The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Bullet Making

Bullet Making  A few Otf Our Walterhog Bullets Being Processed

A few Otf Our Walterhog Bullets Being ProcessedGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| Administrator |

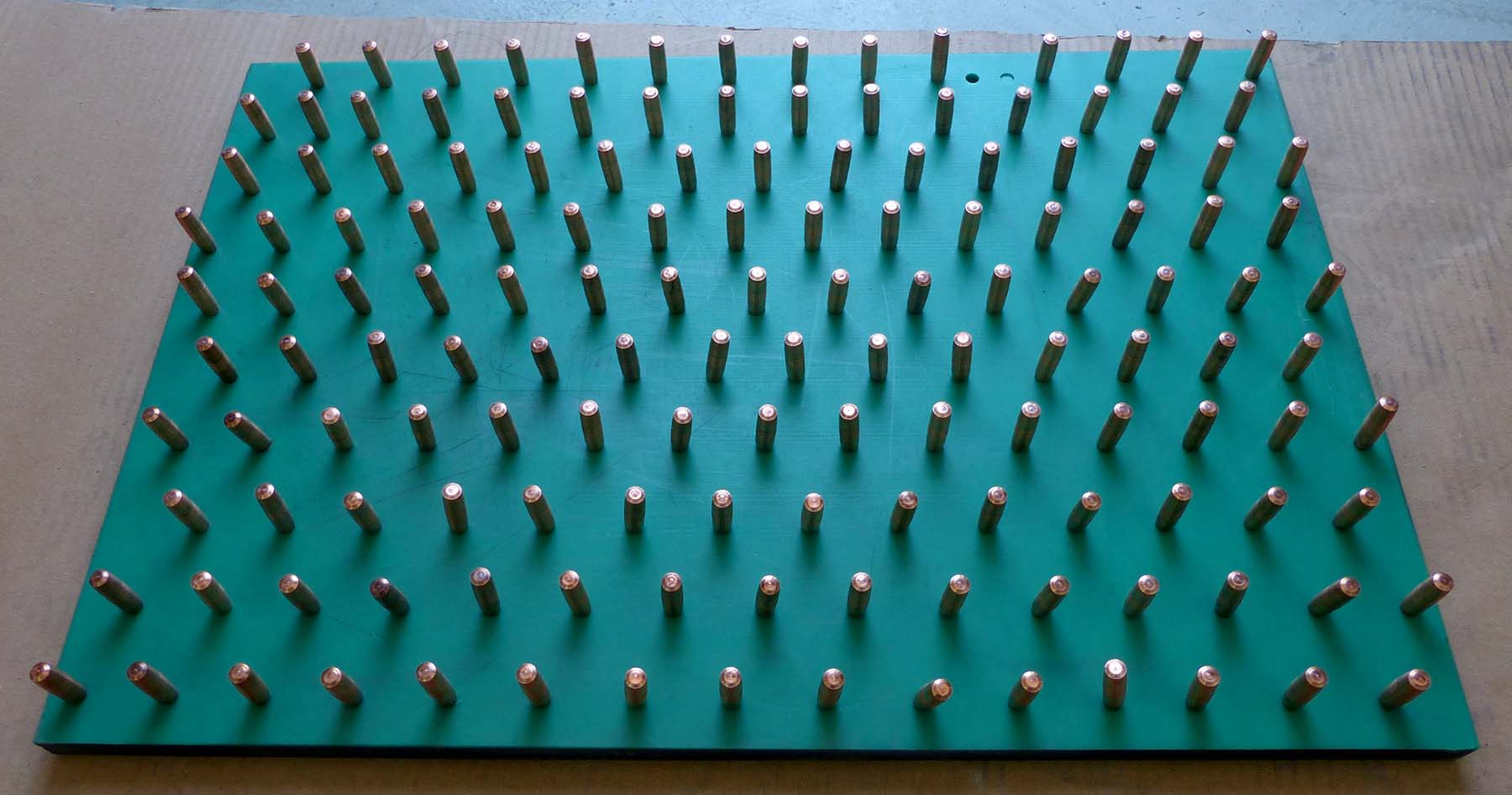

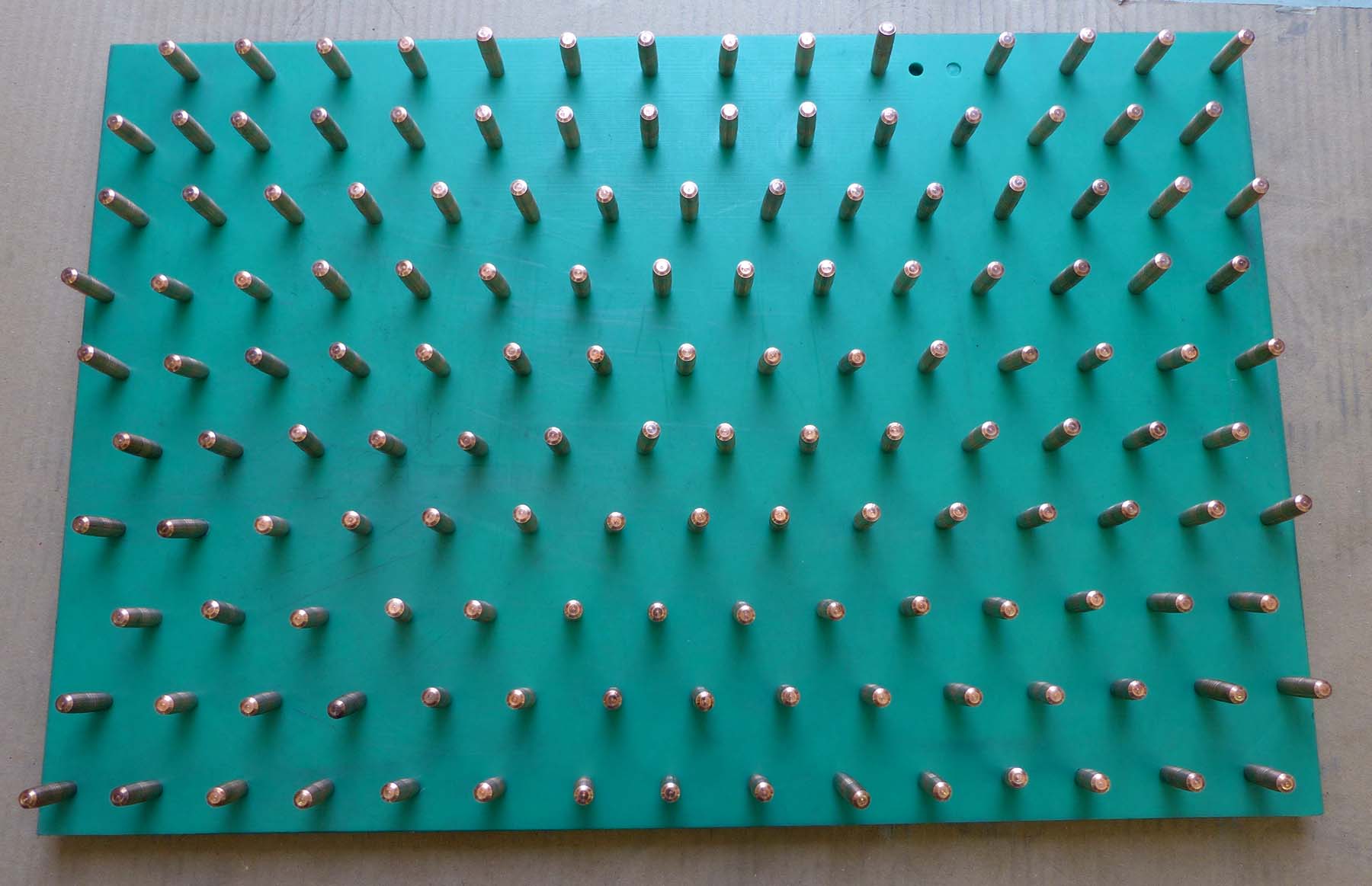

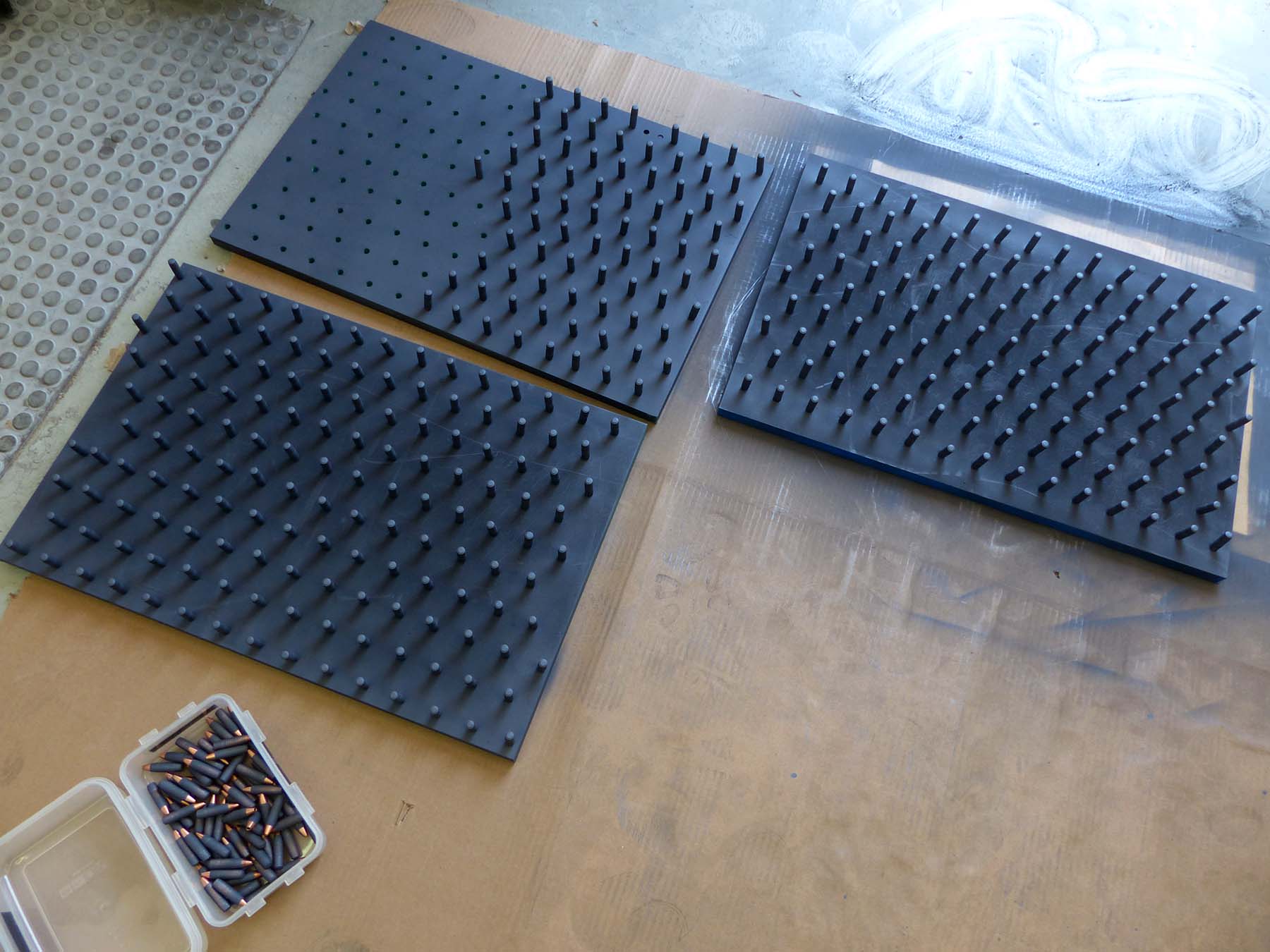

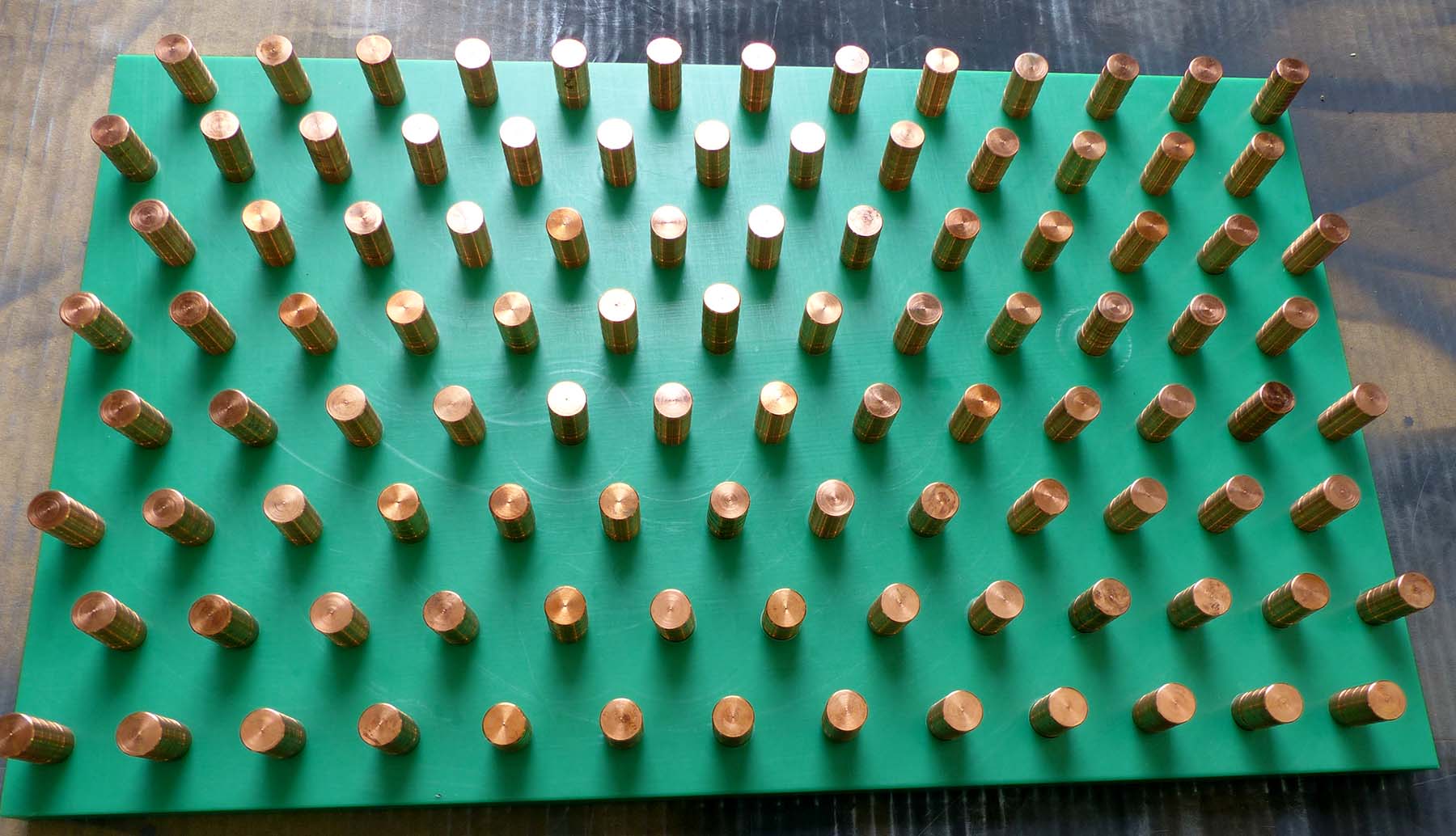

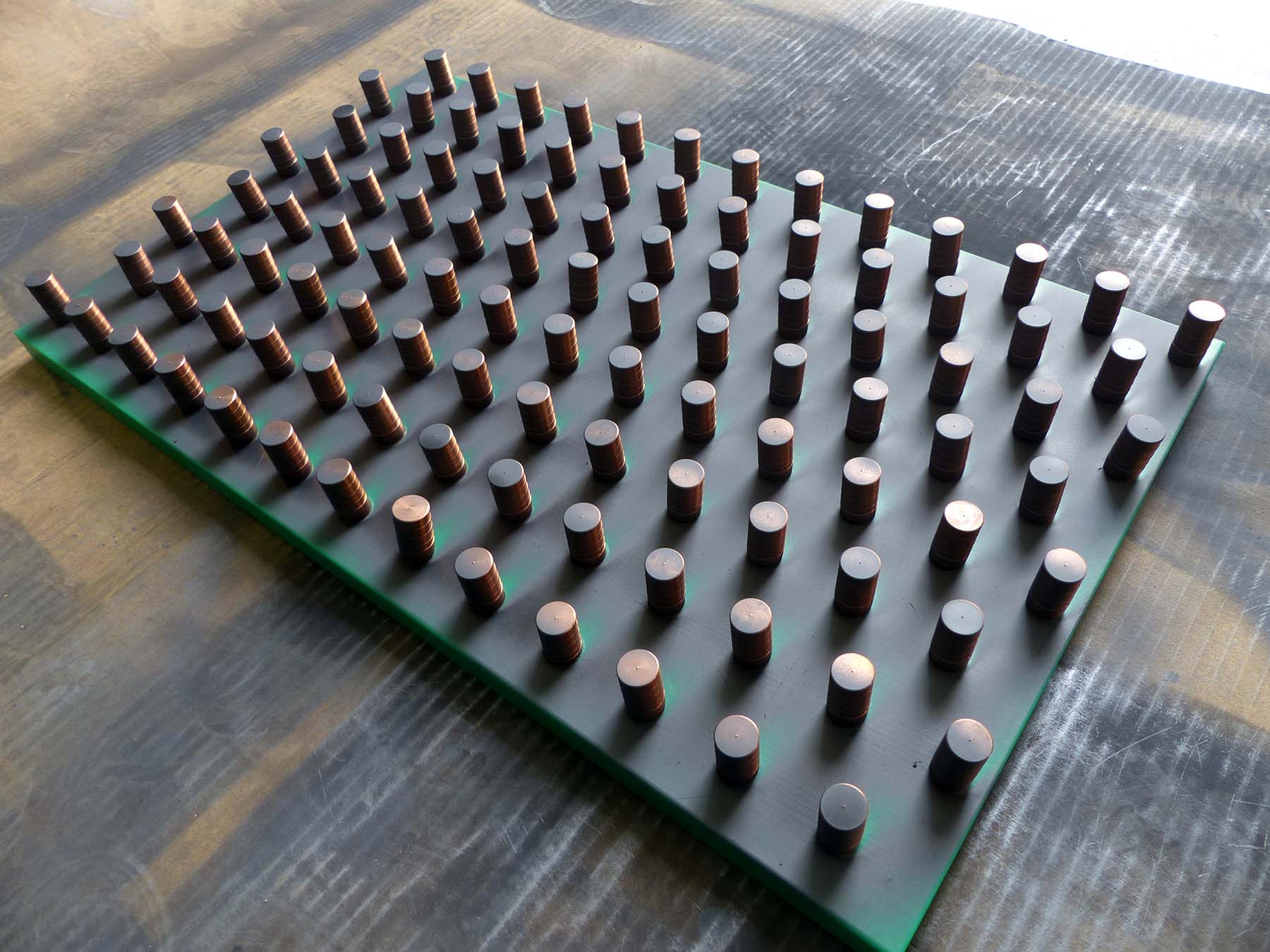

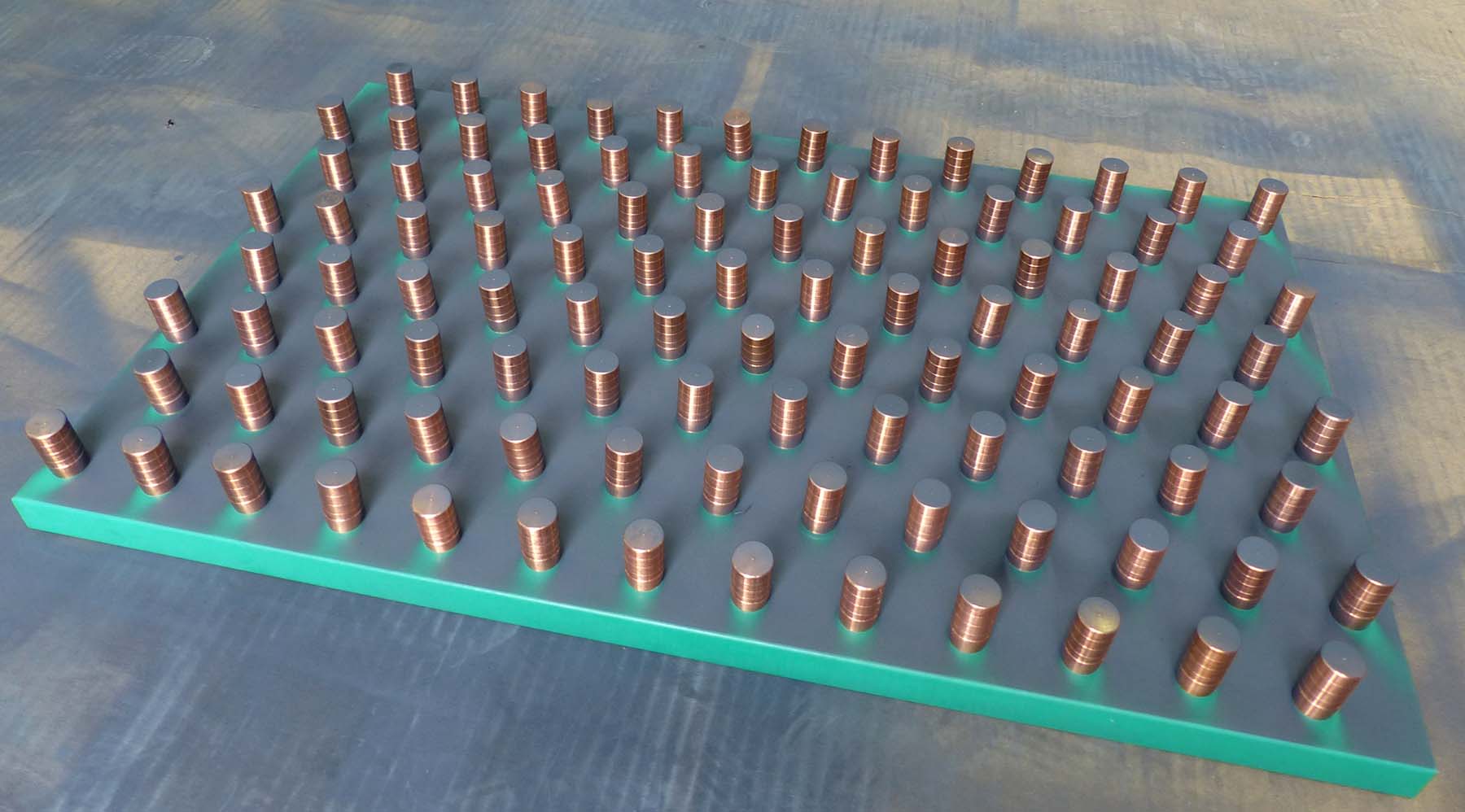

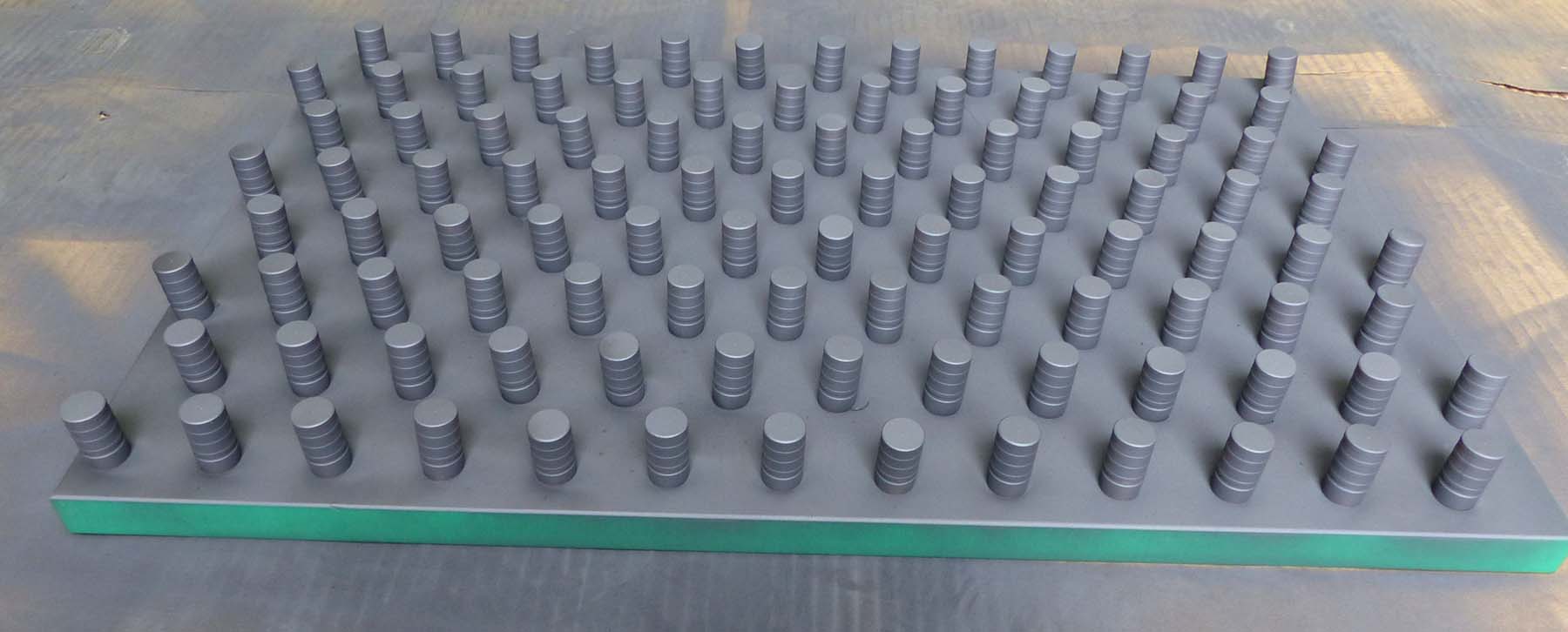

Below are some of our Walterhog bullets, in 375 and 585 caliber. We coat them with Molly, and have found the one shown in the can to be much cheaper than the ones from Outer's, and does just as good a job. As you can see, we use kitchen chopping boards which we drill suitable holes in to place the bullets for coating. We wash them in acetone before spraying them - you can see them being dried on tissue paper.            | ||

|

| one of us |

Saeed What is that green material that you use to put the bullets nose first into ? Jim "Whensoever the General Government assumes undelegated powers, its acts are unauthoritative, void, and of no force." --Thomas Jefferson | |||

|

| Administrator |

Jim, These are chopping boards we buy at the industrial kitchen supply store. I drill the right size holes on our milling machine on them. They come in many colours, and can be quite handy for other workshop items too. I made one to hole our R8 milling machine chucks. | |||

|

| one of us |

Thanks Saeed; You may another business selling those to reloaders and swagers. Jim "Whensoever the General Government assumes undelegated powers, its acts are unauthoritative, void, and of no force." --Thomas Jefferson | |||

|

| one of us |

http://www.kramp.com/shop-gb/e...ay+Lubricant+Aerosol  DM90AC Dry moly spray lubricant Technical information Part number DM90AC Specifications DM-90 Dry moly spray is a solid dry film lubricant composed of Molybdenum Disulphide MoS2. Molybdenum Disulphide has a low coefficient of friction and is effective in forming a low friction surface which is resistance to corrosion. The DM-90 formulation has a very high content of Molybdenum disulfide. DM-90 is ideal for use on surfaces that are not suitable for liquid, wet, and or damp lubrication. DM-90 Dry moly spray is resin bonded to withstand high loads, pressure, and temperature. DM-90 does not attract dirt and dust as it dries to a non oily, non sticky finish. Dry moly Spray is black in colour. DM-90 is idea for use in machine shops, mills, mining, construction, transportation industry, Refineries, industrial gaskets, bearings, printing and other locations where a wet lubricant is not acceptable and where heat is present such as cams and gears. DM-90 is quick drying. Prevents fretting, scuffing, galling, seizing, and corrosion. Use as a dry film lubricant on sliding surfaces gears, bearings and as an anti-galling lubricant on precision threaded components. DM-90 is formulated to dry quickly and still give excellent resistance to seizing. Temperature range -50°C to +450°C. DM-90 withstands alkalis, oils and most acids. The DM-90 dried film can be polished to give a clean, super hard, non slip surface coating suitable for chutes and tracks in workshops and factories. Benefits - Long lasting non greasy dry film lubricant - Touch dry in 15 minutes/ can be polished after 12 hours - Performs well under extremely heavy loads, high pressure and high temperature - Low coefficient of friction - Reduces wear and abrasion - Effective corrosion resistant/ low friction coating - Prevents galling, seizing, and sticking Application - Bearing Lubricant - Anti-rust Paint Consists of - 500ml Aerosol Unit Each Content (ml) 500 Amount Oil (kg or ltr) 0.5 | |||

|

| one of us |

Pretty basic question, as I have never used moly sprays: What is the approximate diameter and weight increase of the bullet after the spray is applied? | |||

|

| Administrator |

Ron, I never measured these, I think they add very little to weight or diameter. | |||

|

| one of us |

Well shucks, now that I know how, I am going to have to start moly-coating the Barnes TSX and TTSX and get out the micrometer and scales, to satisfy my curiosity. Moly-coated 300-grain TSX: Walterpig Moly-coated 250-grain TTSX: Walterpiglet Imitation is the sincerest form of flattery. Maybe they will then shoot as accurately as the GSC HV .375/300-grainer in my pair of .375/404 Jeffery Saeed of 2012 rifles. The GSC coating is not moly. Top secret proprietary. | |||

|

| one of us |

| |||

|

| One of Us |

Saeed what kind of velocity increase/powder decrease are you getting by using the moly? I never really noticed any difference statistically when I was playing with it, but that was for handgun bullets only. I would figure you are getting something noticeable if you go through that much trouble. | |||

|

| Administrator |

Many year ago I did a comprehensive test on Molly coated v non-coated bullets. There was a very slight increase in velocity, and a slight increase in the accuracy as well. But, frankly, not anything to take into consideration at all. My main reason for coating our bullets is to reduce copper fouling. In that direction, they do make an enormous difference. | |||

|

| One of Us |

Saeed Have you ever tried Dow Corning 321 dry moly spray? Every other dry moly spray I've used was junk compared to the Dow Corning product. I have a machine/repair shop and one time we got some over spray on the concrete floor and couldn't walk there for six months without looking like Wiley E Coyote on ice. | |||

|

| One of Us |

I found it odd that Saeed would mention they are much cheaper than Outers. Doesn't seem cost enters into the equation with anything for Saeed. He uses Leupold because of their quality, not that they cost less than some German scopes. | |||

|

| Administrator |

I have tried several makes of Molly spray available locally, but non was as good as this one. Carpetman1, I don't mind paying for quality. In fact, I prefer to buy some of a known quality at a higher price than an unknown cheaper product. But, I found the Outer's wasn't just more expensive, but tend to have a relatively short shelf life. If left standing for a while, no matter how hard you shake it, nothing comes out. | |||

|

| One of Us |

Saeed, certainly with you on buying known better quality, even if initially it costs more. I have several brands I buy even if they cost more. Thorlo socks, Whites boots and Stihl chainsaws and lawn care products come to mind. Not always do I find the most expensive to be the best. Leupold scopes and Rochester NY made Bausch & Lomb binoculars come to mind. You can pay more but not really get more. | |||

|

| one of us |

Are the bullets pure copper or a 5 or 10%Zn gilding metal ? The gilding would be less of a problem in copper coating. | |||

|

| Administrator |

Our bullets are made from pure copper rod. It is the same copper rod used for earthing on building sites. | |||

|

| One of Us |

Is this the same as saying a cheap rifle is superior to an expensive custom? | |||

|

| One of Us |

No not saying a cheap rifle superior to a custom. It's saying you usually get what you pay for. Sometimes just because you paid more, you didn't get more. | |||

|

| one of us |

I could not find the DM-90 spray. Any internet sales of that stuff or direction to stores that carry it? So instead I got a big can of Lyman "Super Moly Spray Lube" easily found locally. I will see how much weight and diameter is added to the TSX 300-grain Walterpig bullets ... This may be required for all naked copper bullets shot in my .375/404 JS rifles henceforth. | |||

|

| one of us |

Experimental Walterpigs need to dry before I weigh and measure them.  10 of the Barnes TSX FB .375/300-grainers: Average weight = 299.97 grains or 300.0 grains +/- 0.5 grains, two of the 10 weighed exactly 300.0 grains on an RCBS digital scale. Diameter at base with caliper: 0.375" all Very uniform for Barnes. The Lyman Super Moly Spray had a problem with starting and stopping, stuttering and sputtering during spraying. Saeed's stuff (DM-90 by Kramp) must be better indeed, IIRC he noted the stuttering problem with other sprays ... related to old spray cans that had been sitting on the shelf a while? Hey, that's what I used on 30 bullets above, without de-greasing the bullets first: OK, fresh new can, the big size, and there was no stuttering and sputtering during the spray, plus I carefully de-greased the TSX bullets before spraying. And, these are the 10 actual bullets that I weighed and measured before spraying the first batch ...  They are dry to touch after an hour. First batch was a powder-sloughing mess several hours after spraying. I will measure the latter 10 bullets for weight and diameter tomorrow, after more thorough drying for 24 hours. Still looking for a source for DM-90, now that I know how to use it. | |||

|

| Administrator |

Ron, I am out of the country till the 10th of next month. I will do some test and post the results. I have a micrometer that goes to at least 5 places of decimal. The trick is how to use it consistently!! The DM90 we have we get from the UK. It is for industrial use, and works very well. No stuttering like the one from Outers! | |||

|

| one of us |

I am ashamed for Lyman Super Moly Spray: Old stuttering can just left powder on the bullets, that wiped off easily with a paper towel. Bullets on right in photo below have been rubbed with a dry paper towel to easily clean off the moly powder:  A fresh new can that did not stutter and sputter gave better results, but the coated bullets still leave smudges on a paper towel with a gentle rub:  Average weight and diameter of the 10 bullets before moly coating = 300.0 grains and 0.375" after moly coating = 300.6 grains and 0.378" The moly rubs off easily, so no worries about over-sized bullets after moly coating. DM-90 is essential for proper coating of Walterhogs, or Walterpigs, or Walterdogs for that matter! | |||

|

| One of Us |

I'll bet your salads have an off taste! NRA Life Member DRSS-Claflin Chapter Mannlicher Collectors Assn KCCA IAA | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Bullet Making

Bullet Making  A few Otf Our Walterhog Bullets Being Processed

A few Otf Our Walterhog Bullets Being Processed

Visit our on-line store for AR Memorabilia