The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Good source for .620 plinker bullets

Good source for .620 plinker bulletsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Looking for a good source for some .620 bullets. Right now I would be happy with some plinkers but everyone seems to be out. Thanks Bob | ||

|

| One of Us |

Call Wayne at AHR, or PM him (he's Bitterroot on AR). He used to stock lead practice bullets for the 600 and 700 calibers. | |||

|

| One of Us |

Not sure if Bruce Bertram does the 600 projectiles (Bertram Bullets in Aus). He does make cheaper bullets for 458 etc. Maybe worth a phone call. Cheers, Chris DRSS | |||

|

| Administrator |

A shame you are not in Dubai. I will be happy to turn some for on our CNC lathe. | |||

|

| One of Us |

I have some dead-tough soft points I'd be willing to get rid of.. How about $30 for 20... Ed DRSS Member | |||

|

| One of Us |

Not exactly plinker bullets but I will take them. Just let me know where to send funds and I will get it out Monday Bob | |||

|

| One of Us |

Not exactly plinker bullets but I will take them. Just let me know where to send funds and I will get it out Monday Bob | |||

|

| One of Us |

Forgive me, guys, as my only large bore is a 58 cal muzzle-loader, but I have touble getting my brain around the notion that anything 5/8" in diameter is a "plinker." Doug Wilhelmi NRA Life Member | |||

|

| One of Us |

Depends on what you mean by "plinkers", how many you want and how much trouble you want to go to get there... There are lead molds for round 20 ga balls and slugs...Lyman has a 325 gr slug mold and slugs are available online...information is found in the shotgun/slug gun sections on several forums and shotgun product catalogs... You can also use 20 ga shot sleeves with 50 cal and slightly larger dia readily available bullets, as "sabots", that have "fairly" acceptable accuracy out to ~75 yds or slightly more that give a satisfying boom and recoil level. I had a mold made at Accurate Molds and had a lead bullet maker in my area make me 250 650 gr slugs until I acquired the casting equipment...most mold makers will do the same. Check with Ede Hubel and RIP here on AR. Doing a search for them will get you there fast. 58 cal bullets are just slightly smaller than 62 cal and with a thin 20 ga shot cup/sleeve fit my brass and plastic hulls. Lots of ways to go...depending. Luck | |||

|

| One of Us |

Beartooth Bullets makes a 1040 grn cast plinker. NRA Life ASSRA Life DRSS Today's Quote: Give a man a fish and he eats for a day. Give a man a welfare check, a free cell phone with free monthly minutes, food stamps, section 8 housing, a forty ounce malt liquor, a crack pipe and some Air Jordan's and he votes Democrat for a lifetime. | |||

|

| One of Us |

Go to the Lyman URL and take a look at the 20 gauge "Sabot Shocker" slug molds. It looks like an overgrown wasp-waisted air rifle pellet, and loads in a standard 20 gauge wad. Might work, and having a 12 gauge version, I can say that they are easy to cast up. Option B, talk to Ed Hubel, he may have a contact for cast. Rich | |||

|

| one of us |

I assume by plinkers he wants lighter bullets, and from experience with our 585HE the Minie bullets make the best plinkers at 15-20% the cost of jacketed of any weight. We use .585" Minies in our 585 for plinking, deer, hogs, plain ole target fun. We can get them on GB by the thousands. Problem is there are no Minie bullets or similiar constructed ones in .620" or even the .615" 20ga, unless you get a mold maker to do special build, and cast you own, Check with Accurate Molds. Or use 20ga CSD thick sided wad from BPI and put .54-56cal minies in it. It is the absolute best 20ga wad for using like a sabot. It can take high speed and Minies used are about 440gr...Ed MZEE WA SIKU | |||

|

| One of Us |

Im pretty sure Bertram only makes 585 Projs not 600 ,there is a Mould Maker here in Oz that makes 3 moulds for the 600 NE .A fellow i met had a setup that bumped 458 projs up to 500 [i wish i had bought it ]if you could get a [made up]die set up to bump 585s up to 600 is probably the best idea | |||

|

| one of us |

I have not done it before, but could CNC turn some aluminum .620 bullets. They will probably go 280-300 Grs. Might go 4000 fps or better. They should be 1/3 the price of brass. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

I was just looking for some inexpensive solids at 900 grains for playing with the scope and getting used to the gun. All I could seem to find were nice high end bullets that were backordered everywhere. It dose sound like fun to try some aluminum bullets and see what kind of velocity we can accomplish. Plus it could be good for prairie dogs. | |||

|

| One of Us |

I have a .620 900-grain mould (no gas check) if that helps. Cal _______________________________ Cal Pappas, Willow, Alaska www.CalPappas.com www.CalPappas.blogspot.com 1994 Zimbabwe 1997 Zimbabwe 1998 Zimbabwe 1999 Zimbabwe 1999 Namibia, Botswana, Zambia--vacation 2000 Australia 2002 South Africa 2003 South Africa 2003 Zimbabwe 2005 South Africa 2005 Zimbabwe 2006 Tanzania 2006 Zimbabwe--vacation 2007 Zimbabwe--vacation 2008 Zimbabwe 2012 Australia 2013 South Africa 2013 Zimbabwe 2013 Australia 2016 Zimbabwe 2017 Zimbabwe 2018 South Africa 2018 Zimbabwe--vacation 2019 South Africa 2019 Botswana 2019 Zimbabwe vacation 2021 South Africa 2021 South Africa (2nd hunt a month later) ______________________________ | |||

|

| One of Us |

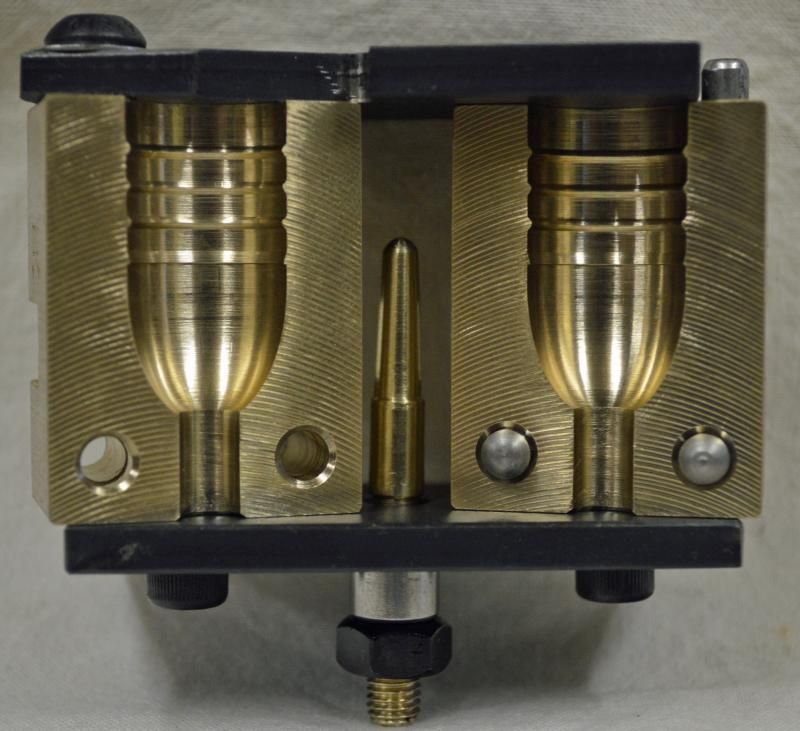

I'm the guy in Australia that can make a few different .622" diameter moulds. you can look at them on the website if you like, www.castbulletengineering.com.au Here's a couple of photos of ones made recently that went to the USA. I can also make a 1000 grain gas check mould. If there is enough interest, I'm happy to obtain a gas check maker and also supply the gas checks to suit.   The HP one in the bottom photo was a special order, it's the 850 grain plain base one (in the top photo) made with a HP pin, they should come out around 800 grains or so. Regards, David. | |||

|

| one of us |

Beautiful molds!!Out of curiosity did you Cnc turn them or use a Cherry? I've msde dome molds by CNC turning but it's a PIA. Years ago I made some using cherries but after I went CNC never went back!-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Made with a good old cherry... Wish I had some CNC gear, but not at this point in time. Thanks. David. | |||

|

| One of Us |

http://accuratemolds.com/catalog.php?page=13 here's some .620 moulds. Talk to Tom and he'll cut you a mould in 3 weeks to whatever you want for a reasonable price. | |||

|

| One of Us |

Ditto on the pretty...Wish I had found you B4, I like that nose profile!!!! I have several molds of different cals from Accurate molds and several from Mountain Molds...http://www.mountainmolds.com/...including a .628" double cavity M.M. two lube, one crimp groove truncated cone nose that casts a 665 gr on one side and I lathe turned/drilled the other side for a slightly longer 740 gr pointy slug. Mountain Molds has built in bullet design program you can use to design the nose profile/number of lube/crimp grooves/weight and OD/brass-alum mold etc. Luck | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Good source for .620 plinker bullets

Good source for .620 plinker bullets

Visit our on-line store for AR Memorabilia