The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Lee Collet/Redding Body die ?'s

Lee Collet/Redding Body die ?'sGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Okay, so the way I understand it, the Lee Collet die has a specifically sized mandrel in it (probably .002-.004 smaller than bullet diameter) that is centered in the die. As the ram is raised, the shellholder contacts a collet, which is forced up and in, squeezing the case neck around the mandrel. This prevents overworking the brass, compensates for differing brass thicknesses in the neck (without alot of different bushings), and eliminates that nasty expander ball that pulls necks out of alignment. At this point, the neck has been sized but the case has not, hence the need for the redding body die which FL or PFL resizes and decaps without touching the neck. Now for grins, lets assume a fellow already has a Redding FL sizer die with the expander ball, and was trying not to buy a $25 body die for all these cartridges he already has, because he is already having to buy all those collet dies. Could he chuck that FL die up in a lathe and minimally drill the neck of that die out so it wont be touching the neck anymore, turning it into a body die? Oh yeah, the sizer button would have to be reduced where it wasn't doing any work either, you could polish it down or just substitute one from a smaller caliber. Is there a reason this method would not work? I realise the die body is going to be hard to drill, but just how hard are we talking? Is it doable at all? Cobalt bit? | ||

|

| one of us |

Yes you could "make" your own body die. It could be done with any full length die. However I seem to remember that the manufactures harden the die after they machine the die. This would require something beyond "...mimimally drill the neck of that die out...". Sounds like a grinding operation to me. Best question is why ruin a good die that costs more than a body die? muck | |||

|

| One of Us |

Well let's just say I'm in the research phase of finding out how I want to change my system, and am playing the devils advocate to try and understand everything to my satisfaction. I realise it is probably not the best way, and may not even be possible without grinding/lapping, but inquiring minds want hear some opinions on it, if for nothing more than from an acedemic standpoint. Probably my simplest solution in reality is to ditch the expander ball and just turn the necks on my cases to fit using woods method. But right now I'm still | |||

|

| One of Us |

They will drill out fine with a HSS bit, I have done a couple and they work well | |||

|

| one of us |

Why drill? Just cut the top of the die off above the part that resizes the case body...that is, at the juncture of the body and shoulder. First remove the expander stem and ball and discard. I'd use a cut-off wheel in a chop saw. | |||

|

One of Us |

Hey JT Looks like Mike A has your answer that they will drill out with the proper bit. onefunzr2 has an idea but you would have to cut it off at the neck/shoulder junction not the case/shoulder junction. You would have to get the cut off just right in order to get the hole the exact size or you would have to do some drilling anyway. But you would ruin the dies for using the method we've all been talking about with turning necks. It might be cheaper to invest in a hand held turner that would do all your different cartridges and leave the FL die as is but remove the expander stem. Then you could have the Lee Collet to neck size as long as possible and the FL die sans expander to push the shoulder back when needed. Outside neck turning is no big deal and one of the processes I look forward to. You only have to do it once for the life of that case. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

Is now a good time to admit to already owning a Forster outside neck turner with all the pilots? | |||

|

One of Us |

JT, I'm already ahead of you, slightly. On my Dillon 550, I punch the primer w/ a Universal decapper die in station 1. In station 2 I run my 260 Rem brass through a Redding FL sizer with the decapper removed and just set the shoulder back about .002". In station 3 I run the case through the Lee collet neck die and seat in station 4 w/ a Redding BR die. What I'm probably doing is oversizing the neck in station 2 w/ the Redding FL die. Accuracy still seems to be top notch. I'm about to order a 308 Win body die this week and will probably just go ahead and order a 260 Rem body too. Alan | |||

