The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case neck tension inconsistancy and accuracy

Case neck tension inconsistancy and accuracyGo  | New  | Find  | Notify  | Tools  | Reply  |  |

One of Us |

I have just discovered that seating depth can be critical but for a reason not often mentioned - in fact, never mentioned! When the bullet is seated past the neck/shoulder junction an inconsistancy can be introduced resulting from tension from the cone of the shoulder. I have just been resizing a few cases, some fired, some new, but the new ones have been through an RCBS sizer die with expander. I re-necksized all of them then passed them through my neck expander. Some of those cases expanded nice and easy while others had a tight spot at the neck/shoulder junction. I also pulled some previous loads because the OAL was less than I wanted and found that some of those bullets were being held real tight! Those bullets were all seated just past the neck/shoulder junction! My suspicion here is that bullet grip could well be inconsistant due to the shoulder cone even though the necks have been expanded. I now wonder whether the collet sizer avoids this problem and might be the major contributing factor to better accuracy experienced but by collet sizer users? Regards 303Guy | ||

|

One of Us |

I have 3 questions. Is your brass all trimed to the same lanth? Do you crimp your shells too? and last but not least Do you champher you cases? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

one of us |

Have you checked for the presence of the classic "doughnut" at the junction of neck and shoulder ? André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| one of us |

I would add that it could be the brass getting harder; a careful annealing could pay. | |||

|

One of Us |

These cases were all annealed and deburred. No crimping. This is exactly the 'doughnut'. Some cases are new while others are reloads. The lengths are not all the same. The neck sizer I use has minimal compression. It's the reloads that are doing it. The shoulder has been fireformed and the neck sized. A few got through without neck sizing and these had the same grip variation at the neck/shoulder junction. One was so tight that the puller slipped off the bullet a few times before the it came out - that was un unsized neck. The bullet could be slid in the neck by finger but did not 'rattle'. It seems that the fire-forming of the shoulder is what did it, not the neck sizing although those cases that I re-necksized also developed the tight spot sometimes. On fire-forming, the shoulder angle gets changed and moves foreward, increasing the definition of the neck/shoulder junction. Regards 303Guy | |||

|

One of Us |

Have you used a consanguinity gauge? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

"Bloody" good suggestion. But I think you mean concentricity gauge. ********************** > I'd rather be a CONSERVATIVE NUTJOB than a Liberal with no NUTS & No JOB > | |||

|

One of Us |

LOL DAMN SPELL CHECKER! GOT ME ALL MESSED UP! I tryed posting that earlyer and it wouldnt post! I dont know whats going on with this pc sometimes! Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| one of us |

My own experience in poking many bullets into all types of sized cased is that neck tension is closely related to annealing, that is brass hardness, after the given of equal neck reduction. If you simply resize and try poking an "m" die into the case, at some point in multiple reloadings the "poking" force goes all over the map. Bingo, tension inconsistency. "Make yourselves sheep and the wolves will eat you" G. ned ludd | |||

|

One of Us |

This M die thing you speak of is something I have yet to hear of or remember. Could you explain more about this or point me in the direction to find out more about this?? Now if anyone could also send me in the right direction to learn how to start annealing? I know of it and I know what it is. Just have never done it my self. Sense this started about lead, besides quenching to harden my lead bullets, to heat treat bullets. I know I can do it in my oven, but is it safe to do in my kitchen and what is the right temp to do it at? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

The "M" die is a Lyman product. It is a belling die that actually sizes to a diameter, one of two. The first diameter is for jacketed bullets, and the second is larger for cast bullets. The"M" dies are available for both rifle and pistol calibers. Annealing: www.gun-tests.com/performance/jun96cases.html ________________________ "Every country has the government it deserves." - Joseph de Maistre | |||

|

One of Us |

THANKS! Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

YOU'RE WELCOME! Check with Lead Bullet Technology. Veral Smith (proprietor) has a book that may touch on hardening. ________________________ "Every country has the government it deserves." - Joseph de Maistre | |||

|

One of Us |

Do you have a website for that Lead Bullet Tech? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

