The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Dillon 550B resizing for .45ACP

Dillon 550B resizing for .45ACPGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

Evening all, I apologize for the previous no show post. Here it is hopefully. Just returned home yesterday from an IDPA match where I traded Dillon 550B stories with two guys that happened to be experienced masters class shooters. After discussing a couple cartridge malfunctions I had during a 120 round match, they asked to take a look at my rounds. They noticed a swelling at the upper end of the cartridge where the bullet seating is. They told me, "you see this, this is what we call coke bottling". We were comparing .45 ACP. One guy was shooting SWC like I was and the other was shooting plated round nose. Both of their rounds were straight up and down on the side walls from the rim to the case edge. No hint or swelling from a bullet being seated. They BOTH told me to prevent that because Dillon sizing/depriming dies are known to size down too far, that they use Lee sizing dies that are .040"over. Never heard of that and always thought my shells looked fine. I am loading 200 gr swc to OAL of 1.225 - 1.230, .471 crimp, 5.2 gr of RedDot. Is there anything else that could be contributing to this very noticeable swelling other than the die sizing too far down? They both also asked if I am using the NEW Dillon dies. they said the older Dillon dies are known to do this. First I heard of this as well. Another thing that I DO have a problem with is every time a shell is pushed up into the sizing die it is never lined up directly centerline of case to centerline of die. I always have to go real slow to make sure the empty case starts into the die without slamming to a stop. Once the case has started into the die then I can proceed with the handle to the bottom and the ram going to the top. Yes I am setting up the sizing die correctly, moving the die with a shell up into the die and leaving the ram there while I lock the die down to the toolhead. Any help with the swelling question and alignment issue would be most welcome. Thanks Sid | ||

|

| One of Us |

Hi cityjackit and welcome to AR! I use a Dillon 650. Have used it for years loading 40 S&W and 45ACP. I have not had the bolttleneck problem. The dies I use are Dillon, but are fairly new, 6 or 8 years or so. Any kind of a die will work on the Dillon press, maybe trying a different die may cure the problem. Be sure to adjust the dies as described in the manual. Progressives can be very finicky. Occasionally a case does not line up as you describe, but a simple jiggle of the case fixes the problem. I just try to get into a rythum and all goes well. Is there an alignment adjuster to center the case that may need attention? I am not sure how the 550 works, but the 650 pushes the case into proper alignment. I have a 550 that I use as a single stage reloading press, so not sure how it works as a progressive. Good luck. | |||

|

| One of Us |

I can assure you that they are not using dies .040 oversize. They might be .004 oversize. For a case to have a grip on the bullet the case has to be sized smaller. When the bullet is seated it expands the case mouth some leaving the step. You might eliminate some of it but not all of it. You can get a die sized right for thick brass that will not size thin brass enough. If you have the die sized for thin brass you will get the typical step. If you have a good eye you can see it in factory ammo too. I doubt that your malfunctions were caused by the snake that swallowed the chicken egg look. But if you want to get rid of it you can look at thinner brass (WW is noted for being thinner) and polishing a die out or buying a larger die. Polishing a carbide die out very far would be difficult and would require using diamond lapping compound. Just remember if you polish a die for thick brass it may be ruined for thin brass. | |||

|

| new member |

Thank you guys. i think my problem with alignment is that little paperclip tensioner pushing my cartridge too far too the right. Thanks again and have a nice night. sid | |||

|

one of us |

I'll second Impala. I'm also using a Dillon XL650 for my handgun reloading (.45 ACP, 44 Mag, .357 Mag, .38 Spl, 9 Para) and have solved all functioning problems, since the day I understood how important it is to adjust case positioning in the shellholder plate at the sizing and priming stations. Every caliber conversion implies a case head of different dimensions which must be compensated for by individual adjustement. Another important step is lubing the cases prior to sizing, TC dies notwithstanding, to attain buttersmooth functioning. André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| One of Us |

Exactly Andre! | |||

|

| One of Us |

No need for any case lubrication while using my Dillon Square Deal with carbide dies. Waste of time and effort. | |||

|

one of us |

That's what I thought after decades of using TC dies and unlubed cases. That is, until I decided to follow Dillon's own advice and give their lube a try. There's a world of difference and I don't exagerate when I say "buttersmooth". Try some .44 Mags, dry vs. lubed, and you might change your mind. André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| one of us |

Agree. And that is not even mentioning that lubing will likely extend the life of the carbide die. No, they are not forever - especially if you omit lube altogether. Sam | |||

|

| One of Us |

I have a Rl 450B and the 45 ACP dies that came with it. This means OLD for both! Yes they are a bit tight and can show the coke bottle effect on some brass. However, it has never been a problem with feeding in my guns. I load everything on that press and yes jiggling and such are sometimes part of the equation but that is true on all presses I have used. "The liberty enjoyed by the people of these states of worshiping Almighty God agreeably to their conscience, is not only among the choicest of their blessings, but also of their rights." ~George Washington - 1789 | |||

|

| One of Us |

your crimp appears to be a bit on the large size. I crimp 45 ACP .466-.470. Have not had a problem with that in over 120,000 rounds loaded on a Dillon 650. | |||

|

| one of us |

The hour glass shape is common. Redding makes a new die that may help. Redding Dual Ring Carbide Sizer Die 45 ACP. Dillon makes an alignment tool.  The Dillon Alignment Tool is in the form of a pin. You place the powder die in station one and drop the pin in. With the shell plate off and the shell platform bolts loose. You take the ram up and down until if will slip in and out of the shell platform plate hole without moving the pin. Then you snug the bolts up and make sure you still have proper alignment. If you do then tighten them screws up and reinstall your shell plate and move your powder die back. You will, of course have to reset your decap/resize die. I do that by keeping a resized case on hand and putting it in station one, running the ram to the top and then screw the die down until it just touches the shell plate. By adjusting it with the case in the die and plate, you have proper alignment of the die when snugging it down. The Dillon Alignment Tool is in the form of a pin. You place the powder die in station one and drop the pin in. With the shell plate off and the shell platform bolts loose. You take the ram up and down until if will slip in and out of the shell platform plate hole without moving the pin. Then you snug the bolts up and make sure you still have proper alignment. If you do then tighten them screws up and reinstall your shell plate and move your powder die back. You will, of course have to reset your decap/resize die. I do that by keeping a resized case on hand and putting it in station one, running the ram to the top and then screw the die down until it just touches the shell plate. By adjusting it with the case in the die and plate, you have proper alignment of the die when snugging it down. | |||

|

one of us |

True, Dillon's alignment tool is quite useful if your press gets out of alignment. I've got one too and the nice side of it is that it's there free for the asking. However , I dont think our friend Cityjackit has that kind of problem. I'd rather guess at 1 of 2 possibilities : - case swelling : maybe Dillon's older dies did cause the coke bottle result (?). If so, there's no cause to worry as it only affects looks. All TC dies do the same with (tapered) 9 Para cases with no ill effects ; - case mouth not centering in sizing die. I believe the cause lies with a wrong adjustment of the case insert camming pin and slide at station 1 (as said previouly, these must be compensated for when converting to another caliber whose case have different dimensions, smaller/larger case head). The same can be said with the locator tab at station 2 (priming). For detailed M.O. on the XL650, look at P. 37-39 from the instruction manual (= p. 11 in the 550B case feeder manual). André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| one of us |

Dillon Linkage Test Worn linkage - The test is to hold the lever parallel to the floor and move side to side. If ram/shell plate rotate, it may be worn. If a problem, have Dillon rebuild the unit. | |||

|

| One of Us |

You would have to live ten lifetimes to wear out a carbide die. I am sure Dillon wants you to use their lubricant with carbide dies. Just like Chevron wants you to add their engine additive with every fill-up at the Chevron station. Not needed in either case; but it does sell product........ | |||

|

one of us |

Why don't you give it a try and gain hands on experience before making up your mind ? André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| One of Us |

Because lubricating cases using a carbide die is like a television set on a honeymoon. Not necessary......... | |||

|

| One of Us |

I reload all my pistol ammunition on a Dillion 550 B. I don’t know what it is about 9mm ammunition, but getting a 9mm case into the carbide die was similar to shoving a big cork in a small necked bottle. When the case did enter, the up stroke was often uncontrollable, and I would bump powder out of the powder horn. That is, until such time as I lubed my cases. I tumbled the clean cases, in my Thumbler’s Tumbler, with a wet patch saturated with RCBS case lube. No tumbling media obviously. Then I ran these cases in the Dillion and it was positively easy to size cases. I have done this in a number of pistol cartridges, even though I use carbide dies. The big cases, like 45 LC and 44 Mag, are butter smooth to size. I also shoot the cartridges as is, don’t wipe off the lube. I think it makes the semi auto’s run smoother and more consistent. I can cut the load down and still get perfect extraction reliability. It takes energy to pull a dry case off the chamber walls of a dry chamber, remove or reduce that frictional force, it is easier on the extractor, and easier on the pistol if I use lighter loads. It is all win, win, except for the part about keeping your ammunition out of the dirt. Lube picks up dirt. | |||

|

| One of Us |

Lube on your brass while in the chamber can also raise pressures sky high. Better invest in some rubbing alcohol and start wiping your cases dry. | |||

|

one of us |

Slamfire, I used to tumble my loaded pistol rounds for 15' to remove the remaining lubricant from cases. That is until I found out that it had no noticeable influence in terms of accuracy, pressure or functioning. Since then, I shoot them as they come from the loading press, just like you. André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| One of Us |

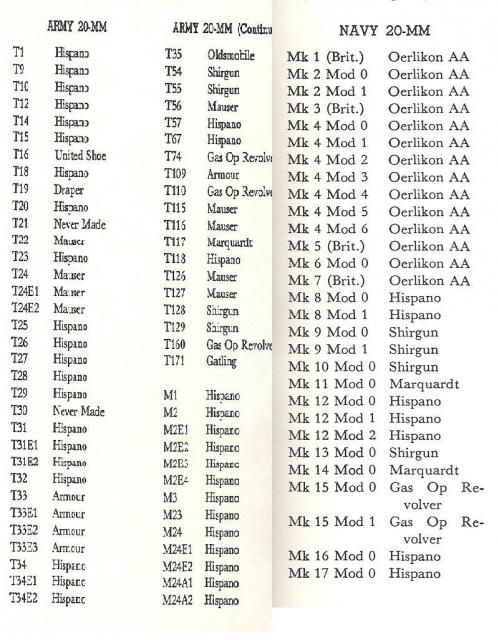

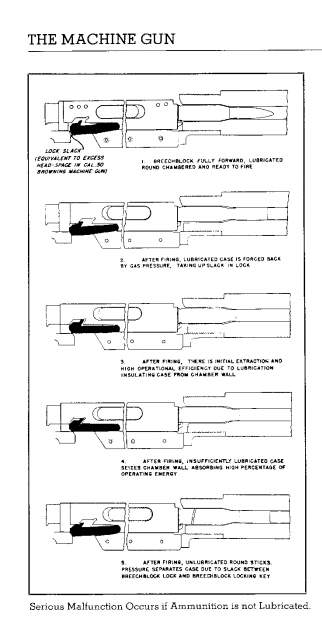

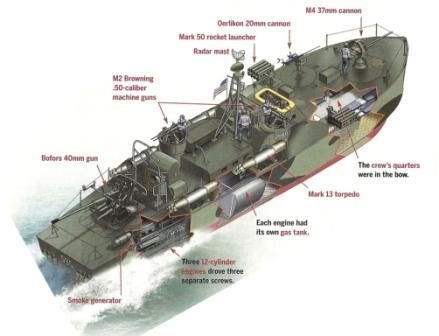

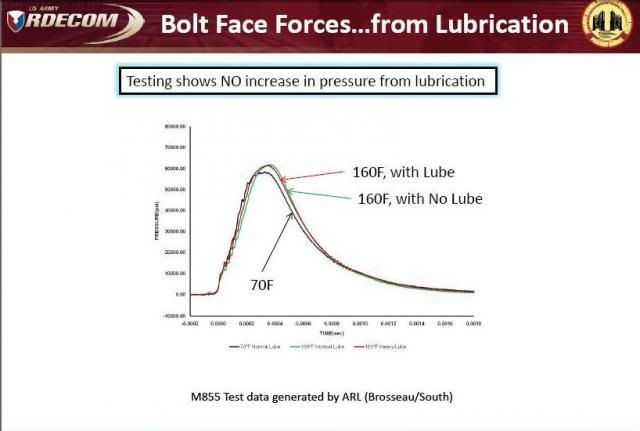

That’s not true. That was something made up by the Army to hide the blowups from the 1 million defective 03’s they made. Also, they wanted competitors to stop greasing their bullets, because they did not want dirt to get on the lube and scratch the chambers of the rifles they were loaning out at the National Matches. This lie would have died decades ago in American if it had not been perpetuated by General Hatcher in his 1947 book Hatcher’s Notebook. Literally billions of rounds with greased bullets were fired by the Austrians and the Swiss: A TREATISE COVERING THE MANUFACTURE Of RIFLE CARTRIDGE CASES, BULLETS- 1916 http://archive.org/stream/cart...c00hamirich_djvu.txt Cupro-nickel jacketed bullets are generally employed for military rifles and are used by the Belgian, British, Canadian, Danish, Italian, Roumanian, Russian, Spanish, and American governments. The German, Greek, Dutch, and Turkish governments use steel envelopes coated with cupro- nickel ; Austria uses greased steel , and Japan, copper. Bullets coated with cupro-nickel are likely to set up metallic fouling in the bore of the gun, consisting of streaks of metal which adhere to the lands and grooves in the bore. Bullets with greased steel envelopes do not appear to cause metallic fouling, but they wear away the rifling in the gun much quicker. The bullet used in the Swiss rifle cartridge is of a peculiar construction. The body is made of a hard lead alloy, provided with a nickel-plated steel envelope covering the point only, the remainder of the bullet being covered with paper lubricated with vaseline. The lower portion of the bullet which enters the cartridge case is smaller in diameter than the jacketed portion. The wounding power of this bullet is great, but its velocity is not as great as those provided with the full envelope. Swiss Service round, greased bullets manufactured 1978  Literally billions of oiled cartridges were fired in machines guns, and it is interesting, you would think that since Gen Hatcher wrote this, he would have also remembered that the Austrian Schwarzlose fired greased bullets: Army Ordnance Magazine, March-April 1933 Automatic Firearms, Mechanical Principles used in the various types , by J. S. Hatcher. Chief Smalls Arms Division Washington DC. Retarded Blow-back Mechanism……………………….. There is one queer thing, however, that is common to almost all blow-back and retarded blow-back guns, and that is that there is a tendency to rupture the cartridges unless they are lubricated. This is because the moment the explosion occurs the thin front end of the cartridge case swells up from the internal pressure and tightly grips the walls of the chamber. Cartridge cases are made with a strong solid brass head a thick wall near the rear end, but the wall tapers in thickness until the front end is quiet thin so that it will expand under pressure of the explosion and seal the chamber against the escape of gas to the rear. When the gun is fired the thin front section expands as intended and tightly grips the walls of the chamber, while the thick rear portion does not expand enough to produce serious friction. The same pressure that operates to expand the walls of the case laterally, also pushes back with the force of fifty thousand pounds to the square inch on the head of the cartridge, and the whole cartridge being made of elastic brass stretches to the rear and , in effect, give the breech block a sharp blow with starts it backward. The front end of the cartridge being tightly held by the friction against the walls of the chamber, and the rear end being free to move back in this manner under the internal pressure, either one of two things will happen. In the first case, the breech block and the head of the cartridge may continue to move back, tearing the cartridge in two and leaving the front end tightly stuck in the chamber; or, if the breech block is sufficiently retarded so that it does not allow a very violent backward motion, the result may simply be that the breech block moves back a short distance and the jerk of the extractor on the cartridge case stops it, and the gun will not operate. However this difficultly can be overcome entirely by lubricating the cartridges in some way. In the Schwarzlose machine gun there is a little pump installed in the mechanism which squirts a single drop of oil into the chamber each time the breech block goes back. In the Thompson Auto-rifle there are oil-soaked pads in the magazine which contains the cartridges. In the Pedersen semiautomatic rifle the lubrication is taken care of by coating the cartridges with a light film of wax. Blish Principle….There is no doubt that this mechanism can be made to operate as described, provided the cartridge are lubricated, …. That this type of mechanism actually opens while there is still considerable pressure in the cartridge case is evident from the fact that the gun does not operate satisfactorily unless the cartridges are lubricated. Thompson Sub-Machine Gun: … Owing to the low pressure involved in the pistol cartridge, it is not necessary to lubricate the case. You might have thought, since General Hatcher was in charge of the Ordnance Department during WW2, which produced and issued hundreds of thousands of 20 mm Hispano-Suiza machine guns, http://en.wikipedia.org/wiki/Hispano-Suiza_HS.404 and should have know about the Navy Oerlikon, http://en.wikipedia.org/wiki/Oerlikon_20_mm_cannon both of which used greased ammunition, he would have known that what he wrote in his book, Hatcher’s Notebook, about greased/oiled rounds dangerously raising pressure was total nonsense. These images are from Chin’s Machine Gun Book series. All of these T series Hispano machine guns fired greased ammunition and majority of the T series machine guns are experimentations and variations that occurred while Hatcher was in charge of the Ordnance Depart.   This is an interesting read on the Navy Oerlikon by a man who used them: http://www.usstexasbb35.com/20mm_gun.htm  If anything, oiled/greased cases drop chamber pressures because the lubricant is squeezed into the throat, reducing the effort it takes to push the bullet down the barrel.  | |||

|

| One of Us |

That is totally baloney.

| |||

|

| One of Us |

How do you know if you have never tried it?

| |||

|

| One of Us |

And that hype is only in bottleneck cartridges not straight wall stuff ________________________________________________ Maker of The Frankenstud Sling Keeper Proudly made in the USA Acepting all forms of payment | |||

|

| One of Us |

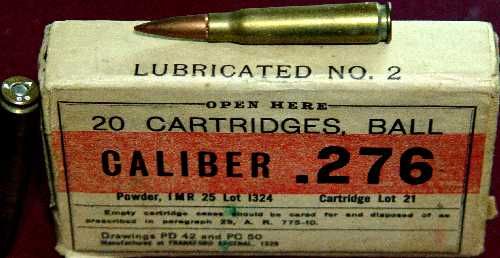

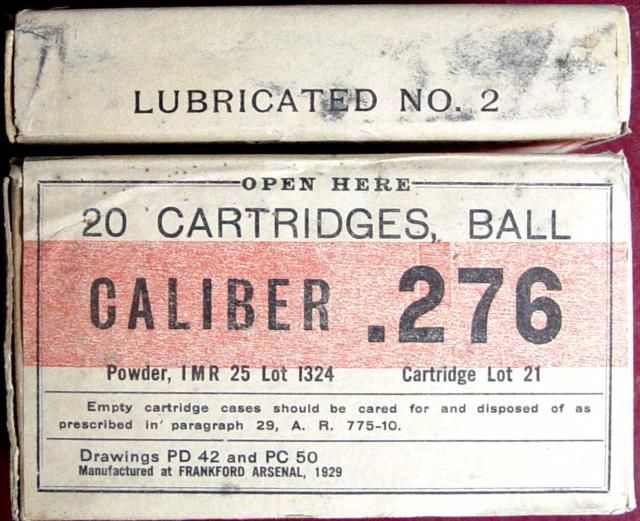

In fact most people have shot cartridges that are lubricated without even knowing it. The most common and most consumed lubricated cartridge is the plain old 22 LR. Not only is the bullet lubricated, so is the case body. This is necessary for the things to function in blow back mechanisms, and I would recommend for everyone to read the section on blowbacks in Vol 4. This entire series, Vol’s 1-5, which cost me several hundred dollars to buy back in the 90’s, is now available for free download here: http://www.milsurps.com/conten...y-George-M.-Chinn%29 If you have ever shot aluminum cases, they are coated with ceresin wax to break the friction between case and chamber. Ammunition manufacturer’s are not interested in rattling cages of lunatic “Hatcherites”, because “Hatcherites” go nut case and start shouting their Holy Hatcher Notebook Dogma. Instead of arguing with the crazies, manufacturer’s tell the public that steel cases and ammunition such as the FN 5.7 are covered with a “polymer coating”. http://en.wikipedia.org/wiki/FN_5.7%C3%9728mm This “polymer coating” is most likely ceresin wax, but whatever its chemical makeup, it is a lubricant. Hatcherities don’t know the difference, for them, as long as it is not oil or grease, they consider it OK. Unless you tell them it is a lubricant. Then they shout and holler. Paper hull shotgun shells are still sold and they are heavily waxed. Under the pressures and temperatures of combustion, the wax turns into a liquid lubricant. Just as Pedersen states in his patent. PATENT OFFICE JOHN DOUGLAS PEDERSEN, OF SPRINGFIELD, MASSACHUSETTS http://www.google.com/patents/US1780566 In the preparation of cartridges having metal cases for storage and for use, it has been found desirable to apply to said metal case a relatively thin coating of some protective substance which will preserve said metal case for comparatively long periods of time against-deterioration, such as season cracking. In the present invention, the material for said coating has been so chosen as to perform the additional function of acting as a lubricant for the case of the cartridge, both for facilitating introduction into the chamber of the gun and the extraction thereof after firing. The most suitable wax which I have found for this purpose and which I at present prefer is ceresin, a refined product of ozokerite; but I wish it to be understood that other waxes having similar qualities may exist which might serve equally well. Some of the desirable features of ceresin are that it is hard and non-tacky at ordinary temperatures having a melting point somewhere between 140 and 176 Fahrenheit. It is smooth and glassy when hard and does not gather dirt or dust. However, when the ceresin on the cartridges is melted in the chamber of a gun, it becomes a lubricant. Other lubricating waxes have been employed for coating cartridges, and the method most generally pursued for applying said coating to the cartridge case has been to prepare a heated bath of a solution of the wax in a suitable solvent, dip the cartridges therein so that a film of the solution will adhere thereto, and finally withdraw the cartridges to permit the solvent to evaporate from the coating film. This former process is comparatively slow and has been found lacking in several important respects Hopefully everyone knows about the bottlenecked 276 cartridge?   | |||

|

one of us |

Thanks gentlemen, for bringing us back on the right track and set things in their right perspective. André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| One of Us |

Um, the Speer reloading manuals advise to remove all lube from both bottleneck and straight walled cases. They are on the 'right track' for the 'right perspective'. Nice try..... | |||

|

| One of Us |

Ever heard : “Nullius in verba”.? It is the motto of the Royal Society, http://en.wikipedia.org/wiki/Royal_Society, and basically means, on the word of no one. You see they were just coming out of a tradition, thousands of years old, where the books, observations, opinions, of ancient Greeks, such as Aristotle and Ptolemy, had become the basis of all knowledge. Even suggesting that these authorities were wrong was cause enough to be executed for blasphemy. You see the Church had incorporated the natural science teachings of these Greeks into its theology. But, it had become obvious, especially by the Renaissance, that the logical deductions of ancient authorities did not jibe with observations in the real world. And so, as the enlightenment progressed, groups like the Royal Society, decided that the best way to understand the universe was by observations of empirical data in the real world, not some ancient authority. In fact, when observations conflict with authority, authority is wrong. This is an excellent standard. Build your world view on observations in the physical universe, and these observations have to be observable and repeatable. Hatcherism is hierarchical and dogmatic. Hatcherities believe that Hatcher, and the Army, have a better understanding of the world then themselves, or anyone else. Evidence that the real world does not function as Hatcher said it does, is discounted and ignored. Hatcherism is also dogmatic as Hatcherities have arrogant views which are based on fallacious theories. Speer, and all those espousing Hatcherite dogma, have absolutely no rationale basis for their beliefs, other than their faith in the inerrancy of Hatcher and the US Army Ordnance Department. It is, in fact, all built on lies and coverups. | |||

|

| One of Us |

Um, and how many reloading labs/equipment/testing data do you own? Nice try.... | |||

|

| One of Us |

Go prove me wrong, or go prove them right. If you spent the time to ask, you will find, they don't have data. They are simply repeating what they have been told. | |||

|

| One of Us |

SlamFire: Still patiently waiting for a reply to my (simple) question........ | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Dillon 550B resizing for .45ACP

Dillon 550B resizing for .45ACP

Visit our on-line store for AR Memorabilia