The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Forster Co Ax has me stumped

Forster Co Ax has me stumpedGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Been using a Forster Co Ax for years and like it. The first thing I did was to install the optional plate that allows you to use regular shell holders. The only thing I don't like about using regular shell holders is they sit up so high some die sets (like the 327 Federal) can't be screwed down low enough for them to work properly. Today, being bored decided to re install the adjustable shell holder that came with the press and decided it is a royal pain in the ass to try to put a case inside the shell holder. Or is there a technique I am not aware of? My biggest fear is when I die my wife will sell my guns for what I told her they cost. | ||

|

One of Us |

I use two of them. Love them. Why these are so great is the die changes are a snap and with the jaws your brass can float and self center in the die. What I think you are missing is the screw with a point on it that you probably took off when you put on the adapter plate for the use of regular shell holders. The point on the screw opens the jaws at the bottom of the down stroke, opening the floating jaws. Mac | |||

|

| One of Us |

Ahhhh........Didnt see a screw in the package I saved with the original adjustable shell holder. In fact, now I remember one of the reasons I went with the shell holder adapter plate was it was a pain using the adjustable one. I think Forster forgot to either supply me with a part or need to take a closer look at the press to see if it hiding anywhere Thanks My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

One of Us |

Not next to one of my presses. But from memory the screw is about 5/16" diameter and about 1.5 to 2" long or so. And its black. Mac | |||

|

| One of Us |

Doubled checked everything as I had all the parts stored in the same place and the press didn't come with the screw. Contacted Forster and they are sending me one but am surprised they charged me for it. I read the instructions numerous times and never made the connection there was a screw that opened the jaws. Thanks again. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

I've had my presses for 48 years now. Would not use any other for long range shooting. I believe it is the best single stage press ever made. The amount of force it can develop is amazing. There are two screws in the shell plate platen. The one on the front side is to adjust the "resting" space of the two jaws to allow the point of the "opening" screw ( rear) to move the two jaws apart. Having this distance set will help prevent bowing of the shell holder frame. With the full set of "jaw" types,there is no cartridge case you cannot fit providing it will not exceed the opening. Gulf of Tonkin Yacht Club NRA Endowment Member President NM MILSURPS | |||

|

| One of Us |

That screw does have to be adjusted properly. I have had my CoAx for years and consider it a superior choice. I used it exclusively when I competed in 1K BR and I did very well, winning lots of matches, setting club records, shooting screamer groups, etc. The only thing I don't use it for is for bullet seating with my 450 Nitro--it's a tad tight for that through I can seat 338 Edge bullets with it. You should especially like your CoAx because the color almost matches your GS. | |||

|

| One of Us |

I've used a lot of different presses. Many of them were just as powerful (or more powerful) than the Co-Ax, and some of them I equipped with spring-loaded universal shell holders to save the hassle of changing shell holders for different cartridges. The one great advantage to the Co-Ax in my view is the ability to mount it n top of my bench without having the handle EVER hanging off the bench. That's why when I recently put all my RCBS and other presses up for sale, I kept my Co-AX. I will probably never load another round of ammo but if I do, my Co-AX is sitting there out of the way on top of my bench, waiting for me to come back to play with it again. | |||

|

| One of Us |

No need to talk me into the Co Ax as I had this one for about 5 years and love it. I think it is the best press on the market. But I do use my RCBS ammomaster for the big boys. Should of asked more questions when I first started using it and would of found out I was missing a screw. My wife has been telling me that for decades My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

couple more thi gs - the "screw" is a stainless stud with a tapered end to spread the jaws. besure that when paying around with the jaws that you keep track of the 2 little springs- they like to go spronging out into the nowhere if you're going to do short cases you can put in a longer stud to open the jaws earlier thus making the handle stroke much shorter also don't forget there are 2 sets of jaws available one with actually fit a 470 case with a bit of playing. the screws holding the jaws don't want to be to tight or they lock the jaws, hence they will work loose during use and if you are working big stuff you can bend the jaws a bit, but they straighten right out again with a slight wap with a hammer if you'd really like to know the history of the whole thing let met know | |||

|

| One of Us |

butchloc how do you get it to fit the .470 case (500 Nitro etc.)? I have looked at the setup and couldn't work out how to make it work! Cheers, Chris DRSS | |||

|

| One of Us |

I use mine for sizing 450 Nitro cases, and I use the LS jaw set--I think I might have had to buy my LS jaws separately... | |||

|

| One of Us |

you use the 45/70 ls jaws and kinda cock one end in and then the other. seating is make shift too. you geetthe case in the jaws and then hold the bullet in the die a bit and slide the die into position- sounds complicated but to anyone used to jack work its really simple | |||

|

| One of Us |

As much as I like my Co Ax it just doesn't do a good job with the really long cases like the 9,3x74R, 375 H&H, 450/400, 450 NE, etc. With the Ammomaster the ergonomics are better and the window is large enough to insert cases from one side as the other hand controls the handle from the other side. No pinched fingers. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

One of Us |

I agree I don't use the Co-Ax for long cases. I have an ammo master as well but I think that is too big. I do most of my Nitro case loading on a Redding Ultra Mag Press and some on a Lee 50 BMG cast press. Mac | |||

|

| One of Us |

@Snowwolfe & McKay: Are your Forsters B-2 or B-3 models? I understand that the newer B-3 supposedly has a bit more room. | |||

|

| One of Us |

I have never had an issue with loading 300 RUM, 338 RUM, 300-338 RUM, 416 Rem, 375 H&H, and 500 NE with my CoAx. They all fit fine. The NEs do require the LS jaws. With the LS jaws the NE cases easily fit in the shellholder without having to bend or wiggle anything. Now the 450 NE, having a 3.25" case, is too long for bullet seating but sizing is just fine. I am not sure which model CoAx I have--I bought it 12 or 13 years ago. I use a Rockchucker Supreme to seat my 450 NE bullets and that is all I use the Rockchucker for. I used am Ammomaster extensively for 7-8 years and it just wasn't precise enough for me--mine had a lot of slop in it. The only other issue with the CoAx is it's hard to use Redding competition dies for anything longer than around a 300 Winny. The top of the die won't clear the opening in the handle in some situations. | |||

|

| One of Us |

Don't know as I can not find any model markings on mine. Anyone know where they are marked? My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

Thanks for looking. I called Forster. They aren't marked. They lady on the phone couldn't give me the exact date or time when they switched from the B-2 to B-3, but she did confirm that the B-3 does, in fact, have more height or clearance. She said that "with the yoke up" the B-2 measured 4" whereas the newer B-3 measured 5.5" ... so an inch and one-half difference, according to her. | |||

|

| One of Us |

Mine is about 4.25 inches. If they did indeed change it to 5.5 inches it would be a damn near perfect press and makes me want to buy another. Did she give you any idea when they changed them? Because mine is only about 6 years old My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

+1000 | |||

|

One of Us |

Not sure on the models of mine. But my older one has the old small yoke and the newer one is the taller yoke so you can use longer competition dies. Mac | |||

|

One of Us |

I would guess it was 4 to 5 years ago that they changed them. Mac | |||

|

| One of Us |

Funny you should say yours is 6 years old. When I called, I sort of told the lady a "little white lie." Basically, that I had an opportunity to buy a used press, but I was concerned about overall cartridge length, and that I heard the new presses were better for longer cartridges, and I didn't want to buy the used press, only to be disappointed and end up having to buy a new press. When she asked how old the used press was, I said I thought it was about 6 years old, and she replied that it was probably a B-2. She said she didn't have the exact date or time the new press was introduced; there were no markings; and the easiest way to tell was to measure with the yoke up. | |||

|

| One of Us |

Time to get a couple of the B3's on order and sell the old one as well as the Ammomaster Now it makes sense how some of you could easily load the big boys. For you guys that have the B3 model what is the measurement from the base that holds the shell holder to the bottom of the piece where you snap in the dies? That's the area I measured that was 4.25 inches. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

FWIW, she also said that they just sent a shipment of presses to Grafs, and a quick check does show them in stock. | |||

|

| One of Us |

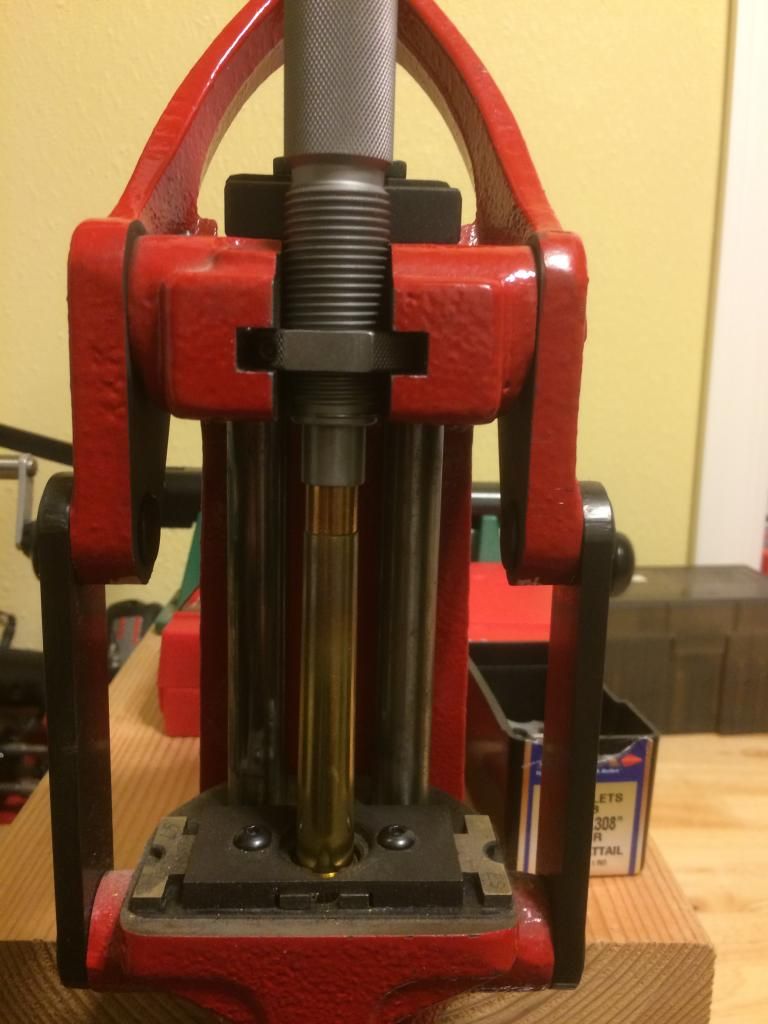

Mine measures 4.1" from the top of the press to the inside of the yoke.....meaning two things. One, I have the old one and the old one works fine for loading all the big boys I have loaded with it. The opening from the where the case rim sits to underside of the press to is 4.23". On the Rockchucker Supreme, the opening is 4.16". The reason the Supreme can seat the 450 NE better is because there is more room to adjust the die upward. See pics. Number two, I now MUST have the new one...................    | |||

|

| One of Us |

I ordered one from Grafs earlier today so hope it comes in before I head over to Tennessee to deer hunt. Not sure what I will do with the B2 model. It could be set up just for 204 Ruger and .223's or I might sell it. Regardless, I'll post here when I get a chance to compare them side by side. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

mine is only a year or so old and was on backorder for a couple months, so i am pretty sure it is the newer model, measure about 4.25 from plate to yoke | |||

|

| One of Us |

If that's the case my old one was the B3 and the new one will be also, lol. Maybe I jumped the gun. My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

If you look at the pic of the new model at Graf's, and then look at the pic of mine, you can see where the yoke is a little longer on the new model. | |||

|

| One of Us |

We will find out when you get your new press, I would like to have two, just keep the old one! | |||

|

| One of Us |

Press arrived and the one I already owned is a B3 model as well. So now I have two! My biggest fear is when I die my wife will sell my guns for what I told her they cost. | |||

|

| One of Us |

Bummer! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Forster Co Ax has me stumped

Forster Co Ax has me stumped

Visit our on-line store for AR Memorabilia