The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Making a Reloading Bench -COMPLETED - Pics added 7/17

Making a Reloading Bench -COMPLETED - Pics added 7/17Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

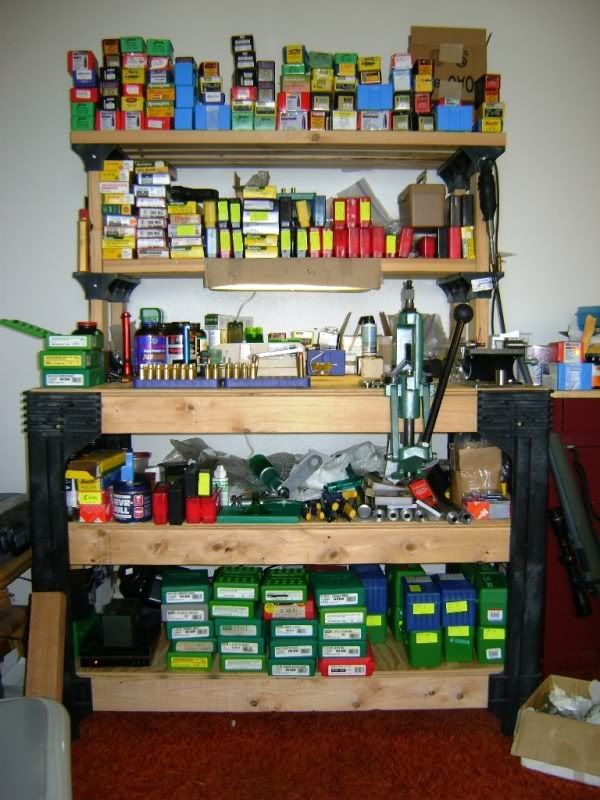

Hi fellas- After deciding I did not want all my rust-prone reloading gear outside in the new man-cave, I now have to build a solid reloading bench. I like to weld and prefer to build things out of steel when possible. So the frame will be made of 4" X 4" legs and 2" x 2" square tubing; all in 0.125" wall thickness. Most of my work is done with an arbor press, but I do bump shoulders and do full-length resizing with a portable Harrels's Magnum press. I honestly haven't use the big Redding in years. The top I purchased was from Gizzly.com. I am squeezing the bench between a wall and a tall wooden wardrobe (where I keep all of my reloading supplies hidden from plain sight, but still in an A/C environment). The maple top is only 36" x 24" x 1 3/4" thick, but I don't really plan on storing anything permanently on the bench, except for some reloading manuals on the top shelf. I planned on putting a recessed fluorescent light under the top shelf. Lastly, I plan to use the router to groove the top so that I may install some of the extruded 80/20 aluminum rails that I have seen others use to slide accessories/tools in and out of and be able to secure them when in use. Any other ideas? Here is the first design I came up with (Google Sketch):  Rails: http://www.8020.net/T-Slot-4.asp  This is REMBRANT1's setup. Thanks for the idea! I pirated the photos below from this discussion: http://forums.accuratereloadin...1043/m/994103278/p/2    | ||

|

| One of Us |

looks like a pretty good plan. it sounds like you don't want a bunch of stuff visible while not in use so another option you could add. put sides coming down from your top shelf the same depth as the shelf. then add doors to the front and peg board on the back for misc small tools. then when you are done working you could hang your stuff and close the doors and it would be all out of sight. you could do the same with the bottom if you needed more storage add a shelf and doors to it. | |||

|

| One of Us |

Your drawing and sksshooter's suggestion seem to be adaquate for a good bench. Mine is made out of 4x4's and 2x4's, with the top being 2x6's covered with an 1/8th plate on one end (the vise end) and 1/2" plywood on the other. I would love to replace it with laminated wood, but it's so big that the cost (custom size) and shipping would be prohibitive. Eric "We must all hang together, or assuredly we shall all hang separately." Benjamin Franklin, July 4 1776 Lost once in the shuffle, member since 2000. | |||

|

| One of Us |

Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| One of Us |

I built mine 20' long and 32" deep, with legs of 4"x6" vertical wood beams every four feet, and used two layers of 1 & 1/2" thick oak plywood as a top. All are finished in several layers of gym-floor clear epoxy finish on all surfaces. I used sheets of 3/4" plywood for a shelf halfway between the benchtop and the floor for 16" of its length. There I store case tumblers, powder measures, presses, lead pots, etc. The other 4' of the length is where I have two approximately 3' tall fire-insulated money-safes under the bench for holding handguns I might be fiddling with. (Though the safes aren't as secure as modern ones, they are both over 100 years old and I like them. They add a nice tone to the room.) On the end wall is a 52 long-gun-capacity safe, while on the opposite side wall are three 78" tall wooden cabinets with doors, each 48" wide, with 5 shelves each. One is for loaded cartridges, one for brass, and one for dies, etc. Next to them at the end of the wall is a large roll-away tool cabinet set full of gunsmithing tools and chamber reamers. Above everything are eight 8' long flourescent lamps with separate wall switches so one can light whatever part of the room they wish, and there are electrical wall plug-ins just above bench height every four feet. It is not nearly as nice as my old layout in Oregon was, but it still mostly suits my current needs. As to suggestions, my bit would be that you use counter-sunk screws to hold everything together...that way it can still look neat and smooth yet be disassembled if needed for moving. I used 4-1/2" long brass screws which take a square drive, for mine. | |||

|

One of Us |

About all I would add would be better lighting. I don't think the light under the shelf will do much more than irritate you. I've worked at production work stations laid out with that kind of light, and it always seemed to be "wrong" for what you're doing. Basically you're hands will block the light from shining on whatever it is you're working on. You're better off with overhead lights. I have 3 different 4 foot overhead fluorescent lights hung over my 3 work areas in my shop. The combination of direct and indirect light works great, and I don't have any shadows or dark areas to deal with. 2 of my benches are steel frame with melonite surfaces, and 1 is the home made one I built out of 4x4 wood and plywood in '86. All 3 of them are lag bolted into the wall studs of their respective shop walls. All 3 are solid and sturdy. Si tantum EGO eram dimidium ut bonus ut EGO memor | |||

|

| One of Us |

I ordered one of these kits. http://www.cabelas.com/product...BSearch-All+Products The local lumber supplier cut a 4x8 sheet of 3/4 plywood for me to use as shelves. No waste. I like the shelf space. It's super functional. I was going to put a back board on it, but put it to work, and haven't got around to the backboard yet. I've had at least four benches befor this one, and I like this the best. I got it because it was easier, and maybe cheaper, than moving my other one here. I plan on taking it with me if I move again. KB  ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| One of Us |

Ummm, it's definitely full. I forgot to mention earlier: I’ve lagged mine to the floor and walls. Concrete. "We must all hang together, or assuredly we shall all hang separately." Benjamin Franklin, July 4 1776 Lost once in the shuffle, member since 2000. | |||

|

| One of Us |

Yea, it was beginning to overflow, and become cluttered, so I keep a lot of supplies on shelves in a small closet now. KB ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ ~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~-~ | |||

|

| one of us |

With MANY rain delays, here is the final product. Small. Simple. Clean. I anticipate that some day, when we get a bigger house and I build my dedicated reloading/hunting/fishing cave, that it will be very easy to pair this up with a much longer version of this bench. For now, it will fit perfectly next to my gun closet/reloading supply cabinet.       After about an hour's worth of sanding and smoothing on the old recycled steel, I applied two coats of Rustoleum white primer followed by a "white shell" color of Rustoleum. I don't like most things bright white; the off-white shell in satin finish is my preferred choice. Gloss shows imperfections a little too well.    Welll, actually I am not totally done. I still need some suggestions on two things: 1) Where in the hell can I find a smaller piece of maple to go across the top? I can't seem to find anything smaller that the top. Any other suggestions/recommendations? It will only hold my reloading books. The main function of this shelf was intended to be a light source (see below). 2) What do you think about this style of light? Please note, this is already going into a well lit room.  | |||

|

| One of Us |

Built like a brick shithouse, looks good! What are the dimensions of the maple you need, I might just have something layin' around. What's the wattage on the lights? | |||

|

| one of us |

Oh, really? I'd be very happy to pay you for it including any shipping/packaging costs. I am at work now, but I'll send you the dimensions when I get home tomorrow morning. BTW, the lights are a measly 20 watts each, but they are xenon. It's about all I could find at the local depot. I considered at (T5?) style florescent, but I have heard that it can interfere w/ electronic scales. I use the new Hornady electronic powder thrower/scale. | |||

|

| one of us |

I just rolled in the door... Looks like I will need a top piece that is 12" X 36" and I really don't care about the thickness. Thanks for looking! | |||

|

| One of Us |

Close as I can come is 14x 32x 1 1/2. It's a piece of solid maple plank. You could probably rip it and band it to get to get a 36" OAL. If you can use it, It's yours for the shipping cost. | |||

|

| one of us |

Those dimensions will be PERFECT! Thank you very very much. I really appreciate the offer, Craigster. I will pay you for both material and shipping. PM coming... | |||

|

| One of Us |

kenati the bench looks good. don't forget to post up some pics once you get it all setup. as for the maple for the top. if it doesn't work out with craigster watch your local craigslist in the furniture section. on probably any day of the week you can pick up a kitchen table that has a top that will match your existing top for little to nothing. i actually just pitched one that would have been perfect it was 3'x5' with beveled edges. you could have cut one end of it and it would have really looked well finished. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Making a Reloading Bench -COMPLETED - Pics added 7/17

Making a Reloading Bench -COMPLETED - Pics added 7/17

Visit our on-line store for AR Memorabilia