The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Forster case trimmer and inside neck turning

Forster case trimmer and inside neck turningGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Hi, following up a recent post, I would like to know your opinion on the Forster case trimmer and especially the inside neck turning option; I'm mainly interested in removing the doughnuts that often build-up at the neck-shoulder junction. Thanks. | ||

|

| One of Us |

I have this set up & it works well. I can't compare it to others as the Forster is the only one I've had & I've not felt the need for any others. There was a recent post on case trimmers & in my mind the Forster seemed to rank as high as any & higher than some. Their inside neck reamers are designed to open a neck up before resizing. If you can't easily slip a bullet all the way into the neck of a fired case it needs inside reaming to remove the donut. If it won't start, you've been very lucky & the necks probably need outside turning to thin them along their length. Steve | |||

|

| new member |

I use one and it just works To get extra neck length, I tend to size down other calibres - e.g. .222 Mag > .204 Ruger and .308 Win > .243 Win. In doing this it's essential to neck ream and outside turn and the Forster does the job perfectly with almost immeasurable variation in neck thickness. Kev. | |||

|

| one of us |

I've made a search, and found an interesting recent post AGAINST inside neck turning, that sounds really resonable: ....OK, go ahead and ruin the concentricity of the necks you turned to get them concentric. Whats going to make the Forster reamer center itself inside the case neck? I can assure you of one thing, there is a reason for all the outside neck turners on the market. Inside neck reamers create more problems than they cure. If the case isn't dead-nutz aligned with that reamer when you cut the necks, it WILL cut one side of the necks thinner than the other. What do you think the chances of getting every case set up perfect on the Forster trimmer? I'd say the chances of getting one of the cases right are somewhere between slim and none..... I'm puzzled.... | |||

|

| one of us |

When I first started shooting IBS BR matches, a couple of fellow shooters were inside neck reaming their 6PPC brass. They all used a die, made with the chamber reamer, to hold the case. This die was held in the chuck of a lathe. When I asked about this, I was told that it was the only way to assure that the inside reamer entered the case neck on center. That was 20 or so years ago and nowdays I know of no fellow shooters, who inside ream their necks. To remove a doughnut I use a neck mandrel and then outside turn. | |||

|

| new member |

With the Forster tool, you neck ream before resizing and neck turn after. Even if the reaming is not 100% concentric, the resizing process should return the inside to being concentric - thereafter the outside neck turning ensures perfect wall thickness. Kev. | |||

|

| One of Us |

That's the way I do it. Don | |||

|

| One of Us |

its best to turn the outside | |||

|

| one of us |

After some thinking I've ordered a K&M (outside) neck turning tool.... | |||

|

One of Us |

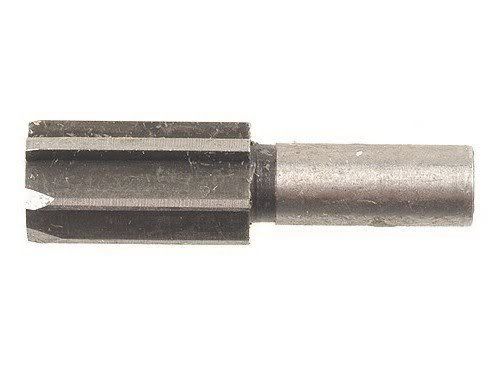

The Forster inside neck reamer is approx .003" larger than bore diameter  that means that in order to work properly the inside diameter of the neck needs to be close to .003" larger than bore diameter in order to take off some brass but not too much. You would not want to inside neck ream .003" off the brass on the inside of the neck! This works very well for a custom tight necked chamber and that's the reason Forster made it that way. The accepted and recommended neck clearance around a loaded round in a tight neck is .003". When fired this .003" transfers from outside neck clearance around the neck in the chamber to add to the inside neck diameter by .003". Perfect for the reamer. I use the hand held Forster turner both as an outside neck turner and an inside neck reamer. Fortunately the reamers have the same mandrel that the outside neck turning mandrels do  and so they will fit in the outside neck turner  that way you can trap the neck brass between the inside neck reamer and outside neck turner and get exact neck thickness. But, you have to set your brass up for that .003" clearance first, then fire it to create the .003" over caliber dimension on the inside of the neck and then you can use the reamer. The Forster reamer is much wider than the K & M mandrel with the cutting tip  and IMO will not ream off center because of that long cutting surface. The K & M will score the inside of the case much more because of that small cutting blade on the end as opposed to the Forster reaming, cutting and cleaning the entire surface of the inside at once after it is fully inserted. So first you do the math and set your brass up for outside neck turning  then after firing you can neck ream and clean up the outside of the neck at the same time  Usually this process will remove about .0005" from before reaming  to after reaming and cleaning up the outside  ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

BUY A WILSON The way it holds the case is so much better I could go on cause theres a whole lot more to say . One other thing.... buy Glen Zedikers book on reloading. http://www.zediker.com/books/handloading/hlmain.html You wont be dissapointed | |||

|

| One of Us |

The Wilson trimmer can also be used for inside neck reaming, but I don't have any experience doing so. They do not offer an outside neck turner for it. If a reamer is being used to remove the "donut", the inside of the main portion of the neck forward of the donut should help guide the reamer. That may be one reason the K&M reamer has a very short cutting reason backed up by a long, non-cutting body, assuming the body and cutter are same diameter (I can't tell from the pic). It seems to me that using a sizing mandrel or expander button to "push the donut to the outside" will not completely work, since the thicker donut will tend to spring back differently than the thinner part of the neck, which result in a non-cylindrical surface on the inside of the neck. Not sure exactly how an outside neck turner will react to that. Andy | |||

|

| One of Us |

I love the Forster for trimming and have used one for 20 years. I prefer to turn the outside of the necks and for that I like the tool that Sinclair's sells. http://www.sinclairintl.com/cgi-bin/category.cgi?catego...m=NT-1000&type=store | |||

|

| one of us |

I've just got and tried the K&M outside neck tool on a couple of 270 WSM brass; unfortunately I couldn't get it work properly, according to my expectations. Luckily, the retailer agrees that I send it back and I'll have a refound. | |||

|

| one of us |

The inside neck reamer has as its only purpose thinning the necks of FIRED brass that is too tight to allow a bullet to be inserted. This is usually a result of using brass necked down from a larger caliber. The inside neck reaming tool will NOT address neck wall unevenness. This is done with a neck TURNING tool, which will both thin and even the neck walls. | |||

|

One of Us |

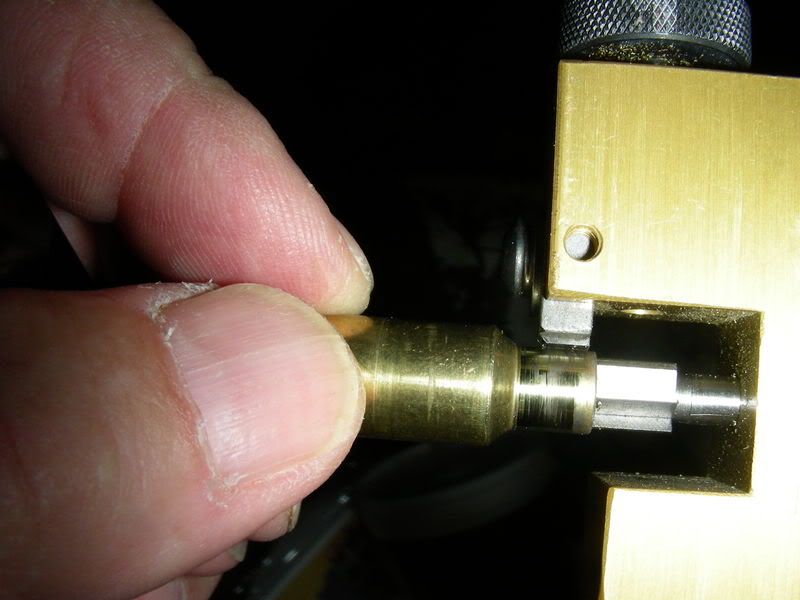

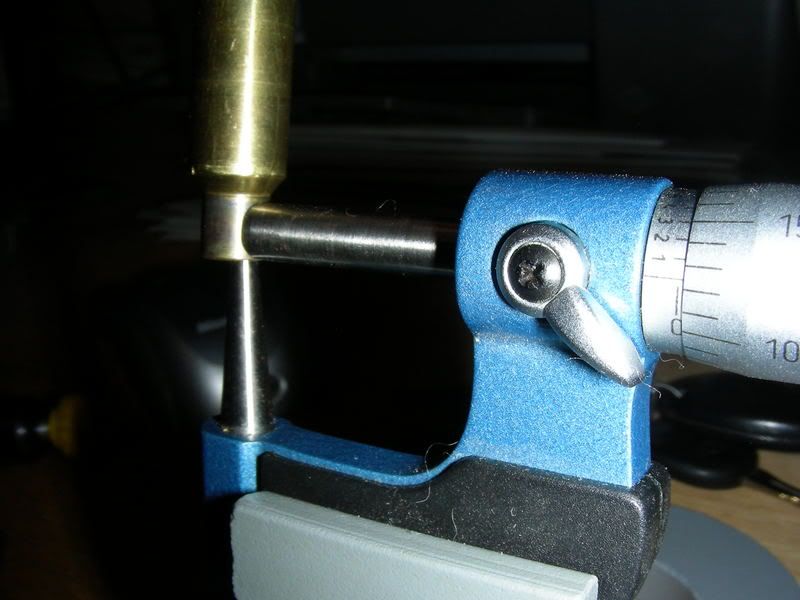

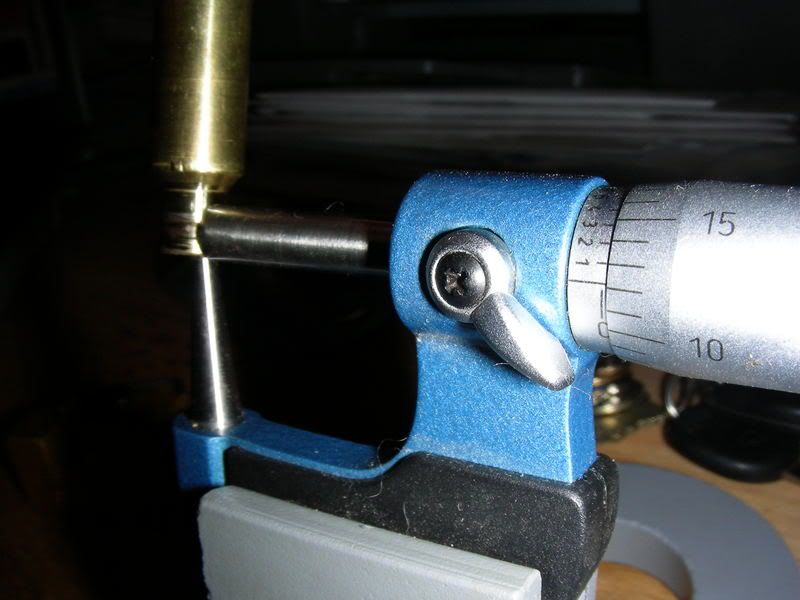

wildboar Was that the handheld Forster outside neck turner like in the pics above or was it the bench mounted turner?  ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Woods, it was the K&M handheld tool, not Forster | |||

|

| one of us |

I have one (Forster)...use it extensively for: 25-284 375 H&H to 300 H&H Cylinder brass to 400 Whelen (Improved) Here's my own invention to make it handier to use. Attached the reamer to a 1X8 board, about 14 to 18 inches long (with wood screws through the base of the Forster). Now, when you need to use it, anchor the board to the workbench with 2 of the plastic carpenter's clamps (they squeeze the jaws together with a grip/trigger) that you can buy at Home Depot. I use my cordless drill to operate the reamer, and then put everything away when done. Very fast and stable when clamped to the bench. Garrett | |||

|

| one of us |

That system works well. The only time I inside reamed was while trying to make .219 Zipper cases out of Thirty-Thirty brass. That's an ugly memory, but I eventually had sixty Zipper cases out of the 100 Thirty-Thirty cases that I started with. Off topic, but I should never have sold that lever actioned varmint rifle; it surely broke the tedium of days spent driving in fence posts and stringing barbed wire (searching for precious cases, too).  | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Forster case trimmer and inside neck turning

Forster case trimmer and inside neck turning

Visit our on-line store for AR Memorabilia