The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Sporterized Military Rifles

Sporterized Military Rifles  shot or tight chambered 300 H&H?

shot or tight chambered 300 H&H?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

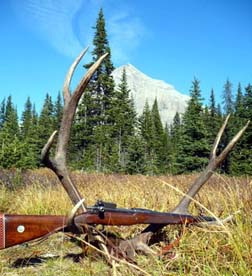

I just finished the work on my 300H&H (stock, trigger, recoil pad, sling, scope, etc.)-- she's an M1917 Remington, milled ears, with the GI barrel cut to 22 ins and rechambered to 300 H&H by a gunsmith some years ago. Anyway, I went to cycle some rounds through her as I intended to hit the range with it for the first time tomorrow, and to my surprise, I noticed whereas all the cases fed and let the bolt travel all the way forward- but only some rounds would allow the bolt to close down. Hmmmmmm? All the cases were full length resized, however not all the brass is new. So I mic'd the cases and found the issue- the bolt closed on cases 2.815 but bot on cases over 2.825 ( interestingly enough, my Lyman reloading book calls for 2.85 case length?!?) I read about some 300H&H being tight and/or short chambered for accuracy-anyone heard of this? The guy I bought it from a few years ago said it was very accurate-but who's gonna say it shots like a 2x4;-) I'm wondering if I should have it a Smith adjust the neck/throat or just trim my cases and enjoy better accuracy (if this is indeed intentional) Any thoughts? Thanks Ronn | ||

|

| one of us |

The issue is likely where the shoulder/belt is and not what the OAL is. Belted cartridges generally headspace on the belt. However, if fired in a long chamber, will contact the shoulder first and prevent the bolt to close. | |||

|

| One of Us |

But... it will close on rounds with the shorter OAL, and not the longer ones. Since they where all FL sized, I imagine if it was a headspace problem overal, the bolt wouldn't close on any round, right? Also, I can see the damage to the edge of the neck of the cartridges on the longer rounds--ground a little shinny by me trying the close the bolt and the case neck rotating against the throat. The single variable appers to be the OAL. Unless I'm not understanding something...which wouldn't be the first time ;-) Ronn | |||

|

| one of us |

Then it sounds like you have two choices. a) trim your cases to a length that will chamber or b)have a 'smith correct the chamber. Maybe you need to do a chamber cast first and see what you have. | |||

|

| one of us |

The 300 is a tapered case with a sloped shoulder, exactly the kind that lengthens with use. You will need to trim cartridges anyway. If it chambers new cases OK, then just trim them all back and shoot. Don't use the long cases and force them in, it will affect pressure. I am not sure what you mean by having a short chamber. The chamber reamer is set by specs, and the neck leade and throat are all fixed in relation to each other. There is really no way with a conventional reamer to selectively ream for a particular OAL case length without altering the headspace. You can use a separate Neck and Throat reamer to lengthen thos dimensions, but not to a length shorter than the reamer dimension. I suspect what you are refering to is reaming to minimum headspace dimensions so the case is held in the best alingment and can't move around excessively. If the case headspaces correctly, the neck length is automatically set by the reamer and should match factory specs unless defective. You mentioned a couple of times about the cases being full length resized. That sometimes doesn't mean all it could. A lot of dies don't do a good job of completely resizing a case completely to the base or the belt. For automatic firearms, there are small base dies available for this use. I recently drug out a bunch of once fired 25-06 cases I had put away years ago. I reformed them to 338-06, and they wouldn't chamber. I used some once fired 30-06 cases I had, and no problem. The 25-06 had been cut with a "generous" chamber, and the 338-06 die didn't size down the last little bit of the base adequately. The 30-06 was smaller than the tight chamber in the 338-06. I haven't seen this often, but it wasn't unique. When swapping cases between rifles, you sometimes run into case/chamber/die mismatches that just don't work well. That's why I generally just buy new cases to start with every new rifle. | |||

|

| one of us |

I check the neck Diam. also it might have a tight neck. | |||

|

| One of Us |

Interesting insights Art, thanks. Short chambered is a term I read somewhere, not being a long time user of this cartridge, Im not familure with what reamers are available. So...I loaded some 165gr BTS with IMR 4831 in virgin winchester brass, which feed through the 'ol 17 fine. At the range I found she liked 67-69 and 70 gr loads (1+ MOA), so I'm going to work up some loads in those area's and see if I can get sub MOA. The neck on the winchester brass is almost 1/8" shorter than my Lee case trimmer gauge--so I guess I'll just trim everything to wincherster length and be done with it. I also found out those Lee case gauges are HARD!!!! I was gonna file it down to the winchester size, not hapening. I'm noticing that its Remingon brass that gives the 'ol girl fits--I even got a Rem round stuck in the chamber at the range. I thought it felt to tight when I was chambering it--but just wanted one more round to get on paper. It "boomed" fine...but then the case stuck fast in the chamber (which is quite a feat with those military claw extractors). But I filled the barrel with oil and went to lunch, when I got back the shell tapped out easy as pie. I think I'll leave things be for now, and we'l see if I find Winchester or hand loads only a pain down the road. Ronn | |||

|

| one of us |

That's a classic sign of the case neck being longer than the chamber neck. I've seen it happen when necking up wildcats, and also saw it in a wildcat I had a smith chamber with a reamer followed by a neck and throat reamer. Mild loads, chambered fine, then would stick on firing with no other pressure signs. I trimmed a couple of cases and fixed it. Since the chamber was cut with a N&T reamer, just ha it lengthened slightly to the proper dimension and all was good. Everything in your case points to a good chamber and lengthened brass due to firing. I would just trim or scrap the long brass and move ahead. Just be sure to check your brass regularly and trim as needed. | |||

|

| One of Us |

Art. That sounds like good advice! Thanks for the input gentelmem. Ronn | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Sporterized Military Rifles

Sporterized Military Rifles  shot or tight chambered 300 H&H?

shot or tight chambered 300 H&H?

Visit our on-line store for AR Memorabilia