The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  280 AI chamber/brass issues

280 AI chamber/brass issuesGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I have a 280 AI just delivered, and virgin and virgin brass once sized both appear to be a crush fit in the chamber. I have tried to push the shoulder back and can't seem to do so with my die???? It's not ridiculous or anything, but just a skoche tighter than I would typically set up new rounds for. The brass is Nosler 280 AI brass, the die is a Hornady. I am wondering could there be that much difference between a reamer and a stock die? Will firing these cartridges help the ammo to fit better or increase the crush fit? The rifle is a Cooper 52 that was rechambered from 280 to 280 AI. Thanks for any thoughts. | ||

|

one of us |

Seems to me it will not be of any help if they are already being crushed. Send it back to the smith and have them ream chamber on more time. It may just need that extra .001. Did the smith test fire? Ted Kennedy's car has killed more people than my guns | |||

|

| one of us |

Doc, thanks, they did, but didn't tell me which brass they used, I suspect they used 280 brass, and fireformed it and went on ahead with that during the test. I share your thought on the fireforming not helping things, but actually had a case with a 300 WSM that was similar, and the fireformed and sized cases chambered nicely??? I was thinking of sending a couple of once fired cases to Redding for a custom die? I am leaning to doing what you said, maybe another thou can make that difference. Thanks--D | |||

|

One of Us |

Hey fish What did they ream the neck to? It is possible that the neck brass is too thick and binding. Can you blacken a case and see where it is hitting? My 280AI has a .313" neck and the Nosler brass I have is .013" to .014" so I turn mine a little down to .0125" for neck clearance. If you can't push the shoulder back with the die then you have a problem. What kind of die are you using? You know that you can use a regular 280 rem Lee Collet Neck Sizer to neck size the 280AI, right? And Redding Body Dies are available. Why would you use a Hornady with an expander ball? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

If you remove a little from the top of the shellholder to allow the die to be lowered slightly, you can push the shoulder back a little more. I had that problem with a 300WSM and it worked fine. | |||

|

| one of us |

I have been shooting a 280 AI for quite a few years and am here to tell you that not all brass is created equal. I've not tried any of the Nosler but sounds as though maybe your chamber was cut a little on the minimum side, which is always a good thing for AI cartridges, in my opinion. I'd do what wrongtarget suggested but attack it from a different angle. Grind a little off the bottom of the FL die and then use the lock-ring to make that final adjustment. But first, you should do what Woods suggested. Blacken a case, all over, and chamber it a few times to see just exactly what part of the case you need to concentrate on. If you do not have both a body sizer and a seperate shoulder bump die you may want to invest in them. There may be times when bumping the shoulder and sizing the body down will have to be carefully coordinated and it's hard to do that with a single die, at times. good Luck. ray Arizona Mountains | |||

|

| one of us |

Woods, didn't think about neck diameter, but the issue is there with an empty case as well as one with a seated bullet-- Should have bought my standard Forster or Redding dies with Micrometer seater, but thought this might be my only 280 AI, so I figured dedicating the Hornady dies to one rig would be OK, I actually like these dies OK typically, they have a 'sliding seater' for the seating die, and I tuned them to produce very low runout..... I will check with my smith on the neck diameter though.... The press I'm using is my Forster CoAx, so no shell holders, I'll keep playing with the die til I can push a sholder back just to see what that does..... Ray, good intel, I will think about different dies, and definitely will try to 'soot' a case and see where she's hitting at as Woods said. Thanks guys--Don | |||

|

| One of Us |

most gunsmiths chamber improved cartridges with a slight crush fit on the shoulder so there are no head-space problems when fire forming cases. most of the time they chamber normally after one firing. if desired you can take a slight cut off of the shell holder or bottom of the sizing die to bump the case shoulder back slightly. even if you have to take it to a machine shop it would be a lot less hassle and expense than having custom dies made. velocity is like a new car, always losing value. BC is like diamonds, holding value forever. | |||

|

| one of us |

Hey guys, thanks for the help. I went the route of grinding the bottom of the die down. (it's nice to have a Burr King 1200 belt sander for these times) and it did the trick. Got it set up where I could get the shoulder back about another 20 thou if I want, found about 10 thou did the trick. Will be interesting to see how these loads do first time out--hoping on Tuesday eve. | |||

|

One of Us |

Also, I have heard that in a properly cut AI chamber that you should get a slight crush fit when chambering the parent case, supposedly from slight contact at the neck/shoulder junction. I tried this in my AI rebarreled and chambered at Hart and the regular 280 brass did not have a crush fit anymore than the Nosler did, so I discounted it. You should not have to push back the shoulder of a virgin Nosler 280AI brass in order to chamber. It is like any other brass in that there is built in clearance. Measuring with my headspace gauge there is .017" expansion forward of the shoulder from new cases to 4 times fired and fully expanded. The Nosler already has the 40* shoulder so there should be some built in headspace there. Lots of possibilities but pushing your shoulder back to where you have excessive headspace, even for one firing, will lead to too much thinning at the pressure ring and decreased case life. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Thanks Woods, I don't have to push it back to chamber it, it just has a crush fit from jump street, which maybe is a good thing, it's just that it's a touch more crush fit than I'm used to with virgin brass for sure. The other conundrum was the die not letting me push the shoulder back, which grinding it fixed. Just so I'm clear, you're saying that from virgin nosler 280 AI brass, your's moved forward .017--after four firings? I want to check and see what mine does, for comparison, also what was the Stoney Point thingy measurement of your virgin brass? I am wondering if I still shouldn't do what Doc said, and have the smith bump the reamer in another thou, or since the brass does chamber should I just let it ride, and just size it enough for comfortable chambering?? Moving the shoulder back from something like 3.130 to 3.125 let the brass chamber with little to no crush fit, so I don't think it would be working the brass too much with those numbers..... I was figuring something less than 20 thou or so movement of the shoulder was pretty minimal--is that proper thinking?? PS, for starting loads I am trying 7828 SSC at starting to mid charge ranges with 140 AB's, what would you estimate for velocity, I'll run a Quickload before I go to the range, just wonder what you thought, I seem to remember you are running 160's though???? Thanks a lot Woods--Don | |||

|

one of us |

What I do anymore is send about 5 brass with any new rifle job so the smith can test the lot of brass I intend to use. I was reading a thread a few months ago on LRH where a guy had chambered a new rifle bbl and was getting crush on his new hulls. He set up the reamer again on the chamber and sure enough, he had stopped the original chambering job prematurely. I prefer that the smith do testing prior to shipment using my cases. This eliminates a lot of headache. I prefer not to modify my dies or shell holders as I do not have the equipment anymore to ensure proper, tight tolerances. Ted Kennedy's car has killed more people than my guns | |||

|

| one of us |

Great point Doc, I usually do, but I didn't have the dies when the smith chambered the rig, I like to build a few dummy rounds and send em to the smith typically--but didn't this time. Your method is a great addition to my 'Custom Gun Work Order' Thanks--D | |||

|

one of us |

Good luck with it D. Let me know how it all works out. Ted Kennedy's car has killed more people than my guns | |||

|

| one of us |

Thanks Doc, will do. | |||

|

One of Us |

Hey fish Just so we all know we are on the same page. To begin I zero the caliper  which is essentially zeroed at 2.000" Then take a measurement on a new Nosler 280AI case  which reads 4.135", or if you take off the 2.000" for the "thingy" it is actually 2.135" Finally a measurement on a 6 times fired case  for a measurement of 4.152" where the shoulder has moved forward .017". This is a chamber reamed by Hart and they hit the neck diameter I requested at .313" right on, so I think they know what they are doing.

I would not call it minimal unless it is less than 10 thousanths and not too much until it gets over 20 thousanths. I keep track of a lot of case growth since I reload for over 40 rifles. Belted magnums have the most shoulder headspace and some of them have so much it leads to case head separations. I have another custom rebarrel by a very good gunsmith. It is a belted magnum and he said he reamed it just inside the "Go Gauge" to minimize shoulder headspace and that shoulder also moves .017". Some factory belted magnums have had as much as .027". One factory rifle I reload for has the minimum I have seen at .0105". In order to minimize the case stretching at the pressure ring and extend case life, it is recommended that you load jammed into the lands, create a false shoulder, downsize larger brass or get a hydraulic form die. Seems to me that you have lucked into what others are trying to do with a crush fit on new cases. If it is in fact binding on the shoulder (not on the case neck for being too thick or the case mouth for being too long) then I would shoot them. However the only scenario that I can think of where there is not a problem in your situation, since you have factory AI brass, is that your neck brass is too thick. i.e., your trim length should be short enough. If your chamber dimensions on the case body are too tight then shooting them would not do any harm and the brass may spring back smaller. Interesting problem. It would be good to know where the case is binding. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Bob, thanks very much for the informative and helpful post, and as per usual for you GREAT photos. I do things the same way with the 'Thingy' and will check my measurements when I get back to the shop next week--Antelope Hunt this weekend in NM! It was in fact the shoulder, I have the die set now where I can set it up like my others, for absolute min shoulder setback. I typically have my other rigs set up where I push the shoulder back enough during sizing that I end up with a SP H&S gauge reading of about 5 thou less than fired, or less than that, so that will be my goal here also. I'll see how that works and then check concentricity as well on 3 or 4 times fired cases, and decide about this Hornady die set.....of course I'll admit that I did go ahead and order the Redding 3 die set with the body die, Micrometer seater and Bushing neck sizer die though | |||

|

One of Us |

Hey Fish I feel for you having to go chase speed goats for a weekend but I suppose someone has to do it! I think you meant 5 ten thousandths or .0005", didn't you? For instance on a 30-06 it develops a crush fit at 2.0515" and I push the shoulder back to 2.0510" for a slight crush fit. That would be .0005". That correction is just to punish you for getting to go Antelope hunting. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Hell, I thought I meant 5 thousandths. The gauge I use is digital on the SP H&S gauge, but I think it only reads to thousandths, like the gauge you show. How are you reading to ten thousandths with a caliper that goes to .001, just interpreting if the needle hits between two indicators?? or is my brain crossed again?? I was getting virgin readings like 2.135 and was setting my die to push back to 2.130, that's 5 thousandths right?? I have so many different gauges reading in different increments that it gets my brain crossed??? Now I AM confused---this is so much fun Let ya'll know how the goat chasing goes! PS, I typiclly go HC style, and just screw the die in a skoche at a time til I get the crush fit I want, and then start measuring at that point, and it is usually something less than .005 from where fired stuff ends up...by the way, I just looked at em on line, and the digital calipers I have on my gauge is .0005 capable, meaning the last number is always a 5 or a zero, 1/2 ten thousandths capable in my mind So am I losing it, or if that gauge read 2.0155 that would be 2 and 15 and a half thousandths?? | |||

|

| one of us |

I would NEVER grind a die back. Shellholders are cheap. If for aome reason one must return the die to the MFR rhey will tell you to shove it. Grind the shellholder if you screw it up no big deal they are cheap. YUMAN "I would remind you that extremism in the defense of liberty is no vice. I would remind you also that moderation in the pursuit of justice is no virtue." Barry M Goldwater. | |||

|

One of Us |

Yep, read between the lines.

Nope, not "1/2 ten thousandths" but 5 ten thousandths, or maybe 1/2 of ten ten thousandths.

Yes again, but that "half thousandths" is 5 ten thousandths! Look, since you're a little confused, best not go speed goat hunting, you might shoot one with horns that are 1.4" long rather than 14" long! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Guessing at dimensions??? ----- The Technical term will put Woods in a dither. | |||

|

One of Us |

Now H C I'm having a hard enough time keeping Fish in line, if you are going to join the fray, that will increase my workload tenfold! If you are gathering material for your book, DUCT TAPE & BALING WIRE: How We Old Fogeys STILL Reload and Shoot, then skoche, which I'm sure is misspelled, will fit right in. You can use it in your chapters on measuring OAL with a cleaning rod, pressure by CRE and PHE and of course in setting your die for PFLR. I would ask you if I am right that you only want to set the shoulder back .0005" from a crush fit or if Fish is right to set it back .005", but I would have to ask you whether you close the bolt with enough pressure to pick a cherry tomato or pull on a cow's teat to get milk. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Ahhhhhhhh!!!! But seriously Woods, is going something between 3 to 5 thousandths too much--In reality, I get variances in headspace measurements of a couple thou from case to case...... Sometimes I think I'm a damn 'Post Turtle' without the post..... At least I'll have a hunting partner with a good 'Stoney Point 'SPREAD AND HORN HEIGHT' gauge, and I won't have to read it this weekend Maybe by next year I can get my brass right to take the 280 AI with me....... | |||

