The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  8x58R Sauer

8x58R SauerGo  | New  | Find  | Notify  | Tools  | Reply  |  |

one of us |

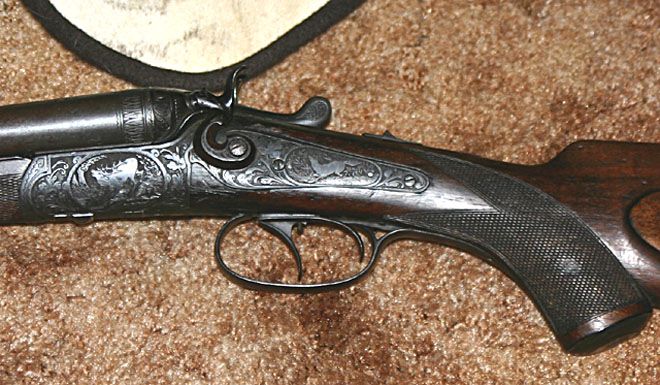

I just started to work with an old hammer drilling that has been in the family for many years. It had not been fired since my uncle bought it (used), and I had to determine the caliber since it was marked in the old gauge system rather than normal caliber notation. It is nitro proofed with steel jacketed bullets, and the action is tight and has a Greener type crossbolt third fastener, so I would prefer to use smokeless powder. A chamber cast revealed that it was an 8x58R Sauer. Groove diameter is .322 to .323, so once I get enough brass formed, bullets should be no problem. Rim thickness is .044, so rims have to be thinned slightly when forming from 9.3X72R, and necks need to be turned to allow adequate clearance for release of the bullet. So far the only load data that I have been able to find was in Cartridges Of The World  . Can anyone suggest another source of data, or some actual loads? Since it was not that uncommon at one time there must be some data available somewhere (it is listed in Quickload, but this type of tapered cartridge presents problems in predicting pressure and velocity in most ballistics programs). . Can anyone suggest another source of data, or some actual loads? Since it was not that uncommon at one time there must be some data available somewhere (it is listed in Quickload, but this type of tapered cartridge presents problems in predicting pressure and velocity in most ballistics programs).Any help will be appreciated. Thanks, Jim  | ||

|

| One of Us |

I found some info in the RWS manual Wiederladen. Firstly it says that in this calibre they never used the .323 "S-type" bullet but always the old .318 bullet. Secondly the max allowed pressure is extremely low at 2000 bar, which is comparable to 32-20 Win @1900 bar and 32-40 Win @ 2100 bar. So I would be very hesistant in shooting .323 bullets in it. The single load that's listed in the manual is for a 195 grn. RN bullet using Rottweil powder. They give a max. velocity of 575 m/s and a COL of 77,0 mm. The book says that you can get brass by simply shortening and full sizing of new 9,3x72R cases. Hope this is of any help. | |||

|

one of us |

dutchgus, Thanks for the info, and the good advice. The groove measurement was determined by actually slugging the bore, plus the barrel is marked with the "S" bore designation. My intent, however, was to use .321 bullets, at least initially. I have some .321 Speer 170 grain bullets, as well as a ring sizing die in this diameter to reduce .323 bullets. I also have a ring sizer for .318 that I use with a J bore 8x57, so I understand the importance of determining actual groove diameter, but your "reminder" is appreciated  . .Your pressure data corresponds pretty closely to the CIP standard of 2200 bar, and I would not wish to exceed that. I am just looking for a few reference loads to use as a comparison to the Quickload predicted data. This should give me a better basis for developing new loads for this rifle. I will chronograph a few rounds of the original published load to see how it corresponds to predicted velocity from Quickload, and adjust accordingly. I assure you that it is not my intention to load too hot for this vintage drilling  !!!! I value it, as well as various parts of my anatomy, too much to do that. !!!! I value it, as well as various parts of my anatomy, too much to do that.Jim | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia