The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  headspace gauge measurements

headspace gauge measurementsGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

i have not used this gauge befor and got it out today, i have measured fired cases and seem to be getting a variance of about 2 to 3 thou. i have measured neck sized cases and they measure approx 12 thou less. i realise the die needs adjusting so there is not such a drop in measurement will the variance in the fired cases effect things? is it simple to proceed to get the head space measurement better? | ||

|

| One of Us |

Do you get the same dimension when measuring the same case over and over? If so you need to determine what is the maximum dimension of the cases that come out of your chamber and set your die to match. I am not sure why you are getting such a variation in the measurement of several cases unless- 1. They have not been fired with high pressure loads (low pressure loads) 2. They were sized way short before firing You variations will be reduced once the cases have been fired with properly sized shoulders locations. If your loads are low pressure you can oil the rounds slightly to help them fire form. Tell us the particulars of your rifle, cartridge and load. | |||

|

| One of Us |

If you are setting your case shoulders back .012", you are in for some excitement in the near future. Case head separations will occur soon. NRA Patron Life Member Benefactor Level | |||

|

| One of Us |

the rifle is a sako 243 AI. i have fire formed the cases with 90gn scenars and h414, if i remember the load was 1 gn from max on standard data. now im using in the formed cases with 68gn custom bullets with 45.5gns of n150, very much a sweet load. is it possible to set the neck die up so that the shoulder measurement only bumps back a couple of thou? | |||

|

| One of Us |

What brand of neck die are you using that actually contacts the shoulder? If it is a threaded die you can check the gap to your shell holder with a feeler gauge and then back it up the amount you need. It sounds that you were checking first time fire formed cases. It is typical that they all do not fire form to the same dimension on the first shot. They should on the second shot. In the mean time you should not be setting the shoulder back .012 when sizing the neck. I would set the die to push the shoulder back about .001 from the measurement of the longest datum to head dimension. After sizing check all cases for fit until you are certain they will chamber. If you have any spare cases of a longer cartridge you can use them to set your die. Take a longer case and trim the length back and size the neck and shoulder back until it just chambers. Measure the dummy and record. Your die should be set but always check several more times to make sure. | |||

|

| One of Us |

This you can count on for sure. I just sent a Savage 7mm RM back to the factory. The headspace based on 2 different sized No-Go gauges was between .008 - .012 inch and I was getting incipient and partial Case Head Separations on 50% of my cases (Winchester) with light loads even after the second reload. ********************** > I'd rather be a CONSERVATIVE NUTJOB than a Liberal with no NUTS & No JOB > | |||

|

One of Us |

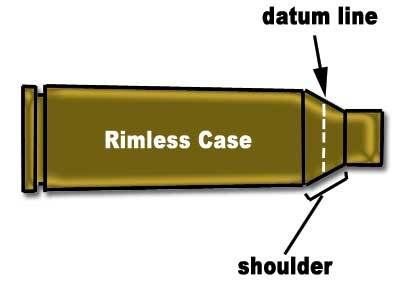

Like SR said, you should not be contacting the shoulder or the case body with a neck sizing die. You need to back the die up until it only contacts the neck and not the shoulder. Even if you were using a full length die then you should not push the shoulder back more than .001" or so. The headspace gauge is very useful and measures the shoulder at the datum point (or close to it)  Since you are reloading for the 243AI then the datum point is going to be at a different place than the parent case. Make sure you are using a 243AI neck sizing die and not a 243 neck sizing die. They are not interchangeable. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

When I measure my cases with the Stoney-Point (a.k.a. Hornady) headspace gauge, I typically observe a variance of .001 - .002" in a sample of about 10 fired cases, say. Yes, it would be possible to observe a variance of as much as .003", I guess, but it has been the exception for me. (Watch it, case lube may cause a variance in measurement, so make sure you measure dry cases, even though it takes a bit longer). What causes this variance? I don't know. Brass varies. The gauge is not exactly a high-cost scientific wonder, it is not fantastic at taking absolute measurements, but it shows up small differences in comparative measurements very well. I measure each case a number of times and decide on a "representative" value for this particular case. This value gets noted for each individual case - e.g. with a marker on the case. It is very possible, that cases measuring as much as .003" below the max headspace mesurement will NOT need the shoulders bumped to chamber smoothly. I try that in the gun in question. I then start with the cases displaying the largest headspace measurement, and set up the die to get me a reduction in headspace of .001-.002" (no more! preferably around .001") for these cases. I verify these cases will now chamber smoothly in the gun in question. Now I try the same die setting for the cases with the smallest (original, fired) headspace measurements. Mostly, for these cases, the same die setting will give me either no or minimal (.001", say) headspace reduction. Thus far, this method had produced smoothly chambering cases for me, with no head separations! Unless I'm willing to measure each individual case every time before sizing it (which I'm not), this method will give me the smallest, quantifiable headspace reduction in my sizing operation. Yes, there will still be variance between the different cases, but unless you are willing to measure each case every time, I doubt there is a whole lot you can do about this. One of the few universal truths about reloading seems to be: "brass varies", and don't ask me why... - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| One of Us |

thanks for the help so far guys. i will look into this a bit more, i will sort cases and see what variances i get, would those cases with the biggest shortfall be best to go in the bin? if i fired them again and blow them back to chamber size could they still be used? ive been using a redding neck die, sat in the press to meet the upstroke then backed off one quarter turn, so i really don't understand why after sizing they seem to be so far off head space? i will look further | |||

|

One of Us |

Hey Alex Perhaps an example of a typical set of measurements with the headspace gauge and a definition of terms might help to make sure we are on the same page. Steyr 30-06 Winchester cases neck sized only new case - 2.040" once fired - 2.0485" twice fired - 2.050" 3 times fired - 2.051"(slight crush fit) 4 times fired - 2.0515"(severe crush fit) If you subtract the 2.0515" from the new case dimension of 2.040" you come up with .0115" which is called the headspace of that particular rifle with that particular new brass. When sizing the brass for this particular gun you would want to set the shoulder at 2.050" to 2.051" so that you would work the brass the least and increase the case life. One question. After sizing is the brass hard to chamber in your rifle or easy to chamber? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

From Funky and Wagnails Dictionary: Reloading Measurement( 1. Lightening Billfolds. 1a. Creating jobs at manufacturing plants. 1b. Creating jobs at Aspirin plants. 1c. Creating jobs in the Liquor industry. 1c-1. See 1b. 2. Creating clarification discussions. 2a. Each one sold creates the need for interpersonal communication(How DOES this Thingy work?????) 2b. Increases long distance phone profits when people call the manufacturer. 2c. Helps fill otherwise routine chatter with colorful language. 2c-1. Creates the need for more PREACHERS!!! 3. Creates more Recycling 3a. Creates trash(aka Thingy) hauling jobs. 3b. Creates trash sorting jobs(Recycle the metal). 3c. Creates Longshoremen jobs(loading the scrap on the ships). 3d. Creats ocean freight demad(haul the scrap to Japan). 3e. Creates Smelter jobs in Japan. 4. Fills time that could be spent waiting for anything "good" in the "change". 4a. Could be Reloading. 4b. Could be Shooting. 4c. Could be Hunting. 4d. Could be cleaning Barrels. 4e. Could be cleaning Deer Trails. List too long to continue. | |||

|

| one of us |

What type headspace gauge? Go? No-Go? Field? My Forster headspace gauge measures a rifle's chamber. I wouldn't have any idea how to use it to measure a fired cartridge case. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  headspace gauge measurements

headspace gauge measurements

Visit our on-line store for AR Memorabilia