The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Bullet Making

Bullet Making  Casting for paper patching a .458 bullet

Casting for paper patching a .458 bulletGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

What size bullet do I need to cast - and where would I get the dies - for a .458 barrel? I haven't settled on a weight yet but these will be for a 45 Colt rolling block action and the bore will be .458". Speer, Sierra, Lyman, Hornady, Hodgdon have reliable reloading data. You won't find it on so and so's web page. | ||

|

| Moderator |

Do you want to cast a 458 bullet or a 452 bullet? A 45-70 uses a 458 bullet in the 400-500 grain range but a 45 Colt uses a 452 bullet in the 200-250 grain weight range usually. Either way, you have quite a few choices for molds. Midway has a very nicely arranged website to see what choices you have for whichever bullet size you want. for every hour in front of the computer you should have 3 hours outside | |||

|

| One of Us |

Wow, I must have been distracted when I wrote my first question. The barrel is .458 and I am using it to make a pistol (just the barrel). I want to use paper patched bullets. If I cast .452" diameter and use two wraps the OD with paper will be .458". Is that a good fit for a paper patched bullet? Speer, Sierra, Lyman, Hornady, Hodgdon have reliable reloading data. You won't find it on so and so's web page. | |||

|

| One of Us |

If you are using smokeless powder, you will want to wrap right up to or a thou or two over groove diameter. I use black in my Gibbs so I patch right up to .461" I do this by sizing my cast bullets down to .451" using a Lee push through die. Then, I patch the bullet and again size it through a Lee die to .461" The paper is surprisingly durable and I use a little lube on the patch prior to final sizing. I suggest you may be able to patch a .452" bullet and then size it back to .458" final patched diameter. You can experiment with different papers of varying thicknesses to fine tune the patched diameter. I use regular copy paper and two wraps generally go +.010" or more. The paper measures .002" but must "puff up" a bit when wet. So, my final sizing is only a thou or so. | |||

|

| One of Us |

Huvius, That is what I needed to know, Thanks! The paper I will be using mikes at just under .003" or 30 tenths for those familiar with machining. Does the paper thin back down after it dries or does the lube keep it "fat"? Speer, Sierra, Lyman, Hornady, Hodgdon have reliable reloading data. You won't find it on so and so's web page. | |||

|

| One of Us |

.003" seems pretty thick. I suggest that you patch a few - you will need the practice anyway - and measure them after thoroughly dried. | |||

|

| One of Us |

Richard Corbin seems especially interested and informed on this topic, paper patching. Sells the paper, etc. And he takes questions by email. I have not gotten to this, I wonder if the cup base for tucking in the tail is all that important? Easy to do with a swage set up. Luck. Happy trails. | |||

|

| One of Us |

Back in the 1980's and 90's I used a tapered nose pour mold with a hollow base for a 45-70. Black powder ctg silhouette was the game. Crane brand bond paper .0025" thick. We used a template for cutting the patches. After wrapping the bullet make sure there is no overlap of the paper edges. A slight gap is OK between the edges. The NRA cast bullet manual has info on paper patch for smokeless. | |||

|

| One of Us |

Cast Bullets by E.H. Harrison c. 1979. Most of the info is from the 50's and 60's I imagine. Crane paper was 100% cotton. | |||

|

| One of Us |

PP bullets are lots of work; why don't you just get a .458, 250 grain mold? Try NEI; they used to make them. Or use 300 grain jacketed .458s; they will still work out of a 45 LC if your chamber will take it. Which will be the limiting factor in using 458 bullets, PP or not. A standard 45 LC chamber prob wont take a 458. I would throat it long, seat bullets out and use the powder capacity to good use. .003 paper is standard. | |||

|

one of us |

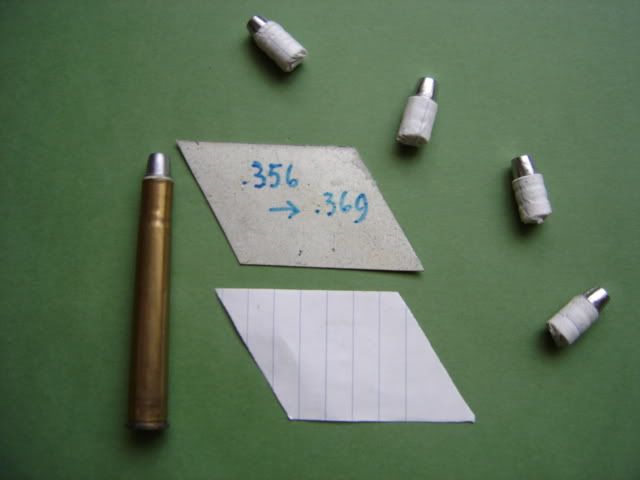

I patched .356 revolver bullets to .369 diameter for reduced loads in my 9,3x74R double rifle. I started with writing paper and used the cut and try method to reach the right diameter after rolling wet and shrink drying (NB : opposing sides of the patch must meet). During the drying process, the "tail" of the patch is twisted progressively until dry and then snipped off.  André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| One of Us |

Very good, Andre! Thanks, too for answering my post in the reloading section. I'm liking this idea very much! Doug Wilhelmi NRA Life Member | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Bullet Making

Bullet Making  Casting for paper patching a .458 bullet

Casting for paper patching a .458 bullet

Visit our on-line store for AR Memorabilia