The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  600 JDJ - LOADING LEAD BULLETS - QUESTION

600 JDJ - LOADING LEAD BULLETS - QUESTIONGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Hello All, As from my previous post of acquiring a Ruger No.1 in 600 JDJ caliber, My new 600 JDJ Ruger No.1 - is "BIGGER" really better? I'm having difficulty reloading with lead bullets. Accuracy at 100 yds is very good with the Jacketed 650g soft nose Hawk bullets, but my attempts with lead bullets is dismal. Not even close to groups, more like an 18" spread. Does anyone have any suggestions? " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | ||

|

| one of us |

For large bore cast lead bullets you need to use Linotype alloy. Drop the bullets from the mold into cold water. The bullets Need to be 0.001 over the bore diameter. You will probably not be filling the case powder so use Dacron fiber to fill the case to the top, then seat the bullet. I do not size cast bullets ever. Look at your bullet holes in the target and make sure they are not tumbling. If they are, your alloy is too soft and the bullets are not engaging the rifling properly.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

Are your cast bullets gas checked? Could never get my plain base cast to shoot in my 404 but got great groups with gas check bullets. Got a setup in a small lathe now where I can quickly turn a shoulder on the bullet bases for a gas check, instant remedy and my bullets shoot perfect when checked. Did notice when shooting the plain base bullets some lead splattering on the case neck. | |||

|

| One of Us |

Wow, not near enough information to help. What alloy? What diameter when loaded? What powder charge and velocity? What weight bullet? What alloy? What lube? We need to know to be able to help. . | |||

|

| One of Us |

Hello All, OK, here goes. I'm using a 650g bullet cast in a custom lathe bored mold from Mike Brooks. As cast is .622 dia. Using wheel weight / linotype alloy at 20 BHN harness. Groove dia of the bore of the rifle slugged at .621 dia I'm loading 70g accurate 5744 with 5/8" dia by 1-1/4" long backing rod foam filler and F15 primers. Measured velocity = 1625 fps. Groups are poor with mixed patterns between 12" and 18". Same results at 2000 fps loads. I tried both blubear lube and Lee liquid allox. Both these loads shoot under 3" groups with 650g jacketed Hawk bullets. I'm using a near identical load / lead bullet in my 18ga vogel schiessen rifle (.644 bore) and get 3" 100 yd groups. I use Lee liquid alox lube. I'm starting to wonder if for some reason the muzzle brake might be a factor with the lead bullets. ? ? " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

I still suspect it's your bullet alloy. Can you obtain some real Linotype metal? Real Linotype has a BHN of 22 and even harder after the cold water treatment. I've used this in a .600/.50BMG with great results. It has a hellacious brake on it. If in doubt unscrew it. All other alloys I tried failed. I've also had good luck with 2400 powder with a Dacron filler. 5744 doesn't need a filler either. Try it without. Otherwise you seem to be right on. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| One of Us |

This is the root of your problem. MB is actually Shootaway. Seriously, I shoot lead often in my .600 nitro rifle. At low velocity accuracy is good until lead deposits in the bore destroy the accuracy. At higher velocities, leading occurs earlier. A good cleaning solves the problem. I have never had much luck with lead bullets in nitro double rifles. The bore rifles and black powder express are fine. Of course, they were made for lead. I don't seem to have the right lube or lead composition or both for nitro rifles. So I use lead only to play when I begin shooting in the spring and then graduate to Woodleighs. I just had 30 boxes sent over and they are wonderful bullets. How is the 20-577 shooting? Cal _______________________________ Cal Pappas, Willow, Alaska www.CalPappas.com www.CalPappas.blogspot.com 1994 Zimbabwe 1997 Zimbabwe 1998 Zimbabwe 1999 Zimbabwe 1999 Namibia, Botswana, Zambia--vacation 2000 Australia 2002 South Africa 2003 South Africa 2003 Zimbabwe 2005 South Africa 2005 Zimbabwe 2006 Tanzania 2006 Zimbabwe--vacation 2007 Zimbabwe--vacation 2008 Zimbabwe 2012 Australia 2013 South Africa 2013 Zimbabwe 2013 Australia 2016 Zimbabwe 2017 Zimbabwe 2018 South Africa 2018 Zimbabwe--vacation 2019 South Africa 2019 Botswana 2019 Zimbabwe vacation 2021 South Africa 2021 South Africa (2nd hunt a month later) ______________________________ | |||

|

| one of us |

I suggest trying a near-full-case load of slower powder. Maybe RL-17. That worked great in the 12 GaFH 3.85" with +1300-grain .730-caliber slugs, at 1400-1800 fps. Even a 209M shotgun primer will touch off 180 grains of that powder in the RMC brass case, fool proof ignition. Using the greater gas ejecta of the greater weight of slow powder will add to recoil, but it will also make the brake more efficient in reducing recoil. Might be a wash on recoil. And no sabots or plastic worms passing through the brake. | |||

