The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  annealing cases ?

annealing cases ?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I'm curious as to other peoples ways or techniques of annealing cases ?. What are the best methods ?. Does anyone make a multi turret station annealing machine ?. That's reasonable to purchase ?. Thanks ... | ||

|

| one of us |

The subject came up recently and there was a multi turret machine in one of the post. Try Varmint Als site for some annealing info also. | |||

|

| One of Us |

Here's the recent thread: Recent annealing thread The consensus of this thread, with which I agree, is to stand the cases in a pan of water, torch the neck of one case, tip it over into the water, and then move to the next case. Varmint Als also has good stuff. LWD | |||

|

| one of us |

If I wanted brass for extreme accuracy I would let new brass age a few years or purchase new brass that has been sitting around for over 3 yrs.I think I wil order brass asap for my Lott. | |||

|

| one of us |

I think one of the reasons I've been having good luck with annealing for the last 5 or so years is because I use one of Todd Kindler's (small caliber news, woodchuckden.com) annealing tips. After all this time, I finally realized it's just about impossible to over heat with that gizmo, and it heats necks very uniform. Sometimes even a blind hog finds an acorn.... FWIW, Dutch. Life's too short to hunt with an ugly dog. | |||

|

| one of us |

I've been annealing case necks for years using the same method outlined at Varmint Al's using a propane torch in a dimly lit room. My Case holding/spinning tool of choice is a Mechanics flex-finger retrieval tool, the four little jaws grip the rim securely, and it's easy to spin the cartridges without dropping them.  Wherever you go, there you are! | |||

|

| One of Us |

From what I've read and practiced over the years there is a whole bunch of bad misinformation regarding annealing brass . Now don't jump down my ass ,I'm simply going to attempt to explain a bad method !. When brass becomes work hardened it becomes brittle . Heating brass then dumping it in water does the same thing !. Only the neck and a touch of the shoulder ( assuming rifle cases and there is a shoulder ) is to be heated to 660 degrees . Then set aside to cool not chill quenched by liquid !. Now 660 - 750 degrees works but 665 is Ideal and is extremely close to factory annealing in most cases ( No Pun intended ) . Someone told me about a turn table with a two torch set up ( one inside one out side ) of the turn table suspended above the cases . Small precise tips direct heat evenly . It would need to have an empty slot or indexing station . So as to fire the torches start the rotation of the table and turn X number of times . Depending on the size or capacity of the table and or size of cases to be done . Once temp. is reached shut off . Portable infer red temp gun could be used to monitor the cases furthest away from torches . So as to correctly know case temp. and not have to guess !. Does anyone know of this unit or if anyone even makes it ?. My friend said he didn't remember where he heard about it or saw it !. If no one has it !. I may just put a retired tool and die buddy of mine on building one !. After all he used to build proto type machines for Japanese company's !. Before CAD designing Computer hard ware for HP . Then making some of the stuff for them to boot !.He has the talent and then some !. ... | |||

|

| one of us |

That quenching routine never made any sense to me either. You quench steel (and other alloys) to HARDEN, then draw carfully for temper. Why should brass be any different? | |||

|

| One of Us |

Let me also add if your cases turn orange or red you've ruined them !. As that is in the 900 degree heat and above range for brass !. Metallurgy says 665 is IDEAL !. Up to 750 will work but shortens use full life of case !. I checked with a Friend in that line of work he agreed 665 is the correct temp. On the neck shoulder area ONLY !... | |||

|

| One of Us |

Correct !. Chill Quenching makes it brittle just like steel !. In steels case you can over come brittleness by heating and oil dunking for case hardening or water hardening or ?. But it's a totally different animal than Brass !. With the cost of Brass as well as everything else sky rocketing . I figure buy the Best Brass and just anneal it after 5 -8 reloads time after time . As long as it doesn't grow real bad , it should last 30 - 60 reloads or more !?. | |||

|

One of Us |

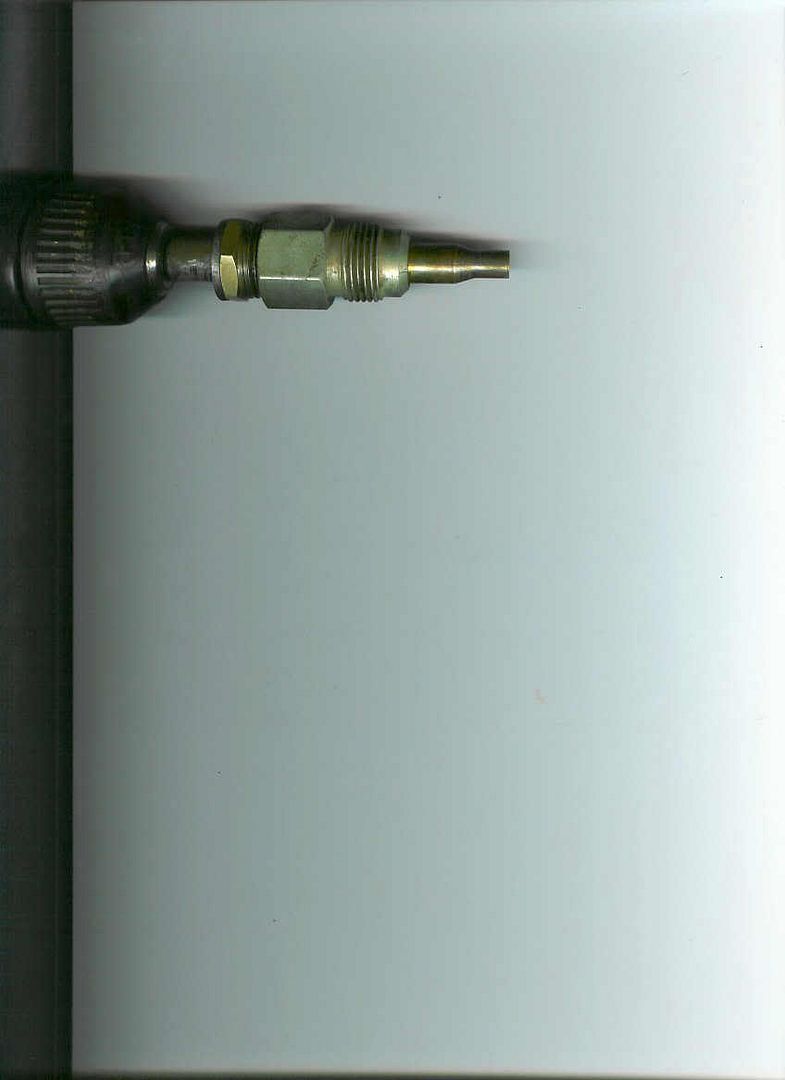

Hey Doc This is probably what he was talking about. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

WRONG!!! | |||

|

| one of us |

I agree with Hot Core on this one. Steel is a ferrous metal. Copper and brass are nonferrous metals. Heating a ferrous metal to a point where it "starts" to turn red then quenching it in water will HARDEN it! Heating a nonferrous metal to a point where it "starts" to turn red then quenching it in water will soften or "anneal" it! The two types of metals are opposites! Chuck - Retired USAF- Life Member, NRA & NAHC | |||

|

| One of Us |

I have some old engineering text books from the 1950's although my training was in 1970's. I bought them for 50 cents each when the school was selling of old books to make way for new ones. They have color charts showing approximate temperatures of various metals as they are heated. Using that info I anneal by using a small butane torch and heating to a "Pale Straw" color before quenching in water and have never had a problem. Red in my opinion is too hot. I ony heat the neck and start of shoulder, basically where the heat tracks to before quenching. Have a look at a Lapua PPC case which shows the annealing marks, I do about the same on my other wildcats that need doing. Also be careful to heat evenly and not get any hot spots. | |||

|

| one of us |

I use the Templaq indicator kit, and put a small dab just below the area being annealed. The case is spun with an electric screw driver using the case holder which comes in the kit. As the case spins, The neck and a bit of the shoulder is heated by a small butane torch. As soon as the Templaq melts, I dump the case into a bucket of water. This method works like a charm and only takes a few seconds per case. I even had a tool maker friend fabricate a case holder for the nitro express rounds. When done, the cases look just like the Hornady factory cases. Try it, it's easy and it works. Geronimo | |||

|

| One of Us |

Well ; I see this is exactly why so many articles and books are written on this subject . I received an E mail this morning from a Gentleman in Finland from Laupa !. They never use water or any other liquid to Chill Quench their brass !. Counter productive is the phrase he used !. He also informed me that the Temp. on brass was about right . They do a Dbl technique which he was not able to elaborate on for obvious reasons !. Bringing Temp of brass up then allowing to cool works for a longer use full life . So long as that heat does not travel down toward the case head !. A friend had been using the OLD Water Pan method for Years and Years !. After I convinced him to try another method ( Reluctantly I might add ) he now knows absolutely for a fact it works better than the OLD method of tipping them over in the water pan . He has a few calibers which he case forms for . Bought the necessary forming dies , followed their instructions to the tee !. Old method 7-8 out of 10 necks were splitting while fire forming ! ??. On the good ones he would get maybe 3 - 5 at most reloads !. Now he has NO neck splits !. What's even more impressive now he is able to reload those cases ten times more than he was able to reload his other good cases !. Have any of you tried NOT Dunking them in water !??. | |||

|

| one of us |

I got a templaq marker for the right temp , but the thing is basicaly worthless. It wont mark good enough on the brass and its hard to see it melt. Color change of the brass is easter to see than the templaq. I use a low speed drill held to the torch setting on the table, Get the right color(dark garage) tilt the drill with (Home made) brass holder/heat sink and drop into a pot of agua  | |||

|

One of Us |

Quite frankly All this inconsistancy in information is the reason I don't anneal dunk it in water don't dunk it in water use tempilaq don't use tempilaq if you heat it till you can see the color change then you've heated it too much heat it till you see the brass start to glow I get consistant bullet release by careful bullet prep and thouroughly steel wooling the inside of the neck. I get 8 to 10 reloadings out of brass and toss it because case head separation would be a worse problem than hard necks. JMHO ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

I might decide to do an annealing test on 308 cases.I will heat the necks only to 650 F and then let them cool naturally.I will then take these cases and fire them and see if there is any increase in accuracy over cases that were not annealed.I will use a Fluke IR thermometre I have to determine when the necks get to 650. | |||

|

| One of Us |

I've never annealed brass, but heating and quenching stainles steel** anneals it- and I have done that to large forged SS discs, to be machined into gears. since SS steel contains much non-ferrous metal, I think the quench method would extend to brass, but that's an uneducated guess. **and I can't testify as to what type of stainless it was. | |||

|

| one of us |

The BIG problem in doing it this way is protecting the Case Head from the Heat. If anyone out there tries this, BE SURE to use some form of a "Heat Sink" to prevent the Case Head from getting too hot. Nothing wrong with "new ideas" when people understand the consequences of trying to prove something that has the potential of blowing their firearm to pieces - due to too soft of a Case Head. Best of luck to you folks. | |||

|

| One of Us |

Alright guys! ya made me get my engineering books out, especially "Metallurgy Theory and Practice" and do some research on brass, (tough on the old brain). Accordingly, Yellow or Cartrige brass, being cold worked has a Tensil Strength of about 100,000 psi, annealed has a strength of about 48,000 psi. So! when ya form or size brass you are cold working the brass, and making it brittle, (but ya all knew that). " Annealing may be carried out by heating the cold worked brass to a temperature range of 1100 to 1200 deg F followed by cooling at any convient rate. The rate of heating and cooling is almost without effect on the size of the newly formed crystals." So there you have it. Sorry if I offended anyones pride. Mike "An armed man is a citizen, an unarmed man is a slave", Ceasar | |||

|

| one of us |

I kept getting bad lots of WW brass that would split or get cracks or pin holes in the neck after once fired. So I started experimenting with anneling. Varmint Al's web site has a good right up on anneling. Brass is different than steel when you quench it in water. Quinching brass DOES NOT make it brittle like steel! Brass is a different animal. Read Neck Anneling Here: http://www.varmintal.net/arelo.htm#Anneal I played around with junk brass , watching the neck change (sweaty looking to dull red to red). Then also tryed a 600F Tempilstik marker, the crayon pencil type. Tempilag also comes in a liquid like a nail polish container that might work beter on brass , but noone carryed the liquid here local. I found it easyer just to watch the neck change than try and see the templaq mark melt on a spinning case. | |||

|

| One of Us |

Hey do what ever works for you or you think works for you !. I never said you couldn't stand the cases in a pan of water !!. Why knock them over ?. It's a safe method of keeping the case head cool !. As for 1000 - 1200 degrees Well you do that !. Not I !!. I trust people in aerospace who's ass is on the line if their wrong !. I'm going to trust Nammo Laupa !. Seems to me they know what their doing . Why would it be necessary to rapid cool the cases ?, what advantage is in that ?. We all seemed to agree " Heating " to a proper temp. makes the brass softer and less brittle , so does it shorten reloading life if Chill Quenched ?. I for one believe it does . There for no longer intend to do it the old way . My shooting partner is convinced on his fire forming it works better , Simply by testing it !. He also informed me because he has read several books on the subject if you wait to see any other color than black grayish you've waited to long . He has a pile of Orange , Red , Red Blue cases that are now junk brass from years of experiments !. He has more obsolete caliber military and civilian cartridges than any body I know . So he's had 40 years of practical experience in doing it . How hard do you think it was for me to get him to change his time tested procedures !??. Ever been in a Bar ? , Ever asked for credit ? Ever see the sign ? See our credit manager Helen Wait ! ? . Almost that hard !!. | |||

|

| One of Us |

I would like to PERSONALLY THANK " WOODS " as I have just looked at ; Sorry I didn't see that link sooner !. ( Hey Doc This is probably what he was talking about. ) I would suggest everyone look read carefully as to what they have written . This is a CORRECT METHOD of Annealing Brass !!!!!!!. | |||

|

| One of Us |

This does seem to be a dark art to say the least. I read the elongated, but informative piece on 6mmbr and I gave up even trying. I wanted to go down the route of annealing for the 17 Rem and the 22-250AI as these two split necks regularly with new brass. The AI is using Norma and I still get the problem.The .17 is using Rem cases and these spilt about 5% per batch. I would not take this to the degree of the wheel system and this seems (from what I read) to be the only reliable way of annealing. DW | |||

|

| new member |

| |||

|

| One of Us |

Burgie: Very good article. That kind of explains it in easy to understand language and a good key on getting the temperature right. "An armed man is a citizen, an unarmed man is a slave", Ceasar | |||

|

| One of Us |

What is white ?. What is Artic White perhaps Nordic White or egg shell white ?. Now let us examine the color Red , Fire engine or Blood Red Orange Red , Crimson or how about a Red Hot Poker too the Eye perhaps ?. Do you see where I'm going with this ?. Perception of Color is just that !. A false sense of Color rendition . Color by Name is what ?. Someone else's Perception of what they believe that color represents !. A Value of BTU is a GIVEN !. As is Fahrenheit , Celsius , Kelvin !. I want a Temp. Value as to know exactly how much heat is enough not a Color value !!. That is why 665 degrees is Ideal . 15 minutes at that temp over all is not how ever !. So more heat on the neck less time for heat to travel down the body !. " Woods " is correct check out the link !. One can use a infra red Temp. gun and now know HOW MUCH TEMP ! Is the correct amount of heat !. When forming cases it's an absolute must !. Least wise for brass life and reloading that brass !. Other wise one ends up with split necks fractured body's or case head separation !. To much heat makes brass to SOFT and the above things happen also !!. I used to be one of those dark room squinter's waiting for color then dunk in the bucket guys !. I also used to shoot some sorry weapons , until I learned about newer better more accurate ones !. I also shot factory Ammo ( Say it ain't true ) Yes I did !. Until I knew better !!!!!!!. | |||

|

| one of us |

This is an Angels-dancing-on-the-head-of-a-pin argument. I have annealed cases (for years) by standing them in a pan of water, and in a dark room, heating the case mouth to a dull red with my propane torch, and then knocking them over into the water. I know 5 or 6 other reloaders who do the same thing. The cases are good for another 5 or 6 hot reloads after that, sometimes more (like the 35 Whelen A.I.) No doubt I've ruined these hundreds of cases by improper technique. And, no doubt it's been just blind dumb luck that none of these cases have let go in my rifes or my friends. If it didn't work for quite a few of us reloaders, it wouldn't have survived as a technique. High pressure quickly seperates "safe" from "unsafe" technique. Garrett | |||

|

| one of us |

For all the Beginners/Rookies out there, Dr. K. would seem to have a valid point - except for one small thing - it isn't all that critical. A few years ago on a different Board the "preacher howl" got would up on Annealing and droned on and on and on.... An extremely astute Handloader presented howl with the infamous "howl C.A.R.E.T. Award". That stands for howl being able to Complicate Any Relatively Easy Task. Old preacher howl can take wiping the sweat off your brow and turn it into a 10,000 page compilation of totally worthless Blather. Basically, Dr. K is making waaaaaaaaaay too much of a relatively easy task. Many simple methods,which are outlined above, work very well to get the Case Necks Annealed. It's just not all that difficult to do. Best of luck to all you folks. | |||

|

| One of Us |

Echo that Hot Core! Just do it if it needs to be done. | |||

|

| One of Us |

The only thing I can say about this thread is I cringe everytime I see someone mention Varmint al! I take nothing that man says as gospel! Some people say what they think! Then there's those that say what they know! And then there's those few that want to know everything! | |||

|

| One of Us |

I have a problem with the 665 Deg F. temp reccomended, unless your talking the C scale. As an Engineer and having been in charge of the metallurgy and heat treatment where I worked, that temp is way out of range for getting the crystilne structure of the brass, caused by work hardening to recrystallize. If that temp was given by an engineer of some foreign brass mfg co. it most ceartinly was in the C deg scale. As stated previously; setting the brass cases in a shallow pan of water, will protect the case head from being softened. A soft case head will loose strength which could be a problem when firing a high pressure round reaching above 48,000 psi. At 48,000psi there is no safty factor for cartridge brass other then the sourounding barrel. The case head being work hardened and the strength may increase to 100,000 psi. I have used the method of setting cartridges in a shallow pan of water and heating them to a dull red with great results myself. and I would reccomend using this method, the accuraccy of the temp for annealing brass is not that criticle, so a slight varaition in the red color is not that important. For those who wish to persue this matter further, might I recommend " Machinery Handbook" or "Metallurgy Theory and Practice" by Del K Allen. Mike "An armed man is a citizen, an unarmed man is a slave", Ceasar | |||

|

| One of Us |

Point was to get Maximum life out of Brass safely by annealing !. Why buy Lapua or RWS when Winchester is cheaper !. I for one NEVER said the OLD method didn't work !. It's just to much variation for my liking is all I said !. Necks and shoulder become to soft if heated above 850 F. I never said they wouldn't work !. Just not real well or long enough for my purposes . Heres a real test do you're annealing techniques and form cases like in a case former then fire form them !. See if the Neck splits or shoulder or ?. If they don't well your lucky , now see how long they hold up to firing !. 10 , 20 , 30 , 40 times ?. Remember opinions are like assholes everybody is entitled to one !. ... | |||

|

| one of us |

I only anneal cases that require a significant amount to effort to form (i.e. not easily available). When these cases finally do fail, it is never split necks. The primer pockets just feel too loose to me as I reprime them, so I throw them out. These are of course cartridges that are pushing the upper envelope of safe pressure. I realize that if you were loading for some older, historic cartridge the issues of significant pressure wouldn't apply. In that case I am sure you could load them 20 or 30 times. I do have a number of historic firearms, but I don't shoot them so much that I have to worry about brass failing. Garrett | |||

|

| One of Us |

I along with several shooting members were having trouble with exactly what you described ( Hard to get or Expensive Older obsolete rounds ). So forming was our only option !. Failures on fire forming were astronomical in terms of splits necks or shoulder problems . This is why I wanted to know everything I could about " Proper " annealing . We had been doing it the Old method for years and years . Now we are quite pleased with this uniform method of annealing . In our case we have about an 90-95% success rate as opposed to 20-30% at best with the old way !. Least wise in our case any way . Shoot straight know your target ... | |||

|

| One of Us |

Regardless of annealing or not annealing, 1 thing I have found with forming cases is to shoot them as soon as possible after putting through dies to complete the forming. I have found the die formed cases crack while sitting around loaded. Once fired they seem ok and I am guessing the firing also provides some sort of stress relief to the brass. I am particularly referring to .17 Ackley Hornet but have noticed the same with a few others to a lesser degree. | |||

|

| One of Us |

I don't anneal anymore. | |||

|

| one of us |

I don't Anneal any less. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia