The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  I give up! I'll just buy my ammo!

I give up! I'll just buy my ammo!Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

What am i doing wrong? I am new to rifle reloading,and am trying to load 220 Swift. I have a Dillon 550 B with a set of Lee dies. The neck sizing die is kicking my ass. By the time I adjust it so I get enough neck tension to hold the bullet, it is starting to crush the shoulder. There seems to be no middle ground. Are the Lee dies too cheap? Should I buy a single stage press and keep using the dillon for pistol? I was told to buy a Redding bushing neck die. Should I buy the Whole set? Also I am looking for a mentor to help me. I live around the Wichita Kansas area. Any input would be helpful. Thanks, Chris | ||

|

| One of Us |

butts, sounds like either a case lube problem or you are not adjusting your dies correctly. OR your dies could just be crap. Lee isn't known for making the best of dies. You have a strange combination of equipment, an excellent, high dollar press and an el cheapo set of dies. But rather than me try to look into my crystal ball and guess your problem...you are on the right track looking for a mentor in your local area. Go out to the nearest rifle range or join a gun club. Shooters and reloaders are ALWAYS willing to help a brother. Don't give up! Reloading is too much fun and the Swift is a blast to load for. Just chill out until you can find a buddy to help. | |||

|

| one of us |

Not sure what you're problem is, I use lot's of Lee die's and they work perfectly. I also use a dillion, but only with pistol rounds. | |||

|

| one of us |

Chris: There is nothing wrong with the Lee necksizer die. If you look in the instructions that came with the die some times depending on the brass used you can't get enough tention. The cure for this is to chuck the mandrel ( the piece that holds the deprimer pin) in your drill and polish 1 or 2 thou off this will allow the die to compress the brass some more. Lee also offers diff. sizes mandrel for there dies. I find Lee dies very good Good luck Martin | |||

|

one of us |

Is the die a collet type? The Lee collet die has to be adjusted very carefully or the collet closes before the neck has traveled completely into the die. The die should be seated to just touch the shell holder and then turned a full turn and locked. If your neck tension is too light give it a 1/8 turn or two but NO more. Any deeper and the die will, as you`ve found, crush your cases. The mandrel (sp) can be polished down .001 with a piece of 600 grit emery useing a drill to turn the mandrel stem. Lee will polish the stem for you if you would rather not try it yourdelf. This may help, I`ve never had to do it with the two sets I have. Neck tension with these dies isn`t as tight as you`ll get with a regular neck or FL sizer but it should hold a bullet well enough you won`t push it any deeper by hand. | |||

|

| one of us |

you can also buy smaller mandrels from lee I think the best idea would to buy a regular sizing die | |||

|

| one of us |

I like the Idea of gtting a single stage press. I have a Dillon I used for pistol loads for years but i am going to sell it cause i don't load many pistol rounds. For your 22.250 the little RCBS partner will do fine andI think they got for about 40.00. If you want to load for a magnum I would get a ock chucker, I use the little lee auto prime for priming and I am on my second one after about 25 years of using them...tj3006 | |||

|

| One of Us |

If you havent got the patience to read a set of die instructions then maybe you should give up. There are plenty things about reloading that can go a lot more wrong than that. If you calm down and regain your composure, then take it slow and learn to do it properly. A few hours with a good reloading manual can make a world of difference in handloading. | |||

|

| one of us |

I have a set of the lee collet dies in 7mm08 and I havent had much luck getting accurate ammo out of them either. They are supposed to load really accurate ammo but they definately arent as easy to set up as regular dies either. I have some of the hornady new dimension dies and I really like them. I dont like how much pressure you need to put on the press to get the lee dies to work and there isnt as much neck tension as I would like. If you are looking for a press you should try out a Lee Classic Cast if there is one available, they are cheap and are getting a bit of a following it seems. | |||

|

| one of us |

What exactly do you mean by crushing the shoulder? Elaborate on what it's doing in more detail please? It's probably a case lube problem... You need to lube the outside of the case of course, but also the inside of the neck with myca. There's a slim chance your dies have a problem, but most likely it's lubrication. | |||

|

| one of us |

I have had that happen several times with my lee dies also, its not actully crushing the shoulder but colapsing it. It is actually kind of cool looking but definately ruins your brass. If its doing that to every one your collet thing might be stuck in the up position, If I remember right. | |||

|

| one of us |

Not to be too much of a smart ass: another case of a fellow jumping in with champayne expectations and a beer level of knowledge. Get you a single stage press -lee dies are fine-, some reloading manuals, AND READ THEM. There is no "open sez me" to reloading! Have you READ the instruction sheets on the press you bought??? Have you read the instruction sheets on the dies you bought? That would be a good start. | |||

|

| new member |

Thanks for all the hints. I should have given a little background on my reloading experience. I started to reload about 12 years ago. only straight wall pistol only. I have reloaded thousands of rounds. The only thing close to a bottle neck round I have reloaded is a .22 Hornet. I am wondering if I might have a bad set of dies. I tried to take apart the neck sizing die and could not get the mandral out of the body of the die. Should'nt it slide out without any problems? This one is stuck. | |||

|

| one of us |

Quote: I always recommend beginner reloaders start with a single stage press. As you are finding, progressive presses have lots of adjustments, ALL of which have to be right for the system to work safely and properly. A single stage press allows you to set up a single operation, get it right, then run through a batch of cases, then on the the next step, etc. Dillon makes a good press, especially for high volume pistol loaders, but I find the single stage works better for precision loading rifle rounds. YMMV! Good luck, and don't give up. This is a really rewarding hobby (obsession  ) when you get the hang of it! ) when you get the hang of it! | |||

|

one of us |

The mandrel should fall right out. The collet dies have a habit of locking up in the closed position. I don`t know with out looking but it sounds like yours is doing this. This could also be the cause of the collapsed necks you`re experiancing. I would tap the stem out (goes in from the top) if you have everything loosened up on my bench top, don`t force it. when you get the stem out polish the collet and all other "bearing" surfaces with 0000 steel wool or 600 or finer emery. Be sure to wipe them with a little grease or oil before reassembling. Check the archives for more on this with the Lee collet die. I`ve seen more then a few threads concerning this problem here and on other boards. Hope this has helped.................... | |||

|

| one of us |

I had that issue with the lee collet die in 300wm. Your die and decapping pin won't properly size the brass because it's neck wall thickness is a bit thin. You say by the time you get good neck tension you are cruching (pushing back) the shoulder. That is because the die body is too far down in the threads, and when the collet closes, the brass is deformed at the shoulder. Polish the decapping mandral down a few .001"s and then take a 1/2turn to 1 turn back off of the die body. The mandral will close with minimal distance past the point where it makes contact with the shellholder. It will only close as far as it can to push the brass against the mandral,..therefore, logic dictates that if the mandral is made thinner, then the necks will be compressed to a smaller inside diameter,..right?!! therfore, taking a few .001"s off the diameter of the mandral, you will size the neck down by that same amount, thus providing the neck tension you need to get a firm grip on the bearing surface of the bullet. If you insist on keeping the die body down too far,..you WILL blow that cheap ass aluminum cap right out the top of the die, and lee does not send them out for free. I had to pay $6 for a new one. | |||

|

| new member |

Do you think I should send the dies back? The only way to get the mandral out is to force it out with a hammer. It is in there and won't move at all! If I get it out should I polish it down a little bit? Again, thanks for all the info. | |||

|

| one of us |

Butts, I would buy an inexp. RCBS single stage press: it allows you to focus on one operation @ a time. Try a set of FL dies, I like Redding, RCBS in that order. Try partial sizing & see what kind of accuracy you can get. I agree, there is something wrong w/ your Lee die. I have a set for my .260AI, but I also have a set of FL dies as I one of the other guys said, sometimes the brass neck thickness won't allow the mandrel to size far enough down. Stay w/ it, if you shoot alot, it's worht the effort. | |||

|

| one of us |

butts,..first try soaking that decapping/sizing mandral in Kroil overnight and see if it loosens up. Before that, try some brake cleaner or parts cleaner to see if it is just hardened/thickened case lube or grease. Then go to the kroil around tha mandral. If this doesn't do it,..it should still make it easier to get out. Use a peice of wood or something to keep from bending or flattening the decapping pin portion. Then polish it down (even where it goes in so as to make reinstallation easier). Turn it down with snad paper while the mandral is chucked in a drill, it only takes a minute or two. remember to recheck it with the calipers often,..you don't want to take but a few .001"s off of it. | |||

|

| new member |

Beemanbeme, Sorry if I offended you with such an experienced question. for some reason I thought this might be a place to ask. I do not expect this to be "open sez me", I was just looking for some help. When it comes to my knowledge of rifle reloading it is neither champagne or beer, but absolute ziltch. I have read and read but the Lee info says nothing about adjustment when using a progressive press, and the Dillon info has nothing on collet neck sizing dies. Thanks, Butts P.S. I didn't think you were being a "smart" ass at all. | |||

|

| one of us |

I use Redding Dies I have tried a lot of other brand they work the best for me. I would say to call the Bullet Stop or the Bulls-Eye but they don't stock Redding dies. There is a gun show on Saturday at the Kansas Coliseum you might find what you need there. The Dillon press is great for pistol ammo but if you want to squeeze out all of the accuracy you are going to need a Single stage press like the RCBS Rockchucker. I have tried the Dillon 550 to load rifle shells, but the powder charge system will not meter stick powder with any degree of accuracy. I use an old Redding powder charger to get close and trickle charge from there. I believe in weighing every charge even though it may not be necessary it removes one more variable from the reloading accuracy process. One of the many reasons I reload is I know what is in each shell and can duplicate any load that my firearm likes. If you find a factory load that works well you won�t know what powder it is loaded with, and they claim it is not available to the public anyway. Good luck don't give up. | |||

|

| Moderator |

Like some others, I suspect the Lee sizer die is stuck closed, do a search here. You have a fine press with the 550B, also remember that you do not need to set it up to do everything at once. Personally I would get a regular sizer die and learn with that, brand isn't too important. Like others I think Lee equipment works good enough, there may be some issues with some items but they are a heckuva bargain. If they make the RGB dies in 220 buy a set of those, then you can use one crimp die as a bullet seater die and crimp with the other and not have to worry about good tension or buckled shoulders. | |||

|

| one of us |

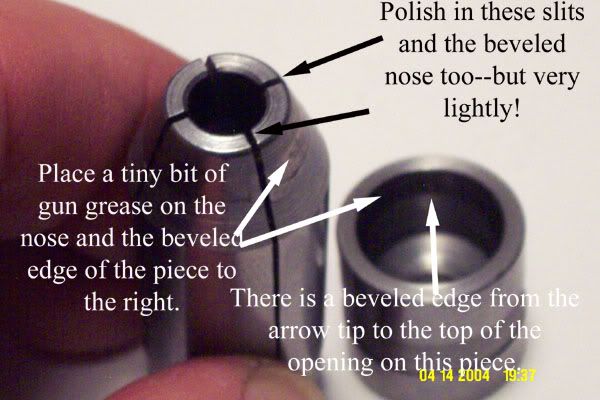

butts--I didn't really catch whether you have the Lee collet die or not. I guess I didn't read very carefully. However, if you do have the Lee collet die, does the following photo look like some of the "crushed shoulders" you said you got?  If yours look like the photo above, then your problem is that you have closed the collet fingers around the mandrel. NEVER, NEVER run the press ram into the full up position on a collet die unless you have a casing in your shell holder. If you run it up without a casing in there, you will most likely lock the collet shut on the mandrel. How do I know?   Yep, been there, and done that!!! Yep, been there, and done that!!! Sometimes the fingers on the collet have some rough edges where the cuts are between the 4 fingers. There may be other rough spots on the collet as well. I would recommend taking the collet out (if you can get it out) and lightly polish the slits between the fingers. Then, take some light gun grease and place that on the nose of the collet. I have not had any problems with my collet die since I did these steps. I do, however, take the die apart once in awhile and clean it out and then put some more grease on the collet nose. Here's a photo illustrating where to polish and where to grease. I hope this helps you. If it doesn't, perhaps you should go with some type of Redding neck sizing die. I just purchased the Redding Type S neck sizing die with the bushings for my .204 Ruger and really like that setup.  | |||

|

| new member |

Silverfox, Stay out of my trash!! Yes thats what they look like! I will try what you suggest. My only question is what do you use to polish? You guysare great, thanks for the info. BUTTS | |||

|

| one of us |

If the die frustrates you, go buy a regular die. Also, as stated, you don't have to use the press as a progressive, and always scale measure your powder for rifle loads IMO. | |||

|

| one of us |

remember that even after you re-open the collet and polish it (something I do on all my collet dies before use) you will still need to polish the mandral down or you will see the same lack of neck tension even after the die is operating correctly. They aren't made to the most exacting tolerances, but when they are tweaked, they do load staright ammo. I bought a set for a factory 30-06 (no need for expensive dies) and after loading, the rounds are ALL at .001" runout or LESS. If I don't use redding or wilson dies, I'll experiment with the lee collet dies, especially for sloppy factory chambers and non-competitive rifles. They do work once you get them set and tweaked. | |||

|

| one of us |

BUTTS--I used 400 grit Wet-Dry sandpaper for between the fingers, on the nose of the collet and the part that forces the collet fingers closed. As the final polishing step, I used 0000 steel wool over the collet nose and the part that pushes on the collet fingers. Make sure you clean those parts very thoroughly after the polishing. Don't forget to put some good gun grease on the nose of the collet and the part that forces the fingers closed. Do the greasing thing often and you shouldn't have any more shoulder collapses! Good luck and let us know if you got things working again. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  I give up! I'll just buy my ammo!

I give up! I'll just buy my ammo!

Visit our on-line store for AR Memorabilia