The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Correct diameter for inside neck reamer

Correct diameter for inside neck reamerGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

Hello, I am forming some 8x57rx360 cases from 9.3x72r brass. When I finish the new brass the inside neck diameter is around 0.304-0.305. The jacketed bullets I'd like to use are 0.318. What should I be reaming the inside neck diameter to?? I am going to be ordering a reamer from Forester. Thanks in advance, rudyc "It's a good day for something" | ||

|

| One of Us |

Do you know what your chamber neck diameter is? Seat a bullet and compare the neck of the loaded round to your chamber diameter. Your loaded round needs to be .004 to .006 smaller than the chamber. If you have to thin your neck turning is a better process since the turning tool is adjustable. | |||

|

| new member |

I have an older loaded / live RWS 8x57r/360 round that chambers with no problem, it came in the bullet trap of the gun. The outside neck dia of that round is 0.340 When I mic the newly formed brass with a .318 bullet seated in it, the outside neck dia is 0.350. The new brass is noticeably bulged and will not chamber. "It's a good day for something" | |||

|

| One of Us |

Right on! Plus, you can use a mandrel in the outside neck turning tool the same size (or very nearly so) as your bullet...then turn the outside of the neck to the diameter which gives you the clearance you want/need for the loaded round. And unlike some neck reaming assemblies, the outside neck turning tool will make the brass the same thickness all the way around the neck, and concentric with the center axis of the neck...both nice add-ons. My country gal's just a moonshiner's daughter, but I love her still. | |||

|

| One of Us |

Rudy: I form .400/.360 2 3/4" Purdey NE from RWS 9.3X74R brass. This is done by running the 9.3 case through a standard RCBS .400/.360 FL sizing die, then trimming from 2.93" to 2.74", then they're ready to load. Sizing the 9.3 case sets the shoulder back slightly. In old lots of RWS brass, the brass in the shoulder was thicker than the brass in the neck, so a "belt" formed in the bottom of the neck that had to be removed. I ordered a reamer from Foerster, but found that it could only be used with a fired case. I was using 300 grain spitzers then that wanted to be seated out for best accuracy. This meant that they weren't seated deep enough to contact the belt formed from moving the shoulder back, so I just fire-formed with full powder hunting loads, and reamed after firing. If you can fire-form before reaming, a .318" reamer will work. That said, if the inside of the neck is uniform, and the thickness of the necks isn't too great to permit normal chambering with a .318" bullet seated, then there's no need to ream. If the brass in the neck is too thick, but thickness is uniform, you're better off turning than reaming. ---------------------------------- "Serious rifles have two barrels, everything else just burns gunpowder." | |||

|

| new member |

Just put it through the first (sizing / caping) die and then used the seating die to seat the bullet. It bulged when seating the .318 bullet. Maybe I'm missing something. There is a .318 expander die that came with the die set. I thought it was only for use with a cast bullet. Will I need to use it for jacketed bullets also? The inside diameter of the neck is .304-.305. Won't running it through the expander die just bulge it like what happens when the bullet is seated. rudyc "It's a good day for something" | |||

|

| new member |

Hey Ray, "Why do I get the impression that you've never reloaded before?" What's the deal? Was that really necessary?? I come here looking for some help and you gotta throw sand in my face?? I have loaded for 7x57, 7-08, .243 and several others, without ever having the problem I'm having now. I don't know anyone nearby who had formed their own cases so I thought I'd ask here in this forum. I have never had to form my own cases until I came across the 8x57r/360. "DID YOU KNOW THAT YOU CAN BUY FACTORY 8x57-R360 CASES?????" I tried to buy cases from several different sources and was told by most of them that they did not make the cases anymore. Not enough demand. The one source that would sell them wanted $100 for 20 cases and he said he made them from 9.3x72r cases, so I thought I'd give it a try. Really sorry to have burdened you, Ray, with my "rookie" questions. "It's a good day for something" | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| new member |

I just finished using the 0.316 expander die provided by C&H. When the bullet is seated the outside diameter is now 0.346 I believe by turning .002-.003 off the case I'll get what I need. Thanks to all that have replied. rudyc "It's a good day for something" | |||

|

| One of Us |

Will your .346 diameter case necks chamber? | |||

|

| one of us |

rudy I sure didn't mean to throw sand in your face. It was a legitimate comment in my opinion. When someone asks if they need to use an expander ball for jacketed bullets it does make me wonder. Don't your dies for 7x57, 7-08, and 243 come with an expander? Try Huntington's for the brass. Sorry if I offended you. Ray Arizona Mountains | |||

|

| new member |

No, they do not chamber. The go down to about 3/16 from the extractor. "It's a good day for something" | |||

|

One of Us |

Hey rudy That's a hard problem to wrap your head around. One thing is that the Forster reamers only come in certain sizes. Those sizes are .0025" to .003" over standard calibers. The closest to you is the for the .323" bullets which means it should be .326". The closest one underneath your caliber would be the one for the .311" bullets which should mean it is .314". If you can work it out with outside neck turning to get the right neck thickness that should work better. If your loaded OD is .346" and your bullet is .318" then that would mean .346" - .318" = .028" /2 = .014" neck thickness If you can expand the neck to .316" then that will give you .002" bullet grip which is just fine. Then you can turn your necks to whatever thickness you want and will fit in your gun. Do you have a fired case so you can measure the OD of the neck and see what kind of clearance you have with a .346" OD? Most custom chambers are made with .003" clearance or most turn the necks to give .003" clearance. But you already figured this out, haven't you? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| new member |

Ray, I too, am sorry for my response to you. I am also thankful for your help. I have no experience with a 3 die set. All the dies I have ever used were two die sets. The set from C&H is the first for me with a separate expander die. rudyc "It's a good day for something" | |||

|

| new member |

Don't have a fired round. The gun is a 1929 drilling and the only brass I had was the RWS loaded round. Now for the next question: What neck turner do you fellas recommend? I have a Forster trimmer and I think they make a neck turner attachment for it. Any others?? "It's a good day for something" | |||

|

One of Us |

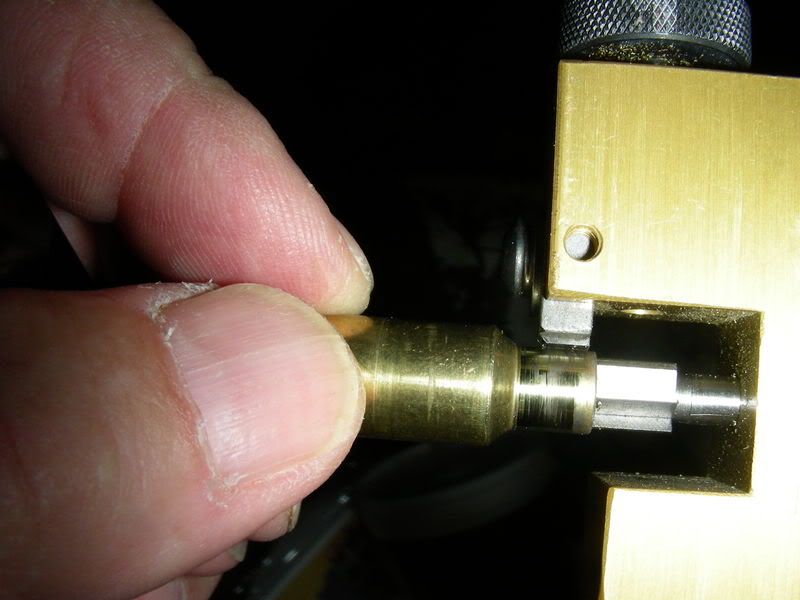

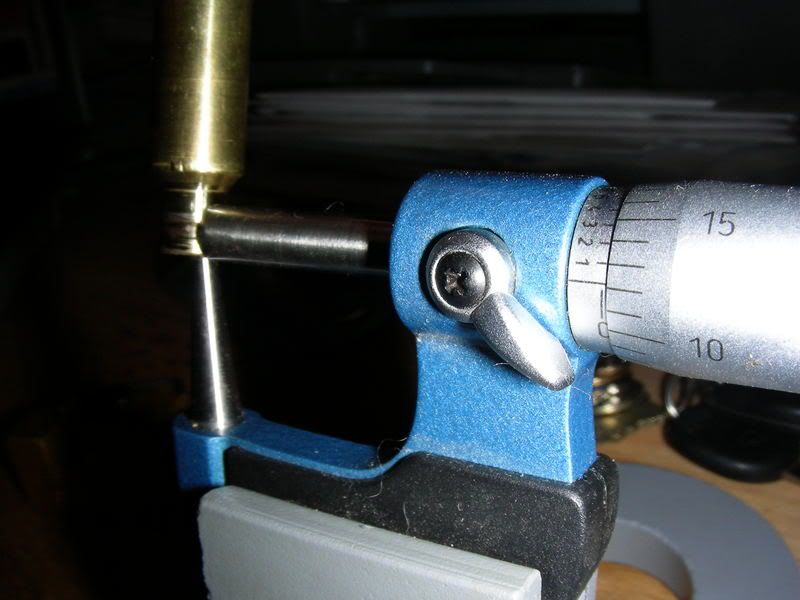

I use the Forster hand turner called the Hot 100 (for some reason)  I started out with a turner that attached to a manual trimmer and that did not work as well for me. It was too ridgid. With a hand turner you have better feel and I get excellent results. There are others as good or better like the K & M which is much more expensive but has more gadgets to attach to it. I have used one and prefer the Forster because it has a much wider blade for a smooth cut   If you ever get to the point where you want to inside neck ream then the reamers have the same size attachement mandrel  so you can outside neck turn and ream at the same time for a perfectly consistant neck  A ball micrometer is almost indispensable if you are going to turn or ream  There are other ways to skin a case but this gets it done for me. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

My Forester came with a neck turner and accessaries. Been using it for years and for small to medium projects it is just fine. It is wise to have a pilot about .001" smaller than your expander. Use lube on the spindle and the pilot. Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Correct diameter for inside neck reamer

Correct diameter for inside neck reamer

Visit our on-line store for AR Memorabilia