The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  QD reloading bench?

QD reloading bench?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

Gents I have a pretty small built on closet in one corner of a room where I keep my gun safe together with my shooting bits and pieces. It is one of those odd shaped things built to disguise the angle of the top of the stairway underneath it. I would like to maximise the space available on the small table I have squeezed in next tot he safe by making some sort of quick detach system so I can mount my press but take it off if i need the whole table to work on. It is important therefore that the table and mounting system be flush and not leave gaping holes in the table when unfilled. I have seen various mounting plates and brackets but they leave protuberances on the table even when empty and so are not ideal. Any ideas chaps? | ||

|

| One of Us |

Here' ya go Goober. Don't ever say I didn't do something nice for you.... http://www.brownells.com/reloa...stand-prod37267.aspx | |||

|

One of Us |

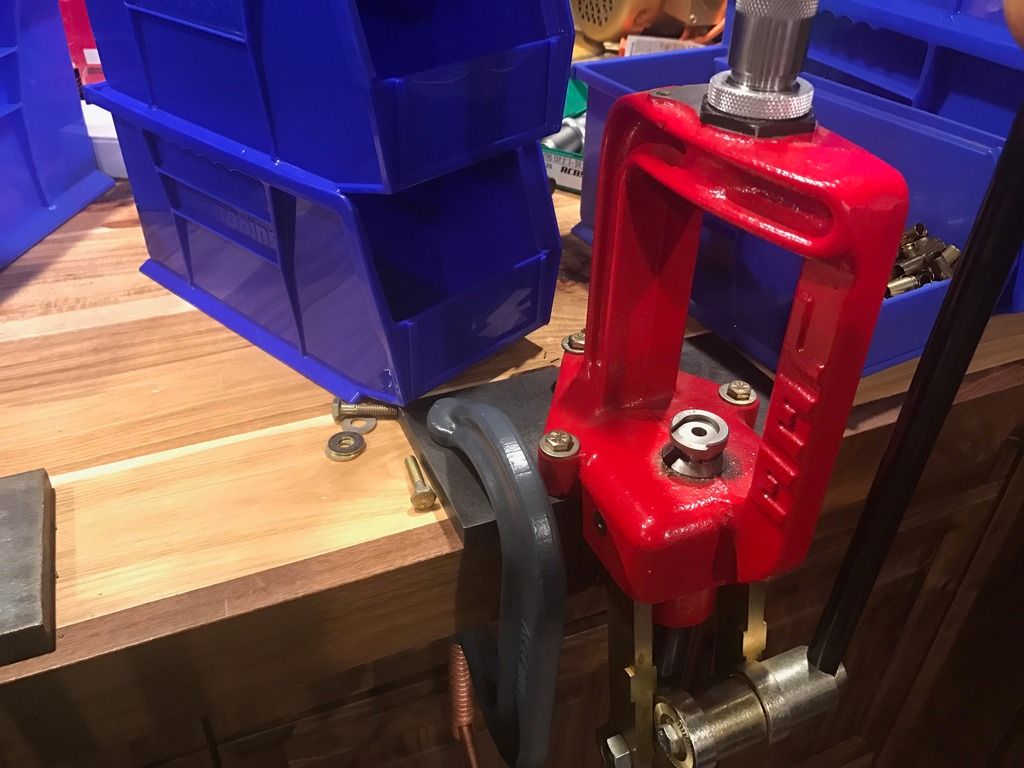

I drill and tape 1/2" thick steel plates to the bottom of all my presses. So it is easy to just use large C clamps to hold them down and move them around. I bolt the presses from the top down with the appropriate length bolt so the bottom of the plates are still smooth. Mac | |||

|

One of Us |

Thanks Mac, any chance of a picture please? | |||

|

One of Us |

Yes will take some pics tonight. Mac | |||

|

One of Us |

Thank you sir. | |||

|

| one of us |

Although I have two bench mounted presses, I use this one a LOT more: https://www.midwayusa.com/prod...eech-lock-hand-press I detest being confined to one area, in one position (bad back) and this little cheaper fills the bill (loads are just as accurate as well). You can also use that small amount of saved space for powder measuring/ weighing. | |||

|

| one of us |

| |||

|

| one of us |

deleted | |||

|

One of Us |

Here is some of the presses I have currently up top. I keep the ones I'm not using in the cabinets below my benches. Sorry for the clutter, it was spotless a month ago but I've been putting together quite a bit of ammo for freinds, built a half dozen AR's recently and just getting set up to make a run of 30K 9mm rounds. If you go this buy a set of transfer punches. Sure does make it easy to layout the holes in the plates. https://www.amazon.com/Neiko-0...rds=transfer+punches I apply a coat of cheap gun blue to the steel plates to keep rust and staining away.        Mac | |||

|

One of Us |

Just the thing, amazing photos and design. Thank you very much Mac. | |||

|

One of Us |

Thank you Danno, I have started with a Lee hand press and although breaking it trying to full length resize without lube found it useful enough to buy another just for fiddling about on the range. Great bit of kit. | |||

|

One of Us |

Ya my Lee hand press did not last either. I picked up one of these though last month and have yet to try it. Seams like it will be the ticket through for the range. Appears to be real nice. http://buchananprecisionmachin...hand-reloading-press Mac | |||

|

| one of us |

Im a firm believer in rock solid loadidng benches, c clamps just won't cut it for me but Im not lacking for space and I do some heavy duty stuff on the bench such as swedging bullets etc.. If I was in your circumstances I would use a 1/4 inch base plate welded to a 4" pipe with a 3/4 inch top plated drilled for my old heavy Hollywood or A-2 RCBS presses...size of the top plate would be up to your specific needs..Something like this is easy to make,not costly, can bolt to the floor and takes up little room, not to mention stout as hell. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

One of Us |

I don't think you paid attention to the size of the C clamps I'm using. I guarantee you there is zero deflection. That top is a little over 2" thick hickory. Does not move even when I am swaying bullets with the 3' Long handle on that megamite press. Use heavy duty Wilton clamps and I promise nothing will move. Downside is they are about $45 each though. Mac | |||

|

One of Us |

I use a piece of 2x6 lumber instead of steel plate with counter sunk nuts. I used to use C-clamps to clamp it to my work bench but found it just as easy to drill 3 holes though the board and my work bench and use bolts with wing nuts to hold it down. It's more firm and only takes a few seconds to remove the wing nuts and bolts in order to remove everything and get it out of my way.  | |||

|

| One of Us |

Are you only mounting a press? Where do you put the press when you "unmount" it. Would a faux table top on top of your table work? You could mount the press, a powder measure stand, a stand for a scale. You could even make a cover and turn it into a storage box. | |||

|

One of Us |

I hang my press on a hook on the wall next to my workbench when I'm not using it. The turret plates with dies and powder measures go in a cabinet. | |||

|

| One of Us |

Those are some serious c clamps. | |||

|

one of us |

https://inlinefabrication.com/...ge-system-base-plate Flush mount. But does have a hole. Hunting: Exercising dominion over creation at 2800 fps. | |||

|

| One of Us |

I also have an inline fabrication unit and think it pretty slick. analog_peninsula ----------------------- It takes character to withstand the rigors of indolence. | |||

|

One of Us |

I don't think I would trust those flimsy little plastic boxes to hold my cartridges. I would think you'd need at least 1/2" steel plate boxes with 3/8" fillet welds on both sides, full length, and stress released. For insurance I'd have the welds X-ray'd and leak tested. | |||

|

One of Us |

HaHa, I tend to do things typically a little in excess of good. Your right I need to look at those bins! Mac | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia