The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  WOW..got the new hornady concentricty checker/fixer tool

WOW..got the new hornady concentricty checker/fixer toolGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I hate to admit that I chase bullet runnout but I bought an rcbs "v" block checker a few years ago. I do alot of my reloading now with lee collet dies and redding body dies and they leave the brass really straight. Anyhow I still occasionally ran into "some" runnout with a few rounds. ANYHOW I picked up this new hornady tool that not only measures runnout but then with a turn of a plastic tipped screw will correct it. First off the knob to the right side of the pic is spring loaded and pushes the case into a holder straight away from it. There are no "v" blocks that pick up imperfections on the cases surface....the casing is basically held in mid air. I'm finding my runnout was probably 1/2-1/3 BETTER THAN the rcbs was showing me. I've spot checked about 4 batches of loads and found that I rarely have one over .003 total runnout. If I do you rotate the case till it's at the lowest reading....crank in the plastic screw....and you'll easily correct it down to .001-.002". I read a quite a few reviews on this before buying it $94. Here's an ad for the tool: http://www.midwayusa.com/Searc...city____-_1-2-4_8-16 | ||

|

| one of us |

FOLLOW UP...now I've confused a bit. This hornady tool is telling me that I have been doing TO GOOD OF A JOB TO BE TRUE. After working with some more batches and then putting them on both the RCBS v-block and hornady tool I see where the v-block might better represent the casing laying in the chamber of the gun. Playing with some 30-378 loading the v block shows me .005" tir and I can actually see the bullet wobble a bit by the spindle of the dial indicator. Yet I put the same casing on the hornady and it shows only .002" runnout. Would the v-blocks better represent a casing laying in the chamber....the hornady tool takes the sides of the casing right out of the equation? If I've done a good enough job explaining this please give your comments/ideas | |||

|

| One of Us |

Anyone used the Sinclair model? http://www.sinclairintl.com/pr...Concentricity-Gauges | |||

|

| one of us |

$94.99 plus shipping to gain .001"? You must be a real rifle looney. | |||

|

| One of Us |

Real interesting considering that no matter how straight your ammo is, the bullet starts out down the pipe crooked. Aim for the exit hole | |||

|

| one of us |

Yes, I have that tool, although in a version with a mechanical dial indicator - as opposed to the digital device shown on the page you linked. It is a good tool, I like it. It offers a good way to verify the quality of your reloading process - although I don't check every loaded round for runout. I have also tried the RCBS tool, and found quite a difference in quality Sinclair vs. RCBS, although they probably both do the job. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| one of us |

Kraky, I like the looks of that tool, and I won't even say what I paid for my Bersin ammo straightners (admitted lunacy caused by DJPaintless) I have the Sinclair gage as MHO does, non-digital--which brings one quick question KRAKY, a friend has this gage (the Sinclair) and was complaining about his ammo being not so straight. I went to his shop and watched him check some ammo, and he was reading TOTAL deviation, meaning that runout would actually be half of what he was reading if you follow me....I'm sure your past that, but just wonder if the gage is the same 'increment' as your other gage...can't really see how it would give you better readings, it almost seems like indexing the cases off of the base in a collet setup like that could cause more runout???? Looks like a good tool to me though...let us know what you figure! | |||

|

| One of Us |

I like the Sinclair type but take the measurement from near the bullet nose, not near the case mouth. Knowing the amount of tilt half way down the bullet seems to ignore the actual amount of run-out. ?? Haven't tried any "straighteners" and don't care to. In fact, I wonder if it actually helps accuracy even as it presumes to improve run-out. I mean, is the pressure bending the neck or bending/deforming the bullet? And, is it not better to use the gauge to find the cause of run-out and correct it in the loading process rather than forcing things afterwards? | |||

|

| one of us |

FWIW...Runnout causing or not causing flyers is always a point of contention. I admit I flip flop on the issue some. A friend is building a 800 yd range and I'm gearing up some scopes to play with longer yardage. Yes I know even a straight bullet starts crooked in a factory rifle....and the trip down the tube should straighten it out....but a crooked one laying in the wrong position would cause an even bigger error in my thinking. Anyhow, after checking reviews at midway a guy definately posted he felt he had better groups and I thought with all the expense of shooting cartridges like a 338 lapua and 30-378 at longer range....why not spend a bit of time tuning EVERY ROUND and taking that variable out of the formula?? I think the problem with this gauge is that it is supporting way too close to the measuring point. Re how it bends cartridges...it flexes the whole casing pretty good. I think I'll call a hornady tech on Monday and see what they have to say about the merits of their idea and why it shows way less runnout. | |||

|

| One of Us |

i bought the hornady tool as well and tested the runout on some older M118LR and some of the rounds had .005" of runout while others had .001-.002" of runout. i used the straightener to correct the runout on some of the rounds with the higher #'s, and as soon as i get my gun back (sent it to get re-barreled) i'll test the rounds that i straightened compared to a batch of un-straightened ones and post the results. ______________________ There is no hunting like the hunting of man, and those who have hunted armed men long enough and liked it, never care for anything else thereafter. | |||

|

| one of us |

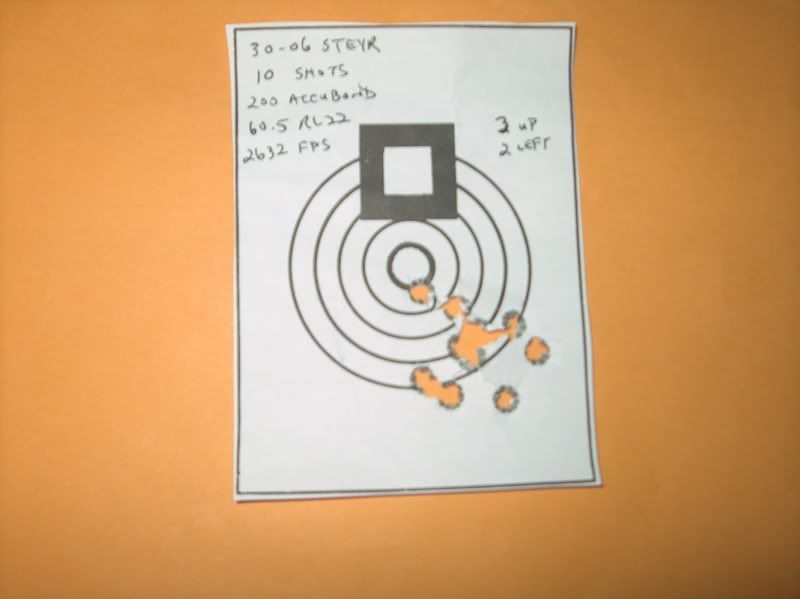

FWIW, I have shot straightened vs non with all other specs being the same, and it did make a difference on the target face at 200 yards. This was only a 100 round test, intermittent 10 shot groups, barrel condition as equal as possible...This is with a 6.5x284 that is VERY accurate, and half of the groups were shot by a friend, to eliminate me being a factor as well....I know it's a small sample size, and it showed some improvement, but I don't chase runout very hard to be honest, except when setting up my dies--with the 'KRAKY' method! | |||

|

| one of us |

Nick...I'm really having a hard time liking this tool. Last night I went through a bunch of 30-06 ammo. Found a couple that showed .005 and .006 on my rcbs that the hornady thought had .001-.002. I could really see this stuff wobble on the rcbs. NOW to the "straighengin thing". I did improve some but I REALLY had to push hard on them. The directions say you may have to go "past" the high spot of runnout slightly. I go .020 at least and sometimes the brass doesn't move. This tool just isn't doing the job like I initially thought. I'm having to crank so hard on the little adjuster that I'm afraid it will break. It doesn't seem to have the "push" needed to correct big cases like my 30-378 or even 300 wby. I'm gonna play some more with it and see what Hornady says but I think this thing will be headed off to "EBAY Land" pretty soon. | |||

|

| one of us |

A thought...I wonder if this tool wouldn't work alot better on brand new or annealed brass. I wonder if a 3x fired case has the neck hardened to much for this thing to be effective?? I've seen first hand how even one firing makes 7 mag brass really hard to form to 270wby...at least compared to virgin. I wonder if the same principle isn't at work here?? Either way if it doesn't work all the time on all my casings it isn't what I thought I was buying. | |||

|

| one of us |

Hmmmm. Supporting the case at several POINTS of contact may miss some high points on the case. That's bad because the chamber won't miss those points. Runout - takes into account all sources of variation. That includes, amoung others, two important ones that we need to address: one, the neck walls being of non-uniform thickness and two) the axis of the bullet being not aligned with the axis of the case. Trying to improve the tilt when the issue is non-uniform neck thickness is a mistake. Tim K (trk) Cat whisperer Chief of Smoke, Pulaski Coehorn Works & Winery | |||

|

| One of Us |

I looked at this unit a couple months ago and seen that it held the case head and didn't take the body into play at all.... This alone told me it was not a tool that I wanted for any price. ________________________________________________ Maker of The Frankenstud Sling Keeper Proudly made in the USA Acepting all forms of payment | |||

|

One of Us |

Hey kraky, been waiting for someone to get one of those and give us a report. I wouldn't give up too soon. It probably has a learning curve, I know the Bersin does. One thing you come to realize is that (if it is like the Bersin) it is a runout reducer. In the tests I have done it has made some difference non-Bersined  Bersined  the one flyer was a flinch from a braked 30-378 going off on the next bench. But I don't have a lot of runout anyway, perhaps if there was a lot of runout on the non-Bersined loads there would have been more of a difference. The number of firings on a case and whether it has been annealed will make a difference, as will crimping, bullet grip, etc. Sometimes the bullets move too damn easy and sometimes you really have to push. Avoid chasing the high point from one side to the other, back and forth, cause it can loosen your bullet grip. If you are working on 50 case or so, by the 4th or 5th "pushing", you will get a feel for how much pressure to put on the cases to move them. You have to learn when to call it good and not do anything more and most of the time don't do anything if you have a low reading. Don't chase perfection and don't be so damn impatient! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  WOW..got the new hornady concentricty checker/fixer tool

WOW..got the new hornady concentricty checker/fixer tool

Visit our on-line store for AR Memorabilia