The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Medium Bore Rifles

Medium Bore Rifles  8mm-06 Ackley Improved ReDeux

8mm-06 Ackley Improved ReDeuxGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Back in 2000 I built my 1st CF Mauser based on the '43 vintage J P Sauer & Sone M98K action. It was chambered in 8mm-06 Ackley Improved & would send .323 Nosler BTs down range @ 2950 fps W/the standard powders I used @ the time. Broadside double lung hits on Whitetails would blow walnut sized chunks of pink lung tissue onto the ground. The problem was, it had the M98K barrel turned down too thin & would walk the POI as the barrel warmed. I sold the barrel & the left over parts languished in my safe for the past 13 years. I have the dies, fire formed cases, a stock, an action that has 1904 Portuguese hinged floor plate bottom metal W/the magazine milled out for the proper stack angle and a good 29" long M98/29 barrel. Below is the stock/action W/the barrel screwed in. The fact that the sights came out @ the bottom means that the remains of the rear sight location hole will be hidden and the front sight will be cut off when the barrel is trimmed.. It won't be as sexy as my 8x57 but it will still be quite handsome I believe. Here are the 2 for comparison, Oberndorf Classic 8x57 on top . The barrel will be shortened by 3" & the replacement ebony grip cap still needs to be blended in.. Kinda looks like an Express Rifle in overall lines.  I sent the action/barrel out to Dennis Olsen in Montana a while back to have the chamber cut, the barrel cut & crowned to 26" & the contour turned down to a medium weight profile. I want the extra 2" to burn as much powder as possible & the added weight @ the muzzle will help tame the 3800 ft# of ME it will churn out with lightly compressed 62k loads of Norma MRP behind 200/220 gr bullets. "Quickload" computer predictions, which have proven to be very accurate W/the powder & caliber, have the 200gr Speer Hotcore @ 2950 fps, a 220 gr Hornady spbt @ 2800 fps. Standard cup & core bullet construction should suffice @ those Mv envelopes. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | ||

|

| one of us |

This particular project posed some unique challenges as the stock had previously been on an action and this time around I wanted to correct some errors. This required a lot of filling with Acra Glass to shift the receiver upwards in the stock where it should be. I had previously done some filling to get the proper seating of the receiver but it still needed some final filling/bedding. The 1st order of business was to fill the voids around the action with Silly Putty. I used to use modeling clay for this, but Silly Putty is much easier to clean up as you will see. Here is the action area of the stock with the bottom metal in place. The area around the magazine box & the trigger well have been filled with Silly Putty.   Next, the side rails on the receiver between the front ring & rear bridge are wrapped in packing tape. 3 layers build up to .005". This will result in clearance in those ares to keep the stock free of contact between the receiver ring & bridge.  The same treatment is done to the front & bottom sides only of the recoil lug. This allows the lug to pull down into the bedding to assure intimate contact with the rear & convex shaped sided of the lug. I used sandpaper on a block to sand over the round nipple on the bottom of the lug to allow the tape to clear in order to contact the bottom of the lug W/O wrinkles.. Next, any metal that is anywhere near the bedding will be covered with 2 coats of polyvinyl alcohol release agent. Since I only need e a shallow fill, I buttered up the metal and the stock recess with a thin layer of compound, said a little prayer, set the action on place and lightly snugged down the action screws.The resulting "squeeze out" of compound was just about right. Q-tips & paper towels soaked in rubbing alcohol were employed to clean up the excess. A few hours later,after removing the action screw & replacing them with headless action inletting studs, I trimmed the excess compound from the edges, then took a hard plastic mallet & gradually drove the action loose from the bedding. This is what it looked like when it was separated.  After trimming the thin layer that squeezed between the metal & Silly Putty with a hook blade Exacto knife, as wel as pulling the Silly Putty from the wood, this is what I ended up with.  A solid, skin tight fit between the stock, front receiver ring/recoil lug & the rear bridge/tang W/O any pressure on portions that don't need it. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

For the last few days I have been farting around with some details & doing some preliminary load development. Unlike my 8X57IS Oberndorf Classic Mauser that has a very short throat in the chamber, this rifle ended up with a very long throat. While the short COAL (3.132") required for the 8X57 works most efficiently with 200gr bullets, the relatively longer COAL (3.420") required to even get anywhere near the land of the rifling with the bullet ogive, lends itself to the longer pointed boattail 180gr 180gr .323 Nosler Ballistic Tip bullets. I can't get enough Norma MRP into the case to get to 60K chamber pressure W/the 200gr .323 Speer Hotcore bullets. Mv plateaued at around 2900 fps. The 180gr .323 Nosler Ballistic Tip bullets allow the use of Alliant RL17 to fill the case to a lightly compressed load and chamber pressures are in the 64K+ range. The sharp shoulder angles & minimal taper of the case (not unlike today's WSM cartridges) will withstand high pressures better than the parent cartridge geometry. I was able to easily top 3100 fps W/the 180gr BTs W/O flattening the primers, but I think I will shoot for just under 3100 fps which is plenty enough snot churning out over 3800 ft# of muzzle energy with a maxium + - 3" point blank range of 300 yds. Back to the build: My old method of using modeling clay to control the bedding compound left a mess in the stock that was hard to clean out. The Silly Putty does not stick tenaciously to anything except itself making removal easier.  A few minutes of picking out the bits of glass and the Silly Putty is ready for another project.   Once the action was bedded I went to work on the barrel channel. After filling in the black nose cap section with some black Accraglas, I scraped the military profile barrel channel to allow at least .040" clearance of the new barrel profile from just in front of the chamber to the fore-end tip which was filled to .030" clearance previously. An application of the release agent was made to the action bedding and the fore-end tip filling to prevent unwanted squeeze-out from bonding to these areas.  I then wrapped .030" thick pattern maker's wax on the barrel from a point 3" in front of the receiver ring. The wax was then covered with packing tape to prevent the heat of the epoxy cure from making a bond to the wax.  This was followed with the release agent application and after it dried the barrel channel had bedding compound applied sparingly and the barrelelled action was placed into the stock and the action screws firmly tightened.. The "squeeze-out" was (again) just about perfect. When the compound had set to a firm, but not hard consistency, I trimmed the excess & separated the barreled action from the stock. After the compound set up over night, I sanded the top of the stock flush with the wood. Now the fore-end is completely sealed from the elements and has a fiberglass "spine" to help prevent warping.  Look closely & you can see the .030" "free-float" gap between the stock and the barrel starting 3" in front of the receiver ring.  Here is what the progress looks like to this point. As you see it, the rifle weighs 8# 6oz. Not bad for a 26" barreled rifle with a full sized 3-9 scope that will achieve ballistics equal to or greater than a .300 Win Mag.  Thats' enough for this post. I will follow up with some PIX of Dennis Olsen's excellent gunsmithing talents. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Some pictures of Dennis Olsen's Handywork. Here are 2 M98K actions. Both have M98/29 barrels. The top has been cut & crowned to 26" but it is still the military profile after the rear sight sleeve has been removed. The bottom action has the same barrel contoured to my specifications.  Here is a before & after comparison of the bottom metal. Except for some shaping I did on the trigger bow & a "straddle" floorplate, the one on the left as as issued W/the locking screw arrangement. The one on the right has had the lock screw holes filled and finished as well as some nice contour work on the trigger guard bow.  Same treatment to the front action screw.  I had Dennis stamp the camber W/the cartridge. (notice the eagle and swastika on the front portion of the receiver ring at the top right corner of the picture)  Finally, a closeup shot of the muzzle crown.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Very nice project and what a capable round. There is hope, even when your brain tells you there isn’t. – John Green, author | |||

|

| One of Us |

Nice project. Interesting read RL17. I have an 8x60s which others have said does really well with Viht N550. Any chance of some photos of the loaded cartridges? | |||

|

| one of us |

I get almost identical performance from Vv-N550 and Rl-17 in my 8X57 albeit with about 3gr less N550 than Rl-17. I use a drop tube & compressed loads of either.  I switched to Rl-17 because it was easier & cheaper to get. I have no loaded cartridges in 8mm-06 Ackley Improved but I just prepped & primed 100 cases. I will be doing some up in the next few days & will post PIX of the 8mm-06 A.I. and 8X57IS for comparison. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

8X57IS on the left, 8mm-06 Ackley Improved on the right.  GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

I think you said the case capacity was 75 gr of water? The 8x57 is 62 gr, 8mm-06 is 70 gr, and the 8x68S is 87 gr. Seems the 8-06 AI is getting pretty close to the 8x68S performance with less powder. I know you are seating your AI the same as the 8x68, so that will get some more capacity. Impressive! "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

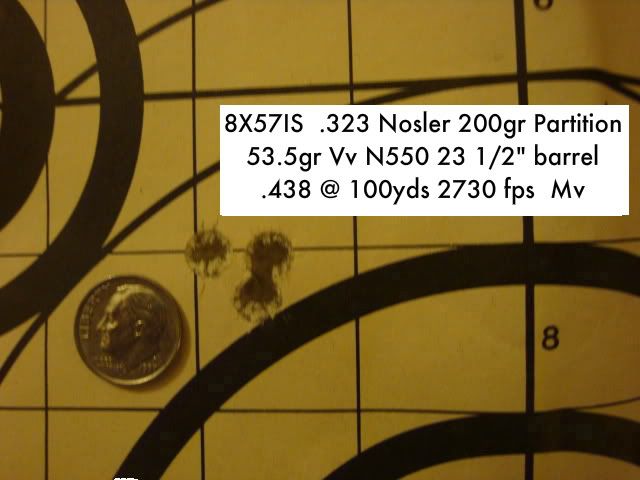

| One of Us |

That's a hot load! What's your COL? Assume max. And the Partition is shorter than the Accubond I use. I get 2,450 fps from a 20" barrel and 46 gr of Varget. "Evil is powerless if the good are unafraid" -- Ronald Reagan "Ignorance of The People gives strength to totalitarians." Want to make just about anything work better? Keep the government as far away from it as possible, then step back and behold the wonderment and goodness. | |||

|

| one of us |

COAL is 3.125", the throat is very short on the military barrel that I used, Very short throat, polished chamber, and the best looking rifling I have ever seen, perhaps lapped. Make me wonder where it came from. I bought it for about $45 from Numrich several years ago as "very good to excellent". It had military sights but no serial number. The pressure is not any hotter than SAAMI 30-06. I have canisters of varget, IMR 4964, IMR 4350 and IMR 4320 sitting on the shelf gathering dust. Vv N550-N560, RL-17 and Norma MRP will up another 100fps with most cartridges over the old stand-bys W/O increasing pressure over that of moderate modern cartridges GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

I got a coat of oil rubbed in today. Thinned to about 50% with turpentine to aid penetration.   Once the grain is filled, the figure will come out more. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

The 8mm/06 Ackely IMP. is the most underrated caliber in the field in the USA, sorely overlooked, but anyone that gives this ole girl a try will be pleasantly surprised..I would be a bit surprised if you entered all into a compluter and asked whats the most efficient and best killing combo on the 30-06 case it would be the Ackley 8mm-06 IMP..right there with a .338, 9.3x62 and 35 Whelen, and just maybe a tad better than all of them.. I only used one some years ago, and Ive always wondered why I never built another one! It shot flat, killed good, and was accurate.. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

Interrested in the color of the stock, is it just dark wood or did you use something like Alkanet root or leather dye to get that rich red color? The reference to PIL thru me also? whats that. At any rate it looks great. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| one of us |

I used Birchwood Casey's "Rusty Walnut" water based stain as well as their regular "Walnut" water base stain to darken it a bit. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

75 gr of H2O is at the relatively short case length of 2.465" When necked up & fire-formed, the neck of the 30-06 brass tends to flow back as the shoulder is blown out. The near 8X68S COAL is not by design but due to some miscommunication with my gunsmith. The chamber was to be cut W/a 30-06 A. I. piloted reamer and the throat cut in a separate operation. Apparently his 8mm-06 A.I. reamer had a long throat. Fortunately the 1904 Portuguese magazine box had enough meat at the front & rear and I had opened it up to 3.5" I D with some skilled work with a mill file. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| One of Us |

.....sorry to interupt, but I have the same question as Ray.....Whats pil ?? Roger | |||

|

| one of us |

Yep "p" is too close to "o" sometimes. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

Of course! duh on my curmudgeon grey matter! Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Roger | |||

|

| one of us |

The 8mm bore seems to be very efficient in medium capacity cartridge cases. Even the 8X57 is a marvel of efficiency churning out over 3300 ft# of Me when loaded to at or near 30-06 pressure. At the standard 30-06 2.494" case length, (which the case will grow to after several loadings) the H2O capacity will be 75.7 grs. That isn't that far behind the .325 WSM that is listed at 81gr H2O capacity on Quickload. There's a reason why Winchester opted for the 8mm version over a .338 WSM. The 8X57 is perhaps the most efficient of the lot with slightly diminishing returns as the case capacity increases. The .325 WSM being the top of the envelope. Going with anything more, & the .338 gains more efficiency. P.O. Ackley was said to be fond of the 8mm bore cartridges. GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| one of us |

IT"S GETTING THERE! I'm still rubbing in coats of boiled linseed oil & buffing it with a cloth. The bad news is, it takes forever! The good news is, I can go ahead & hunt with the gun and keep rubbing/ buffing. Once the metal is done rust bluing I can assemble the weapon and hunt with it. When I come in from the woods, I'll give it a coat of boiled linseed oil. That will help preserve the metal finish too. It is starting to take on the sheen I'm looking for, but there are still a few pores that haven't completely filled yet..     I got a rust blue cycle competed last night. The way it took color, I think 4-5 cycles will get it dark enough to suit me. The last one I did took 9 cycles.!   My Dakota Arms 3-position shroud/safety left the USPS hub in Rochester Sunday evening. I'm hoping it gets here today so I can fit it & start rust bluing it. I'm running low on solution so I want to have all the parts ready so as to not waste solution by throwing the pads soaked in it away. I wasn't going to do the safety right now, but I scraped up the $$$ to buy one. I found a pretty good price on it so I went ahead and bought one. I'm hoping to have it done by Saturday morning so we can have a watermelon smashing session on the 200yd range at the local club. I have about a dozen large & perhaps 10 small round "icebox" mellons that didn't get ripe before the frost killed the vines) We'll be taking the 30/40 Krag, (with a new taller front sight & new loads) Curtis' 7mm-08 AXIS II, the 8x57 Oberndorph Classic, and the 8mm-06 Ackley. Maybe I'll get some videos? GOOGLE HOTLINK FIX FOR BLOCKED PHOTOBUCKET IMAGES https://chrome.google.com/webs...inkfix=1516144253810 | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Rifles

Rifles  Medium Bore Rifles

Medium Bore Rifles  8mm-06 Ackley Improved ReDeux

8mm-06 Ackley Improved ReDeux

Visit our on-line store for AR Memorabilia