|

| one of us |

More like the cherry tomato, but then you have to define the specific stage of Ripeness being mostly Green and just barely a hint of Red. You got a Thingy to measure Color Phases??? | |||

|

| one of us |

It is the sign of a limited mental capacity to only be able to spell a word "one way". - Mark Twain | |||

|

| one of us |

I did always like Mark Twain | |||

|

One of Us |

IME, the "crush fit" cycle goes for about .002" (that is 2 one thousandths inch), that is it goes from very slight contact to severe crush fit when the shoulder moves that distance. I gauge the crush fit with the thingy and with the gun set up in a vise to gauge bolt closure. (In HC terms that is going from the force necessary to pick a very ripe cherry tomato that essentially falls off in your hand If you are getting measurements that vary as much as you say then it is possible that you have not fired the bras enough to fully expand the brass or you are not keeping batches of brass together that have the same number of firings. Spring back needs to be consistant and it takes 3 to 4 firings to get that shoulder out to it's maximum distance from the case head.

____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Woods, you keep mentioning HART. Is it the gunsmith HART in Nescopek, PA or HART the barrel maker in LaFayette, NY? They're cousins. Just curious. | |||

|

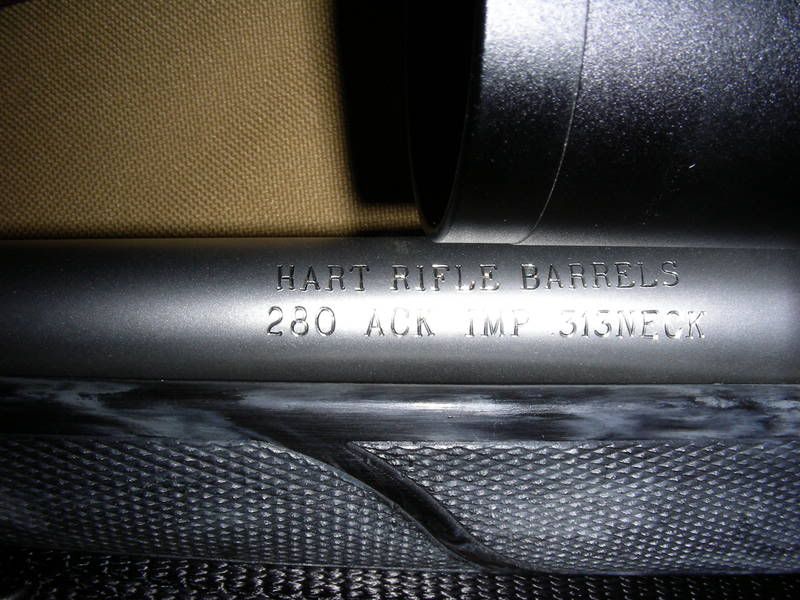

One of Us |

The one in LaFayette, Ny. I sent the whole rifle and they fitted a 26" Sako 75 contour 1-8 barrel chambered to a bullet seated where I wanted it. Wasn't cheap but it came back ready to shoot   excellent shooter after I figured out how to get rid of the do-nuts. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

And they even put the Neck Size on the barrel - as it should be done - Outstanding! Darn shame to waste such a nice barrel on a Sacko. Hey Woods, The Tomato "Strength" reference is obviously quite variable. Perhaps a more definitive value would be of assistance in your quest for doing a P-FLR correctly. Cut a 1"long x 0.5"wide piece of Duct Tape and stick half the "length" to the botton on a non-oiled barrel. Pull the Duct Tape off and that is very close to the amount of Force a person should have to close the Bolt on a properly P-FLRed Case. I need to add this as a Chapter in the Book. | |||

|

one of us |

I put one on a Ruger! Damn fine shooter too! Will be testing it on TX antelope in 23 days, and on Hogs in about 20 days. Ted Kennedy's car has killed more people than my guns | |||

|

| one of us |

Hey Doc, Best of luck on the Hunts. Good Hunting and clean 1-shot Kills. | |||

|

one of us |

Thanks HC. I'm hoping for a great time and hunt. Ted Kennedy's car has killed more people than my guns | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia