The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  L.C. Brass in my M1A

L.C. Brass in my M1AGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

First, I'm asking in this forum because I feel the most knowlegdeable people are here. Also, although I've been reloading for a long time it's mainly been neck sizing my 460 WBY and various pistol calibers. The only .308 I've loaded has been unfired LC Match. Fill them up and shove a pill in. I started a thread on neck sizing L.C. brass a while back. Mixed dates, none marked LR. Probably machine gun fired. I pushed 100 of them through my RCBS SB die using Imperial sizing wax, camming over center on the die. I know 100 isn't all inclusive but they weren't bad at all and I never felt like one would stick. However, I've never experienced tearing a rim off a case either. I could see all the action was at the shoulder and neck. The base, near the extractor groove, looked like it wasn't touched. They drop right into my Lyman case gauge and feel perfectly flush. They also drop into the chamber of my rifle and fall right out. Is there a chance these weren't run through an MG? Also, if any experienced bottle neck case reloaders care to comment I would appreciate it. | ||

|

| One of Us |

Do you have a headspace comparator? I purchased several boxes of factory ammo over the years to use as reference ammo. If you were able to measure the reference ammo you would have a basis for determining what may have happened to the used brass you have. Bolt gun fired headspace hopefully being only several thousands longer than the reference ammo, and semi-auto and MG fired anywhere from .015" to .030" longer than reference. I don't know that there is a definitive way to differentiate between MG and a semi-auto, maybe the case body is much wider in MG fired, but at least you would have factory ammo for reference. Maybe you just got lucky and got brass fired in someone's bolt gun with a match chamber. Without some measurements it would be hard to say just by looking at them or how they go through dies. | |||

|

| One of Us |

best brass there is. and yes it well may not have gone through a machinegun | |||

|

| one of us |

IMO, a headspace die is required if you intend to load LC, WCC..........or any other bulk once-fired 7.62x51 brass. It will reliably tell you if the case was overstretched. You could try to make a determination with a dental pick, looking for an incipient separation. I do not recommend this approach. If you simply will not spring for a headspace die, you would be safer with unfired pull-down (Midway often has this) or new unprimed IMI brass. There's also commercial, though powder charge weights will be higher. | |||

|

| One of Us |

You do not have a problem; your brass, die, and chamber are all doing what they are supposed to do. You are in no danger even if a case separates. Not sure why safety is mentioned. I have loaded and fired thousands of rounds of 7.62 Nato brass that was fired from M240 machine guns. No issues. True, some dies do not bring the shoulders short enough for some chambers, but that is easily corrected. I have also fired many many thousands of rounds from the M240 (on tanks), but those weren't reloads. | |||

|

| One of Us |

The numbers are, that the 7.62 Nato chambers used in US machine guns, allow .006 longer headspace on the no go gauge, and about 7 thou on the reject gauge. Those are max dimensions, of course, most chambers are much less than that. The real culprit is the thicker brass for military brass, which makes them harder to size back down to fit a civilian chamber. Do not be afraid of military brass; just learn how to manage it. | |||

|

| one of us |

We are running in circles. As it stands, Joe will not likely have problems. He knows his sizer die results in brass that fits both his case gauge and chamber. At that point a question about prior use in a machinegun is moot. No a case separation will not kill you. "Safer" in context just meant less problematic. Then, I suspect you knew that. Whether the result is a full (or even partial) separation or rounds not adequately sized to allow full battery, it's silly to waste powder/primer/bullet when a headspace die will separate and cull "at risk" brass. | |||

|

| One of Us |

I'm working on a batch of 100 right now. Last step before I load them will be to trim all of them to exactly 2.000". I figure after I fire them and measure them again I will know a lot more. I appreciate the input here. | |||

|

| One of Us |

I am not sure what you are looking for; checking the case length is not going to tell you anything after one shot. | |||

|

| One of Us |

If they go in exactly 2.000" and come out the same length, won't that indicate they are not stretching any more? Less chance of a case head separation? That is what I'm hoping to find. I also plan to anneal them and see how that goes. If I'm missing something or doing things in the wrong order, someone please let me know. I do have some brass that I believe went through an M60. They have the half-moon ejector marks. After I resize a few of those I'm going to carefully measure and compare them to some unsized pieces and start making notes. In the next day or two I'll do the same with the mixed LC brass. Like I said, all the resizing action seems to have occured around the shoulder and neck. As I said before, resizing .308/7.62 brass is new to me. And using military salvaged brass adds a few more dimensions I think. | |||

|

| One of Us |

If they fit your chamber properly, meaning you didn't set back the shoulder and give it too much head "space" , then you will be fine. If you created excessive headspace, then they will stretch and so will any other brass, regardless of origin. You should always check your sized brass fit against your chamber, not with a gauge; it doesn't know the dimensions of your chamber. Do not assume anything; there are tolerances in this system between dies and chambers. Brass gauges actually tell you nothing relevant to your particular rifle. It tells you where your brass is in relation to that gauge; made somewhere within the fairly generous SAAMI tolerances. The assumption is, of course that your chamber is also in that tolerance range; it might be or it might not and I never assume that. Whilst it is true that some military brass that has been fired in machine-guns is stretched, the bulk of it is not. MG chambers are not the huge sloppy caverns that many think; they are cut to very precise dimensions. Which, as I indicated above, are slightly longer in headspace than the .308, but the tolerances do overlap. The biggest challenge in using some military brass is that it is thicker and harder to bring back down to fit the chamber. You do not have that problem. Nor any other problem unless you set your die to make it significantly shorter than your chamber. All this is easier with a bolt action because you can size it until you "feel" the bolt close. actually, you can do the same thing by removing your extractor and making the brass just short enough to close reliably. I don't mean oal. Sorry, too many words here. I am sure you will be fine; just shoot it. | |||

|

| One of Us |

I buy bulk once fired Lake City 5.56 and 7.62 brass. The M60 chamber was slightly larger in diameter and made sizing the brass much harder to size than the newer M240. If you have hard sizing 7.62 brass that strains your press you can size the cases in two steps First use a 30-06 full length die or a .45 acp carbide die to reduce the body diameter. Then size the case again using a standard .308 die. You can reduce brass spring back after sizing by pausing at the top of the ram stroke for a few seconds. I prefer using the carbide .45 acp die for pre-sizing the cases. The cases do not need to be lubed and are very easy to size. Lake City uses harder brass than commercial cases and the 7.62 cases are thicker in the base. Bottom line, don't over think sizing cases fired in a machine gun. The biggest problem you will have is brass spring back after sizing. And this will make these cases hard to extract. If this happens you will then need to size the brass with a small base die at least once. The JP Enterprise case gauges are cut with a finish chamber reamer and check for minimum body diameter. Meaning these case gauges are smaller in diameter than a Wilson or Dillon case gauge. A case fired in a semi-auto needs to be sized .002 to .005 smaller in diameter than its fired size. This insures the fired case will spring back from the chamber walls and extract reliably. A small base die sizes the case body .002 to .003 smaller in diameter. It will also push the shoulder back .002 to .003 more than a standard die. | |||

|

| One of Us |

Or do what I do; face off ten thousandths from a regular die and that gives you room to coax the brass down to where it will fit your chamber. Good advice to not over think it. It's not rocket surgery. | |||

|

| one of us |

It's not unreasonable to view a headspace die as unnecessary if you have brass deriving from one chamber, or if you use new brass. Fit in your chamber is what you really want to know. And bulk once fired mil is usually going to size just fine, even if you do need a couple strokes. Some board members have posted here that they see no need for a SB die. I used to feel that way. You need one the day you need one, I guess. (The .45 ACP carbide sizer sounds interesting.) Anyway, the main reason I own a headspace die is as a means of rapidly detecting (for cull) overstretched cases. An example would be a 1919 loosely headspaced so to make it run better with crap ammo. Most stuff you buy from bulk vendors will be fine, but you can run a batch of brass through a headspace die while watching a game on TV going by feel to pick up the odd case that's way out of whack. | |||

|

| One of Us |

Lots of great info in these last four posts. A while back someone told me to gather all my brass and take it to the scrapper. Another said they were getting 4-5 loadings. Answers like that prompt me to ask more questions. The advice about presizing with a 45 acp die and trimming my s.b. die is very interesting. Thanks again for the comments. | |||

|

| One of Us |

The use of a 30-06 die or carbide .45 acp die for once fired Lake City 7.62 brass came from reloaders in the CMP reloading forum. And used by reloaders using the M1A in competition. (meaning it isn't a crazy wild ass idea) "The Civilian Marksmanship Program (CMP) is a national organization dedicated to training and educating U. S. citizens in responsible uses of firearms and airguns through gun safety training, marksmanship training and competitions." CMP reloading forum | |||

|

| One of Us |

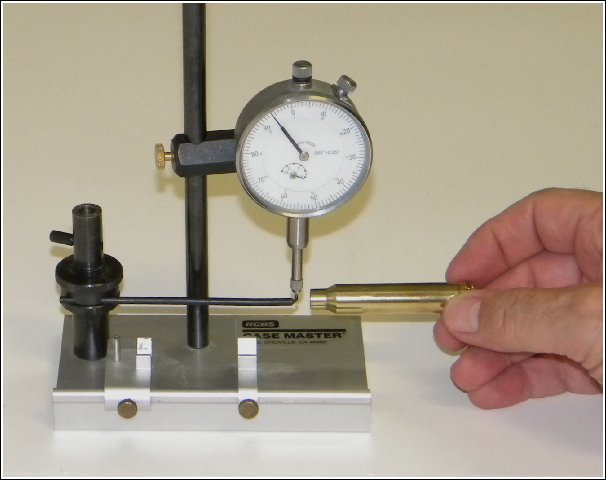

You do "NOT" need to trim the bottom off a small base die. A small base die pushes the case shoulder back .002 to .003 "more" than a standard die. Meaning the small base die will size the case to minimum SAAMI dimensions. I use Redding competition shell holders that will push the case .002 to .010 "LESS" into the die than a standard shell holder. You can do the same thing by placing a .002 to .010 feeler gauge between the shell holder and die during setup for less shoulder bump. I prefer using the Redding competition shell holders that lets the die make hard contact with the shell holder with the press reaching cam over. This eliminates the flex in the press and gives you more uniform shoulder location. And again pausing at the top of the ram stroke greatly reduces brass spring back. I use a +.004 Redding competition shell holder to get .003 shoulder bump. If I used the standard shell holder it would push the shoulder back .007. Military chambers are "longer" in headspace settings and even a standard die can bump the shoulder back more than needed. Meaning over sizing resulting in case stretching and case head separations. And only once in over 47 years of reloading did I ever need to lap the top of a shell holder to get proper shoulder bump. And modifying a shell holder is far cheaper and easier than modifying a "hardened" sizing die. I also use a RCBS case mastering gauge to measure case wall thickness and case stretch and thinning.  The once fired factory loaded Winchested .303 British case below stretched .009 on its first firing.  I have not found any once fired Lake City 5.56 or 7.62 cases that stretched and thinned using this gauge. | |||

|

| One of Us |

I just finished loading some that were shot in M60. They sized fine and trimmed fins as well. When i first got them i punched out the primers and de-crimped them. After a short time in the Lyman the primer pockets were checked for crap and all of the primers went in like Flint. The de-crimper is the one made by Dillion. I have shot 130 grain to just get the rifle on paper and was surprised when the 150 grain match Sierra's almost went in the same hole as the 130's. I have 10 loades up with 168 grain match HP bullets made by Winchester. So when it cools down some i will try them as well. You should have no problems. | |||

|

| One of Us |

What are the dates on your 7.62 cases, most 7.62 ammunition is either fired in a M240 machine gun or a M134 Minigun.I may be mistaken but I do not think even the Nation Guard or Reserve uses the M60 machine gun any more. Most complaints about sizing effort of 7.62 brass came from older ammo fired in a M60. | |||

|

| One of Us |

Active Navy. The dates were back in the early 90's. Some were IMI. | |||

|

| One of Us |

At bigrdp51, great info there, especially the point about inserting a feeler gauge. Things are getting very interesting. This entire thread has been very helpful and I'll be going over it again and again. Lots of knowledge here and thanks for everyone's input! | |||

|

| One of Us |

This thread was not intended to document an odyssey. I'm getting good info from people with more experience with me.

I stripped the bolt on my M1A and when it is locked I get slight fore and aft movement between the lugs and the receiver, about .010" I'd guess. When I drop in a resized LC case the bolt easiliy closes and locks but there is no perceptible fore and aft movement. Same when I drop in a round of Portuguese 7.62 surplus, no movement and closes easily. When I drop in an unfired LC match case I get barely perceptible fore and aft movement of the bolt, maybe .003" I'd guess. So with the die turned about 1/4 turn past touching an empty shell holder I think I'm getting exactly what is correct. The Lyman case length gauge shows perfectly flush at the max length. I'm not sure if it was just dumb luck or my dies were well made. I will load 100-200 rounds and see how they work. And for the fifth time, thanks everyone for sharing your experience with me. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia