The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  RCBS small base die=BIZARRO!

RCBS small base die=BIZARRO!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

new member |

May I first start by saying "hello" to all my fellow firearm enthusiasts as this is my first post on this forum. Im fairly new to reloading and have noticed something very peculiar. Im using the RCBS SB .308 die #15507 on a Dillon 650XL. Using my Hornady headspace gauge and Starret calipers I wanted to check the changes in case dimensions. I also used a Dillon .308 "drop in" case gauge to check my resized cases to SAAMI specs. The unusual thing is this. I set my die and all my "once shot" cases are being re-sized perfectly to specification. I then decided I should run my brand new Winchester .308 brass through the press. Many of the cases had deformed necks due to shipping ( nothing serious that would render it unusable,just needed some straitening out). Just for gits and shiggles I took some readings with my Hornady head case gauge equipped calipers and noticed something strange. I notice after re-sizing the new brass that the shoulder/datum line would push back several thousandths and when checked against my Dillon case gauge it would be undersized to SAAMI specs. All I can figure is that the cases are sized with a full length die at the Winchester factory and are being re sized to tighter specifications when I run it through the small base die. Here are some pics: My calipers "zeroed" out:  My pre sized .308 "shot once" case measurement:  And then my resized measurement after running it through the RCBS small base die:  Dropped it in the Dillon case gauge and it's perfect. This is the case neck of several of my new brass and the reason for my re sizing. Not to mention that I have had issues with some of my new brass not cambering in the past.  Now here is the new brass pre-sizing measurement:  And the post sizing measurement along with it nestled in my Dillon case gauge. Its hard to tell but the case is definitely below the minimum spec. shelf.   These will be utilized by my AR10. So let me ask you this-hypothetically speaking,would you still fire the undersized cases AND will this issue cause too much of a head space issue to where it may cause "head separation"? I would think that due to the new condition of the brass this should not be too much of an issue as long as my OAL when loaded is in spec.. Then again, I am rather new to reloading and my assumptions are based off my inexperience=DOH!!  The following is a super slow motion video of a round leaving the muzzle of my AR!!!  Congress has recently stumbled across an area of significant savings. They have found that they no longer have to use tax payers’ dollars to receive a colonoscopy. They’ve found that all they have to do is open their eyes and look around. | ||

|

| one of us |

First, never full length size new brass unless you have an undersized chamber. Just run it in the die far enough to round the necks and load and shoot. Next, if the shoulders are being set back further than fired brass is set back it is probably because the new brass is softer and does not have as much springback. Fired brass is hardened just by the firing process and will have a bit more springback than virgin brass. Finally, case head separations are caused by excessive working (stretching) at the "pressure ring" (the point just in front of the case head where the brass case walls become thin enough to expand against the rifle's chamber.) You won't get a case head separation from excessive headspace (using new brass) on the first firing, or usually even the second. But if you continue to push the shoulder back with each reloading, not only will you get overly long cases which must be trimmed back, your case wall thickness at the pressure ring will grow progressively thinner due to the case head being pushed back against the bolt face and pulling the case wall with it like stretching a piece of bubble gum. Resize your cases, both new and fired, ONLY enough that they re-enter the chamber without resistance. I'm not sure why you have purchased the SB die (although your rifle may require it.) But don't set it so that it sets your shoulders back any more than required for the bolt to close. | |||

|

| One of Us |

That Sinclair Comparator is not a calibrated gage. I know Wilson type case gages are, because I have dropped chamber gages in them to verify the step heights. Set up your dies with the drop in case gage. For the cases are undersized, your case life is likely to be short | |||

|

new member |

Stonecreek=good idea! I will just run the die down enough to re-shape the neck and not a complete re-sizing. I understand what you are saying about the stretching/thinning of the case walls as a pre cursor to case head separation and am trying to avoid it. Glad I only tried it on one new case. Slamfire=the "drop in" case gauge is made by Dillon and they claim that it is formed to exact SAAMI specifications. I used a Forster go/no go/field head case gauge to confirm that the high/low shelves on the Dillon "drop in" gauge where at the correct levels. As far as the Hornady loc-n-load head case gauge I can only assume that it is used for approximate measurements as one die is used for many different calibers. I have used it to check for variances in spent cases so as to get a better idea of my chambers head space clearances. Thank you for any and all input as I am rather new to reloading. The following is a super slow motion video of a round leaving the muzzle of my AR!!!  Congress has recently stumbled across an area of significant savings. They have found that they no longer have to use tax payers’ dollars to receive a colonoscopy. They’ve found that all they have to do is open their eyes and look around. | |||

|

| One of Us |

Actually the comparator guages are very accurate. Assuming the datum diameter hole is pretty close and you should check that before you use it. All you do is zero the caliper dial and they should be right on the button. If you are new to loading just consider your chamber the gauge and make the ammo an exact fit other than .001 to .002 clearance for easy bolt closure. If using an auto loader more clearance maybe (.002 to .003) maybe required but keep it minimised to make your brass last. You can vary how much the shoulder moves with a given die setting by the amount of lube use, the speed you size the case (very slow with a dwell at the stop). Repeating the sizing of a case will set the shoulder further back. By uniform lubing, slow sizing and rotating the brass and double sizing with a dwell at full ram extension you can make brass to about +/-.001. When you do this you will notice your accuracy improve. | |||

|

| One of Us |

Because you are shooting a semi-auto, not a bolt-action, I'm going to disagree with a few of the earlier comments. In part because you mentioned you have had some feeding problems, I think it makes sense for you to full length size your new brass with a small base die. If that seems to help the feeding, then continue doing that. Even with your fired brass, you should set the shoulder back slightly further than you would with a bolt action rifle for reliable feeding. As long as there isn't a difference greater than say ".010, then I'd full length resize the brass every time...especially if reliable feeding is more important to you than getting the last .1" of accuracy. You will get less brass life than you would with partial re-sizing, but if I understand your post correctly you are only pushing the shoulder back on your new brass by .0075 from your fired brass. That is not a huge amount. By the way, its not unusual to see case necks on new Winchester brass like in your picture. | |||

|

| Moderator |

Hi guys, maybe it is because I have not had my morning coffee yet but it seems the concern here is for the shoulder set back? If so, then just back the die off or try a different shell holder until the shoulder is where you like it? I am no expert on small base dies, I have a set for a 243 (RCBS) that I got in a trade, and eventually had a friend who has a 243 come down and we used the set to find a load for his brass but other than that no experiences. However, since it was a bolt gun I was sizing his once fired brass using the "turn the die in until it chambers, then a tiny smidge more for good luck" method. There was still a bit of space under the shellholder when I did that. As I said, I am no expert on the small base dies but it would not surprise me if they are cut a tiny bit tighter in length in addition to base diameter, but the issue here seems to me it is just set too low. If the shellholder is contacting the bottom of the die right now, just figure out how much higher it needs to be and use a feeler gauge between the two when you set it. Or am I missing something obvious that will jump out at me when I re-read the thread immediately after I post this? for every hour in front of the computer you should have 3 hours outside | |||

|

| Moderator |

OH, and welcome to the forums Coal Miner! for every hour in front of the computer you should have 3 hours outside | |||

|

| One of Us |

No you have it right. Regular dies squeeze a case down way more than enough diametrally. Even enough for autoloaders, pumps and lever guns. All that is needed is to set the case to the chamber length with a little clearance. The .0075 clearance is going to be close to no-go length headspace. Not good for case life or accuracy. | |||

|

| One of Us |

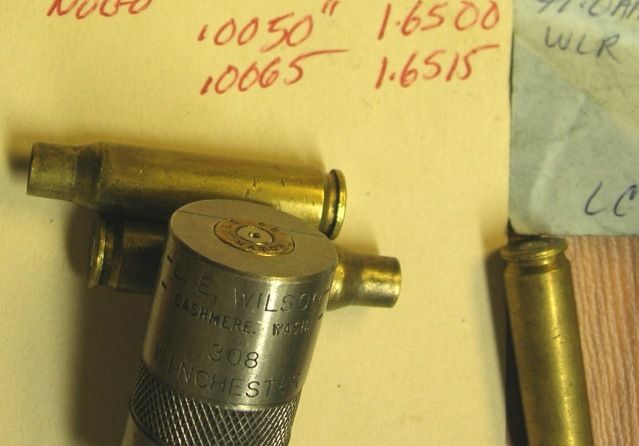

I am an advocate of small base dies in gas guns, but you have to set them up with case gages. You should push the shoulder back about .003" from the chamber, so shoot some rounds and see what the OAL is. However gas guns stretch cases. These rounds were fired 23 times in my Super Match M1a. Last I fired them was during Rattle Battle at Camp Perry and I picked up most of them. The pockets were starting to get large and I retired them. Anyway, as you can see, they are over length because there is stretching during extraction from a semi auto.   For a semi auto you have to be much more precise in your case preparation than a bolt gunner or your semi auto will jam. Now beating a bolt closed, or open, would seem to be the normal practice for those bolt gunners who partial neck size, or just neck size. Given the massive cams and long bolt handles on bolt guns, these sloppy reloaders never notice the interference fit between their ammunition and chamber, until they have to pull the mallet out. Until then they think their techniques are the pinnacle of perfection. But try to run those rounds through a precision built semi auto, and you better carry a big, big mallet because semi autos don’t have bolt gun leverage in feed or extraction. For years I was very mad at the gunwriter Mike Venturino as he kept putting in print that shooters did not need to use small base dies for military semi autos. In this July’s Gun’s magazine he tested a new AR-10 and M1a, and guess what, his reloads, sized in his standard sizing die, jammed in these rifles. He had to take the things out back and beat the bolts open, with live rounds in the chamber, using wood blocks. Maybe gunwriters are capable of learning something especially after using 2 X 4’s to open the action on the rifle they are shooting, but then, we will see. | |||

|

| One of Us |

Slam fire do you know the exact headspace of the rifle in the photos above. It appears that the fired cases have a bit of excess headspace. I applaud your use of the Wilson gauges. Those I have measured have the precision of a true headspace gauge. However many think the internal shape is that of a chamber when it is not. It is a very accurate shoulder gauge and not a body gauge. Unless you gauge and dry run your ammo 100% sooner or later a volume type loader will let a case get through with a long shoulder. Even speed of sizing, dwell time at the end of the sizing stroke and the amount of lube on the case will affect the precision of the sized shoulder placement. It is easy to detect the differences with a Hornady gauge or the Wilson gauge if you are careful. I have a dial indicator that I can use with my Wilson gauges but for the most part I use the Hornady gauge during loading operations. Even a random case with a neck and shoulder that is harder than the rest will size differently and stay longer if you do not pay attention to each case. With all that is said above if you load on a progressive loader, be sure to check your loads 100% after loading. Just because you have a good machine does not mean every case will come out with the same exact shoulder placement. | |||

|

| One of Us |

A Sinclair/Hornady head space gage that should be called a case comparator gage, a Wilson case gage correctly called a L. E. Wilson case gage, and I agree, the Wilson case gage is not a chamber gage, I know, there are those on other forums that insist they use it for that purpose. Again, I am the fan of standards and transfers, and I am the fan of verifying, for standards, transfers and verifying I use the feeler gage, I have a pile of tools and micrometers and gages, I have a pile of gages. I took a picture of my micrometers and gages, the picture weighed 400 pounds. The Wilson case gage is a precision gage, it does not have a shoulder for the case to sit on, it has a datum, the datum for the 308 Winchester chamber/case is .400, like the 400 pound picture, this stuff does not lock me up, when using the precision Wilson gage I use a straight edge across the head of the case then measure the gap between the straight edge and Wilson case gage, the feeler gage gives me a reading in thousandths, the protruding case head when measured above the gage indicates the length of the case when compared to minimum length/full length sized. Then there is that part of the case that protrudes from the other end of the Wilson case gage, that measurment represents the length of the neck from the datum/shoulder of the case to the end of the neck. I have case heads that protrude from the Wilson case gage .014 thousandths, and that is OK, the rifle I load for, a M1917 Eddystone has .016 thousandths head space, the Wilson case gage tells me the case is long from the head of the case to the datum and correct in length from the datum/shoulder to the mouth of the case. Small base dies, I have small base dies, I have BMG dies, I do not use them but JIC, I have them, I have tried using them, with all of my micrometers and gages? I had trouble finding a difference in the effect they had on sized cases. I had a Winchester Model 70 chambered in 300 Win Mag, Winchester and I had words, I sent the rifle back, they thought I was difficult, then they thought I became impossible, all I wanted was a chamber that fit my dies OR a set of dies that fit Winchester chamber, that chamber was the ugliest chamber I have ever seen, gouged, too large in diameter, too long from the face of the bolt to the shoulder of the chamber. And they said the could fix it, they would start with polish, then hone? then ream. I could not see how any one of the remedies would reduce the ugly, length or diameter. I measure before and again after, and I measure the length of the chamber before I start, meaning head space gages are usless, we all/should know the go-gage will chamber, I want to know by ‘how much’ by not getting locked into the ideal “You gotta have a head space gage” I measure the length of the chamber in thousandths, but if I did have a head space gage I would use it to set up by sizer die in the press, or I would use it to check the accuracy of the sizer die, again, this stuff does not lock me up. Back to small base dies, when using a small base die to size a case the case should get longer (from the head of the case to its shoulder), the diameter of the case is reduced, when the case diameter is reduced, the shoulder forms a small radius. I make gages for measuring case length from the head of the case to the shoulder, I form cases, my favorite forming die is the 308 W, if I had one forming die it would the 308 forming/trim die, I am without a clue as to why reloaders insist on owning head space gages, when reloading my whole world evolves around thousandths, there are 3 options when using a 30/06 set of head space gages, go, no and beyond, between go and beyond there are 3 options, one is the go-gage, next is the no go-gage and then there is the field reject (beyond) gage, when I check the length of a chamber, I can go from go-gage length to infinity in thousandths. Place a case in the Wilson case gage, with a metal frioendly hammer hit the case head to drive the case into the gage, then use a round drift/punch and hit it the case head again, the shoulder of the case will form to the datum/radius while the case disappears in to the gage, Point??? there is a lot of room in the Wilson case gage. Do not forget to lube the case, lube makes it easier to drive the case out of the gage, I stand the gage up on a block of lead, the mouth of the case is driven into the lead, lead is friendly to the gage and case. F. Guffey | |||

|

| One of Us |

Coal Miner: I think you are going a little overboard on the situation. You need to know what is the size of you chamber is. Have you ever fired full powder loads in this gun? If so, would the cases fit back into the chamber without sizing? If they did fit, what was the dia. of the base and what was lenght from datum line to the base of case. That is the size of your chamber and that is what you have to work with. You need to stop trying to fit the cases to gages and fit the ammo to the chamber. How much clarance is there between the rear of your chamber and the web area of fired case? You should try to findout who built barrel and find out much clearance they recomend. You might have bought into the "have a auto-need a small base die" when a normal FL die would have been better. | |||

|

new member |

Man,been a looong week! Wow, you guys are awesome! It will take me awhile to absorb all this good information. I talked with the local reloading "guru" today and he said that brass will last much longer when you use a small base die over a full length resizing died. He compared full length dies as the old to the smallbase dies being the new and better way of resizing. Im not too sure I buy into all of that. Need to do some more researching. Regardless, I have been having some VERY consistent reloads with my Co-Ax press over my XL650. My original question was why when I resize my "once shot" brass do they all come out consistently within SAAMI specs.. Then when I resize my brand new brass with the same die setup why it goes way under SAAMI specs. After researching and reading through your posts its clearly a newbie question as I did not fully understand shoulder and datum line forming when resizing brass. I have since used my small base die to resize my new brass but set it up specifically for the new brass. They are all within SAAMI specs. now. As far as resizing my brass to my AR chamber I am torn as I often go shooting with my friend who uses my rounds. I have a LWRC and he has a Rock River. I am not entirely sure that if I re-size my brass specifically to my chamber that it will chamber in his Rock River AR?? You guys really praise the Wilson gauge, is the Dillon drop in gauge I have any good? It was my understanding that the Dillon gauge measured the datum line to the case base/bolt face to determine weather it was in SAAMI spec.? Am I misinformed? "Fat Albert"-when you say "full load" are you referring to "max load grains"? I have always (yea, ive been reloading for a wopping 4 months) leaned more toward the "suggested starting" grain load. Is it really necessary to lean toward the max load to find your chamber dimensions? So gentlemen-in your opinion/experience what IS the best way of finding your chamber dimensions and reloading accordingly? Thanks again fellas for all the good info! The following is a super slow motion video of a round leaving the muzzle of my AR!!!  Congress has recently stumbled across an area of significant savings. They have found that they no longer have to use tax payers’ dollars to receive a colonoscopy. They’ve found that all they have to do is open their eyes and look around. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  RCBS small base die=BIZARRO!

RCBS small base die=BIZARRO!

Visit our on-line store for AR Memorabilia