The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Bullet Making

Bullet Making  Machining bullet using cad

Machining bullet using cadGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

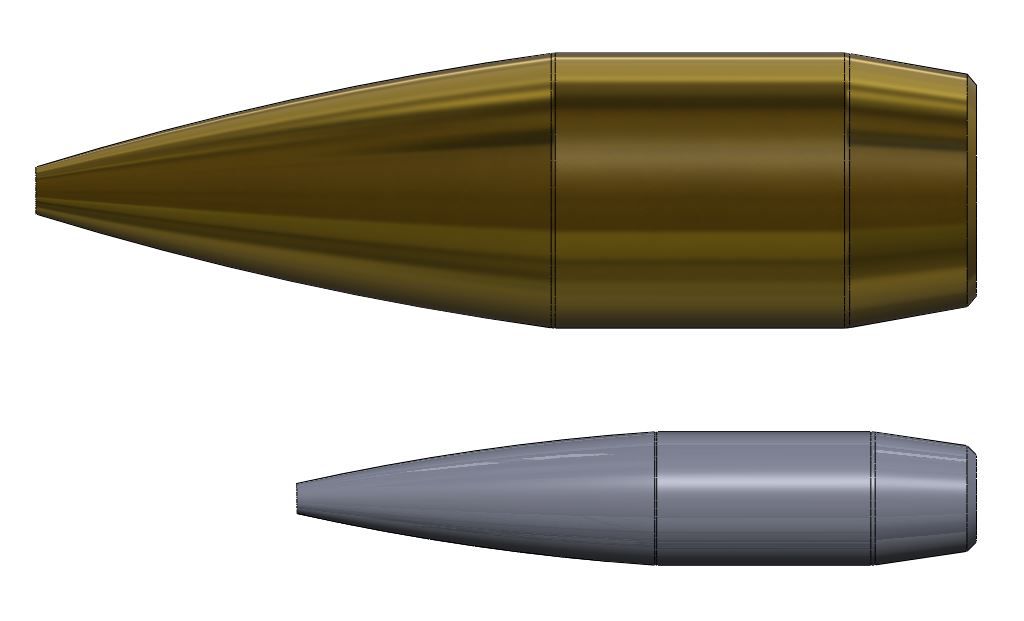

Any of yall machining your own bullets ? I have a guy helping me draw up some vld bullets for my 585 HE . Probably uses usnc36000 brass Lehigh uses it for his bullets. Or would some type of copper be better ? Its basically going to be a scaled up berger style bullet .the 7mm 168gr to be specific .  | ||

|

| One of Us |

There is a lot of waist on that long bullet. You might consider a "wasp waist" design to reduce friction in the barrel as well as in flight. It will give a higher BC at supersonic velocities. How do you plan to control expansion in this bullet? Speer, Sierra, Lyman, Hornady, Hodgdon have reliable reloading data. You won't find it on so and so's web page. | |||

|

| One of Us |

Since a bullet is an expendable you are looking for the least expensive material that will have the mechanical properties you need. If you don't understand the terminal forces on the bullet you can calculate them. Talk to your solid modeler and find out if he has finite element analysis (FEA) in his CAD package. If he does he should be able to model the impact characteristics of your design. You will learn there are trade offs in design. Copper is more ductile but it tends to foul more. In big bores the rifling twist is often not fast enough for a long heavy 5 radius nose spitzer. | |||

|

| one of us |

Why not? I think I read somewhere that the 50 BMG was a scaled-up 30-06 (which in turn was a slightly scaled-up 7x57 mm). TomP Our country, right or wrong. When right, to be kept right, when wrong to be put right. Carl Schurz (1829 - 1906) | |||

|

| One of Us |

driving bands will lower the pressure, and if spaced properly, give you the choice of a couple different lengths for crimping. | |||

|

| One of Us |

Brass is cheaper than copper but it is not cheap either. You will find out. But if you have a CNC lathe with a bar feeder, go for it. Still cheaper than buying lathe turned ones. Yes, definitely turn bands on it to reduce the pressure. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia