The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Who's the foulest of them all....

Who's the foulest of them all....Go  | New  | Find  | Notify  | Tools  | Reply  |  |

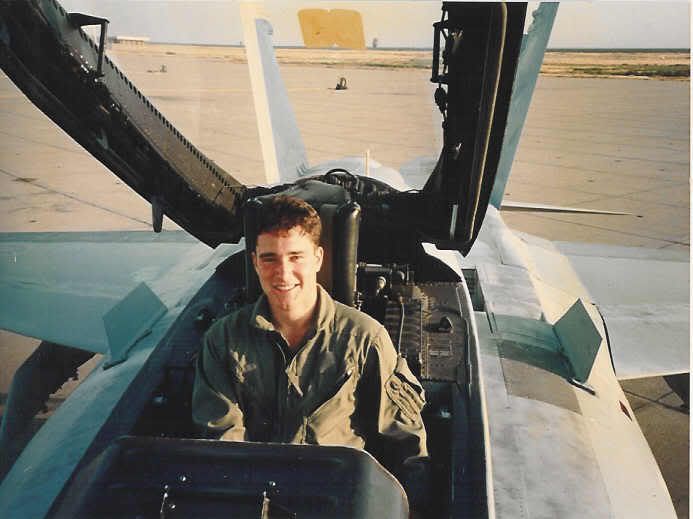

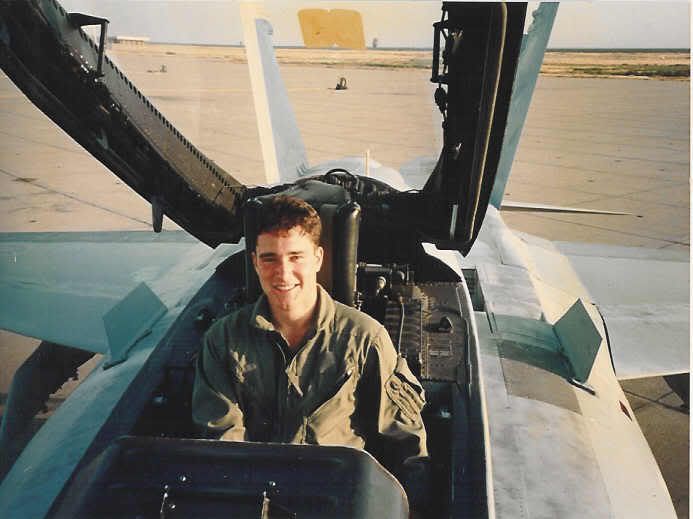

one of us |

My 460 Weatherby gets this vote. I've spent the weekend trying to get the copper out after feeding it a steady diet of Barnes-X's. After four separate 8 hour sessions using the Outer's Foul Out reverse electroplating tool punctuated with aggressive brushing/patching of the bore with Montana Extreme solvent, sanding down of the zinc annode to get thick accumulated copper off each time, and repeatedly changing the solution, the fouling is still coating the rod throat to muzzle. I've borescoped the interior between Foul-Out sessions, and it's reasonably free of the interior factory machining marks that I've seen create that kind of build up elsewhere. It'll be interesting to see if my 500g African Grand Slam solid reloads leave anywhere close to the same level of metal in the recesseses of the grooves as Weatherby's factory 450g Barnes-X ammo. Is this just a function of the softness of the Barnes-X copper, the high pressures/speeds of ~2700 fps, or me not liking to clean a big bore every 10 rounds or less?..... Any other big bores ever done this to you? Stuntpilot | ||

|

| one of us |

stuntpilot2..my 378 is worse than my 460. Try Wipeout. http://www.sharpshootr.com/ I spray and let sit over night. 4 patches later the barrel is very very clean!. BarnesX are the worse!..steve | |||

|

| One of Us |

STp2: What Steve says is good info! If you are shooting regular Barnes Xs and not TSXs, they are notoriously bad foulers. The Wipeout product, espcially when you get the "accelerator" component with it, works wonders on copper. Pre-64 Model 70s are just about the worst foulers in existence and Wipeout works on them. jorge USN (ret) DRSS Verney-Carron 450NE Cogswell & Harrison 375 Fl NE Sabatti Big Five 375 FL Magnum NE DSC Life Member NRA Life Member | |||

|

| One of Us |

I tried the product on a barrel that I thought was clean, had carbon AND copper come out. I was amazed. | |||

|

| One of Us |

I think I'd be using another bullet. Barnes made a lot of different ones for me in the '60's and '70's and liked them for certain uses when bullets were tough to get. Even brained elephants with them. However, the way I figure it, life is too short to be fighting bullets that foul as bad as the current items I read about here on AR. Just a thought. There are a lot of satisfactory bullets today! | |||

|

| one of us |

One of my bench rest shooting buddies, mixes Kroil with his Shooters Choice and lets it sit in the barrel overnight with good results. Seems that the Kroil will work it's way under the copper and carbon. Jim "Whensoever the General Government assumes undelegated powers, its acts are unauthoritative, void, and of no force." --Thomas Jefferson | |||

|

| One Of Us |

Wipe 0ut 1) Fill the bore and let soak according to directions ( i let it soak overnight) 2) This is what you see the next morning...  3) The first patch through the bore looks like this...  4) This shows the puddle of copper that dripped out of the barrel and what the fist patch pushed through the bore.  5) This shows the second patch through the bore and the black on the patch is powder fouling.  That's why the guys that use Wipe Out reccomend it so much to the guys that don't. PS - no ammonia. | |||

|

| One of Us |

I've recently been using Gunslick's Foaming Bore Cleaner. It takes two or three treatments but does the job very quickly compared to CR-10 or other meathods. 465H&H | |||

|

| One of Us |

Holy crap!! How many rounds have you fired befor this threatment???? I have used bore foam for many years, and never seen the like!!! Bent Fossdal Reiso 5685 Uggdal Norway | |||

|

| One of Us |

Newguy, my 416 Rigby looks the same when I use WipeOut. I'm all out! I have to find a way to get some more to France! _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

| one of us |

I've also been using Gunslick's bore foam. If you let it sit for 25 minutes it takes only one application to remove visible copper fouling, most of the time. If I've been lazy and let it go too long, it takes two or three. Either way the bore benefits from a good scrubbing with a brush after a wet patch of your favorite cleaner. 25 or 30 minute soak vastly outperforms a 10 or 15 min soak. And its so easy to use there is no excuse to let it go. JPK  Free 500grains Free 500grains | |||

|

one of us |

I'm wondering if any of the users of the various bore foams have done before and after examinations of their rifle throats with a borescope. Or, if anyone who did an "overnite" with one of the foams that resulted in clean patches at the end of the next day's scrubbing out of the resultant blue goop ever did another overnite that resulted in pushing out white/clear liquid after the second 24 hour sitting (no firings in between). I've found that with even the most aggressive chemical cleaners, the "clean patch" axiom can be deceptive about the barrel throat. Especially in my rifles with MVs over 2700fps. In those, even after I start getting "clean patches", they often retain a gilding in the first few inches of barrel like the roof of a Greek Orthodox Church. My borescope has validated that most bore pastes on patches wrapped around copper brushes work on stubborn throat fouling. But, it's not effortless. | |||

|

| One of Us |

I also have a 460 that fouls really badly. Is there anything that can be done to the barrel to get it to foul less? Thanks. | |||

|

one of us |

Kenneth, I had the same problem, and did something about it that will likely make my Benchrest buddies cringe: I fired a course of Tubb firelapping rounds thru it. Accuracy stayed the same, but the fouling definitely went down. As I read thru the great information in the posts answering my original question, I had a funny thougtht: Does all my 460's fouling really matter.... After all, across every one of the Big 5 from last year's safari, I didn't fire a shot at DG outside of 70 yards. And, most were inside of 40. How much usable accuracy am I really losing at those ranges? I may never clean this big boy again! | |||

|

| One of Us |

stuntpilot2, Thank you for the reply. I may give those rounds a try. I checked to see if MidwayUSA has them and the reviews for this product are pretty much all positive. | |||

|

| One of Us |

I have always had good success with Sweets 7.62 bore solvent...but do NOT leave it in a barrel more than 15 minutes. I sue Sweets and then finish with Kroil, left in the barrel. Clean patch or two and go shoot some more. Rich | |||

|

one of us |

Update - It's been three days and 9 repeats of the Outer's Foul Out cycle: Empty used fluid, sand accumulated copper off collecting rod, swab/brush bore, refill with fresh fluid, re-insert rod and start again. After each cycle, the bore exhibited "rough spots" where the patch met resistance on the first push thru to clean out the used fluid. When I've examined these spots with my borescope, I saw an accumulation of copper under carbon under copper in a multi layered parfait. The Foul Out device was ripping the copper portion from the formerly smooth "firelapped" fouling plating, leaving a roughened carbon surface that was more vulnerable to bronze brushing than the original hardened mix. I hadn't done anything but a "quick clean" in hundreds of practice rounds. Clearly, that wasn't sufficient to stop the gradual build up of the copper/carbon parfait. I've just now gotten down to bare metal everywhere but in the first 3-4 inches of the bore. Unless my 460 literally puts them all in the same hole the next time it goes to the range, I'm afraid I'll be left wondering if there was any material benefit to this whole exercise. My quick cleaning was apparently good enough to prevent corrosion. Short of starting to get pressure signs from factory ammo from the parfait creating a "constriction" in the bore interior, it'll be hard to convince me I shouldn't have simply used one of the bore foams as has been suggested earlier..... | |||

|

| one of us |

My Sako in 416 Rem Mag: Five rounds with Swift A-Frames and I have enough copper to sell on the spot market. The best thing going for me is Wipe-Out. My Outers Foul-Out (iteration III) is too much trouble. I will use Foul-Out two nights running. I would fire-lap it, but it shoots three shot clover leafs. As grandma used to say, "don't fuck with perfection Charlie". Much less fouling with North Forks. Clover leafs also. Amazingly accurate factory rifle with minimal tuning. LD  | |||

|

| one of us |

I can honestly tell you that I've been a Barnes shooter for many years. Wipe Out has simplified my life! Quit banging your head against the wall and go get some. And yes I have tried the second application trick as you've stated. Wipe Out works! Period. | |||

|

| One Of Us |

Not that many... remember there are TWO barrels being cleaned in the photos. | |||

|

| One of Us |

Well i do not have so much rifles but the 460 Weatherby is with Hornady Interlock even worse than my fast 8x68S!!! I do not know if my new TSX-load is better! But it seems that the 460 is a fouling caliber no doubt. | |||

|

| One of Us |

i have a 7mm RUM sendaro that gives me trouble with cleaning all the time. i used the link to try to get two bottles of that wipe-out stuff as soon as i saw the pics of what it did to that side by side. i sent the guy an email, haven't heard anything in a few days, tried calling the number and nobody picked up the phone. anybody know where i can get a can of that stuff online at another store or somethin? i appreciate it | |||

|

| One of Us |

| |||

|

| One of Us |

thank you sir. 2 on the way | |||

|

| One of Us |

If find from my own experience that claims of "hideous fouling" that gets blammed on Barnes bullets is the result of either using them in a NEW barrel OR using them after there is already a layer of guilding metal in the barrel... I will say that the pure copper fouling from the Barnes bullets may "build up" faster in a few of my barrels I will also say that the pure copper seems far easier to remove chemically. Switching back and forth from Barnes to conventional bullets is IMO begging for an exercise in masochism when cleaning time rolls around. AllanD If I provoke you into thinking then I've done my good deed for the day! Those who manage to provoke themselves into other activities have only themselves to blame. *We Band of 45-70er's* 35 year Life Member of the NRA NRA Life Member since 1984 | |||

|

| one of us |

Get the bore foam. And DON'T use the X bullets before or after conventional jacketed bullets without a thorough cleaning. Use a pristine bore with X bullets. Maybe go to the Barnes website. They give those instructions. X is great and Triple X is better. I'm looking forward to the MRX in 225 gr .358". Packy | |||

|

| One of Us |

Do you see any difference with the Barnes XLC bullets, the ones with the blue coating? _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

one of us |

The tale of the Borescope on the 460WBY: Since last weekend, I've tested five cleaning methods starting from a visually verified 100% bare metal clean bore: 1) Wipeout with Wipeout Accellerator 2) 50/50 mix of Kroil & Shooter's Choice - Patching and Bronze brushing 3) Barnes CR10 patching and bronze brushing 4) Outer's Foul Out 5) JB bore paste on a bronze brush Between cleanings, the bore was re-fouled with 10 rounds of full power (2615fps) hand loaded 500g African Grand Slam bullets. My methodology: With the rifle already set up in the cleaning holder/vice, time myself following the wipeout/accellerator directions. Then, allow the same amount of time with the other four methods to do the best cleaning you can. Between tests, if the cleaning methodology didn't produce a 100% bare metal result, I used JB Bore paste and a bronze brush to "finish" the preceeding methodology's job. The ranking from cleanest to dirtiest of the five methods tested: 1) JB Bore paste 2) Outer's Foul Out (although this method was "disqualified" for taking FAR longer than the wipeout time allowed) 3) Wipeout with Accellerator 4) Barnes CR10 with bronze brushing 5) Shooter's Choice/Kroil Only the JB bore paste left the bore interior 100% cleaned. That was after three continuous minutes of back and forth with the paste on a bronze brush. (Note: If you're going to do this, be sure to put an empty plastic bottle on the end of your muzzle as the liquified paste will splatter everwhere each time the brush exits the muzzle.) Those three minutes were followed with two minutes of a patching with clean patches and patches wrapped around a clean bronze brush. The Outer's Foul Out took far longer than all the rest (hence my "disqualifying" it above). It was the only other method that got all the metal fouling out. Unfortunately, in addition to being time consuming and messy, it left behind a residue that required a quick brushing and patching to remove. Wipe out produced an impressive amount of blue liquid on both the first "20 minute" sitting, and the "overnite" sitting (I stopped the "clock" when I stepped away from the cleaning bench to let it sit). After the overnite, and patching dry, I examined the length of the bore's interior with the Hawkeye borescope. It showed approximately 30% of the surface area of the grooves still retained a significant coating of bullet jacket material. Outside the bounds of the experiment, I repeated the cleaning with Accelerator & Wipeout per the instructions and rotated the rifle upside down halfway thru the nite as another poster had suggested. This time, I was rewarded with a somewhat less blue liquid the day after. But, the amount of "in the groove" metal fouling appeared to be only marginally less. Barnes CR10 and brushing removed about the same amount of material as the first wipeout session. In fairness, I thought it was about tied. Kroil/Shooter's choice stripped out as much powder fouling as any of the other methods. However, it left the metal fouling virtually untouched. The bore was still 75% metal fouled after 5 minutes of wet bronze brush scrubbing and patching. | |||

|

| One of Us |

When I clean with an aggessive copper cleaner I patch and let sit for the alotted time then clean patch out. I never use a bronze brush when using the copper cleaner. The cleaner attacks the brush just like the copper it attacks in the bore. You end up leaving bronze in the bore. I clean with the copper cleaner and then patch out and brush with Kroil then patch out. Works well for me. The only easy day is yesterday! | |||

|

| one of us |

Good point. I use nothing but nylon bristle brushes, patches, Gun Scrubber (or equivalent degreaser/solvent) as first rinse and patch dry, Wipe-Out, and BreakFreeCLP as lubricant/rust-preventive at the end. A 20 to 30 minute soak with Wipe-Out is repeated once, routinely, for two soaks total while I am doing other things. I do this after every 20 to 30 shots if possible. I do not sweat any small amount of residual copper fouling as long as the rifle is shooting well. I just store it away with a coat of BreakFreeCLP in the bore, and muzzle down if possible. Wipe-Out is just so easy to get satisfactory results. I am nervous about the abrasive effects of too much JB Paste and wish to conserve the elbow grease. | |||

|

| One of Us |

Stuntpilot, I am curious about your JB paste method. Are you able to go back and forth in the barrel with a patch covered bronze brush? I think I could do it with a nylon brush but it would be impossible for me to change directions in the barrel with a bronze brush. Also, if I push the brush all the through, out the muzzle, there is no way I could keep the patch on the brush for a return stroke. So, how are you doing this? _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

one of us |

Wink, I haven't had that much trouble getting a bronze brush inside a patch to reverse in the barrel. For whatever reason, it's much harder to get an unwrapped bronze brush to reverse in the bore (and, it's not recommended). I finish with several Kroil coated clean patches around a clean clean bronze brush to finish. These also reverse in bore with out too much effort. The results thru the borescope look immaculate. And, the thin coat of Kroil seems to help keep the metalic fouling from the first round down the cleaned barrel minimized. Thanks, Stuntpilot | |||

|

| One of Us |

Stuntpilot, Maybe it's the kind of brushes we both use that make the difference. I use Dewey brushes and I don't think you could get them to reverse even if wrapped in silk. What do you use? Wink _________________________________ AR, where the hopeless, hysterical hypochondriacs of history become the nattering nabobs of negativisim. | |||

|

| One of Us |

Stuntpilot2, You might want to try some Aqua Ammonia. Its not for the faint of heart but will work better than any commercial copper removers. Add about 5% ivory dish soap. | |||

|

| one of us |

Wink, In my experience, any well used brush works. A new brush works too but reversing direction takes a lot of effort. The patch stays on the brush, regarless. JPK  Free 500grains Free 500grains | |||

|

| one of us |

Borescope your barrel! I had a weatherby 340 that had 1 inch of land missing in the last 3/4 of ther barrel! It shot great 6 inch groups at 50 yrds. When sent back to Weathercrappy they sent me a target with a 2 inch group at 100 yrds. I sold they gun after that! No more weatherbys in my gunsafe!-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  Who's the foulest of them all....

Who's the foulest of them all....

Visit our on-line store for AR Memorabilia