|

| One of Us |

Still think gas checks are the way to go. The target below shot two weekends ago was with aluminium gas checked cast bullets in my 404J with a single grease groove using 'Beaver Grease' lube (I think made here in NZ). Absolutely clean burn of Vectan AS shotgun powder (equiv burn to Red Dot). The first clean barrel shot up a bit in MV and all the rest extremely consistent. Velocities recorded on my old Chrony. Not a sign of leading. The bullet holes are not all distinct due to the target backer board being covered in raised staples and bits of other shooters targets but all 7 shots are in there. The 404 shoots well with Red Dot and Unique for light loads and also 63.0grs H4350 for a 1800fps heavier load. Plain base cast a waste of time in the 404, could never get any groups to speak of.  | |||

|

| One of Us |

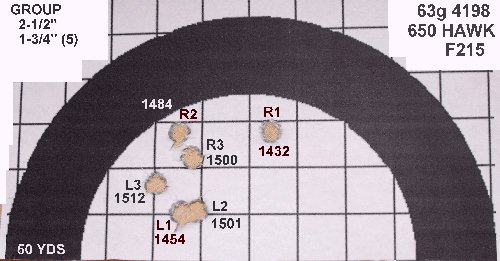

Hello Robgunbuilder, I'll try a different alloy and see what happens. I've used backing rod foam filler with 5744 in a dozen big caliber rifles and have had improved accuracy and more uniform velocity than without. Unfortunately my muzzle brake cannot be unscrewed. Hello cal pappas, I've not had any leading at all with these bullets and the lube I'm using. I'm going to try a couple of paper-patched bullets next, just to see what happens. I've not tried the Woodleighs bullets yet. I had HAWK make some 650g thin jacket soft points for hunting, and they work just fine. Just trying to come up with a lead bullet load for less expensive "fun shooting". The 20-.577 is doing great. I've been fine tuning the load. Here is one of my latest targets using IMR 4198. I'm testing some 5744 today because I generally get better ignition. I've fired over 100 rounds with 4198 and had 1 miss-fire. But, that's one too many for me so I'm going to try some different powders.  "UPDATE" I Just got back from the range so I edited my post and added this info. I had several loads prepared using 5744 - starting with 66g and up to 72g. I stopped testing after the firing the first load. "I"M DONE TESTING THIS ONE"  Hello RIP, I've been using backing rod foam as a filler in reduced loads in a dozen big caliber rifles from .375 up to 16-bore, and everything in-between. I've even reported my results to AA on several occasions and they have never commented NOT to use it. A 1-1/4" piece of 5/8" backing rod weighs only "one grain" and is totally disintegrated within the barrel before it leaves the muzzle. (not like a plastic wad) And as mentioned, I do get very good accuracy with jacketed bullets using the backing rod foam, but so far, not with the lead bullets. And I again shot my 18-bore (.644 dia 600g bullet - same alloy, same lube) using 60g 5744 and backing rod foam. I got a 3" 100 yd group. Could be that the Krieger barrel doesn't like lead. Perhaps its the hard-chrome plating. Not sure if that's just on the outside, or in the bore also. " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

What is the twist on the 600 Krieger barrel.. Most companies make 600 rifling deeper than needed and if twist is to fast, with the deep rifling, sometimes .010" deep, and sometimes doesn't agree with lead slugs. May be swaging strips of lead outwards and hanging on muzzle or dragging on the brake. Your 20-577 looking good and most of those 577 barrels the industry makes rifling the right way, about .005" deep and a sensible moderate twist..................... And you have results to show difference....Ed MZEE WA SIKU | |||

|

| One of Us |

Buck: That lower target is one dreams are made from. The only way I can get a target like that is to tape the target to the muzzles. Cal _______________________________ Cal Pappas, Willow, Alaska www.CalPappas.com www.CalPappas.blogspot.com 1994 Zimbabwe 1997 Zimbabwe 1998 Zimbabwe 1999 Zimbabwe 1999 Namibia, Botswana, Zambia--vacation 2000 Australia 2002 South Africa 2003 South Africa 2003 Zimbabwe 2005 South Africa 2005 Zimbabwe 2006 Tanzania 2006 Zimbabwe--vacation 2007 Zimbabwe--vacation 2008 Zimbabwe 2012 Australia 2013 South Africa 2013 Zimbabwe 2013 Australia 2016 Zimbabwe 2017 Zimbabwe 2018 South Africa 2018 Zimbabwe--vacation 2019 South Africa 2019 Botswana 2019 Zimbabwe vacation 2021 South Africa 2021 South Africa (2nd hunt a month later) ______________________________ | |||

|

| One of Us |

Hello cal pappas, You don't think I should try to "tweak" the load to get them all into one hole? " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| One of Us |

No most definitely not, the load looks great but you could try a little grinding of your left barrel muzzle just to get that perfect horizontal L R group | |||

|

| one of us |

Congratulations on finding a great load for that historic, non-muzzle-braked, priceless-provenanced rifle. This flies in the face of those who say not to use filler with AA 5744:  I have done it too, and survived to tell of it. I still think fillers and muzzle brakes don't mix. Some of the pulverized foam may be going out the side ports of the brake, too much chance for variable pressures on the base of the bullet as it exits the muzzle. | |||

|

| One of Us |

Hello RIP, Well, I've never had a problem with jacketed bullets and the foam filler. But, that should be easy to test. I'll just fire a few Lead bullets without the foam and see what happens. I'm also going to try some paper card wads to protect the base of the bullet. Just by the way of discussion, I've shot over 8,000 rounds through my Stevens-Pope 32-40 Schuetzen rifle, plain base lead bullets, all with foam filler. It still shoots under 1-1/2" at 200 yards. I also shoot the following calibers with 5744 powder and foam backing rod filler: 375x2-1/2", 416 Rigby, 416 Rem Mag, 10.75x68, 45-70, 458 Win Mag, 460 Wby Mag, 475 A&M Mag, 505 Gibbs, 500 bpe, 577-500 bpe, 20-.577, 18-bore, and 16-bore. I've never had a problem with jacketed, Lead plain base, Lead gas checked, or Lead paper-patched, bullets. Today I spent a couple of hours melting down and "recasting" the .620 bullets, and this time I dropped them in ice-water right out of the mold. We'll see if that helped any. " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

buckstix: You are not getting my point at question: I am only saying MUZZLE BRAKES may cause a problem with use of fillers in your load, in this rifle, 600 JDJ with big gill slits MUZZLE BRAKE. Of course fillers may improve a load in many ways, in a firearm without a MUZZLE BRAKE. I have numerous examples of that too, with Dacron fiber or foam wad. MUZZLE BRAKES and sabots are a definite no-no. I have never used fillers or sabots through a MUZZLE BRAKE. Regarding all of your successes with fillers listed above: Were any of those done with a MUZZLE BRAKE? Maybe the 460 Weatherby with the old Pilkington style integral, tiny-hole porting on the barrel? That might be close enough to a non-brake for success. None with gilled brakes like on the 600 JDJ I bet. | |||

|

| One of Us |

Hello RIP, I do get your point. A simple test of loads without backing rod foam will tell if the MUZZLE BRAKE is a factor. My 375 H&H, 458 Win Mag, 460 Wby Mag, and 475 A&M Mag, all have a MUZZLE BRAKE. The 375 & 458 have gilled brakes, only the 460 & 475 have a Pendleton brake. " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

OK, That makes it clear for me, I get YOUR point. I held a match near the edge of a piece of foam backing rod, 5/8" diameter. It is astonishing to see how fast it just vanishes with that low heat, no smoke, just POOF, gone. The foam is indeed mostly air. No doubt the caulk backer rod foam is pulverized and incinerated to almost nothing, scant dust and gas, by the time it gets to the muzzle brake. OK, not a factor. Not so the Dacron polyester which was created as a fire retardant furniture, pillow, and Teddy Bear stuffing. That creates a snowstorm at the muzzle and could create an obstruction in a muzzle brake, like a sabot could. It would at least be unpredictable accuracy wise, if it did not damage the rifle. OK, no problem with me using backer rod foam in my muzzle braked rifles too. But I doubt I will ever do it, since that is like gilding the lilly, using "reduced" loads in a muzzle-braked rifle. Too bad the 600 JDJ brake cannot be removed. The no-filler myth with Accurate 5744? Anecdotes abound on the internet: "Before he left Western (Accurate Arms), I spoke with Johan Loubser (AA's ballistician) and he told me emphatically that one should not use filler with AA5744." rob@ramshot.com is the current technical specialist. Will see what he has to say about it. I have done it too, and I lived. | |||

|

| one of us |

buckstix, Do you see much unburnt powder left in the barrel of the 20-577 AH with that 66-grain charge of AA 5744, 650-grain Hawk, and foam filler? They say the only way to not have unburnt powder with AA 5744 is to get pressures up. What do you think your pressure is with that load, QuickLOAD, etc? I gave the link to this thread to the brains at ramshot.com, expect to hear in a day or two what they think. I think the AA 5744 load with foam filler in the 20-577 Alex Henry double rifle is superb.  | |||

|

| One of Us |

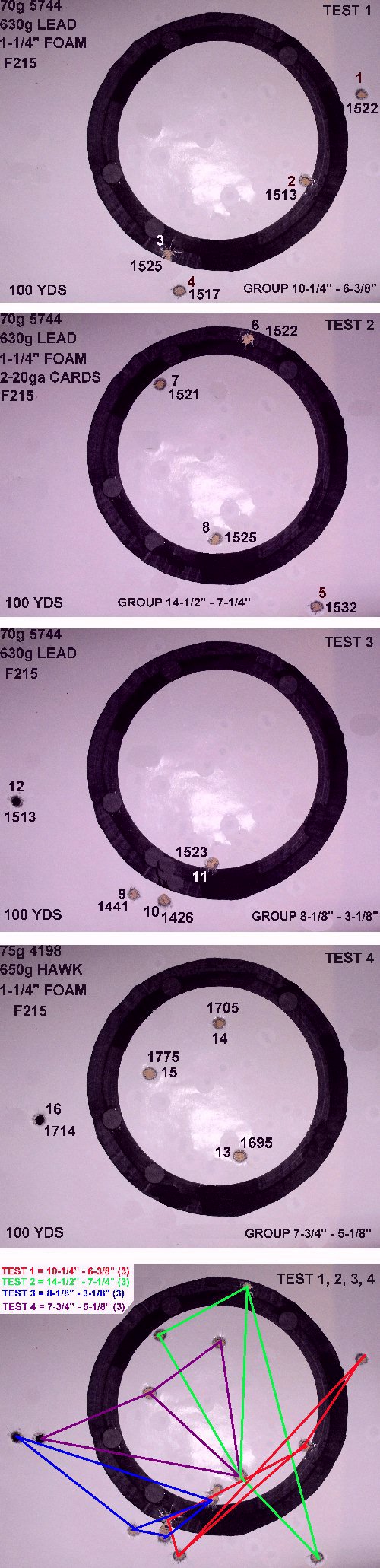

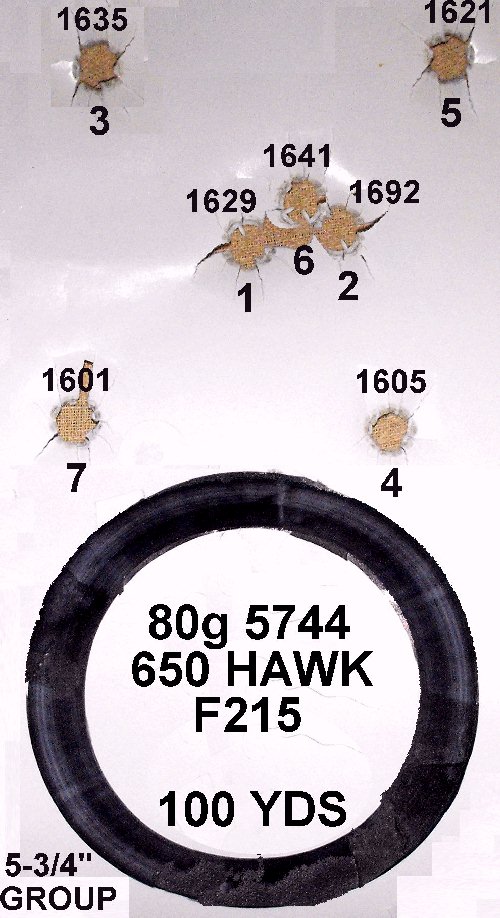

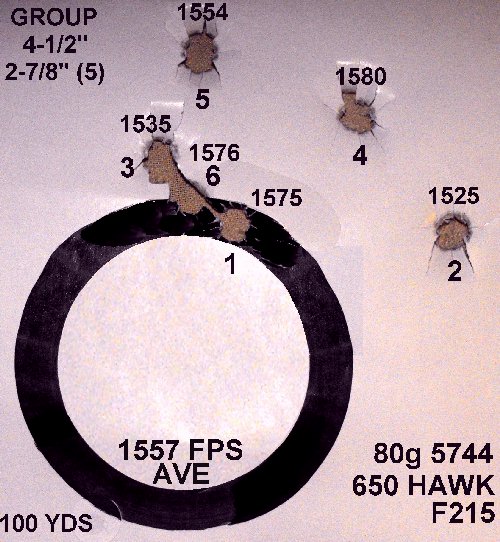

Hello RIP, There is no unburnt powder left in the barrels of the 20-.577 Dickson. There is some left in the 600 JDJ. A small trickel that runs the length of the barrel. However, as you can see by the following data, the velocities are quite uniform. Test 1 through 3 use the same powder bullet combinations with only foam / paper wads being changed. Test 4 was with a different powder. Look over the results and give me your opinion please. Targets show each overall 4 shot group, and then the best 3.  " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

Get the speed up. Got to get through brake faster. Retire part loads 4198... Try filling case full of RE17. For both jkt and lead. I mean 100% to bottom of bullet..Ed MZEE WA SIKU | |||

|

| One of Us |

Hello RIP, I'll go up a bit in velocity, but I'm trying to come up with a load at around 1500 - 1800 fps. I want some FUN loads for most of the time shooting. Not really wanting a good dinosaur load at this time. " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

Maybe if you have dinosaur load that's accurate back it down, and maybe it'll be accurate. RE17 is as slow as IMR4350 but a better pressure curve. But because bullets are 650 not 900 gr should go ok. If full load to hairy go down too 90%, if still too hairy then try full load RE25/ I have inkling that you got to do about 18-1900 to get groups decent.Ed MZEE WA SIKU | |||

|

| One of Us |

Maybe I missed it but What is the length of your cast bullet and what is the twist of your rifling. What I have seen used is 20-1 lead - yes it is soft. Shoot it about 1100 to 1400 fps with SR4759. How I determine the right charge - starting loads will leave unburned grains (zombies) in the bore. I increase the load until the zombies just disappear. I do this so the bullet is not running over unburned power. I use no filler. What I wind up with is like a large caliber .22 LR. If you want anything more fool proof use a gas check and the same alloy. You need to shoot only jacketed or only cast. The jacket fouling can interfere with smooth passage of the cast bullets. Take your bullet length and twist an put it into Miller's stability calculator. You are probably spinning the bullet way too fast. | |||

|

| one of us |

buckstix, I see your targets "patterning" the 600 JDJ with cast bullets, but I still have no idea why the rifle is shooting like a blunderbuss. Did the scope go tits up? I believe your Krieger barrel has a 20" twist. That ought to be good but the Stability Factor computation (as SR4759 suggested) would be interesting if I had the length of the 630-grain/.622" cast lead bullet, as well as the length of the Hawk 650-grain/.620". Unburnt AA 5744 suggests very low pressure load, like 20K psi or less? Have you done a QuickLOAD estimate of pressure? That would be interesting on this rifle as well as the 20-577 AH, which is burning all powder, and super accurate. RL-17 at about 85% fill with a foam wad on top of it sounds good to me now, in the 600 JDJ, since I have resolved my phobia of muzzle brake with that caulking backer rod wad. You need to try something very different in quest of better accuracy. Ed is a wildman. RL-17 will ignite well with any primer, any fill, Ed taught me that. Large doses of RL-25 probably not. Ed? I am afraid the technical department at Accurate/Ramshot/Western Powders is couching everything in legalese. He said corporate-wise they only recommend Dacron and Puff-Lon as fillers. He did not say anything specifically about AA 5744 and filler of any kind, though that is what I asked about. Other than that he said he had looked at this thread and did not see anything wrong with what buckstix is doing. And he said, ironically, that he was currently working on an article about AA 5744 and filler. I am asking him now where I can read about it, when published. My guess: I do not think they have any evidence, no science, so are just doing the corporate CYA due to lawyers and uncertainty. If I learn anymore, I will post. My SWAG from this thread: Using caulking backer rod foam wad with AA 5744 works great, if chamber pressures are less than 40K psi, by QuickLOAD, just treat the foam wad like air space, and add 1 grain to bullet weight. Also, no worries about using that foam wad through a muzzle brake, since it vanishes by the time it gets to the brake. | |||

|

| one of us |

The RE 25 with large rifle primers should do ok in 600 JDJ as actual base size is same as 577HE., Same as base size ahead of the belt as 600 OK. With tryng to go slow, arrel time may be leaving bullet in barrel and/or brake just as barrel starting its recoil, disturbing bullet. That is why lot of guys with with slug guns and slow loads cut barrels off, to get slug out of barrel before barrel moves.rather than speed up loads. Ed MZEE WA SIKU | |||

|

| one of us |

Re25 in large cases works just fine. -Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| one of us |

| |||

|

| One of Us |

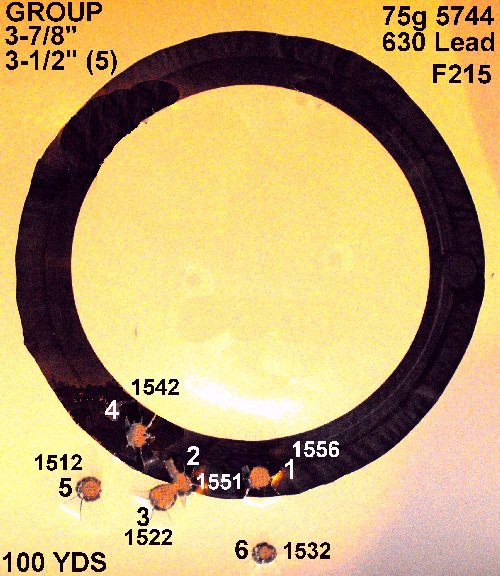

Hello folks, Well, I think I'm finally making some progress. I'm starting to get groups instead of patterns. I upped the 5744 powder to 75 grains, changed the lube to liquid alox on the lead bullets, and shot over boat cushions instead of using a front rest. Note that I left out the backing rod foam on these loads. I will continue with this load, perhaps upping the powder a bit more, to see if its repeatable. If its repeatable, I'll test to see if the backing rod foam disrupts the groups.   " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| one of us |

That's better. Here is the latest on Accurate 5744: http://blog.westernpowders.com...sition-and-pressure/ There is no explicit recommendation against using a filler (or "buffer" as author calls it) with AA 5744. In fact it seems they are OK-ing the use of filler with AA 5744, as long as you start low with the powder charge and work up to a prudent desired velocity, such as would be correct for the historic load velocity of the antique, or whatever is equivalent for a wildcat mimicing an old BP, BPE, or NFBP load. Whatever that means, just my interpretation of the vague advice there: "POWDER POSITION AND PRESSURE" July 9, 2014 Powder migration within large cases by small charges of powder accounts for many unexpected problems experienced with reduced loads. Be aware that loads using small charges often exhibit different pressures created by changing powder orientation within the cartridge. A look at powder position and its effect on pressure within cartridges All powders exhibit some form of positional sensitivity within a cartridge. SAAMI recognizes this by publishing strict guidelines governing the testing of ammunition. These guidelines are intended to control powder position within a cartridge by orienting it to generate the highest pressures for a given load. SAAMI guidelines for testing require that the loaded cartridge be twirled slowly end over end to loosen the powder within the case. It is then carefully oriented with the primer end down to settle the powder rearward within the case. The technician then inserts it into the test barrel, being careful not to move the powder forward and away from the primer. This powder-rear orientation produces the highest pressure and velocity for that load combination and provides the baseline for published data.saamitech72 Cartridges filled to near the top of the seated bullet have very little room for powder migration within the case, making them relatively immune to powder orientation caused pressure changes. This is one of the reasons that fuller cases have lower standard deviations. If that same cartridge is loaded with a faster powder, perhaps one that only fills 70 percent of the available case volume, powder may become oriented away from the primer which will reduce pressure and velocity. The ability for powder to migrate throughout a case is a major cause of higher standard deviations between shots. In Handguns Positional sensitivity is increased by unused case volume. Older cartridges designed to work with black powder and at low maximum pressures are the ones most commonly affected by this problem. The .45 Colt and .38 Special are two that fall into this category and both can have real powder position issues with lighter loadings. Our lab was contacted by a shooter who was looking for loads in his .38 Special that would operate in the 450-500 fps range from a Ruger Vaquero using very small (he referred to them as economical) charges of very fast powder and light bullets. His goal was to create an inexpensive competition load he could use in the local cowboy action shoot. He suggested using a load far below our starting loads and wondered if it was safe. The answer was no. It was unsafe. Here is why: A pistol carried muzzle down in a holster orients powder forward against the bullet, a situation that creates the least pressure for a bullet/powder combination. As the pistol is raised to eye level its powder charge remains forward. If the round is already under-pressured by design, it has now been subjected to an orientation that further reduces pressure. Muzzle velocity may drop to zero, as the bullet fails to emerge from the barrel. Published data is provided with a powder-rearward orientation and the load range is calculated by regression using the maximum SAAMI pressure guidelines. The regression is based on a safe reduction of that pressure accounting for potential shifts in pressure produced by individual firearm characteristics and by positional issues that may be created by the lowered charge weights. Going beneath them risks a stuck bullet and a trip to the gunsmith. Always treat the lowest (and especially untested lower charges) with skepticism until they prove safe in your personal handgun. There is no corner to be cut here; light loads can lead to stuck bullets. Test them carefully. Avoiding Powder Position Issues in Handguns Overcoming positional issues with handgun loads is not difficult, but may require a bit of research. The best solution is look for loads that come closest to filling the case up to the base of a seated bullet. When researching load data, watch for powders that have a lower bulk density like Accurate #2. This powder has BD of .635 and fills more case volume than denser powders using the same charge weight. It is a very good choice for reduced pistol loads in the .38 Special and 45 Colt cartridges. Fillers in Pistol Cartridges The use of fillers like Puff-Lon or Dacron usually produces higher pressures in loads that were developed by handloaders without a buffer in place. Remember, powder orientation within the case has probably run somewhere between the minimum and maximum pressure positions. Cartridges are usually stored bullet down, loaded in a revolver with the muzzle aimed downward and then brought up to eye level to fire. Each of these scenarios indicates that the powder will be orientation forward, reducing pressure and velocity. Using a buffer will force the powder rear-ward and raise the pressure potential for that combination as well as adding additional mass to the projectile. If it is your decision to use a filler like Dacron or Puff-Lon, it important to work up loads with those components in place. Don’t try to save a step and take a pet load and add a filler to the mix. Be smart, reduce the load and work it up like you would any other handload, watching for pressure signs. When done properly, good fillers can substantially reduce standard deviations in cartridges like the .45 Colt. Position Sensitivity in Rifles In rifles, the two most common areas for positional issues lie with the older blackpowder cartridges and with reduced loads for large calibers. In both instances, small charges of powder within large cases can produce several distinct and reproducible pressures curves. These pressure changes are directly linked to powder orientation within the cartridge itself. We used the .45-70 Government loaded with Blackhorn 209 to test positional sensitivity. It was chosen for several reasons, including the fact that Dacron, Puff-Lon or over-powder wads are recommended by our guide for this load. The baseline testing was done using SAAMI methods to produce a standard load range for the powder/bullet combination that will eventually be published in our new guide. The second test used the same charge with forward-orientation and no buffer. The final test used the same charge with forward-oriented loads and a compressed buffer of Puff-Lon. The results highlight the role powder orientation can play in pressure and velocity. The standard test, which followed SAAMI protocols for rear-oriented powder, produced a mean pressure of 17,767 psi with 26.0 grains of Blackhorn 209. The case fill was 74%. The average velocity was 1,143 fps with a standard deviation of 20 fps. The same load, tested with its powder oriented forward against the bullet, and then placed carefully into the universal receiver, generated considerably lower numbers. The average pressure dropped to 9,000 psi and an average velocity of 950 fps. These cartridges were loaded at the same time as the test run and shot within an hour of the previous test to limit environmental changes in the data. This difference is caused by powder orientation within the case. For the last test, we used 26 grains of Blackhorn 209 and then filled the case up to the mouth with Puff-Lon, leveling it with a straight edge. The bullet was then inserted and crimped using the same depth and crimp settings as the other loads. These loads were also tested using a powder-forward orientation like the non-buffered loads. The loads using Puff-Lon averaged 18,040 psi and a velocity of 1,134 fps with a standard deviation of 17 fps. In this case, it is clear that using a filler limited positional sensitivity within the large cased .45-70. Overcoming Positional Issues in Rifle Cartridges As in pistol cartridges, the best solution for rifles is to choose bullet/powder combinations that come close to filling the cartridge to the base of a seated bullet. This will typically reduce standard deviations and accounts for one of the reasons why slower powders, and their fuller cases, tend to produce the best accuracy in rifles. In larger cartridges, especially those that were created for black powder, there may be no powders that offer a good case fill at the desired velocity. One option is to search out data using Accurate 5744. Accurate 5744 is an unusual double-base extruded powder which ignites easily and tends to take up quite a bit of volume within the cartridge. As a double-base, it is less position sensitive and tends to produce consistent pressure and velocity in larger cases without using a buffer. Our guide has extensive data for this powder, including reduced loads for large caliber rifles. Our technicians also have access to data for antiquated or little seen cartridges that may not yet be published. The easiest step for the handloader looking for reduced rifle loads is to consult with our customer service people if the information is not available in our guide. If you are shooting a reduced load that has been privately developed without filler or an overwad, it is important to understand that adding a buffer will orient the powder to produce the maximum pressure for that powder/bullet combination. It will produce higher pressures than the unbuffered loads and may prove damaging to the firearm. Always develop new loads intended for use with fillers with the fillers in place. Should I use a Filler? When handloading for cartridges designed for smokeless powder, the general answer is no. The best solution is to use bullet/powder combinations that provide good case fills and that have been tested in a laboratory environment. When loading older rifle cartridges, load guides will stipulate when a wad or filler is used. Following this data should produce safe loads. Utilize tested data using Accurate 5744 if available for reduced loads or antiquated cartridges. When using fillers, develop the load from a lowered starting point and work toward the desired velocity. For commonly used pistol cartridges like the 45 Colt and the .38 Special, which have large capacities and low SAAMI pressure guidelines, it is best to stick with published loads using the most voluminous powders available. If denser powders are used, increasing the charge weight within published guidelines will limit the differences between maximum and minimum pressures created by powder orientation within the case. The safest route is to avoid extremely light loads. If you choose to shoot the lightest loads possible, below the guideline minimums, be sure to account for each shot fired because the threat of a squib load is very real. Summary Powder migration within large cases by small amounts of powder can account for many unexpected problems experienced with reduced loads. Be aware that loads using small charges often exhibit different pressures created by changing powder orientation within the cartridge. Use of a filler will control these fluctuations, but will do so by forcing powder against the primer which increases pressures. Always develop reduced loads with the filler in place if it is to be used at all. Be careful of extremely light loads, that when paired with powder-forward orientation may result in a squib load and a stuck bullet. And finally, use published data whenever possible. Let us experiment with pressure and you can enjoy the results. Take care and good shooting. | |||

|

One of Us |

Good reminder. Thanks for posting Ron. Jim "Life's hard; it's harder if you're stupid" John Wayne | |||

|

| one of us |

To keep powder in an absolutely uniforn place in the case, squarely and level above the primer, you can use easy to get 20ga fiber wads like we use 24ga wads with reduced fast powder loads in our 585HE. See the picture 585HE thraad. Ed MZEE WA SIKU | |||

|

| One of Us |

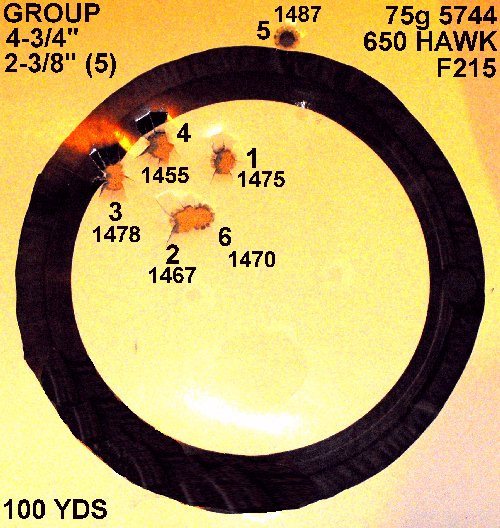

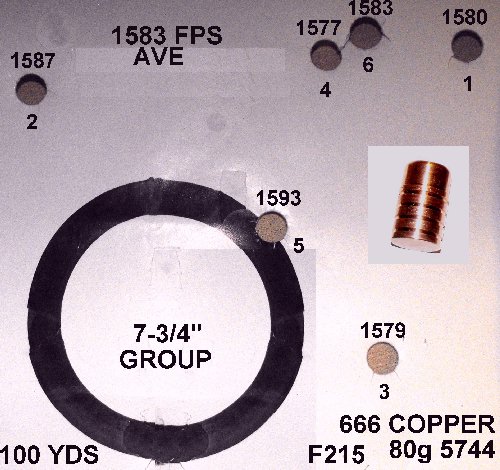

Hello all, Well, I've had some ups and downs with additional load testing. For the most part groups fell apart and went back to look like patterns in the 12" range. I won't even bother to post those. However, those poor results got me to thinking. During that testing I had 3 primer failures. They failed to ignite. Two fired on the second strike, but the other one never did fire. Could poor ignition be the cause of my poor groups? I shimmed the hammer spring on the to get a little more spring tension. This helped, and I never got another failure. In addition, I made a point of grasping the rifle a lot more firmly thinking that inconsistant "loose" support may be affecting the groups. And then yesterday, I started having more success. Not great, but better. I even tried making some of my own bullets on the lathe to see how they would do. The copper wadcutter bullet that I made is shown in the last group.    " .... you never pay too much for something, you only buy it too early .... " How to Hunt Wisconsin Whitetail Deer with a Cannon How to Hunt Feral Cats with a Mortar | |||

|

| new member |

Buckstix hi. I cast a 935 grains pure 20/1 alloy for my 600 Overkill and only run through a size die to install the lube. its 0.001" over bore and I use the AA 5744 x 60 grains for 1300 fps average. this powder dose not require any fillers & insensitive to low volume powder column as stated by AA. its a proven fact a soft pure alloy will engage the land & provide a perfect seal thus improving accuracy not to mention maintaining weight & expanding post impact as proven in the black powder era. try it & you'll find out. harder alloys & water quenching will render bullets too brittle & may shedder upon impact so, go with what has been proven, ask the black powder competitors what they're using. Avi | |||

|

| one of us |

With all due respect have you measured your bore and assured yourself that it doesn't have any loose sections particularly near the muzzle? Carefully inspected the crown? I'm sure your aware of the lead lap test? I had a Weatherby that had a loose section near the muzel and sprayed bullets just like your seeing. Are you turning your bullets by hand? How close in weight are they? You want some 900 gr brass bullets less than 0.1gr difference in weight to test that are known to work? In my experience soft lead bullets only work in very slow twist barrels as were used for black powder. In barrels with twist rates below 1:20 you need very hard lead bullets to avoid stripping the bullets in the rifling and leading the barrel. Paper patching is a very good way of making soft lead bullets work in fast twist barrels. I've had great results with heavy loads of 5744 and Linotype alloy as I've said before,up to velocities of 2000fps using no filler or some Dacron if necessary.-Rob Never underestimate the power of stupid people in large numbers to do incredibly stupid things- AH (1941)- Harry Reid (aka Smeagle) 2012 Nothing Up my sleeves but never without a plan and never ever without a surprise! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  600 JDJ - LOADING LEAD BULLETS - QUESTION

600 JDJ - LOADING LEAD BULLETS - QUESTION

Visit our on-line store for AR Memorabilia