|

One of Us |

Then just get the Lee Collets and you are set to go. The Lee Collets are perfect for expanding the neck to the right dimension for the Forster turning mandrel. So with the new case you can use the Lee Collet to set them up for turning and then neck size with it until you need to push the shoulder back and then use the FL die sans expander. Or if you want the greater bullet grip from the start then size with the FL after turning. But you probably got all this figured out already. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I did an experiment with my .223 last night. I pulled the expander out of the die and risized three cases with it. On each case I took 2 measurements 90* apart, for a total of 6 readings, avg was .2423. I took 3 loaded rounds and did the same, for an average of .2470. Difference was .0047, or nearly 5 thousandths. Now I have read on here that .002-.003 is about right for neck tension, and you can find that information other places as well. Another thing I have read on here is that you start getting greater runout again when you get up in the neighborhood of .007-.008 neck tension due to the pressure it takes to seat the bullets bending the neck out of alignment. I seem to be right in the middle of the two numbers, but unfortunately do not have a tool to measure runout. Of course, you can just shoot them, but all you could prove would be positive results, if it shot better. If it didn't you still would not know if it was runout causing the problem or if that was just as good as that rifle was going to shoot. How hard is it to set that Forester trimmer to take off just .002 or so? I dont have the hand model, it is the one that attaches to the bench and uses a crank. Whenever I have used it I have just set it to clean 50-75% of the necks, because none of my guns are tight necked. I have never really tried to hit an exact number. | |||

|

| one of us |

outside neck turner Forster claims .0001" accuracy. But you can't just turn a dial to the desired outside diameter. It's by trial and error, measuring after each cut across the neck's length. I've done it. You'll get the feel of how many parts of a revolution on the carbide cutter equals .001". You only need make the initial adjustment once...then the remaining case go through quickly. | |||

|

One of Us |

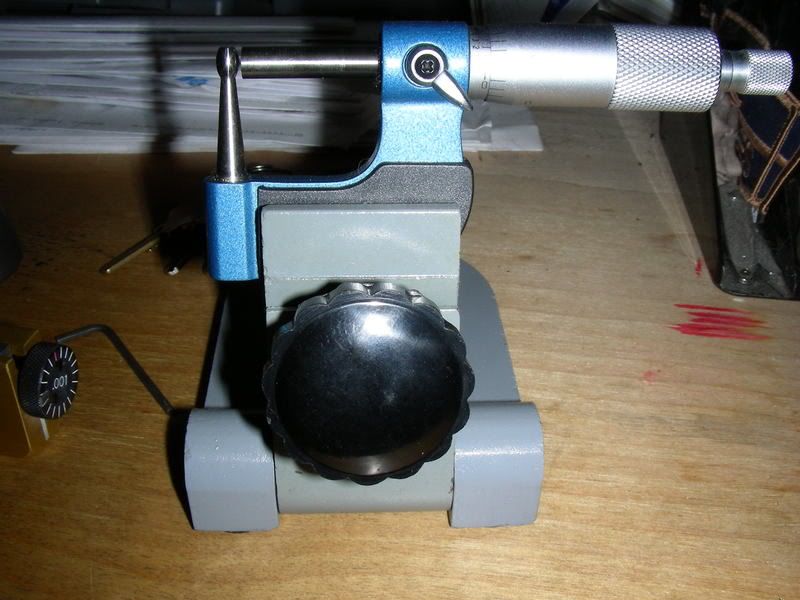

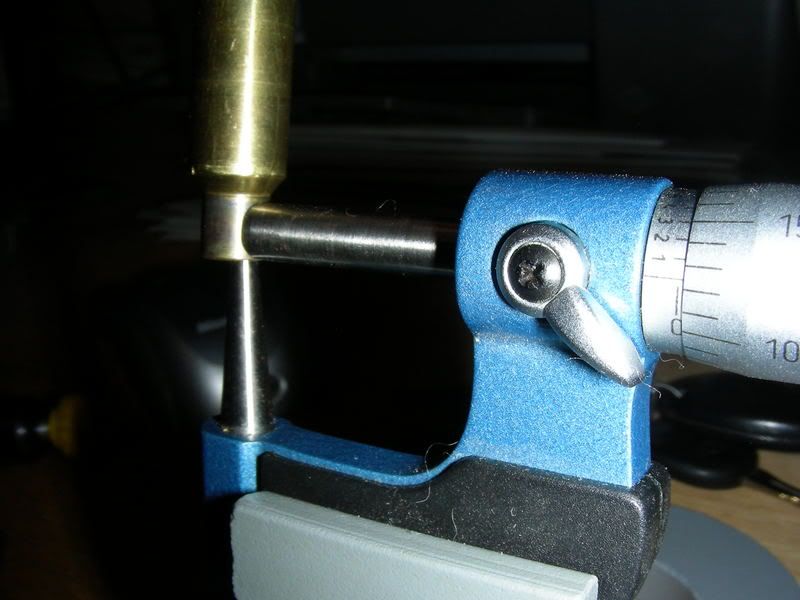

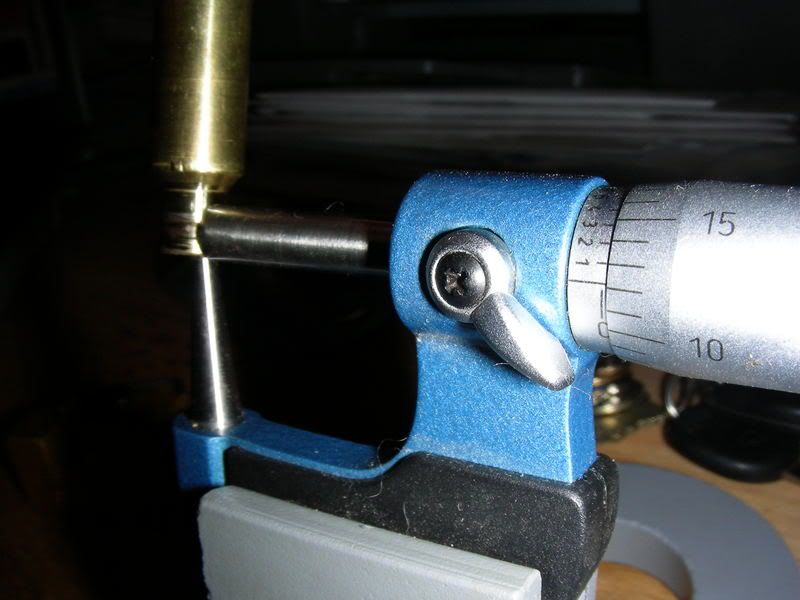

Hey JT IMO the most important part of being able to turn your necks to a specific thickness is a good way to measure what you are doing. I had a hard time until I got a ball micrometer and a micrometer stand  You can measure easily down to .0005" as demonstrated here where I cleaned the case from .0125"  to .012"  I'm not sure how well you are going to be able to do with the bench mounted Forster. The one I had trouble with was the Lyman and I never got consistant turning but I would think that it would depend upon how tight your mandrel is in the neck. With the bench mounted units you have to lock the case in and it may not be perfectly aligned with the mandrel shaft and you could force it a little off center. With the hand helds the mandrel is not forced one way or the other by the case head being locked in. Is now about the time you tell me you already have a micrometer and stand? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

No, I really don't have a ball mic and stand. Also on my list to get is 1/2 lb of cerrosafe. I have some questions about a couple of my chamber/die relationships that I really want some answers to. A freind of mine is doing an order next week so I am going to have him throw that in on his order. I have a 7x57 with a problematic chamber, and I want to do some experiments with it before I just sent it off and have it fixed. If it's going to cost me, I at least want to learn something from it. I think the bench tool will probably do what I need. The Forester is supposed to be the best of the bench tools I beleive. Probably what would help more than anything would be to run it through a lee collet first and get that neck straight. All I have had before was the dies with expander balls and they may have been pulling the necks out of line and making the tool run out of true. Lots of experimenting left to do. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Lee Collet/Redding Body die ?'s

Lee Collet/Redding Body die ?'s

Visit our on-line store for AR Memorabilia