The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Overall length vs head space

Overall length vs head spaceGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

I'm new to reloading and trying to have a good understanding before I begin loading for my 22-250. My question is regarding bullet seat depth. I'm using the Hornady gauge to dertermine overall length. However, the shoulder is what actually determines bullet placement relative to the rifling correct? So, if the headspace on my brass is different then the modified brass I'm using to take overall measurements then the bullet placement will be incorrect right? Also, how far off of the rifling is a good place to start? | ||

|

| One of Us |

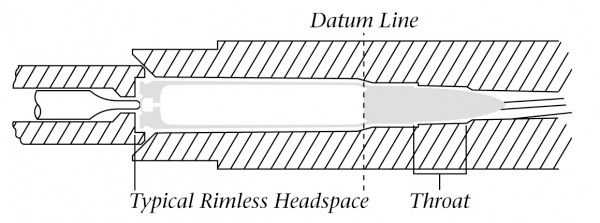

Head space and overall length are two separate measurements. Head space is a measurement of the base of the cartridge to a datum line (a line of a certain circumference on the shoulder). This line is determined by the cartridge or parent cartridge. This is why some go no-go gauges work in more than one caliber. So a rifle case/chamber is measured at a point midway up the shoulder. The case (trim to) length is from the base to the mouth. It’s a presumption that the case is already properly sized before it is trimmed. The cartridge overall length is measured from base to bullet tip. Again a presumption of proper sizing is made. You can set back the shoulder too far (excess headspace) and still jam the bullet into the lands (over length). This is sometimes done intentionally when fire forming to move a shoulder out to a new dimension like Ackley shoulders. To answer your question, the point on the ogive of the bullet that you are measuring is measured from the base of the cartridge. For a start 5 or 10 thousandths off the rifling. After you determine your most accurate charge you can adjust the length both ways to see what the best length is. A bad day at the range is better than a good day at work. | |||

|

| One of Us |

the shoulder doesn't determine the oal of the round. the distance from the base of the case to the ogive of the bullet will determine the oal. this corresponds with/to from the bolt face to the start of the rifling. | |||

|

| One of Us |

Since you are new to reloading and asking such questions, I have to wonder what you are considering "modified brass" and what you are doing to come to that? If you arent sure what you are doing with altering brass and headspace then you are entering into potentialy dangerous territory. Sam is correct that Headspace and OAL are two seperate measures neither of which are relative to the other. Headspace insures that the case is the perfect fit in the chamber which is critical for saftey. OAL is the length of the cartridge including the bullet, which if too long could cause excessive pressure from the bullet touching the "lands" of the rifling in the barrel. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I recommend you read and understand, several reloading manuals, and talk to at least 3 people who successfully reload, so you can learn the basics before you assemble any rounds. Your questions indicate that you don't have a good grasp of the basics. I would he glad to help you; i started reloading in 68 and load everyting from 223 to 50 bmg, including BP cartridge. But it is a fun and rewarding hobby and actually hard to hurt anything if you follow some simple rules. Like gassing up your car; it can kill you but nobody ever actually gets killed. Well, rarely anyway. | |||

|

| new member |

Thanks for the replies. The modified case that I'm referring to is the case used with the Hornady OAL gauge. It is drilled and tapped to be used with the gauge. I'm by no means modifying any cases. As long as the headspace is a reference and in no way affects OAL then it doesn't matter if the headspace of the brass being used to measure OAL is different from the brass that I'm loading. | |||

|

| One of Us |

OAL is the overall length of anything. COL is the Cartridge Overall Length and defines itself quite well. Headspace is the distance from the breech to the case head when the case is as forward as it will go and should be in the thousandths of an inch. For rifle cartridges, a better measurement than COL is the length from some point on the bullet's ogive to the case head. Where the point of measurement is on the bullet depends on the ID of the "part" contacting the bullet. Standard COL is not that precise as the bullet tip can vary due to which die was used to swage it, any nose damage during shipment handling, and other such causes. Headspace in a bolt action can be zero, but must be at least 0.001" for most other actions to close completely. Reading manuals will help. | |||

|

| One of Us |

Please, I don't mean to be critical, but you are confusing the OP; headspace is NOT the distance from the bolt face to the case head. That measurement would be "excess headspace" which is usually allowed to be from zero to .006. Headspace is measured from the bolt face to wherever the brass case is stopped from forward movement and varies with each type of case (rimmed, belted, and rimless0 and of course, varies with each different caliber. Although some are the same like .308 and.243. It is not complicated but there are a lot of definitions to get straight. For a beginning reloader, do not worry about headspace. | |||

|

| one of us |

Actually, it's a LOT more than 0-.006, as most chamber headspace measurements have a 0 to +.007, and the cartridge has a headspace measurement tolerance of -.001 to -.008 for a "bolt to case clearance" of .001 to .015 and still being in spec. SAB, I took the trouble of looking up the SAAMI headspace specifications for your 22-250 Rem. Case HS measurement spec is 1.571 to 1.578 (.007 difference) Chamber HS measurement is 1.5749 to 1.5849 (.010 difference) So in your case, anything from .001" (min chamber, max cartridge) to .018" (min cartridge, max chamber) clearance would be within SAAMI specification. http://www.saami.org/specifica...nformation/index.cfm | |||

|

| One of Us |

I understand completely the ins and outs of headspace. I was referring to chamber dimensions, (as rifles are gauged and fixed as far as headspace goes, and you can make brass any length you want) not worse case of a min case and a max chamber. My main point was that the poster had defined "headspace" incorrectly and that might confuse the OP. | |||

|

| One of Us |

Actually you said it wrong. Head space is head space, it's a specific measurement with a +/-. What you are talking about or describing is excess clearance. | |||

|

One of Us |

You are entirely correct. The modified case will have a different headspace than one of your fired cases or the size of your chamber. It will throw your seating depth distance from the lands off by that amount. That is why some drill and tap one of their own fired cases for the Hornady Gauge. Everyone has an opinion, but I like to start seating depths at .020" or .025" off and seat deeper in increments of .015" at a time to tweak a load. Loading too close to the lands can increase pressure and it is almost impossible to seat a set of bullets with less than .005" variance in seating depth. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

sab, you're bound to be more confused now,after reading these replies, than you were when you started the thread, huh? You don't need to worry yourself silly with the headspace right now. You need to find the measurement to the ogive of the bullet when a round is chambered. You're on the right track. Taking the Hornady modified case, and using the bullet you're going to load, you will determine the distance to the lands (rifling) that is critical to accuracy. You will need a Hornady bullet comparator set ($20) that will give you the measurement you need. Go to youtube and search the Hornady bullet comparator, and the Hornady OAL guage you already have. You will find detailed video on how they're used, and why it matters. That will be far more helpful than it trying to be explained to you. Once you see the videos you'll immediately understand the process. After the video session, and you take the measuremnts of your own rifle, start those bullets about .005 off the lands. When you find a powder charge that gets accuracy like you want, there's only one way to go from there if you want to fine tune your load.....seat it gradually lower and see if it helps. Good luck and have some fun with it. | |||

|

| new member |

So, if I'm correct (as Woods implies) then I should factor the difference in head space into the OAL. Or as you say, use a fired case. I know I'm probably over thinking it, but I'm trying to obtain a full understanding of this before I start as most of you suggest. Maybe I should just focus on OAL for now and forget about head space. JG, I do have the Hornaday guage. I've watched youtube videos and read manuals. I've taken OAL measurements for each of the bullets that I plan to load. Tailgunner, thanks for taking to time to look up the info. I apologize for my confusion. I'm enjoying the process of learning to reload and becoming a better shooter. I appreciate the replies and can assure you I'm not jumping into this w/o seaking the proper understanding. | |||

|

| One of Us |

Sab Most of the posters are correct in some way when defining head space but simply put and easiest to understand without getting too tied up in terminology, head space is the gap between the bolt face and the rear of the head of a chambered cartridge or case irrespective of whether it is a rimmed case, a belted case or a rimless case, all of which come to a stop when 'chambered' on a different part of the case; The front of the rim (rimmed case), the front of the belt (belted case), the shoulder (rimless case), or the case mouth (straight sided rimless cases). Because excess head space is usually quite apparent in a rifle that has it, it is not something to have to think about when determining the overall length of a cartridge in a modern rifle. Usually you should not be setting your cartridge OAL with a certain bullet to be within .005" of the lands in the barrel. As others have posted, start at least .025" off the lands and decrease (or increase) in small increments to find the sweet spot. Almost impossible to seat consistently .005" off the lands with standard reloading kit and asking for trouble with hunting ammo to do this. | |||

|

| One of Us |

Wow, Ok, maybe you guys will believe that the Nosler bullet people know what headspace is; (that is where I got this picture) .Perhaps I did mis-speak about the clearance thing but my definition of headspace is correct. If your RIFLE has too long a chamber, you have excess headspace. If your brass is too short, you have excess clearance. Anyway, OP, don't worry about any of this; Just seat your bullets to the crimp groove; (Hornady bullets have them), and shoot. You can refine things later.  | |||

|

| One of Us |

My post was not doubting what the term head space actually means and I made that clear, but as I said it is much simpler to see it as it actually manifests itself irrespective of the type of case, the gap between the bolt face and case head. After all it is that gap when excessive that allows primers to back out bridging the gap and case heads to bridge the gap on firing and cause incipient case separation at the web. This is much easier for a novice to understand than talk of datum lines (which is absolutely correct) or even the Nosler diagram which only shows one type of case. As I said, push any case into a chamber and if you have a gap between the bolt face and case head then that is for all intents and purposes, the head space. How you correct it is when you have to start thinking of the datum lines for the different case types. | |||

|

| One of Us |

Sab7896. You are right headspace can change bullet "jump" a scosh. However the primer pushes back and the case moves forward against the shoulder. The case stays forward until the pressure rises to somthing like 20-40 kpsi, then the shoulder stays forward and the case stretches back against the breech. Headspace is exactally what is says, the space at the case head. A chamber cannot have headspace without a cartridge case in it. | |||

|

| One of Us |

The reason I like to get the ogive of the bullet .005 off the lands, which with a bullet comparator gauge is not very hard........You obviously start load development roughly 10% below book max and work up in .5 grain increments (at lest I do). You keep going up with your powder charges until pressure signs are reached (at least I do). Obviously with the bullet seated out that close to the lands, pressures will be higher than if they're farther off the lands. It's all about pressures, which directly affect velocities and often times accuracy. Many times the best accuracy is at near max or max pressures, safe pressures. When you find a powder charge that gives you good accuracy, a guy may want to tweak the load some to induce even better accuracy. At this point this is done by fiddling with seating depths. Given you started at .005 off, there's only one way to go from there......seating the bullet deeper, which will obviously lower pressure. When I do this I seat bullets deeper in .005 increments and see what effects its having on groups. You never have to worry about exceeding safe pressures when you start out on the lands and back off. Conversely if you start out .025 off, and seat bullets further out (closer to lands) you increase pressure. At that point you really need to back off your charge to make sure you have a safe working pressure, and you've created more work for yourself. I also don't worry about the OAL of the loaded round as long as it fits in the magazine. Distance to lands is the key, not OAL. Let's say your loading 160 nosler accubonds for a 7mag. Even though they're from the same lot, the ogive measurements to the lands can differ between individual bullets. Sometimes by .001-.004. If you are only measuring OAL, in this example, the bullets may vary by how much they're off the lands in the loaded round by this same .001-.004. For lots of good hunting rifles with good barrels this may not matter much, but it could matter a lot. | |||

|

| One of Us |

"A chamber cannot have headspace without a cartridge case in it." Well, no, as I have stated before on this forum.e. Why don't we all use the SAAMI definition to avoid confusion over one another's terms; "HEADSPACE The distance from the face of the closed breech of a firearm to the surface in the chamber on which the cartridge case seats. HEAD CLEARANCE The distance between the head of a fully seated cartridge or shell and the face of the breech bolt when the action is in the closed position. Commonly confused with headspace." Commonly confused with headspace." | |||

|

| One of Us |

Wow! How then does a gun manufacturer set up the correct headspace? With a cartridge in the unchambered chamber? Don't tell me a head space gauge because that is used after a cut is made with the reamer to check the head space. | |||

|

| One of Us |

The chamber is cut to the Datum Line of course. Measured against a headspace gage. When the cartridge is chambered you may or may not have headspace. For example if you push the shoulder back on a case you will have headspace without changing the chamber. Headspace depends on the relationship between the chamber and the case or the difference if you will. | |||

|

| One of Us |

Nope, you are flat out wrong. Just as Dpcd pointed out you don't have to have a cartridge in the firearm for it to be head spaced correctly. According to what you are saying the manufacturer just cuts a chamber and it's up to the end consumer to make the case fit correctly. Nope...just doesn't happen that way. If your case doesn't fit correctly either the chamber head space is incorrect or the case is incorrect. Here are a few head space gauges: Go No Go Field Manufacturer Fitting Gauge | |||

|

| One of Us |

All talk about cutting chambers etc, etc, is of course mostly thinking rimless cases. Lets go back to basics when there were only rimmed cartridges and where the ammunition manufacturer controlled the rim thickness. Other than the mechanics of the lock up of the bolt, the relationship between the bolt face and the rear of the case head was set by the rim thickness and nothing else irrespective of how the chamber for the case was cut. Off the face double rifles or shotguns i.e. gap between barrel and standing breech face have developed excessive head space just as some rear locking bolt actions or other action types developed head space over time and use. Sure to be technically correct, the datum line for head space was the front of the rim but for the average rifleman though, head space manifested itself as the gap between the bolt face and the case head (head clearance if you will). Those of us living in the the British Commonwealth countries cut our teeth on the venerable old 303 LE or SMLE battle rifles and know all about using the three different length bolt heads marked L long, M medium, and S short, for these rear locking bolt actions to take up HEAD SPACE, knowing this and first taught this by the military in high school cadets, as the gap between the bolt head and the case head. To me at least it is far easier to to think of head space in this term which avoids a lot of confusion when talking of cartridge overall length and bullet seating depth to lands etc, which is where sab7896 was starting to get confused or at least seeking clarity on. To be honest after a lifetime of reloading mixed with some years of gun-smithing I have never heard or used the term 'head clearance' and if I asked any hunter today what head-space was I know what 99.9999% would say. Maybe we think differently down under | |||

|

| One of Us |

As your SMLE's got worn and developed excess clearance (that is larger then the maximum called for from the original head space) you used those different bolt heads to correct it. If the larger of those bolt heads didn't correct it then the rifle went back to the armory for repair. Head space is a given dimension and it has a +/- for machining tolerances. If the measurement is too large then it's excess clearance. If it's too tight they it is not enough clearance. A Go gauge is for acceptable head space and a NO GO is to show if the chamber has excessive clearance. If the action closes on a NO GO it's too excessive a clearance and so be corrected by a gunsmith. A Field gage basically shows a head space that has excessive clearance, but not within the danger limits. The manufacturing head space gauge is used for assembly. I believe them to be just a tad tighter then a GO gauge and they assume as the action parts wear in that the headspace will fall within the correct headspace +/- limits. | |||

|

One of Us |

The OP's question can be answered and illustrated like this These are measurements on a custom rebarrel 375 Ruger on the MODIFIED CASE  NEW CASE  FIRED CASE  The gauge read 4.253" on the modified, 4.255" on the new case and 4.257" on the fired case. That means if you used the OAL measurement from the modified case to set your seating depth there would actually be a .004" difference in the distance to the lands from the comparator measurement to the loaded fired case measurement. IOW if you set the OAL at 3.285" for a distance to the lands of .050" from measuring with the tool, after reloading fired cases and using the same OAL you would have a distance to the lands of .054" Think we'll all agree not much of a problem with a gun with a low head clearance But, take another gun like my 30-06 Steyr MODIFIED CASE  NEW CASE  FIRED CASE  which is a difference of .010" between the reading on the modified case and the final dimension of a fired case. In that instance if you set your OAL to have a jump of .020" with the Hornady tool, you would wind up having a jump of .030" if you used the same OAL measurement ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

OAL really depends where your seat your bullet too. It doesn't matter what the case length is. Look at it a different way. Say the magazine is the limit to how long you can make OAL or seat your bullet out. The magazine doesn't care what length the case is or what length the case is from head to shoulder datum...but overall length of the cartridge..that is from head to tip of bullet. Yes I know when loading into a chamber that you have to take into consideration at what point the bullet ogive will touch the rifling. | |||

|

One of Us |

I suppose you've got a response for everything and I really don't want to get muddy But

Nobody is talking about case length but if you meant to say dimension from case head to datum line (which is in discussion), then it does matter

The OP's question and my answer was directed toward what difference using the Hornady modified case would have on bullet jump. In your example in a magazine, if you take an OAL with the tool and set your bullet seater to that dimension, you will have a different jump to the lands with cases that were fire formed to your chamber and bullets seated to the same OAL. Maybe this example will explain it:

Doesn't matter if you are loading to magazine length or not ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Woods, I don't have an answer for everything, if I did I would write books on all of it. We're not going to muddy the water. Just a discussion. All I was trying to point out was if you measure a case from the head to bullet ogive or bullet tip (which is different then what you are talking about) the case length doesn't matter. An analogy: you can load 38 Specials to 357 Magnum OAL, but more of the bullet will be seated out of the case. See what I'm talking about? With your Hornady device it would make a difference, but not everyone uses that. Many still mark the bullet with a marker pen and try a dummy round in the chamber to see where/when the bullet just touches the leade in and then set the bullet to their preference away from the rifling. Oh Woods, I apologize for being off topic. The topic went off after the very first reply. Your post were not off topic. | |||

|

One of Us |

You are sorta right, the length from the case head to the tip of the bullet or the ogive (whichever you are measuring to) can be the same, but what I am saying is that they could have a different jump to the lands. When the firing pin hits the primer and the primer fires, the case will move forward to contact at the shoulder (on an unbelted case). IOW if you could load a modified case at a certain OAL, then loaded a fire formed case to the same OAL, they would have different jumps to the lands. It needs to allowed for if you are interested in being exact. Same principle as loading a new case and a fire formed case to the same OAL, they will have a different jump to the lands. Yeah I don't use the Hornady either. Have a tool that measures all calibers for a TRUE OAL without regard to headspace. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

SmokinJ has an answer for everything except the question being answered. | |||

|

| One of Us |

Ogive to lands is all you need to worry about with hunting loads. | |||

|

| One of Us |

Feel better? | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Overall length vs head space

Overall length vs head space

Visit our on-line store for AR Memorabilia