section. This "hard configuration" has a 10" compartment depth and 3 boards per compartment. The 9 quart waste baskets for water are really neato. One 5-gallon bucket dipped from the pond will fill two of them. The rest is just details and adding on side members and brackets to hold the boards and stiffen the heavy-duty impact end of the IWB. This thing was dissassembled from previous 8" compartment spacing and reassembled to 10" spacing to accommodate those waste baskets and three boards per compartment. A few of the angle-iron brackets were damaged by previous round nose solid exits out the sides, and they were replaced. Modular repairs are easy. Ten of the 10" compartments is a good recipe. I separate the front/heavy section from the back two for transport. Four bolts with wingnuts make it easy to break down. All the rest of the nuta and bolts use a 1/2" box wrench and 1/2" socket wrench and there are two washers with each nut and bolt. I humped all by myself yesterday, from truck to strip pit pond, in several trips, hand carrying everything. It would really be nice to build one and leave it set up in place, covered with a tarp between shoots. You could fill the waste baskets with anything if you don't like water. Start with 4 pieces of 1.5" 14-guage stainless steel square tube 36" long, with pre-drilled hole spacing 1" on centers. Be creative. You may come up with something better than I have here. | |||

|

| one of us |

RIP WOW GREAT test I am glad I send you same bullets. The weight issue is due to the fact that this batch of bullets had a cutting edge that was remooved, this may have resulted in the uneven weight loss. Making the grooves larger seems logical, after all speed is a big thing The bullets was designed for all DG but buffalo was on my mind when I designed it.

You got it bro The expansion to about 11mm sounds great, maybe more with an ajusted groove dia? Boy I am glad they stayed straight in the IWB. Thanks for the great test and report. Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

Andre', You are welcome, and thank you! Now all bullets will have to be compared to your Cup Point performance in the IWB current configuration. You have set a performance standard. Go kill something with it and tell us how it performed. I have .395's to blood ... | |||

|

| one of us |

RIP Thanks for the kind words. I sure seems like the right mix of penetration and transference of energi into the animal. Now all I have to do is "Go to Africa and shoot 10 buffalos and see how they perform Cheers, André Always always use enough... GUN & KNIFE | |||

|

| One of Us |

Cool! André, I may have to kill a cape buffalo with one of these this year. Mike Wilderness is my cathedral, and hunting is my prayer. | |||

|

| one of us |

Fantastic report RIP! Now I know, due to the excellent pics (am I a--kissing? Hope not), what you meant in past posts about the IWB. And you are right, the .395 tests and blooding! Andre, congrats on your wonderkind. Ideas such as yours and the effort to perfect them keep moving the sport ahead. .395 Family Member DRSS, po' boy member Political correctness is nothing but liberal enforced censorship | |||

|

| one of us |

MR Lexma That would be a great way to confirm the design. You would get free bullets from the new and improved batch. Cheers, André Always always use enough... GUN & KNIFE | |||

|

| One of Us |

You got it!!!! Want to start testing some different stuff (Kodiak Vs Woodleigh softs, Woodleigh solids Vs ???) Be interesting to see how the Woodleigh solids do... I'd like to use a different caliber for control data and comparison purposes...probably a 458 Winnie... Anyway, I'm king procrastinator but I'll try to start construction soon... I'll let ya know how I do... Thanks allot for the specs! Matt V. ______________________ Sometimes there is no spring... Just the wind that smells fresh before the storm... | |||

|

| one of us |

Matt, I had old configurations of one and two boards with 8" compartment depth, but now have a new standard to calibrate too. The lesser boards and shallower compartments allowed greater resolving power, but I have decided just testing for true and straight tracking and a straight scale of 1 to 10 on number of compartments is good enough. 10 in this current configuration is impossible to achieve, I submit. I challenge you to try to get to the back wall of the tenth compartment with your 600 Overkill. | |||

|

| One of Us |

I’ll give it a “shotâ€â€¦.. I’ve got to give you thumbs up for the design… I like the ease of repeatability and flexibility to use other mediums… I’ll try to build mine to closely resemble yours for comparability purposes (10 compartments)… I’m going to use a 458 (unless someone can suggest a better caliber) to establish a base line for comparisons to the 600s performance… I’m really interested in comparing soft points…especially the Kodiaks vs. Woodleighs and eventually AHRs mono-metal expander… Luckily I’ve got a place where I can leave it set up… Now I’ve just got to explain to the wife why I’m not doing any chores around the house in order to build an Iron Water Buffalo!!! Matt V. ______________________ Sometimes there is no spring... Just the wind that smells fresh before the storm... | |||

|

| one of us |

RIP- Have you considered filling the buckets with ballistic gelatin? The buckets could be modified to incorporate some self sealing plastic "windows" so that the gelatin could be re-heated and re-used. That would be interesting and probably more informative than building materials and water tanks. The bullet appeared to start to rivet but thats it. Is the bullet of uniform hardess? try annealing the metal then firing again as dead soft copper. I'm just curious.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

Great! Good plan with the .458 baseline, but make sure it is an FN solid for starters. GSC bullets are best. The S&H style or Bridger style brass FN's ought to do great things too regarding straight-line penetration. You can deal with squirrely round nose solids veering out the sides after you get some happy results with FN's first. Round nose expanding soft points like the Woodleigh will stay on course but only go half as far as an FN solid of same weight, caliber and velocity. But those softs do make for some nice splintering of boards and water explosions. I imagine the 600 Overkill will be spectactular with softs. Hard cast lead FN boolits ought to be good straight-line penetrators if they do no fracture or smash their noses at their lower velocities. | |||

|

| one of us |

Rob, Since your comment about filling the 5-gallon buckets with ordnace gelatin, the 9-quart water baskets resulted. How about eliminating the boards and just using the gelatin in the buckets, and raw cowhide covering the entry port? Too much trouble and expense for me. Have to keep the temperature constant by refrigeration and calibrate the mixture with a BB gun penetration test before each shot. Water is consistent. It gets harder with velocity. The wood and plastic have consistent resistance with any velocity. All consistent from shot to shot, at any given velocity. Just have to have new baskets and boards for each shot. Three-board averaging makes each compartment wall consistent, if knot-hole boards are thrown out. Even ordnance gelatin is not identical to the skin, bone, lung air, blood, and guts, and muscle in a game animal bullet path. Something consistent that gets harder with increased velocity will do as well as anything for comparing penetration of FN solids. The IWB is just a yardstick in different units. It would be interesting to dismember a hog and fill the buckets with the entire carcass and shoot into that. Metallurgy: Maybe Andre' will comment about his bullet composition and any ideas on annealing? My approach would be to fire the bullet at higher MV, as it is, but maybe the annealing would be helpful with that too. It would certainly be a good idea if it was used at lower velocities ... I'm just beating around the annealing bush until the bullet designer has a chance at it. | |||

|

| One of Us |

..........RIP and Andr'e ..... .If it can,t be grown , its gotta be mined .... | |||

|

| one of us |

RIP -you have free outdoor refrigeration. I was thinking about building a 12 ft sealed wooden trough filled with ballistic gelatin and some emersion heaters at the bottom to re-melt it after each shot. That might give a more realistic result. I have always wanted to see what those results would be like. I have had some success with making a aluminum heat sink drilled to hold bullets 1/2 way up the shank. Refrigerate it and then heat the bullet tips till red hot, then allow them to cool with the base under refrigeration. The nose winds up much softer than the shank and should expand better.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

Andre', Did you get that? What Rob said. And what kind of copper would a person on this side of the pond order from a copper rod supplier if he wanted to make .395-caliber copper cup points? I would want to anneal those to shoot in the 400/.395 Nitro Express.  | |||

|

| One of Us |

RIP, I've got my money on TH5000's 600OK for ten feet plus You might recall my parallel experiments with a setup similar to your IB. In my case, I had a tall dock to shoot from and an ocean full of water below. I built a 2x4 frame and installed plywood "recording" slats at one foot intervals along the depth, submerging the frame so that it hung down just below the surface. A stake affixed to the outside was used to help align the shots. After many initial failures of RNs, and subsequent successes with FNs, some of my final tests included simply cutting meplats on 500grain Barnes RN monos. I cut one at 0.275" diameter, one at 0.325", and one at 0.375 and tried them sequentially. The 0.375 made it between seven and eight feet, the 0.325 made it to between nine and ten, and the 0.275 made it out the baffle at ten feet - no problem - no deviation of path. These were from a 1-14 twist barrel, .458Lott, approximately 2200fps muzzle. For kicks, I truncated one of those Barnes to the full 0.448" front shank diameter and it made it between six and seven feet and SOAKED me, 25 feet above. Talk about a smack and a geyser in return! I didn't get a chance to go the other way and reduce the meplat until the bullet was instable but from the other results, I surmise that there's a minimum diameter to ensure stability in water and more than that becomes a trade off from shallower depth of penetration to greater peripheral effect. With the 600OK's "modest" speed and the proper minimum meplat, perhaps it will define the limits of water penetration for a shoulder fired weapon? | |||

|

| one of us |

PWS, Yep, I recall, and that sounds right. The water pressure on the outside of your submerged wooden 2x4 frame must have kept it from being demolished by a single shot. You must have been using 1/4" plywood? Thicker wood does add to resistance and decreases the water travel. With one nominal 1/2" plywood board and 7.5" of water per 8" depth of compartment, I got past the tenth board with FN copper solids at 2500 fps, whether .375/300-grainer or .475/500-grainer. 80" plus. | |||

|

| one of us |

Rob

RIP

Sounds like an interestinf experiment, and easy to do. I might heat up some bullets and see if they expand more. One problem would be to heat the bullets the same, if the heating trick works. I like uniform bullets and think it would be difucult to control the heating process. Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

What calibre do you shoot? I might make a version in the .375 Cheers, André Always always use enough... GUN & KNIFE | |||

|

| One of Us |

André, I am switching to Barnes banded FN solids and TSX bullets at 570 grains for use in my .500, but assuming that your bullets can be made to expand better than they did in RIP's tests, yours would be an excellent buff bullet. FYI, I measured and weighed all of my "Danish Cup Points" and they were pretty consistent. They averaged a shade under .5085" (from a low of .5080" to one that was .5095") in diameter at the driving bands, and 555.3 grains (from a low of 554.1 to a high of 556.3) in weight. Another thousandth or so in diameter would be perfect, I think. I will be shooting them for accuracy and speed when the weather breaks. 2,500 fps ought to be achievable in my rifle with 110-112 grains of RL-15. Expansion may be difficult to gauge, however. I will try to dig one out of the sand bank that serves as the backstop at the 100 yard range I use. That will be an awfully tough test. It turns 600 grain Woodleigh PP softs inside out and abrades nearly all of the lead out of the core at 2,500 fps. Mike Wilderness is my cathedral, and hunting is my prayer. | |||

|

| one of us |

MR That sounds great. I do however think that the bullet will NOT expand as much in real game. The IWB is tougher then real Buffalo IMO. Maybe RIP van comment on this? Expansion was not my No. 1 priority I only wanted the bullet to expand a little to make the nose heavy and lead the way/not turn. 110-112 grn of RL15 sounds great! I will use 118 grn of N 140 Thanks for the kind words and for helping me test and develop these bullets. You will also get some more bullets when the next batch is made. Cheers, André Always always use enough... GUN & KNIFE | |||

|

| One of Us |

.............Andr'e .....I primarily shoot 9.3 ,, .416 , 458 ,, But a 500 A-Square is supposed to get built this year so the .509-.510 bullets would be perfact ...... .If it can,t be grown , its gotta be mined .... | |||

|

| one of us |

Geat you will be on the .510" list Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

In a months I'll have my SL-10 going and will shamelessly copy your design and make a few changes. I will however, always give you full credit for it though. I have some ideas I want to try with respect to partially annealing the shank in a reliable manner. The approach I described is crude but at least in my experiments there was a noticeable increase in expansion. At one time, I drilled a small hole and added a steel BB epoxyied in place. That was interesting!-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

Rob That sounds interesting, I look forward to seeing your version of the Cup Point Solid. I hope that you can get some good quality copper Cheers, André Always always use enough... GUN & KNIFE | |||

|

| one of us |

I just loaded up some of my Cup Points. If you seat then as the last groove they are within CIP specs 3.454" (87,75mm) and with 118 grn of N140 it is not even a compressed load. I hope they will go +++ 2400 fps. Time will tell. Cheers, André    Always always use enough... GUN & KNIFE | |||

|

one of us |

Nice work with the camera -- is that a leather Surefire holster in the background? The cup points look good and I look forward to hearing the test firing results. ------------------------------- Some Pictures from Namibia Some Pictures from Zimbabwe An Elephant Story | |||

|

| one of us |

Charles Yes that is a Surefire holder from Westley Richards Cheers, André Always always use enough... GUN & KNIFE | |||

|

one of us |

Very nice -- I need to look that one up. ------------------------------- Some Pictures from Namibia Some Pictures from Zimbabwe An Elephant Story | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  500 Jeffery Bullet Launched in Denmark Captured in Kentucky

500 Jeffery Bullet Launched in Denmark Captured in Kentucky

Visit our on-line store for AR Memorabilia