It doesn't seem to be fully functional at the moment, but was fine a couple of weeks ago when I last accessed it. It will probably be OK later. www.lbtmoulds.com/ ________________________ "Every country has the government it deserves." - Joseph de Maistre | |||

|

| one of us |

TRY ; www.cast boolits.gunloads.com "Make yourselves sheep and the wolves will eat you" G. ned ludd | |||

|

One of Us |

Yup. I shall be avoiding seating any bullet past this point. In fact, I indend to do something along the lines of what AC describes, using the 'dough nut' as a seating stop. I have already used it as a cardboard wad stop! Not sure if it did any good 'though. Regards 303Guy | |||

|

one of us |

To ream out the "doughnut", you'll need an inside case neck reamer and die. RCBS sells them, among others. However and unless you're dealing with some hard to get cases, it's up to you to consider the added cost of buying a reamer-die set or simply replace the offending brass. André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

One of Us |

Andre, it seems that all my cases have that. Normally I do not seat past this point anyway so when I did seat past that point, it took me by surprise. Normally I do not size to this point, that being so as not to disturb the shoulder or body in any way. My cases all fit with a slight 'tightnes' on the bolt. Concerns for locking lug and reces face wear makes me keep those parts as well as any other sliding parts lubed. I normally load mild but my 303-25 will probably end up closer to its limits due to the nature of that caliber, so I need to be careful what I do! Regards 303Guy | |||

|

| One of Us |

OMG the dreaded doughnut strikes again!!! I learned from an old BR shooter to ream my new brass necks before anything else for various reasons, not the least of which is the DD. I've found that doing this wih Lapua brass means that a good many cases never need neck turning at all. BTW, another problem with too deep a bullet seat, is that you may get more bearing surface than you want and if you go really deep you change the internal ballistics, most notably the powder column. If the enemy is in range, so are you. - Infantry manual | |||

|

One of Us |

Is it OK to seat just up to the 'doughnut'? Would leaving it there influence combustion - the 'doughnut' might vary? Oh, I forgot to answer James Kain - no I haven't measured concentricity. (I did once with my hornet loads but not having a gauge I used a lather and a dial gauge. I could not detect any runout at all! But then I do not size the hornet cases at all so if there had been runout it would have meant an out of line chamber.) amamnn, what do you mean by "you may get more bearing surface than you want"? I have wondered about how the protruding bullet (into the case) might effect combustion characteristics. One thing with a full case, I suppose, but if there is free space anyway, powder granules may be wedged between bullet and neck or something? The shape of the combustion chamber changes and so on. But then, it also changes just by varying the seating depth in the neck. (Well, more in volume than in shape.) Regards 303Guy | |||

|

One of Us |

Do you have a photo of the case? Can you see this "dough nut"? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

One of Us |

I could take a photo but it wouldn't show up. Sometimes, after seating the bullet, one can make it out if the bullet is seated close to the 'doughnut'. I can very definately feel it if I neck expand from the top down. I used to push through it but now i don't as I think it would increase the odds of runout by 'bending' the neck a little. Regards 303Guy | |||

|

One of Us |

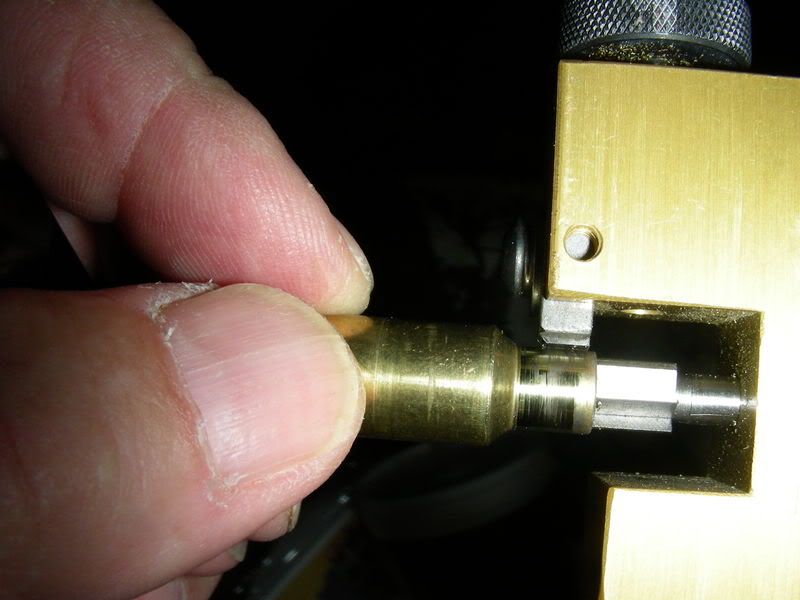

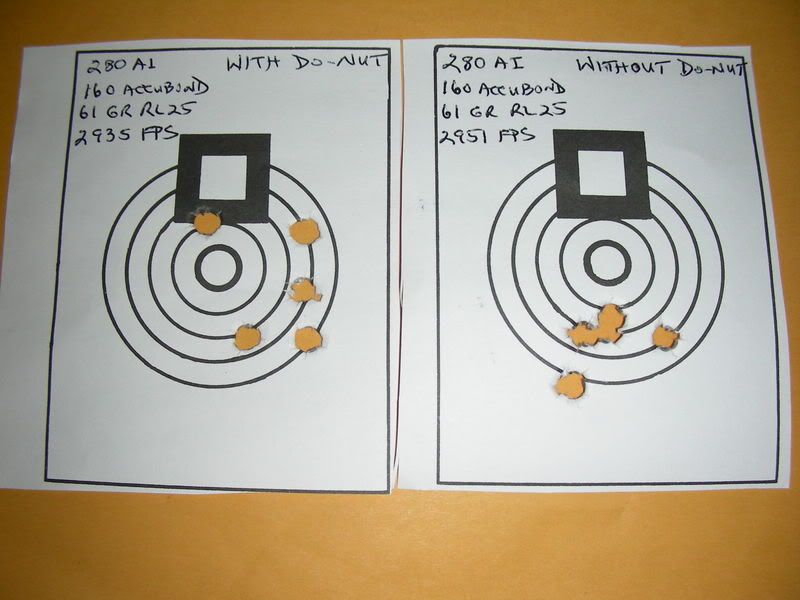

Hey 303Guy The only way I know of to see if you have a do-nut is to push a bullet by hand into a fired and unsized case. If the bullet movement is stopped at the neck/shoulder junction like it is here on my 280AI  then you have a do-nut. I am not sure you can detect a do-nut on a sized neck by inserting an expander or by feeling resistance from seating bullets. Perhaps if you had some pin gauges then you could detect a constriction at the neck/shoulder. One of the first things I do after a range session is to take a bullet and push it down the neck of the fired cases to check for do-nuts and so far only my 280AI when using Nosler brass develops them. Normally do-nuts are affiliated with tight necked custom chambers of which I have 4. But again only the 280AI develops them. For the 280AI I then use a reamer which removes them handily   ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

My case trimmer also has a pilot/reamer to line up the neck. Maybe that's why I never run in to the issue. this is good to know Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

One of Us |

Thanks for that woods. Well, I went and had a look at my fired cases and only found one with the 'do-nut'. Mmmm... There were definately more but these were after sizing. When seating the bullet, there was definate resistance at the neck/shoulder junction on some cases. this particular one I found now is generally tighter in the whole neck. Odd! I means it did not expand as much as normal (or rather, it sprang back more than normal). All these case are supposed to be once fired after annealing! The primer on that particular case seems to display a little more flattening than on the others. Does this mean I have another problem? This is all the same brand and batch of cases. They were new and primed, I found a problem so I dismantle the loads, annealed the necks, resized and reloaded them. Regards 303Guy | |||

|

One of Us |

Annealing makes the case last longer, true? I have some reading to do! Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

One of Us |

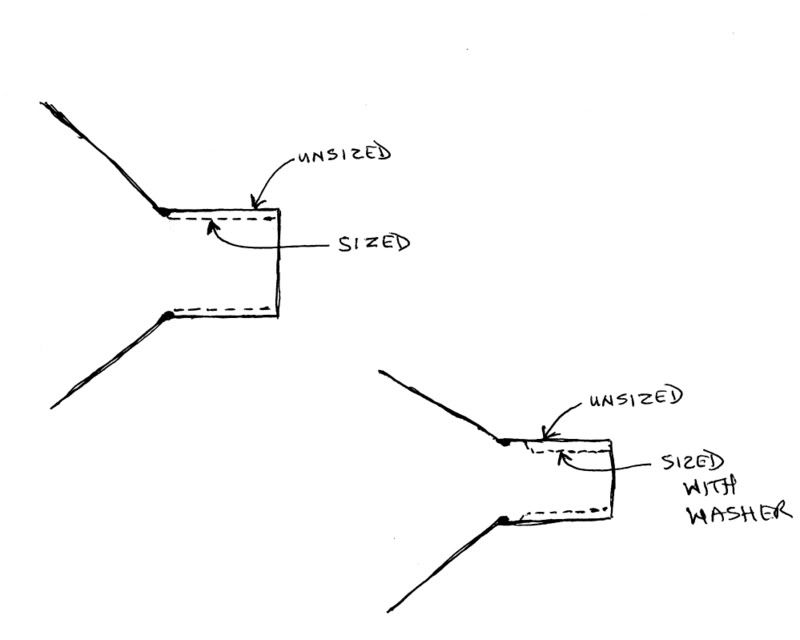

Do-nuts can make a big difference in accuracy, probably due to not being totally consistant. The do-nut is probably larger or protrudes more into the neck on the side with thicker shoulder or neck brass  When you size the neck, the neck brass is sized at 90 degrees toward the centerline. If you are sizing or pushing back the shoulder then that brass is being pushed at an angle. Because of this I think that if your neck/shoulder junction does not hit the bullet when pushed into the neck on an unsized case, then it will not be pushed in with the sizing process  Need to get some pin gauges and test this though. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

Thank you once again! Well, I have certainly got a lot of work to do. I was just so unaware of this! I used to size as per the second diagram and the bullets did not extend past this point but with the longer bullets in my 303-25, I have been sizing right up to the shoulder junction as in the first diagram. Pin guages it will be! Regards 303Guy | |||

|

one of us |

If you don't seat your bullet past the doughnut, the latter shouldn't bother you. As for me, I avoid them by turning necks, up to cutting a small bevel into the case shoulder (the neck turning blade has already the right bevel). André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

One of Us |

are there anything brass or die set that is more prone to this? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

One of Us |

James Do-nuts normally develop in tight necked chambers where there is minimal clearance in the chamber around the neck, usually .003" after turning. After firing the inside neck diameter is just barely open enough to slide the bullet in and then it will catch on the do-nut because the bullet fit is so tight. With a factory rifle there is more neck clearance and the bullet has enough room to slide past any do-nut (if there) without catching. Since it does not bear on the bullet before sizing then it should not cause a problem after sizing. After sizing there is no way to tell unless you have a set of pin gauges. Just stick a bullet down your fired cases and 99% of the time you don't have a problem, unless you have a tight necked chamber then it is a 50/50 chance. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

One of Us |

My Swedish Mauser will have a custom barrel when I get it back. I will have to keep a eye out for this. Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case neck tension inconsistancy and accuracy

Case neck tension inconsistancy and accuracy

Visit our on-line store for AR Memorabilia