The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  .243 Winchester Reloading problem

.243 Winchester Reloading problemGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Sonofa...well I,ve never verified, checked, pondered, or even wondered about the deck height of a shell holder. Since I,ve essentialy got a free floating combustion chamber, could somebody kindly edjamacate me on the significance of the deck height for the shell holder. Not tryna be arguementive, just wanting to take one step back from being a complete ignoramus in this regard... | |||

|

| One of Us |

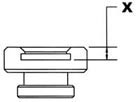

I think "deck height" of a shellholder is a trademarked term of Guffey's.  What he's referring to (at least I think he is) is the distance between where the case rim comes in contact with the shellholder and the top of the shellholder. I refere to this as dimension X. If you shave the top off the shellholder, you can push the case farther into the sizer pushing the shoulder of the case back further before contacting the top of the shellholder. Until yoteman89, measures his shellholder, we won't know! | |||

|

| One of Us |

Muttly one of us Posted 10 October 2012 00:59 Hide Post Sonofa...well I,ve never verified, checked, pondered, or even wondered about the deck height of a shell holder. Since I,ve essentialy got a free floating combustion chamber, could somebody kindly edjamacate me on the significance of the deck height for the shell holder. Not tryna be arguementive, just wanting to take one step back from being a complete ignoramus in this regard... Muttly one of us Posted 10 October 2012 00:59 Hide Post Sonofa...well I,ve never verified, checked, pondered, or even wondered about the deck height of a shell holder. Since I,ve essentially got a free floating combustion chamber, could somebody kindly edjamacate me on the significance of the deck height for the shell holder. Not tryna be arguementive, just wanting to take one step back from being a complete ignoramus in this regard... Muttly, The maximum ability of a die and shell holder to restore a case to minimum length is determined by the distance from the deck of the shell holder to the shoulder of the die, the best way to determine the distance from the deck of the shell holder to the shoulder of the ide is with a go-gage, again, the length of the go-gage for a 30/06 is .005” longer than a minimum length case from the head of the case to its shoulder, if the primer punch/neck sizer button assemble is removed a head space gage can be used to check the die and shell holders ability to size a case. With the go-gage installed the gap between the top of the shell holder and bottom of the die should be .005” (In the perfect world). It is not necessary to install the die in the press, it is not necessary to install the shell holder on the ram, both methods and or techniques work ‘for me’. For years advise given by a reloader to another reloader was “Grind the top of the shell holder when you find cases that are full length sized will not chamber”, and I thought that was mindless, no regard was given to the possibility the case had more resistance to sizing than the press, die and shell holders ability to overcome the resistance. For years I have insisted it is not necessary to grind the top of the shell holder, I have insisted it is not necessary to grind the bottom of the die, I have insisted Redding Competition shell holders are not necessary, anything that can be accomplished by grinding or Redding shell holders can be accomplished with a feeler gage + (plus) cases for short chambers can be sized with out grinding anything. If someone ground the top of the shell holder to reduce the deck height the amount of shell holder removed can be determined, again, the gap can be measured with a feeler gage/thickness gage. Advise always given: Screw the die down an additional 1/4 or 1/2 or 1 turn to reduce the length of the case from the head of the case to its shoulder, if that does not fix-it? Grind the top of the shell holder or bottom of the die or both? Again, the die and shell holders ability to size a case is determined by the distance from the deck of the shell holder to the shoulder of the die. F. Guffey | |||

|

| One of Us |

I think "deck height" of a shelllder is a trademarked term of Guffey's. What he's referring to (at least I think he is) is the distance between where the case rim comes in contact with the shell holder and the top of the shell holder. I refere to this as dimension X. If you shave the top off the shell holder, you can push the case farther into the sizer pushing the shoulder of the case back further before contacting the top of the shell holder. Until yoteman89, measures his shellholder, we won't know! Call RCBS 1 800 533 5000, ask RCBS to explain ‘deck height’. Again, I said I size cases for short chambers, I described a distance of .017 shorter than a go-gage length chamber. A case that is sized for a go-gage length chamber is said to be minimum length/full length sized and is .005” shorter than the chamber (30/06). “If you shave the top off the shell holder, you can push the case farther into the sizer pushing the shoulder of the case back further before contacting the top of the shell holder” I will assume you did not understand the “I size cases for short chambers...” I size cases for short chambers without grinding the top of the shell holder, or bottom of the die. “I refer to this as dimension X”. X is deck height, X = .125", the dimension is .125” F. Guffey | |||

|

one of us |

Guffey you're full off hot air. When you're done explaining something that doesn't need explaining in order to make yourself feel more highly regarded you might go ahead and answer the real question. I really am looking forward to your answer. I'm sure you'll enlighten us all. | |||

|

one of us |

Just in case you forgot what was the topic of discussion.

| |||

|

| One of Us |

Bignate, “Everyone I have spoken with has never encountered a problem like this. Any help will be greatly appreciated” Any help? I am help, again, none of this runs me into the curb. I am not lecturing Yoteman89, I disagree with the answers he is getting, I reserve the luxury of disagreeing, in my effort there are many that have chose to disagree, in my opinion, in a manner rather rude, but on the outside chance there could be someone out there that is reading thread that is not part of the choir, I make the effort.

Bignate, I understood the question, “The rifle will cycle factory Ammo just fine so I do not have a Head spacing problem”. ‘SCARY PART’ his question made sense to many posting on this forum, not my fault, from the beginning I determined the length of the chamber first, I do not fire to form, I form then fire, again, the scary part, no one on this forum understands what I am talking about. Back to the original question and his statement “I do not have a Head spacing problem”, he does not have a clue, he assumes chambering a factory round, that is minimum length/full length sized, assures him he does not have a head space problem (he does not understand ‘HEAD SPACE’ he never will unless he understands ‘THE LENGTH OF THE CHAMBER FROM THE BOLT FACE to the shoulder of the chamber), nothing could be further from the truth. I have a M1917 Eddystone with a chamber that is .016” longer than a minimum length/full length sized case. my rifle, like his rifle will cycle factor, new, over the counter store bought ammo, The chamber in my old army rifle is .016”longer than a full length sized/minimum length case. AGAIN, this stuff does not lock me up, I form cases for that chamber, when I fire formed cases in that chamber there is .002” difference in length between the chamber and length of the case from the head of the case to the shoulder of the case. A reloader knows how to measure the length of the case from the head of the case to the shoulder of the case? A reloader knows how to measure the length of the chamber from the bolt face to the to the shoulder of the chamber? A reloader knows how to measure a head space gage from the from the head of the gage to the shoulder of the gage??? I think the manufacturing process yields variances. That's why there are minimum and maximum dims established. So if your gun is on the max side and the dies minimum you'll have much more headspace. Again and again etc., Head space, over and over, when does it become the length of the chamber is off set with the length of the case, “There are anomalies. My '06 fired the ammo that would not shoot in his without a hitch at all” Bignate, you do not know the length of the chamber of your 30/06, you do not know the length of the chamber in your dad’s chamber, you do not know the difference in length between the two, not knowing is not a problem, not wanting to know "HOW’ to determine the difference in length between the two chambers is a matter of methods and techniques, I make gages, I make tools to check gages, my favorite tool is the most lowly and humble tool of all, if in my effort I was trying to impress I would purchase the nice comparators that are advertised as head space gages, nice tools, not necessary, just nice. F. Guffey | |||

|

| One of Us |

F. Guffey, that's because everyone else here is too damn dumb (at least in your mind) to understand what head space is and how to adjust a sizing die to provide proper head space in the gun the ammunition is fired. | |||

|

| One of Us |

first, “I think the manufacturing process yields variances. That's why there are minimum and maximum dims established. , then, F. Guffey, that's because everyone else here is too damn dumb (at least in your mind) to understand what head space is and how to adjust a sizing die to provide proper head space in the gun the ammunition is fired. I have one standard, I will not lend to be a friend (most interesting story, before computers), “So if your gun is on the max side and the dies minimum you'll have much more headspace”, back to the unfair part, my dies are adjustable, my presses have threads, meaning my adjustable dies size cases for long and short chambers, all I need to know is the length of the chamber from the bolt face to the shoulder of the chamber. I have dies, I have forming dies, neck sizing dies, small base dies, I have BAR dies, hammer in and hammer out dies, home made dies etc.., my favorite go to die is the versatile full length sizer die, I size cases, in thousandths, from .016” shorter than a minimum length case from the head of the case to the shoulder to infinity, that would be a case that is longer by .016” than a minimum length case from the head of the case to its shoulder, counting? That is 28 different length cases, again, from the head of the case to the shoulder of the case. “I think the manufacturing process yields variances. That's why there are minimum and maximum dims established” I cut most of my chambers, for chambers I do not cut there are threads on my presses and dies. F. Guffey | |||

|

| One of Us |

OMG! Brilliant! Sizing dies have threads.......who would have thought it?! | |||

|

| One of Us |

rdharma, No matter how slow I type when I hit the send button, it comes out at the same speed, not my intentions to provoke you, it is my intension to prove some to think, on the outside chance there are a few members reading this and other threads I make the effort. Brilliant? It is not my responsibility to inform you the die has threads, if you were keeping up and I was not typing so fast and if I could provoke you to think you would recognize the short coming of the full length sizer die, the full length sizer die is limited to sizing a case to minimum length or full length size. A short chamber is shorter than a go-gage length chamber, it is possible for a chamber to be shorter in length from the bolt face to the shoulder of the chamber, meaning, a full length sizer die will not size a case for a short chamber no matter how far the die is screwed into the press. Back to the part you failed to understand, it is possible to size a case for a short chamber, it is possible to size a case for a chamber that is that is longer from the bolt face to its shoulder than a case when measured from the head of the case to its shoulder. Yes, a die has threads, that is a good place to start, then there is the ‘understanding the purpose of the threads’: A reloader does not have to make wild guestimates when adjusting the die to or off the shell holder, understanding the incline plain is to understand the adjustment of the die below, to of off the shell holder. One more time, I size cases for short chambers, I size cases that are minimum length/full length sized, I size cases that are no go-gage length, I size cases that are longer than a field reject length chamber, I do not make wild guestimates when adjusting the die to, below or off the shell holder. F. Guffey | |||

|

one of us |

Back to the question: Why will it cycle facotry ammo and not his reloads? That is what you need to explain. | |||

|

| One of Us |

Hey guys, I am new to this fourm and really need help. I have been loading for years and never had this problem. I have an old Lyman Spartan press from the 50's or 60's I acquired from my Uncle. I set the die down till it touches the shell holder and it makes good contact. I am running these rounds through a Remington 700, when I use the resized brass the bolt will push it in to the chamber but when I lock the bolt down it will not grab the live round or the resized brass to Extract it. The rifle will cycle factory Ammo just fine so I do not have a Head spacing problem. Everyone I have spoken with has never encountered a problem like this. Any help will be greatly appreciated. Thanks yoteman89 “Any help will be greatly appreciated” He starts with “I have been loading for years and never had this problem”, THEN! he says cases, after full length sizing the cases chamber”, “I set the die down till it touches the shell holder and it makes good contact”, then it becomes vague “I use the resized brass the bolt will push it in to the chamber but when I lock the bolt down it will not grab the live round or ( ‘on?’) the resized brass to Extract it”, his Remington is a push feed, it is not a control feed, Back to the part where his Remington cycles new, store bought, factory ‘MINIMUM LENGTH AMMO’!!!!, then further back to the part where he has been ‘loading for years’, and all the accumulative experience of this forum: There is no excuse for anyone on this forum offering help not to know how to compare the length of a case that chambers and extracts with a case that will chamber and not extract on a push feed chamber. http://www.gunreports.com/spec...lt-action1777-1.html Back to the part where his rifle chambers and ejects factory ammo but not his full length sized cases: Yoteman89 must be able to determine the length of his minimum length/full length sized cases, he must be able to measure the length of a case from the head of the case to its shoulder, he must be able to compare the length of a cases that chambers and ejects with the length of a case that chambers and will not eject from the head of the case to its shoulder. On a control feed Mauser98 type receiver, in the sequence of chambering the first event is the case is pushed up from the magazine in front of the bolt face and the case extractor cut/groove engages the extractor ‘THEN’ the case is pushed forward. On the control feed the case is pushed forward when the bolt is closed, the extractor is spring loaded, it jumps the extractor groove when the shoulder of the case comes in contact with the shoulder of the chamber. (in Africa, around the camp fires they talk about the Americans that got nervous and cycled a round into the chamber, then, pulled the bolt back again because the were nervous and or scared ‘or both’) we all know there is not enough room in front of the bolt for 2 rounds, then the story get more exciting, the pointed bullet of the second round hits the primer of the first round, anyhow, African guides like the big extractor like the Mauser and on early Sakos. Their story always starts out with “It’s all in the Claw”. http://www.huntnetwork.net/mod.../wfsection/html/Ahit'S%20All%20in%20the%20Claw.pdf I make comparators, “The rifle will cycle factory Ammo just fine so I do not have a Head spacing problem”, focus on “I do not have a head space problem”, DEDUCTIVE REASONING: He says he does not have a head space problem BECAUSE.....? MY opinion, his rational is flawed, he does not know the length of the chamber, he does not know the length of the case when measured from the USUAL PLACES. Unless he can figure a way to talk the case out of the chamber he is going to forced to learn how to learn a process called ‘process of elimination’. Last week I returned from a trip to Alabama, knowing there was a rifle that would not chamber (3 boxes) reloads, I took a box of new, factory, store bought, factory loaded ammo that I knew was minimum length (= to full length sized) from the head of the case to its shoulder, all 20 rounds chambered and ejected, I returned to Dallas, dug out a Belgium 7mm Mauser and attempted to chamber all 60 rounds one at a time, one round offered (slight) resistance to chambering, the other 59 chambered with room to spare. Before I left for Alabama I was told I was not to do anything gun related or build any computers, so I left without tools or build CDs, the rifle in Alabama has a minimum length chamber, a go-gage will not allow the bolt to close with out effort, that leaves less than .004” difference between the length of the chamber and length of the case when measured from the usual places. and I came home with an Ohaus 2610 three beam scale, most accurate, but, in grams. Should not be a problem, I have a 1010 Ohaus with 2 beams, one in grams, the other in grains. Determining the length of a chamber, methods and techniques, most will purchase another tool, I am the fan of knowing everything I can about a tool I own, I have a press (presses_+), I have dies, I have shell holders, I have purchases cases, lots of cases, cheap, new, unfired military 30/06 cases, match and standard for as little as .05 cents, I have acquired once fired military cases for .01 cent each, 1,400 cases for $14.00, I have forming dies, lots of forming dies, because I form cases, I form 30/06 cases I paid .01 cent each to 308 W, 8mm57, 7mm57, 35 Whelen, 8mm06 etc., etc.. My favorite case is the 280 Remington, after that I prefer cases that have been fired in trashy old chambers, chambers that are longer than my chambers, for me it is easier to adjust my dies to size cases that fit my chambers by moving the shoulder back, meaning getting the shoulder forward is the most difficult for reloaders, my 280 Remington cases have a shoulder that is forward of the 30/06 by .051” all that is required when deterring the length of a chamber ,like the 30/06 chamber is to form the 280 Remington case to chamber by progressively reducing the length of the case from the head of the case to its shoulder. Same for 243 Winchester chamber, I can use 7.7 Japanese or the 7mm/8mm Mauser or the 30/06 case, if I am not forming to fire I do not have to worry about the dreaded? ‘DONUTS’ when going from 30/06 to 243W, or further from 243 to 25 cal and 22 as in 22 Remington wildcats. As stated, yoteman can chamber new, factory, store bough ammo, he says his full length sized cases will not eject, focus, the Remington 700 is a push feed type receiver, some of the elite have opted to change the extractor to the big claw, on some big claw designs getting the extractor to jump the case rim is a work out. F. Guffey | |||

|

| One of Us |

“.Well I have backed the die out but instead of the die making any kind of contact with the shell holder the die is about 3/16" to a 1/4" from contacting the shell holder. The brass is cycling great but I am just concerned with the die being that high from the shell holder. Could this be an issue? I heard from very reliable sources that it is not wise to load anything yet due to the fact that something still is wrong with the die being so far from the shell holder. Thanks for all your input guys I really appreciate all the help”. “Thanks for all your input guys I really appreciate all the help” From .187” to .250” off the shell holder? “something still is wrong with the die being so far from the shell holder” go back and determine when the issue was about the die being off the shell holder as much as .250” In the beginning the die was adjusted down to the shell holder “I set the die down till it touches the shell holder and it makes good contact” Then there is “I heard from very reliable sources.....” again? the reliable source, My opinion, the reliable source is reliable when giving an answer, I do not believe his answers are reliable. Backing the die off the shell holder .187” to .250” would be neck sizing, but if the case was holding the die off the shell holder when the ram reaches the top of the its travel with the die adjusted to full length size would indicate another problem. Knowing something about the tools used and owned, the deck height of my shell holders? .125”, I have a set of Redding Competition shell holders, three of the 5 are off by .001” each, I did not assume Redding checked the deck height, they are luck I purchased them, most reloaders would not know to check, others would not know what to do with the discrepancy, as I said before, this stuff does not drive me to the curb, anything I can do with with a Redding Competition Shell holder set I can do with a standard shell holder with a deck height of .125, only, twice as good, Redding offers 5 options between .125” and .135, I have 10 options, and I can correct the .001” discrepancy. F. Guffey | |||

|

one of us |

So in a nutshell, He does have an issue of head space, and needs to learn to adjust his die accordingly. | |||

|

| One of Us |

Yoteman, are you absolutely sure that your rifle is a 243 and not a 244, or 6mm. If it's a 243 as you stated I would return it to whoever you bought it from if changing dies and shellholder doesn't correct it. 1/4-3/16 is huge, something is severely wrong somewhere. I've never encountered a set of dies made by a major company that were that far out of specs. Unless you have a very old shell holder that is not the correct height for the dies. I have encountered shell holders that did not size properly with different brand dies, but not by that much. Somebody could have taken metal off the bottom of that die, possibly trying to make a small base dye, or maybe altering that die to reload some wildcat or european cartridge. If done years ago by a machinist it might be hard to notice the alteration, velocity is like a new car, always losing value. BC is like diamonds, holding value forever. | |||

|

| One of Us |

We're thinking along the same lines..... but yoteman89 stated...."I have tried the same procedure with a RCBS Resizer and Lee Resizer. I have to set all the dies the same Distance from the shell holder for the brass to sized right." It sounds to me like yoteman89 used different sizers in the same press with similar results. That makes me want to eliminate the sizer as the possible problem and begs the question.... Did yoteman89 use the same shell holder for his sizing with the different sizers? | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  .243 Winchester Reloading problem

.243 Winchester Reloading problem

Visit our on-line store for AR Memorabilia