The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  30-06 accuracy issues

30-06 accuracy issuesGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

Hi there, this is my first post, and im brand new to the reloading scene. Basically I've just started reloading for my 30-06. I've reloaded some nosler 180 grain ballistic tip and some hornady 165g ballistic tip. For both loads I am using ADI powder: ar2206h. It is equivalent to the following: Hodgdon: H4895 Imr: IMR4895 Accurate Arms: AA2230 Vectan: Tu 3000 So here is my problem... Using the absolute cheapest factory ammo i can find... federal 180g lead points i shoot a one inch group at 100 yards... Using my hand load stuff the bullets end up about 6 inches to right and about two inches down at 100 yards! and the group size is awful. about 2 and 1/2 inches. What i've done... For both projectiles bullet seating depth has been achieved by putting a projectile into a spent shell so it's quite lose fitting, and loading it into the gun. I then remove the bullet and press the bullet in 1/16 of an inch more. ie I have a 'jump' of about 1/16 of an inch which I've heard is a good starting point. for the 180g nosler im using exactly 43g of 2206h and for the 165g im using exactly 45g of powder. Basically i dont know where to start? do i change the amount of powder, is the bullet seating depth wrong, etc etc Any help is going to be appreciated greatly! Thanks in advance, Steve Edit: *Using federal primers *Using Remington brass *Savage stevens rifle *Adi suggests that my muzzle velocity with the amount of power I'm using will be about 2500fps for the 180 grains and 2690fps with the 165 grains. *Bullet run out looks absolutely fine | ||

|

| One of Us |

Welcome, DU. First, you might give us a little more info-rifle, brass, bullets, etc. What do the loading books say your velicity should be? One of the things I check first is bullet runout. It's easy to check, and lots of handloaders don't even think about it, but it can play havoc. Runout is, simply, whether the loaded cartridge is straight or not. You can buy devices to measure this, but if you can see a lot of wobble when you role a round on a smooth surface, you have it. For load testing I use the ladder method. Many comp. shooters do, too. Works like this: Prepare 8-10 rounds with charges increasing from, say 53.5 grains to around 57 grains, in .3 or .5 increments. Shoot starting with the low end. Have a duplicate of your target on the bench. Using a spotting scope, mark each hit on the duplicate. You will like3ly find that somewhere in the string the bullets will make a group. Saves a lot of powder and shot. General advice: Obtain and read several loading manuals Don't hesitate to ask questions here. Most will have been discussed already, so do some searching. Most fun I ever had was shooting possums in Tasmania. Thump! Thump! | |||

|

| One of Us |

CAUTION, DU. The grain weights I mentioned were just theoretical. Do not exceed book loads. | |||

|

| new member |

Glad you enjoyed the possum shooting... there is something special seeing them hit every branch on the way down... did someone say sadistic? lol Anyway, i added the information you requested and checked my run out, looks fine to me... Are you suggesting that my problem lies with the amount of powder im using or you're just saying thats where i should start | |||

|

| one of us |

AR 2209 would be a better powder. You seating depth is Ok for starters. Bullets hitting low right from factory mean you need more powder as you are not at maximum charge weight now. Your loads with AR2206h are right in the middle of start and max. You can safely go up 1/2 gr at a time with your AR2206h, worth a try before changing powders. The more pressure, possible better accuracy. Learn pressure signs, like hard bolt lift, flattened edge of the primer, or primer flowing into and arould firing pin. Shiny ejector mark on brass head. Different bullets may give different pressures than what are listed here. http://www.thalesgroup.com.au/...ders-guide/rifle.asp | |||

|

| new member |

Thanks heaps 243. I will pump out some hotter loads and let you know how i go. I will also do some reading on pressure signs. Cheers, Steve | |||

|

| One of Us |

My first step for seating would be to set my seating depth with a factory round. That way you have the same overall length as the factory round with the same bullet. Then run both yours and factory over a chronograph to get the same velocity. Once you copy the factory round then change one item. Either charge weight or seating depth. Once one is at it's best then play with the other. The other way to play with powder is to copy the round for seating then do a ladder test to determine a powder charge. Check this out for ladder testing http://www.washtenawsportsmans...loads/incredload.pdf A bad day at the range is better than a good day at work. | |||

|

| new member |

Thanks for the reply sam. Unfortunately I don't think your idea will work in my situation as the federal 180 grain soft point projectile is a completely different shape projectile to my nosler 180g and completely different again to my hornady 165g. So simply by measuring overall length will not insure that i am achieving the same jump as the factory rounds... Thanks anyway. Also, at this stage, I'm pretty happy with a 1/16 jump. I've spoken to heaps of people about it, and they all have pretty much agreed that it's the best place to start. I'm also going to give that ladder test a go. Seems pretty handy and its only 20 shots. beaut! | |||

|

| one of us |

Seating depth. Start with the base of the bullet at the neck/shoulder junction. If a boatail bullet, the full diameter of the bullet should be at the neck/shoulder for starters.Then do your powder increase testing. When you find what grains powder works best, then try different COL. Read about "Partial Full Length Resizing" also. | |||

|

| new member |

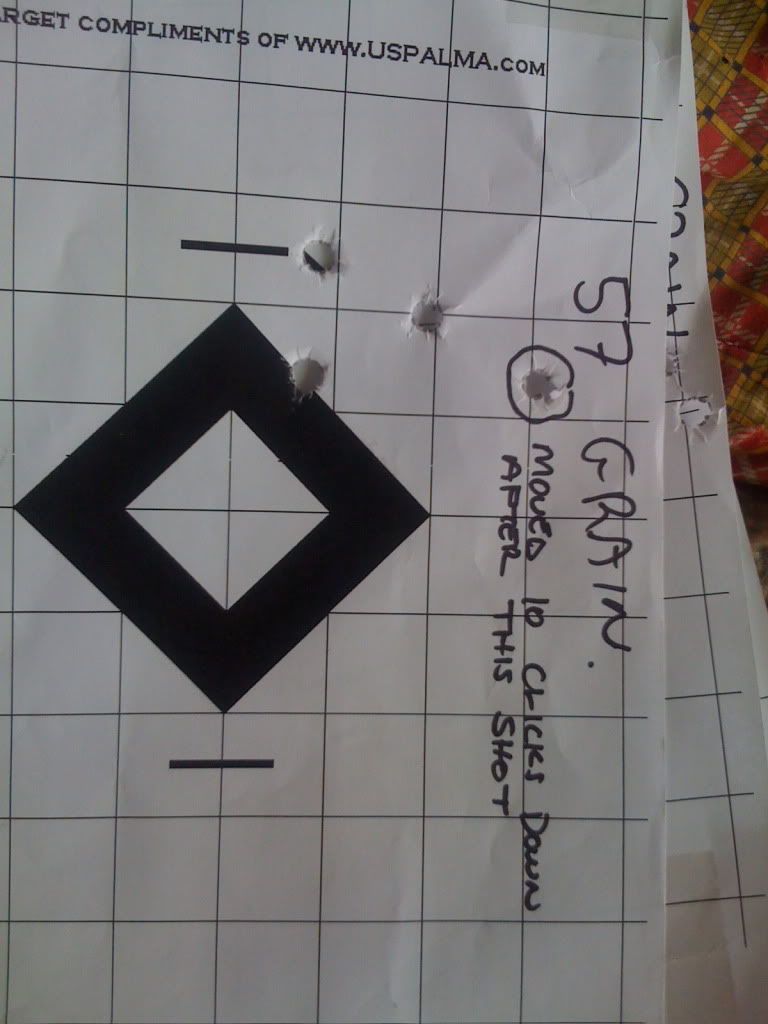

Right-i-o... 243, read up on partial full length resizing, and I've just got back from my powder testing. I'm am so fucking confused as what to do now... Here are some photos...    These shots were at 100 yards When i reloaded for the .22 hornet, i shot the factory ammo, and then shot my loads, and the only thing that changed was the groups got tighter. Here it moves 6 inches?!?! The only thing I can think of is the powder... I really think this 2206h is the wrong powder. When i reloaded the .22 hornet the projectile touches the powder when seated whereas my 30-06 has quite a larger 'air' gap. If I use 2209 powder i will be using almost 10 grains more. I also noticed that adi recommend 2209 for the 30-06. The only reason I have the 2206 because that's what the guy at the gun store told me to use. So with that information in mind, i want to know what you guys think! Once again, any help/suggestions will be greatly appreciated. btw, thanks for all the suggestions from you guys thus far. Steve | |||

|

| one of us |

DU, you have just experienced a totally normal shooting and reloading snafu: 1) the price of ammo has no bearing on how it will shoot in a particular rifle. If the cheap stuff shoots well, smile and be happy. 2) any load and any bullet means a new hand of cards in terms of POI and accuracy. If the load you have put together for your rifle does not shoot, try another bullet, or try another powder. H4895 (or the Aussie equivalent) is on the fast side for the .30-06 in any event, try to get hold of the equivalent of H4350, and your burn rate will be more suitable to the caliber and bullets you are loading for. Even when you do eventually find a handload that shoots well in your rifle, there will be ZERO guarantee it will shoot to the same POI as another (e.g. factory) load. It would be nice if all loads shot to the same POI, the sad truth is, that it is more the exception than the rule that they do. If loads happen NOT to shoot to the same POI in your rifle, you'll have to make up your mind what you want to shoot with this particular rifle, or bear the expense (ammo, time, barrel life) of resighting your rifle as appropriate. We all have our tricks and beliefs about what works in handloading. Personally, I doubt any amount of fiddling with parameters such as run-out and seating depth is going the shrink your group size from 2.5" to 1-1.5", say. How do you size your brass?? Do the bullets seat with (reasonable) consistency in terms of neck tension (or does one bullet seat seat noticeably lighter than the next)?? What brass are you using?? If cheapo factory brass reloaded, take a deep breath and see if you can get hold of some high quality stuff such as Lapua. It might be hard to stomach the expense at first, but it can do wonders to your group in my experience. From your ladder testing it is kind of hard to suggest a load "node", but one does notice that there seem to be a lot of impacts in the area of 44.8 - 47.5 grs. But then again, I think your powder will not produce the best velocity for you, so maybe testing more with this powder is a waste of time. Your call. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| new member |

Cheers mho for that impressive response As far as sizing brass goes, im using all lee stuff. I'm doing full length sizing, a collet sizing die and a lee bullet seating die. All bullets feel very even when seating. It's Remington brass that Im using... As far as powder, I totally agree with you. I've spoken to some people here locally and the general consensus is I'm wasting my time with this powder. Would you suggest I do another test like the one I did today with the the 2209 (H4530 equiv.)? Cheers Steve | |||

|

| One of Us |

Eventually, you'll decide what works for you. I don't use the ladder method. For cartridges the size of 30/06, I start at the lower end of published recommended loads and work up in 1 grain increments until I start approaching maximum recommended loads at which time I switch to 0.5 grain increments. I load 3 cartridges with each load and use them to shoot 3 shot groups. Usually, groups get smaller to a certain point as a load is increased and then start to get larger again. The load I select is where the groups are smallest. I then test loads of 0.3 to 0.5 grains on either side of the best load found and shoot more groups of the apparent best load to be sure it's really the best. You say you're full length sizing and also say you're using a collet sizing die. A collet die does not full length size; it only neck sizes. Though I've found Lee Collet Dies to work well many times, I have a gun in which cases necked sized with a collet die produced ammo quite a bit less accurate than that produced with new cases or cases full length sized or sized with another type of neck sizing die so, it's possible your die is responsible for some accuracy issues. | |||

|

| one of us |

DU what you have to realise is that each rifle is a law unto it self .LIKE WOMEN! ignore what all your mates say about seating depth etc etc, your rifle is an individual and treat it as such As far as the 06 goes you are not useing the optimum powder, start with H4350 ...2209 R19,R17 R22 i have shot out more 06 barrels than you will fire shots through your rifle, so if you need a hand drop me a line, but to start with chose one powder , and start from there, also another suggestion dont waste your time with 150 and 165 gn proj, get a good 180 /200 gn proj and work up a full power load and go hunting....i sugest the 180 /200 gn partition Also what length barrel does your rifle have as a matter of intrest Get some H4350 behind a 180 gn proj start at 53 grain and work your way up to 58 grain, fire 5 shots with each powder incremet increase, and see how it groups , and rememberKEEP THE BARREL COOL dont over heat it, and in a few hours you will know if you have a good load Daniel | |||

|

| One of Us |

I have been working on loads for a 458 Lott recently and with a couple of powders it shot the solids 3-5" below the soft nose even at the same velocity. I then tried IMR4320 and the solids and softnose shot to the same point of impact as long as velocity was close to the same. I have several 25-06's and in one I load a 100gr Swift A-Frame, in the others I load a 100gr Sierra. In all of them, the Sierra's impact 4" below the Swift bullets even though they are all pretty close in velocity. I think you should try two or three powders and shoot 3 shot groups to see what powder and load the rifle likes best. Unless you use the same bullet type as the factory ammo, your point of impact will most likely be different. | |||

|

| one of us |

Change powder to AR2209. Seat bullets as i said above. For a 180 gr start in the middle of the powder range listed, this would be 54.5gr. Load at least 3 rounds, i load 5 and shoot for group.Then increase powder charge 1/2 gr. at a time looking for accuracy. Dont matter where the group forms on target,compared to factory. DO always full length resize when testing. This makes the brass the same each and every time. After you find a load to you liking, then play with the collet die. | |||

|

| new member |

Try Hornady 180gr sp flat base bullet, start at mid-charge, and work up towards max load. I have a Savage 30-06 barrel that does the same. It will not shoot boat tails, but will shoot moa with flat bases. My load is 57gr H4350 and 180gr Hornady SP Isa 42:6 | |||

|

| One of Us |

Hi down under, Looking at your target each round is of a different load, normally i would load 5 of each load, shoot 3, let the barrel cool then shoot two. I would then evaluate which load produced the best group, there should be no need to emulate the factory load on a scoped bolt action. | |||

|

| new member |

Well well well. Once again an overwhelming amount of information provided by you guys!! So I've condensed what you guys have said and basically you all want me to change to 2209 powder, and no longer continue to us the collet resize die, only use the full length die. Also you want to drop that style of ladder testing suggested by sam, and use the convential 4-5 shot groups with .5 grain increments. Also I wanted to ad, none of the above shots were done with a hot barrel. Ample time was given between shots to cool the barrel. Well i'll be doin all of this throughout the week, will post up pics when I'm done. Steve | |||

|

| one of us |

DU, nothing wrong with the Lee Collet die. It produces very straight ammo for little cost. It is not particularly strong in producing consistent neck tension, though, so you need to verify whether this is the case for your reloading setup. The Collet die sometimes has problem producing sufficient (and consistent) neck tension - e.g. if it is used with work hardened brass. Check that sized cases hold bullets firmly (press point of seated bullet against the side of a table does it move?) and check how seating bullets feel. If that feels consistent in terms of forec needed to seat bullets, you are probably good to go with the Collet die. If not, follow the die instructions and polish down your mandrell with .001 - .002", that will normally provide the tension needed. That said, some rifles react well to neck sized (and thus tight fitting) brass, and others prefer brass sized FL or partial-FL. Sadly, nobody will be able to tell you from afar, so you have try this out.

I personally like "ladder type" methods for load development. It is good way to try to minimize components and time expended coming up with a new load. What I found difficult in your data, is that a single shot says comparatively little about POI of a GROUP - and group POI not shifting (too much) is what you are looking for with ladder methods. A single shot could have been pulled and thus distorted the data. Shoot 3 shots per group, and see what POI does. Personally, I would probably have started with somewhat less load variants, just to save on amount of components used for load development. So varying loads in increments of .3 grs is very fine grained. You could also load in 1 grain increments, and once you find a load you like refine to 0.5 or even 0.3 grs steps around that. You may also choose to start 2-3 grains below book max, and try to work up from there. It is rare (but I admit it does happen), that minimum book loads are needed to be safe in your rifle. Another way to save a bit on your components and barrel budget Don't worry, we have all gone through load developments that did not work quite as planned from the start. It is often a matter of gaining experience, and you'll benefit form past snafus in the future. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| One of Us |

I ladder style test is not a bad thing, it can tell you alot. It is usually where I start, so I know where to look to start refining my loads. You can do the same thing by shooting 3 shot groups as well, main thing you are looking for is point of impact shift. What happened to the 46.9 charge weight when you shot it? It may just be me, but I'm not seeing it... Reason I ask is because 46, 46.3, 46.6 asnd 47.2 all go into a pretty good group, and I suspect you may be finding an accuracy node around the mid 46 grain range. That is where I would be looking from what I see on your target. Get your powder charge and bullet combo worked out first, IMO that is 90% of getting a good load. I wouldn't worry about seating depth yet, you should be in a range that is okay. Maybe tune it later, but get the big things taken car of first. Good luck. | |||

|

| One of Us |

Let me take another stab here, and see if you can follow where I am going with this. Look at your target, and you will see all the shots in the 43 range somewhat go into a group. This appears to be the lowere accuracy node. As the charge weight increases, the barrel begins to vibrate differently, and the bullets are exiting the barrel at the wrong point in the vibration cycle. 44's and 45's are going all over the place, spreading all over the target. As you get up into the 46 range, things are tightening up again. You are getting back into the right vibration node again, the higher node. That is what you are looking for. One test is by no means definitive, you need to test some more. Don't worry about them impacting the same as factory rounds, you can adjust your scope later. Try and find a place where for several charge weights the bullets want to land in the same place. That will give you a good stable loads. Take that area, load some three or five shot groups and test it further. Tune it in. Hope this helps. | |||

|

| new member |

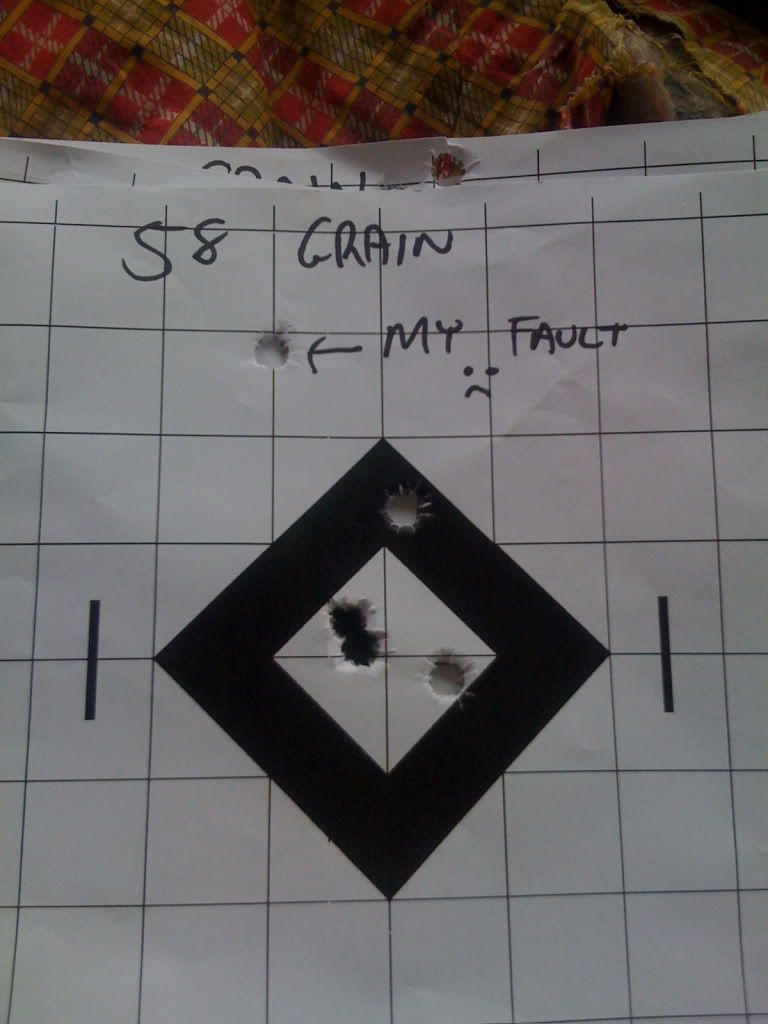

Just came back from the range and finally I started seeing some good results. I'll let the pics do the talking.      I'm reasonably happy with that group size on the 58g sheet. However, I am keen to hear your thoughts on improving my results further still. earlier on in this topic mentioned my .22 hornet and the fantastic results i got with my handloads. I'd love to get similar results for the 30-06. This group was done at 100 yards.  Thanks again, Steve | |||

|

| one of us |

try useing federal 210 primers what weight proj were you useing take your target out to 300 and then 500 and see how it groups | |||

|

| One of Us |

IMO, the best advise in this thread is to switch to 4350 powder. Work up a good load behind a 165 or 180 and you're good to go. My loads FWIW are 57gr 4350 behind a good 164 and 55grs of 4350 behind a good 180. Not barn burners by any means but my experiences have been that the '06 doesn't react well to hot rodding. The '06 is so accomadating that the more exotic methods one hears that are needed for accuracy, aren't. I have an '06 that shoots common old Core Lokt bullets better than any others. Aim for the exit hole | |||

|

| new member |

m98- for this bullet testing i was using federal primers... That pics are a bit misleading. I'm almost out of them so I went to buy some more and i couldnt get federal, they were out of stock. 165g proj wasbeeman- if u read up a bit i have changed powder to 4350. and these pics are the results of that... | |||

|

| One of Us |

Down Under, good job. As to primers, I've switched around amongst the standard primers and once again the accommadating '06 showed an indifference. Switching to magnum primers may give a more radical POI. Aim for the exit hole | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia