The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  How long will powder and primers stay at 100%

How long will powder and primers stay at 100%Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

How long do reloading components hold their full potential when stored in a dry area? Have several sealed containers of H4831 and some older large rifle primers both are probably over 10 years old but I see no signs of corrosion or other problems. Did some shooting over a chronograph for the first time in a lot of years and the 280 REM /150 gr Nosler's seemed to do well with 57.5 grains of the old H4831 from the one container that has been opened over the years. Vel ranging 2880-2895 ft per sec. | ||

|

| one of us |

A long time 15fps velocity deviation is good even for fresh powders. I have reloads more then 30 years old that preform just fine. | |||

|

| One of Us |

I routinely shoot WW2 ammo; no degradation noted. I have a rule not to load with primers over 60 years old. Maybe more. Ten years, is the same as brand new to me. Smell the powder; IMR powders will always smell like ether. If any powder smells like acid, it is bad. | |||

|

| One of Us |

This topic has been all over the web in the last three months. Nothing more than internet hype about powder and primers having a set life or starts to decompose.Who started it is anyone's guess. If powder was properly made as well as primers,they have no life. If properly stored from heat and moisture there is no reason both should not outlast you. I have powder from WWI that I still use and nothing has changed with loading data. The Original batch of Bulls Eye powder still exist and is used to compare every batch made today. And that batch is over 120 years old. The original batch is stored underwater away from heat and O2. Gulf of Tonkin Yacht Club NRA Endowment Member President NM MILSURPS | |||

|

| One of Us |

From SAAMI here: "Although modern smokeless powders contain stabilizers and are basically free from deterioration under proper storage conditions, safe practices require a recognition of the signs of deterioration and its possible effects." | |||

|

| One of Us |

I found a carton (1000) of really old "Winchester Western Staynless" primers from a local source. They have been discontinued for decades! I have used up about half of them and so far they have performed flawlessly. AK-47 The only Communist Idea that Liberals don't like. | |||

|

| One of Us |

I had some 748 and CCI primers that must have been at least 20+ years old and it all loaded and shot fine. Dave In 100 years who of us will care? An armed society is a polite society! Just because they say you are paranoid doesn't mean they are not out to get you. | |||

|

| one of us |

Federal has said 10 years. You will know when they go bad.  | |||

|

| One of Us |

Thanks, I have some old red dot from the late 60's but not loaded in since the 80's. I was Curious with the old CCI LR primers from the very early 80's, Federal Large rifle Bench Rest primers in the thin packaging and 1000 box of the thicker "new" packaging. I have gotten lazy the last 10 years and found that the Nosler boat tail bullets shoot within the same 3/4 and less as the hand loads but you give up 100 to 200 fps but where does it make a difference before 300 yards. I was just swapping out the Remington bullets with nosler but I have not been long range trophy hunting either. I am getting ready to retire and going back to reloading. Thanks for confirming my opinion. | |||

|

| One of Us |

LET me ask The old federal 210M primers did not have a coating nor does the older CCI 200's BUT the new Federal Premium GM210M have a red coating over the primer. HAS this made a difference in performance for those of you that use the Federal primers? | |||

|

| One of Us |

I'm using the last of my Winchester small rifle primers in many 223. My cousin gave them to me when he went 100% archery in '73. | |||

|

| one of us |

Properly stored, a very long time. I used up some old surplus H4831 a couple of years ago. I bought that powder about 1960. Dave | |||

|

| One of Us |

I have posted similar replies over the years to this question and since I usually go to the range on New Years Day to test my old ammunition, this years results are the same as years past--the 30-06 ammo that I reloaded as a kid in 1962 still go bang. In all honesty I did not chrono the stuff but it all fired flawlessly. Now down to appx 30 rounds left from that era of reloading. Reloads are in a Win case with a 150 gr. soft point over IMR4064 all dated May 1962. Storage has been indoors for that period of time, basements, closets and under beds but never in the garage so temps were somewhat stable. About the only thing I wish I had done was to save the powder cans as collector items but then again I wish I saved my comic books and baseball trading cards too LOL Gary | |||

|

| One of Us |

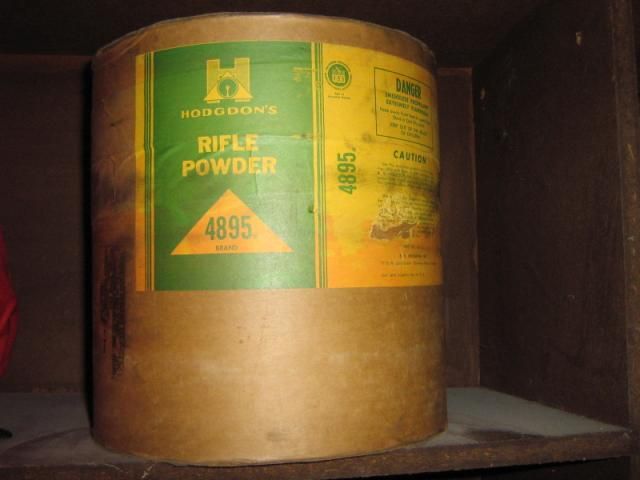

The only powder I found to go bad was 4895 ( surplus WWII ) Got rid of 8 # of it and burned a large section of my lawn after I mixed it with 33 gals. of water. Old age is a high price to pay for maturity!!! Some never pay and some pay and never reap the reward. Wisdom comes with age! Sometimes age comes alone.. | |||

|

| one of us |

Ten year-old primers and powder are like six week-old whiskey: Too green to be at its best. The little dab of WW-II surplus 4831 I have left is still some of the most consistent powder I load. And the Herter's small rifle primers (made in Japan), purchased before the 1968 GCA, are what I go to when I have a gun with a weak firing pin since they are more sensitive than most current primers. | |||

|

| One of Us |

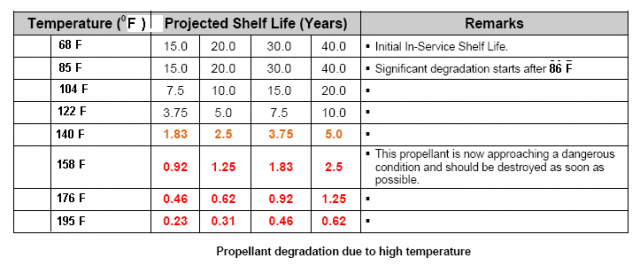

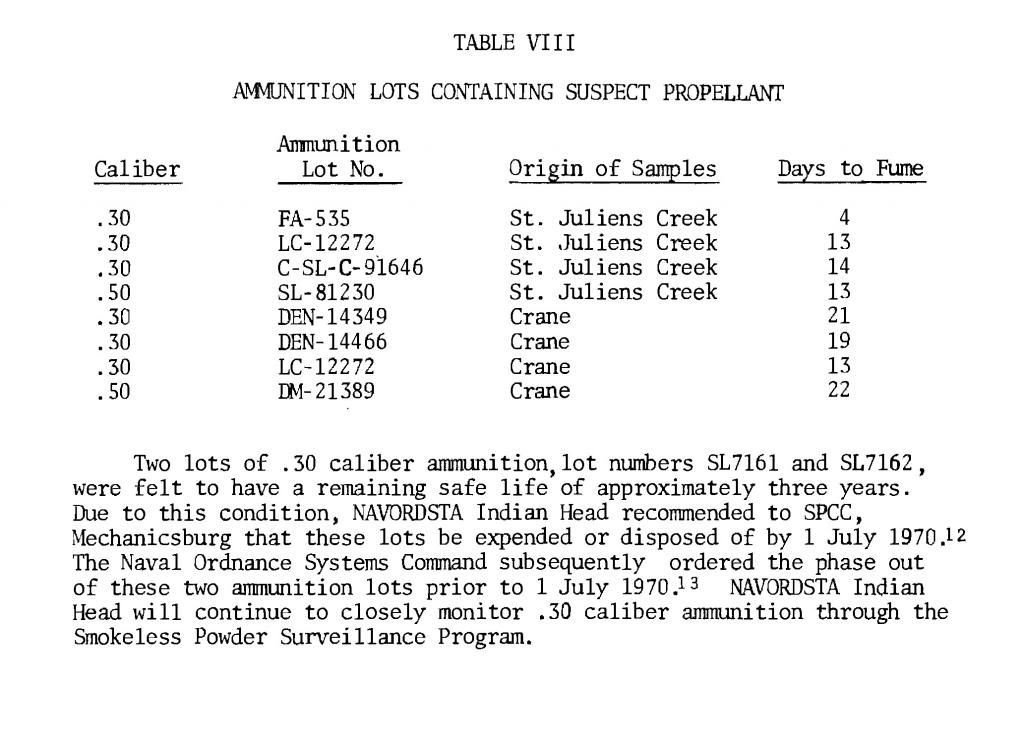

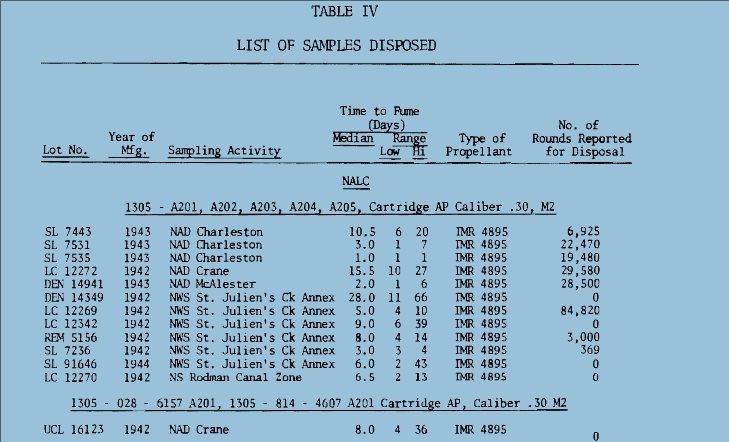

Whether powder is good is not easily answered unless the powder has gross indications of going bad. The gross indications are the bitter smell due to NOx, red powder granules, fuming gas emissions, others have said “red gas”. By the time you see this the powder went bad a long time before. Half of all the surplus IMR 4895 I purchased went bad. The first 16 lbs, I used up eight pounds quickly. For whatever reason, I pulled the bullets on some of that stuff and found green corrosion on the bases of the bullets. Similar to these pull down bullets from old US ammunition. Not the horrible one, but the small green spots.   I don't remember what US ammunition these came from I pulled them decades ago. It took a while till I found reason to use the rest of that surplus IMR 4895. When I opened the bottle top, it smelled bitter, red dust flew above the opening. I decided to get rid of it, but not have it wasted. I gave the jug to a machine gunner guy and he put it in his laundry room. Passing by the laundry room he tossed soiled shorts at the hamper, but missed. The shorts ended up on top of the powder bottle and stayed there overnight. Next day my friend found that escaping acid gas from the bottle had eaten holes in his shorts!! :what: This so unnerved my friend, he poured the powder out over his lawn. Actually this was the best thing to do, and had I know of the hazards of old deteriorated gunpowder, I would have poured it out on the lawn and not given to him to shoot. Since then I have had more surplus 4895 powder from a different vendor go bad in the case. Visual inspection of the ammunition revealed green corrosion on the bottom of the bullets and cracked case necks. This powder never smelt bitter at all. I shot this powder in highpower matches and it shot exceptionally well, but case necks cracked after firing. I also received “funny” retorts and the occasional sticky extraction. The longer the ammunition was unused the more cases necks would split when fired. In time virtually all of the remaining 700 loaded cases experienced cracked case necks without being fired. From what I had read on the internet, which is a repeat of what is said in gun magazines, powder has an “infinite” shelf life. I think we all remember reading statements to the effect that powder lost energy as it got old, making it essentially benign. This information is not only wrong, it will get people hurt. Years later I ran into a Naval Insensitive Munitions expert. This IM expert explained that powder is deteriorating the day it leaves the factory. Nitrocellulose decomposes through the reduction-oxidation process, he called it Redox. The expert said “The molecular stability of the functional groups on the organic chain determine the life time of the nitrocellulose molecule.” This guy actually writes and talks like this, he is extremely bright with a PhD in Chemical Engineering. The bottom line is that nitrocellulose is a high energy molecule that is breaking down to become a low energy molecule. Anyone who has taken thermodynamics will realize that this is obvious, everything is breaking down to a lower energy state, but somehow, shooters have been lulled into thinking that the second law of thermodynamics does not apply to our sport. Heat accelerates the deterioration/decomposition of powder and the rate is directly proportional to the Arrhenius equation, which is an exponential function. Maybe this is a simpler way to say it: the lifetime of ammunition decreases exponentially as temperature rises. This table is instructive on how quickly heat deteriorates smokeless propellants: UN manual on ammunition inspection. See section 7.3. Surveillance and in-service proof - the United Nations[/B http://www.un.org/disarmament/...ice%20Proof(V.1).pdf  If you read Insensitive munitions literature, you will see that they use high temperature to accelerate aging of smokeless propellants. As gunpowder gets older it does not get safer to shoot. Old gunpowder will, and has, blown up firearms. The basic reason is something called “burn rate instability”. For all your cartridges you want a nice and smooth pressure curve. If the burn rate is irregular, because the nitrocellulose powder grain breaks down irregularly, there will be peaks and valleys instead of a smooth pressure curve. These irregularities can interact in such a way that pressures spike. Double based powders are a combination of nitroglycerine (NG) and nitrocellulose, the NG is there for an energy boost, but unfortunately NG causes a new set of problems. NG is apparently not bound to the powder grain but is a liquid and it migrates. NG is wicked to the surface of the powder grain over time, one causal reason, water condensing and evaporating on the powder grain surface. Apparently the evaporating water molecules pull on the NG. I was told that created a NG rich surface. So, even though the total energy of the grain has decreased due to breakdown, the surface is NG rich and that will spike the initial burn rate. Another thing NG does is accelerate the breakdown of the base nitrocellulose molecule by attacking the double bonds holding the NO molecules. Unfortunately all ionic compounds attack those double bonds, water is a main offender because it is always in air, is a polar covalent ion (acts like an ionic compound) and thus you know the reason you were told to store gunpowder in a cold and dry environment. Quality ammunition is manufactured in humidity controlled environments, between 40% and 20% humidity, but they don't go lower due to electro static discharge concerns. Incidentally rust is bad and that rust that came out of those old tin cans accelerated the aging of gunpowder, and I think, is why they went to plastic containers. This is from the Dec 2003 Propellant Management Guide: Stabilizers are chemical ingredients added to propellant at time of manufacture to decrease the rate of propellant degradation and reduce the probability of auto ignition during its expected useful life. As nitrocellulose-based propellants decompose, they release nitrogen oxides. If the nitrogen oxides are left free to react in the propellant, they can react with the nitrate ester, causing further decomposition and additional release of nitrogen oxides. The reaction between the nitrate ester and the nitrogen oxides is exothermic (i.e., the reaction produces heat). Heat increases the rate of propellant decomposition. More importantly, the exothermic nature of the reaction creates a problem if sufficient heat is generated to initiate combustion. Chemical additives, referred to as stabilizers, are added to propellant formulations to react with free nitrogen oxides to prevent their attack on the nitrate esters in the propellant. The stabilizers are scavengers that act rather like sponges, and once they become “saturated” they are no longer able to remove nitrogen oxides from the propellant. Self-heating of the propellant can occur unabated at the “saturation” point without the ameliorating effect of the stabilizer. Once begun, the self-heating may become sufficient to cause auto ignition. Actually there are only a few compounds used as stabilizers, and as the Propellant Management Guide tells us, stabilizers are consumed with age. Hodgdon provides an excellent short summary about this: [b]Gunpowder stability]/b] http://www.hodgdonreloading.co.../gunpowder-stability Our Armed Services have stockpile surveillance programs (but each Service does theirs a little differently) and one of the easiest things to show that gunpowder is at the end of its service life is that red fuming nitric acid gas. Of course there are a lot of tests, if you want to see all the different tests the military uses look at Mils Std 286 Propellants, Solid: Sampling, Examination and Testing to be found at https://assist.daps.dla.mil/quicksearch/. One common test for gunpowder age is placing the suspect powder in an oven at 65 C (150 F) until it fumes. If the sample fumes within 30 days the lot in the field is either chemically tested for the percentage of stabilizer or it is simply scrapped. This is from a 1969 Symposium:  This is from a 1970 Symposium:  The fume test for evaluating the stability of propellants is well established in the Insensitivy Munitions community. The rationale behind the 30 day period can be found in the 1973 Picatinny Arsenal report AD-763-879 [b] Prediction of Safe Life of Propellants states

Each service has its own peculiarities, the Navy expert told me they keep master samples in test tubes. In the test tube is a methyl violet paper, if the paper changes color, they track down the powder lot and test to see how much stabilizer is left. If the amount is less than or equal to 20%, the lot is scrapped. I think this is called the Methly Violet test, or Talliani test in Mil Std 286. The Army must do something similar because page 5-11 of the 2003 Army Logistics Propellant Management Guide provides the protocols for their Stockpile Propellant Program. The trigger for investigation is: "When Master Sample Stability Failure Occurs" The Navy and Army are consistent in that they scrap powders and propellants when the stabilizer is decreased from 100% to 20%. So, what do you do if you don’t have a chemistry lab to check the percent of stabilizer? Well all you have left is the gross indications of seeing fuming nitric acid and smelling a horrible bitter smell. The smell will knock your socks off. If you see or smell fuming nitric acid the powder went bad long ago. The stuff is absolutely unsafe to shoot and unsafe to store. More on the second point later. My Navy expert provided 'rules of thumb' concerning the safe lifetime of double based and single based propellants. The rules of thumb are: Double based powders and ammunition are scrapped at 20 years, single based 45 years. In his words “These 'rules of thumb' are particularly useful when the protocol fails. The protocol can easily fail when workmanship or good housekeeping measures are not followed during manufacture of propellant and/or rocket motor or during storage of the weapon system components, respectively.” I want to say, given hot storage conditions, sloppy manufacture, the lifetime of your gunpowder can vary considerably. Rules of thumb are best guesses and best guesses are guesses. Sometimes best guesses work out the way you predicted, when they do people will call you a prophet and you will pat yourself on the back for being a genius. When best guesses go wrong, you will wear the dunce cap and wonder what that word “hubris” means. Take these numbers with a grain of salt, early in the last century the storage lifetime of smokeless powders was considered to be 20 years or less: Army Ordnance Magazine, June 1931, page 445 says:

Federal says their ammunition has a ten year shelf life: Federal Ammunition http://www.federalpremium.com/company/faq.aspx

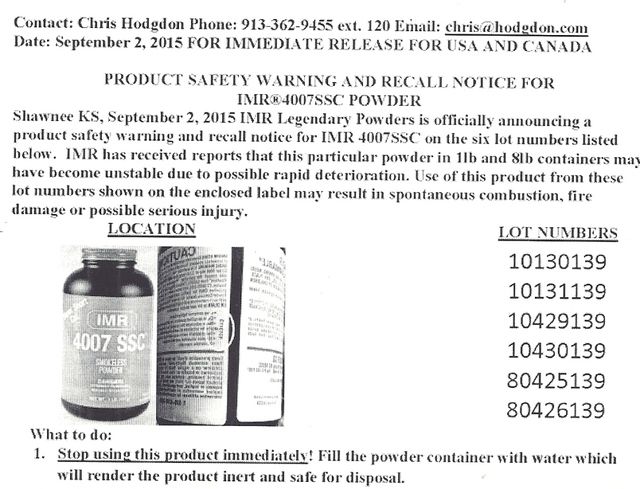

This is a recent recall of powders that had to be less than eight years old before they went bad: http://www.ssusa.org/articles/...imr-4007-ssc-powder/  I believe the most prudent approach to gunpowder is to regularly sniff test bulk gunpowder. Break that seal and cautiously sniff for fuming red nitric acid gas. Red nitric acid gas is extremely bitter. Examine the powder for clumping, grains that have changed color. Get rid of any powder that looks like this: http://thefiringline.com/forum...old+gunpowder&page=3

As gunpowder ages, pressures rise. Gunpowder grains deteriorate unevenly causing burn rate instability. Old gunpowder has, and will, blow up fire arms. Just search for reports of blown up guns with old military surplus ammunition, there are lots of them. The reporters don’t know why their guns have blown all to heck, and neither do the posters to their threads. Given that every one believes ammunition is immortal, the explanations become ludicrous, often, racist. I do not believe any military purposely manufactured or issued dangerous ammunition, but they certainly surplused it when it became so. [b]Why We Don’t Use Turkish 8mm Surplus https://www.forgottenweapons.c...turkish-8mm-surplus/ http://www.usrifleteams.com/fo....php?showtopic=21886 Posted 17 July 2012 - 01:29 PM 'Tailgunner', on 17 Jul 2012 - 13:16, said:

Westerners buy old Pakistani, Turkish surplus, think they have bought “day old” bread at a bargain price. I can assure you, the Pakistani, Turkish militaries had a reason to get rid of that stuff, and they have made a tidy profit on the ignorance of gunowners. They are laughing all the way to the bank. For those hoarding 50 year old gunpowder, I recommend you shoot up the stuff as soon as possible, before it autocombusts and you die in flames. This section is from the Dec 2003 Propellant Management Guide:

Military Surplus Powder autocombusting http://www.ar15.com/archive/to...tml?b=6&f=3&t=248538

1. 10-02-2009, 11:02 AM#6 Cincinnati Kid Platinum Bullet Member Join Date Dec 1969 Location Cincinnati, Ohio Posts 421

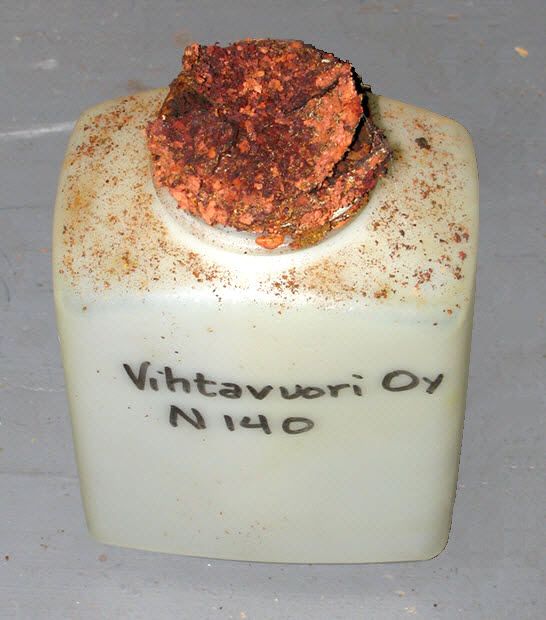

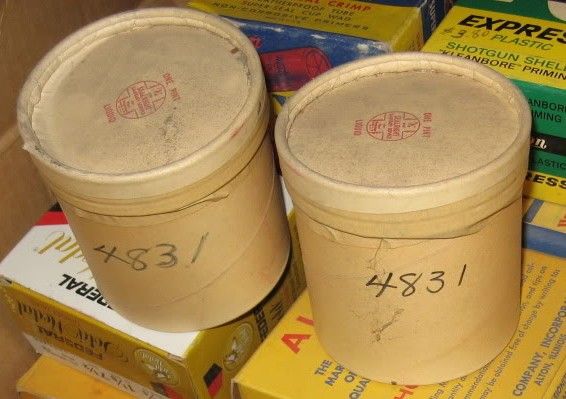

Old WW2 era powder, such as the powder in these containers, are well past any shelf life and yet the owners of the stuff store them sealed in their houses. They just don't know the risks with old unstable gunpowder.   | |||

|

| One of Us |

Slamfire, this is excellent information. I've read your posts on this topic before, and I think this should be continually brought up until the myth of "infinite" shelf life finally expires. I myself have experienced the bullet corrosion you mention. Also ballistic deterioration (without the accompanying red gassing) with powders that have been "opened" for various lengths of time. It's curious but not unexpected that many folks would rather believe in myths rather than to look at the actual facts.. A good job is sometimes just a series of expertly fixed fark-ups. Let's see.... is it 20 years experience or is it 1 years experience 20 times? And I will have you know that I am not an old fart. I am a curmudgeon. A curmudgeon is an old fart with an extensive vocabulary and a really bad attitude. | |||

|

| one of us |

A very impressive treatise, slamfire, but misleading. Different lots and types of powder will deteriorate at different rates. If this were not the case there would be no reason for the large stored quantities of powder cited by Slamfire to be monitored. Just destroy them when they reach their "burn on" date. But there is no such predictable "burn on" date for powder. The fact is that batches of powder that have been properly formulated will last virtually forever. Every element has a half-life, so the diamond in your wife's wedding ring is deteriorating as we speak, but I'm not worried that it won't last eons. Every now and then, as with the IMR 4007, a bad batch is formulated which goes South extraordinarily quickly. But if it ain't gone bad in ten years, it's not likely to go bad before you do. Powder going bad has little to do with chronological age and lots to do with its formulation and manufacture. And powder sold as canister grade has typically been formulated more precisely than that which goes into bulk uses. | |||

|

| One of Us |

Thanks.

Agreed. That is the basic problem with nitrocellulose based propellants, their lifetime is unpredictable. If they simply failed after a predictable number of years, then first world militaries would not have to have sampling programs, chemical analysis laboratories, to determine just when the propellant has to be scrapped. Third World countries cannot afford expensive monitoring so they just let their ammunition age to the point that it autocombusts. Just Google Ammunition Depot Explosions, every month there is about one blowing up somewhere.

This is an amazing example of Confirmation Bias. I suspect you really, really want your stash of gunpowder and ammunition to last forever. Well, I certainly want my ammunition and myself to last forever, but, unfortunately, that is not going to happen no matter how earnest my wishes. If you ever figure out how to make or detect that properly formulated gunpowder, you need to patent the process for you will become fabulously rich. The United States military alone scraps about $1.2 Billion in munitions a year, out of a stockpile of $70 billion. Army Not Producing Enough Ammunition http://www.nationaldefensemaga...es/Army_Not3866.aspx

* I think what is meant, 7-8 percent per year after 20 years. In so far as the lifetime of gunpowder, nothing in these documents suggests that gunpowder is a stable compound that will last forever if properly made. ROLE OF DIPHENYLAMINE AS A STABILIZER IN PROPELLANTS;ANALYTICAL CHEMISTRY OF IPHENYLAMINE IN PROPELLANTS

http://www.dtic.mil/dtic/tr/fulltext/u2/783499.pdf Ammunition Surveillance Procedures SB 742-1 https://acc.dau.mil/adl/en-US/...%2022%20Nov%2016.pdf Chapter 13 Propellant and Propelling Charges , page 13-1 WARNING Nitrocellulose-based propellant can become thermally unstable as they age. The normal aging process of the propellants involves deterioration of the nitrocellulose with an accompanying generation of heat. At some point, the propellant may reach a state where heat is generated faster than it can be dissipated. The accumulation of heat can lead to combustion (autoignition). Chemical stabilizers are added to propellants to slow the aging process. In time, the stabilizer levels will drop to a point where the remaining effective stabilizer (RES) is not sufficient to prevent an accelerating rate of decomposition. When this point is reached, the propellant may autoigniet, with possible catastrophic results to property and life. Monitoring the stability level of each propellant lot is essential for continued safe storage. Page 13-5 , Table 13.2 Propellant Stability Codes . Stability Category A 0.30 or more Percent Effective Stabilizer Acceptable stabilizer loss: safe for continued storage C 0.29-0.20 Percent Effective Stabilizer Significant stabilizer loss. Lot does not represent an immediate hazard, but is approaching a potentially hazardous stability condition. Loss of stabilizer does adversely affect function in an uploaded configuration. Disposition instructions will be furnished by NAR. All stability category “C” assests on the installation must be reported in writing… One year after becoming stability category “C” a sample of the bulk propellant lot or the bulk-packed component lot will be retested. If the lot has not deteriorated to category “D”, it will be retested each year until it has been expended, or it has deteriorated to category “D”, at which point it will be demilitarized within 60 days. D Less than 0.20 Percent Effective Stabilizer Unacceptable stabilizer loss. Lots identified as stability category “D” present a potential safety hazard and are unsafe for continued storage as bulk, bulk-packed components , or as separate loading propellant chargers. Bulk propellant, bulk –packed components and separate loading propelling charges will be demilitarized within 60 days after notification of category “D” status. Propellant Management Guide http://www.fas.org/man/dod-101.../docs/prop_guide.pdf | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  How long will powder and primers stay at 100%

How long will powder and primers stay at 100%

Visit our on-line store for AR Memorabilia