The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  cocking piece sights

cocking piece sightsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

"I spoke to Jim Wisner on the phone today about Tom Delucchi's cocking piece sight. He said it was a "low priority" for him, and didn't anticipate production for a year. I was disappointed. Garrett" "it seems a bit sad to take a product off the market for a year because it is a "low priority" item...just a high enough priority item to buy Tom out. I really like Jim and the stuff he makes, but waiting a year sucks. Rich" To claify things. I spoke to Tom Delucchi on the 3rd of Jan. He had been down with the flu so had not even shipped any samples from his last batch, out to me yet. I expect to see them in the next few days. I did not buy out Tom Delucchi on this sight rather we have a Gentleman's agreement that allows me to make the sight. Otherwise it would simply disapear from the market. Once I get the sights then I can I start the process of the CAD work, CAM work, tooling and cutter work, as well as the proofing of the CNC programs, to make the parts of this sight. This is after I finish the work I already have started so I can start on a contract that should finish in May hopefully. The parts in that contract have not been seen since Winchester was making them 80 to 90 years ago in New Haven. Then I get to figure out the Winchester M88 358 Win magazine and follower, so that will be a production item. Then I can worry about the cocking piece sight. Yes once I get the peep worked out and in production you will see batches of 50 sights compared to the dozen or so that Tom was putting out. "Contact Scrollcutter I have found Tom Delucci's work first rate. Much better than Wisner's. The old Wisner Gunshop in Chehalis turned out some real crap. Lovu Zdar Mickey" Mickey, you should talk about something that you know of and not something you have no IDEA of what you are talking about. WRONG WISNER, I grew up in Dad's shop and worked full time for for him from 1972 until 1986. At which time I started Precise Metalsmithing Enterprises, did custom Metalwork, made and sold CUSTOM gun parts, all over the world. In 2002, I had to shut it down after the 9/11 aftermath to the economics. I then went back to work for DAD and bought him out in 2004. We currently make and carry over 950 stocking line items of reproduction and custom gun parts. One nice example of my metalwork can be seen on the ACCG webpage as the #21 Raffle Project, www.acgg.org Dad shut down the gunshop in 1994 after his head gunsmith of 7 years asked one Friday in May 1994, could he have two days off next week because he had a job interview in Denver the next week. At that Time the shop had 5 full time gunsmiths and would repair over 3400 guns a year. Mom and Dad had moved the gunshop to Chehalis in 1989, I would come in from time to time and do the high end repairs. One that I still remember is the Krieghoff Drilling that I had to set up and machine the rib out so the Claw Mount Bases could be soldered in place to match the customers other Drilling. That was a lot of sweat making sure everything went well. They shut the gunshop down by Dec of 1994 so Mom and Dad could concentrate on the reproduction parts. It is interesting that Scrollcutter started working at Wisner's Gunshop as a Pistolsmith in the early 80's. Once he started Engraving one of his first paying jobs was a Browning 1886 that I redid the metalwork and made a complete new stock for. Roger did some very nice scoll work on the receiver, and he had a hard time of cashing the check for it since Hank Williams Jr had writtten it out. All I can say at this time is that I will get to the sight when I can. Jim Wisner Custom Metalsmith | |||

|

| One of Us |

I can only talk about personal experience. I have a Marholt rifle 98 Mauser on a Commercial action. It was ruined by one of your gunsmiths. It was to be rechambered to a 300 H&H from a 30-06. It is a fully engraved rifle that was a beautiful weapon. First. No gunsmith in his right mind would have attempted to rechamber the rifle with out first attempting to talk the owner out of it.. The bottom of the chamber was cut out, as was the rear bridge. Did I mention it was fully engraved? Second. The rechamber is sloppily done. It expands the neck of the shell to where it won't go into a die. Max velocity of Federal Premium 180 grain is 2325 fps. Third. The calibre mkg 30-06 on the barrel was polished off and the rust blue on the barrel was removed and the barrel was hot blued with the new marking. Super 30. Super 30? Fourth. The rifle was glass bedded by Wisner's Gun Shop. When the rifle was picked up and taken home it was full of bedding compound and bedding release, a superficial attempt at best to clean it up. The gentleman who had the work done took it back, a 90 mile drive each way, because the rifle would not fire. He was told it was not Wisner's problem as it was an old rifle. I took the bolt apart and it too was full of bedding release. A little interest by the gunshop would have found this. The owner was so depressed by the mess that was made he gave it to me. I offered to reimburse his cost but he said Wisner's had charged him $700.00 for ruining it. A real sloppy bit of work by incompetent people who obviously didn't care and only wanted the money.. | |||

|

| One Of Us |

Gottfried Prechtl makes cocking piece sights (part number WT02201), and a hell of a lot of other M98 parts such as 3 pos. Win. M70 types safeties etc. and of course new M98 actions in both standard and magnum length : http://golmatic.de/Waffen_EN/buechsenmacherbedarf_en/visier_en.htm Gottfried Prechtl - FIREARMS Auf der Aue 3 D - 69488 Birkenau / GERMANY Phone +49 6201 167 88 Fax +49 6201 18 27 01 golsniper@t-online.de | |||

|

| One of Us |

ErikD, any idea what the sight costs? Rich | |||

|

| One Of Us |

Sorry Rich, I don't. But "frau Schmidt" (Prechtls secretary) is usually quite fast at reponding to such questions. FWIW, they read and write English reasonably well, although speaking on the phone can be a bit more difficult sometimes. | |||

|

one of us |

The Prechtl sight runs in the neighborhood of 5 to 600 dollars IIRC. Roger Kehr Kehr Engraving Company (360)456-0831 | |||

|

| Moderator |

Scrollcutter, Did you get the PM I sent you a while back regarding the Auto5? Mark for every hour in front of the computer you should have 3 hours outside | |||

|

| one of us |

Mickey1 I have thought of many replys I could make regarding your statement. You have your mind made up and nothing will change that. But I give you this. I never was the owner of Wisner's Gun Shop. I was a full time and part time employee of the Gun Shop for a number of years. I never have rechambered a rifle to 300 H&H, heck I did not even own a reamer in that caliber until 2004, 10 years after the gunshop you are uspet about closed down. The time frame of the work would have been from the summer of 1989 till the fall of 1994. That is a long time sitting on the sidelines and not taking the gunsmith to task. Yet you still have the gall to say anything with that name on it is no good. Go tell that to Wisner Park in Elmira NY, the town of Wisner NE, Wisner Camera's of NY, Wisner Creek here in Washington. I have never had any other gunsmith work for me in MY SHOP, all of my custom metalwork work is stamped J.L. WISNER. As far as I can recall you have never purchased any of my gun parts nor have me do any custom metalwork. Regarding Tom Delucchi, I have known Tom for 24 years now. He has done a lot of work for me and I for him in this time period. You should like his bolt knobs, because I have made them on my lathes for the past 5 years. As well as other short run gun parts for him, currently I have 25 of his M98 sleeves in my shop awaiting machine work to install the two position M70 safety conversion I market. Scrollcutter, I first worked with and having known for 22 years now. I still sometimes get a call from him about how in the heck can this part be made. My standards for quality gun parts is well known by many Gunmakers and Gun Companies here in the USA, England and Europe. The list of repeat purchases in the past 21 years would read like an who"s who list of the fraternity. Jim Wisner Custom Metalsmith President Wisner's Inc. www.wisnersinc.com | |||

|

| One of Us |

I was speaking of Wisner's Gun Shop. I knew that your Father owned it. You clarified who owned it in your first post. You are correct, I have not had anything done by you but I have seen some mod 70 safeties that you have done for others. | |||

|

| one of us |

Jim, To let you know, I had purchased multiple items back from PME, and had nothing but a positive experience. When I was building up my 300 Dakota on a FN Mauser, you got on the phone and gave me quite a few tips that really helped out. I was just disappointed about the Oberndorf style cocking piece sights as I wanted one for a .25 caliber rifle of mine. If you're telling me now that it is something you'll get to eventually in 2007, I can wait. Regards, Garrett | |||

|

one of us |

Mark, Either I overlooked it or forgot to respond. In either case, apologies. You have a PM. Roger Kehr Kehr Engraving Company (360)456-0831 | |||

|

| new member |

Idaho Sharpshooter, D&D doesn't have a sight department per say. To get to the pictures I posted: On the opening page, click on the British flag in the lower left corner. From there click "Work In Progress" At the bottom of that page, click "steps of fabrication" under "Best Quality Plain Game Rifle .300 HH Mag" That page shows numerous pictures of the 300HH including the ones I posted. As for prices....I have no idea, but their complete rifles are very high. | |||

|

| One of Us |

MFC, thank you. I may have found a source for those cocking-piece sights for under $200 USD. I will see. If it is good and fits up properly I WILL report back here to the group. Rich | |||

|

| One of Us |

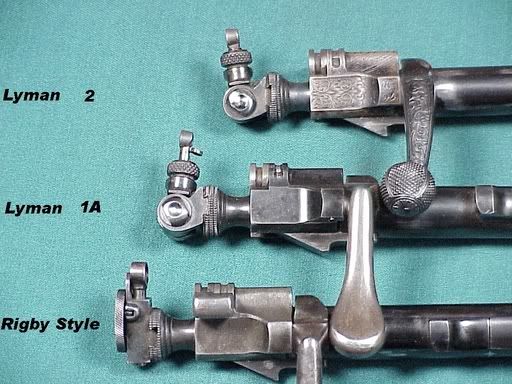

Looking at the sights, it appears that there is no windage adjustment. Is that correct or am I missing something. Is the windage adjusted by the front sight? Never rode a bull, but have shot some. NRA life member NRA LEO firearms instructor (retired) NRA Golden Eagles member | |||

|

| One of Us |

Rolland, The entire sight body is moved in the dovetail to adjust for windage, in most versions. You will see different versions. H&H made one integral with the cocking piece that required, as you asked, that the front sight be drifted for windage. It was adjustable for elevation only. Rigby made on without the "wheel". You just pulled up on the stem. Lyman made the 1A as shown. I have another version the "Howe-Whelen" that is very complex, too much so. It is very heavy and too large. But it is an interesting piece. So there are different patterns. Someone mentioned that the 1A as shown above may contain new parts. There are spare stems around in the hands of dealers in metallic sights. I recently sent a Marbles tang sight to a gentleman in Alaska that bought the entire Marbles inventory. So like so many things in life, it just takes a little money. gduffey | |||

|

| One of Us |

gduffey I was mulling over the idea of making one based on the photos shown here. Moving the sight in the dove tail makes sense. Thanks Never rode a bull, but have shot some. NRA life member NRA LEO firearms instructor (retired) NRA Golden Eagles member | |||

|

| one of us |

I'm sorry it happened to anyone else Jim, but I don't feel like the lone ranger nhow about getting hammered in the 9/11 aftermath. I opened my my medical clinic in early 2001. Things were going pretty well until 9/11. The following two years were rock soup the whole way.  | |||

|

| One of Us |

Let me say this: EVERYTHING I have handled from Jim Wisner's shop has been first-rate, and without issue when put to work. The 505 Gibbs I posted about here was one Jim did for a friend. He has three rifles from Jim. He is presently engaged in trying to talk Jim into building him one more, "...just one more...". If I ever hit the lottery, I am going to try and just "Rent" Jim for about a year. I like to think we are becoming friends...he is a good person. Rich | |||

|

| new member |

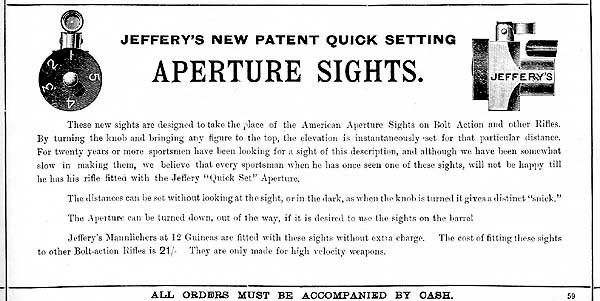

I found this picture over on nitroexpress.com  It is a little hard to read, but interesting none the less. | |||

|

| one of us |

Jim W. When you get around to making these sights or a copy what will you make them from? I do not like the thought of all that weight attached to the firing pin. I would be interested in a copy made out of titanium or similar lightweight material. Thanks James | |||

|

| One of Us |

Here is the site that Wisner will be making on a 404 Jeffery.  | |||

|

one of us |

Mr. Wisner, I will most likely want one of your cocking piece sights. If you ever get around to it, I think there is also a sizable market for straddle flooplates for Mark Xs (like your 09 Arg floorplates) and I also think you could sell alot of straddle triggerguard floorplate assemblies (like Sunnyhill, Blackburn) if you can beat their prices. To return to the topic, here's an old Lyman on a Springfield cocking piece:  NRA Life Member, Band of Bubbas Charter Member, PGCA, DRSS. Shoot & hunt with vintage classics. | |||

|

| one of us |

The dovetailing is elegant but I suppose y'all realise that the cocking piece is harder than a whore's heart at yuletide? A gunsmith out our way makes them, he sweats them on to the piece - the piece sits in a circular recess in the sight. Sights are adjustable for windage and elevation and way too expensive for anything but a bespoke rifle. If Chuck Norris dives into a swimming pool, he does not get wet. The swimming pool gets Chuck Norris. | |||

|

| One of Us |

HOW MANY GUYS WOULD BUY A RIGBY STYLE PEEP IF OFFERED AT $200 TO $225 ? I WILL TRY TO ORGANIZE A GROUP BUY OF THE GERMAN MADE RIGBY SIGHT PICTURED HERE. CONTACT TOM ONDRUS TEL 814 774 5739 CROWNPRESS@ALLTEL.NET TOMO577 DOUBLE RIFLE SHOOTERS SOCIETY | |||

|

| One of Us |

heck Mickey, sounds like you came out of the deal with a rather expensive rifle FREE! You shooting it, or what has become of it? Just curious, since you opened this whole can of worms. Rich DRSS | |||

|

| One of Us |

No, I don't shoot it as it would need a new barrel. Ideally I would change it back to '06 and get a new bolt fitted. Nothing can be done about the removal of part of the rear bridge and the engraving. Someday I might rebarrel it. It feeds like shit too, always jaming. That would need to be corrected. I'll post some pictures if anybody is interested in seeing it. The gentleman who gave it too me has since died and it has nostalgic value to me. | |||

|

| one of us |

The best cocking piece sight by miles is the Parker Hale Sportarget, with click windage and elevation, came for both Mauser and Mannlicher-Schoenauer. | |||

|

| One of Us |

vigillinus, where can I get one, and how many yankee dollars? Rich DRSS | |||

|

| one of us |

Idaho, watch ebay .... very hard to find tho. | |||

|

| One of Us |

H & H-        | |||

|

| One of Us |

as one would expect, very nice! Rich DRSS | |||

|

| one of us |

about 6 or 8 years ago a guy advertised having some for sale in The Gunmaker. I called him last year to see if he had any and he had (I beleive) 3 and wanted to sell them very badly. I think he wanted $325-350 for them. If soemone has th eback issues of Gunmaker (I do) and the desire to flip through them (I don't) then you may luck into soem of these sights. After becoming a busienss owner myself, it has always amazed me how people make sentimental statements and blast busienss owners for not doing things basically just for the sake of doing them and because it sound romantic. I do not know Jim Wisner, but I do feel fairly confident that if he saw a vast untapped market for these sights, then they would be moved to the front burner. | |||

|

| One of Us |

Greetings To all, My first post here. I am friends with Gary Duffey, and he alerted me to this thread. I have serious interest in building some of these peep sights. I have 10+ years experience with CNC machining in wire EDM and milling. I own one of each. This would be my first forray into gun parts, but I have been making high precision folding knives for years as well as dabeleing with various tool and die projects. An item like this would be perfect for me to keep my machines running and have a side project to keep shop life more colorfull. If anyone has a piece I could blueprint, or drawings, or can point me in a direction to find the info needed, I can get going right away. My website is www.bradshawcutlery.com Thanks!! Bailey Bradshaw www.bradshawgunandrifle.com I'm in the gun buildin bidness, and cousin....bidness is a boomin | |||

|

| One of Us |

Marc, Tom D never was able to keep up with the demand for these sights, after working his full time job all week. He made his deal with Jim Wisner based on the notion that Jim was interested in making them as a business; and that that would result in more of them reaching customers, quicker, and as a mass-produced item, perhaps a bit less $$$ than batching them a (comparatively) few at a time. God Bless Jim, he's one of the best at his craft in the country. Better yet, he is a genuinely good human being, and a credit to his race! There is just a tremendous sense of disappointment, especially to customers who have had one ordered for some time, who now may be looking at another whole year...or longer, to get one. What would your response be if you had promised a customer a rifle with one of these cocking pieces about a year ago, you got the rifle done yesterday; and then you get the news today that it is going to be 2008 before it arrives? There's no "Bad Guy" in this scenario, just frustration by customers and some general sadness that a desirable product is off the market for the foreseeable future. regards, Rich DRSS | |||

|

| One of Us |

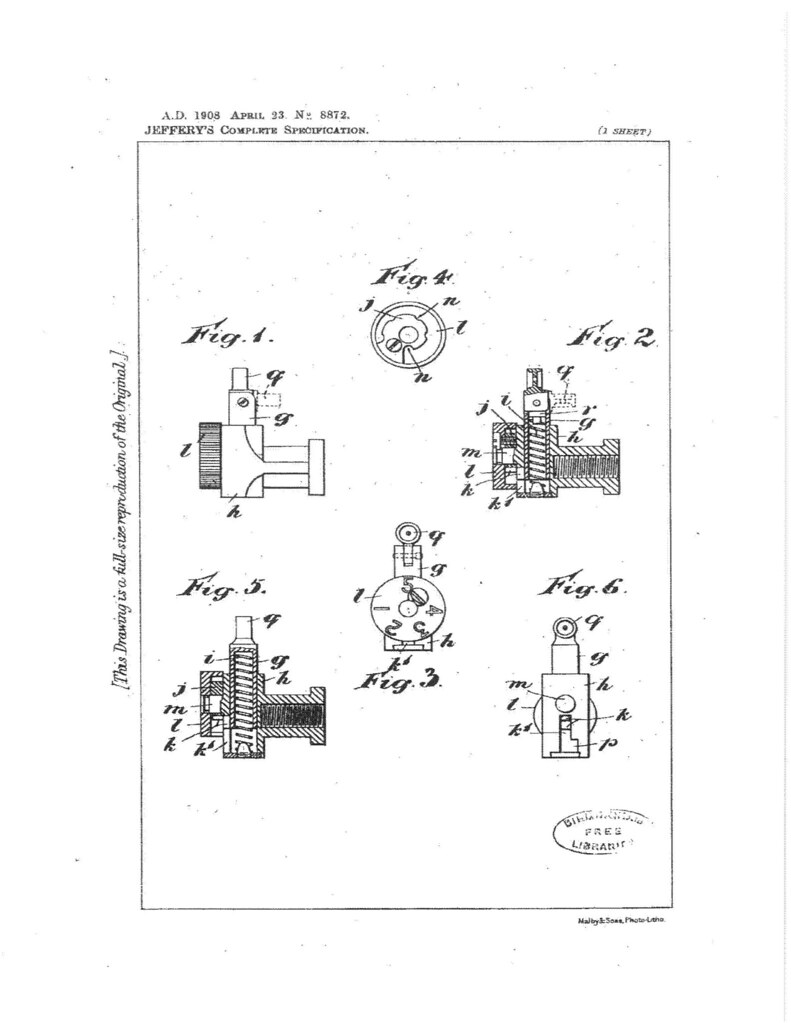

Here's the page of drawings from the patent application for the W.J.Jeffery Patent 8872 sight seen above. Has anyone here seen or used one of these? I'd love to see a photo of one. Note it's a regulated multi-range quick-adjust indexed peep sight...  Thanks for ant input. --Tinker _________________________________ Self appointed Colonel, DRSS | |||

|

| new member |

The_Captaine et all.....I have a 275 Rigby M98 with aforementioned sights. To answer your original question about ensuring some sort of shot to shot repeatability, this is how they did it. The forward edges of the cocking piece nose are milled to form a flat faced triangle. A mating "V" is milled into the sear, thereby forcing the cocking piece and sear to remain more or less in alignment. Obviously, if you attemp to do this will shorten the firing pin fall. My guess is thet Rigby built up the back edge of the sears to compensate. Hope this helps, Kevin. Any man who is willing to trade his liberty for a few pieces of gold, deserves neither and will probably lose both. | |||

|

| One of Us |

Better News!! I had a PM from Jim yesterday, and it is looking like August. Tom had the flu and just got the sample to him the first part of January. He has it slotted on the "TO DO" schedule and will be measuring and programming shortly, and then make a small batch, 10-15 pieces, to see how it comes out of the machine. Then a production run. My suggetions would be to send a polite PM to Jim here and let him know you are interested. Looks as if the "next year" talk was a bit premature, and I apologize for any part I may have inadvertantly played in this issue. regards, Rich DRSS Wisner fan | |||

|

| One of Us |

Some originals, with and without windage.   | |||

|

| One of Us |

On the subject question of how the sight/striker 'recalls' to a repeatable zero, my Jeffery mannlicher's bolt settles to the same elevation every time as I take up the first stage of the trigger. The 'windage' location (no adjustment per se besides it's position on the striker's threads,set with a set screw) goes to the same 'home' position every time I set the bolt into battery. The sear/striker notch aren't delta shaped as the rigby is said to be above in this thread. I'd requested a copy of the W.J.Jeffery leger page featuring my rifle's serial number, and recieved a page featuring rifles exactly 1000 guns newer than my rifle. When I get the right page from Jeffery and confirm or deny that my rifle actually was equipped with the 8872 sight from the factory I'll post that here for your reference. As it is, the sear engagement features are prerry standard looking and the bolt goes home to the same place with monotonous regularity. Still, I'd love to see actual photos of one of these sights on a rifle. --Tinker _________________________________ Self appointed Colonel, DRSS | |||

|

| One of Us |

Thanks a bunch for the pull back to the core question. Not that all the pics of these great old sights are boring to look at! Any chance of you posting a pic of how these parts look on your rifle? I'm trying to see how much the Rigby modifications might help, esp considering what a.tinkerer posted about his sight having great repeatability on just a normally configured cocking piece. ============================== "I'd love to be the one to disappoint you when I don't fall down" --Fred Durst | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Big Bores

Big Bores  cocking piece sights

cocking piece sights

Visit our on-line store for AR Memorabilia