The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Coated Bullets/ Epoxy Etc.

Coated Bullets/ Epoxy Etc.Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Is anybody doing any experimenting with coated bullets? I've been asked to do some test firing and I'm not the only one that is finding that coated bullets are not as accurate.I've fired several bullet styles and a couple of calibers and they all produce the same undesirable results; some worse than others. Here are a couple of test targets; same bullet, same load. same gun just one coated and the other conventional lead and wax lube:   I'm not done testing yet, there are other options to try and improve accuracy and I'm trying another casters coated bullet. Anybody else have any experiences they would share? Buy the way these were fired from the bench on a Caldwell stand sighting through an iris so there is minute shooter error. | ||

|

| One of Us |

Not cast or lead bullets, but larger caliber rifle bullets with baked on coating wouldn't shoot at all for me in rifles that would do what your first target shows with standard bullets. _______________________ | |||

|

| One of Us |

Yea I'm working with the bullet caster on this and one theory I have to explain the loss of accuracy is that these coatings dont live up to the lubrication a bullet gets with wax. He's going to give me several more samples to try so I suggested the lube some coated bullets to see if that makes the loss of accuracy go away. The only other explanation is that these coatings are applied and need to cure in a variety of ways depending on the coating and could be making the bullet weight out of balance. I have a bunch of targets and will post some of the worst; it's a problem. But the good news with coating is your barrel can be cleaned with a patch and no brush and if your barrel is ported, you dont get the lead splatter in your ports or muzzle breaks or even a revolver spitting between the barrel and cylinder, but accuracy is an issue.   | |||

|

| One of Us |

Coating with what? Back in the early 1980s, we experimented with moly paint like coatings; they worked but didn't perform any better or worse than plain cast bullets, so that idea died off as not gaining anything. Looks like you might be going down that same path. And the moly powder coating for jacketed bullets that was touted to be the best thing since sliced bread in the late 80s or early 90s; I forget now;; it wasn't. I still have hundreds of them and the moly powder too. Some ideas are just not that great but don't let that stop you from experimenting. | |||

|

| Administrator |

We coat all our bullets with spray on Molly, and have not noticed any deterioration in accuracy. In fact, I did a very comprehensive test on Molly versus non-Molly, and found very little difference apart from slight velocity increase with the same load. That was with a rifle, not a pistol. | |||

|

| One of Us |

The coating is an epoxy type of coating. It does leave a lead free barrel and some say less smoke (which I dont notice, I look at the sights/target). After shooting the 45's, maybe close to 100 rounds, I cleaned the barrel with a cleaning solution soaked patch; nice but if you're thing is accuracy, an easy cleanup isn't a fair trade for the loss of accuracy. Picture of early coating samples.   | |||

|

| One of Us |

When the previous poster mentioned Molly coating I thought, yea there's kind of a fad that nobody seems to talk about anymore and I'm thinking with the problems trying to get a recipe that doesn't make accuracy go out the window, this alternative will likely be short lived in popularity if it even survives. Though there are shooters that wouldn't notice the loss of accuracy and remain tickled to death about the cleanup benefit. I'd rather have to run a bore brush several strokes and have my bullet go where I want it to. Believe me I appreciate all of your input, I'm working hard with the caster to see if this is viable. I'm curious; since the Molly coating doesn't do much for you but a bit more speed; why do you continue to use it. And I'm just curious..not trying to insult you or anything. | |||

|

| Administrator |

Basically it cuts cleaning time quite a lot. Applying it does not cost that much in either money or time. And the time saved in cleaning I find more than makes up for using it. | |||

|

| One of Us |

Thanks | |||

|

| One of Us |

Hard to tell from the pics but your red paint looks uneven and crinkled; that could be your problem. Thin out your paint. The stuff I used was quite thin and we just dipped the bullets in to it. It would stain your fingers black for a month if any got on them. Rubber gloves were for sissies back then. | |||

|

| One of Us |

Yea there was a round of samples since then I didn't photograph where the coating was thinned out and those shot better but still not like waxed lead. The first pictures I posted in the thread were shot with coated bullets that were so thinly coated they almost looked plated. I still think it's that the coating does not adequately lube the bullet. The next batch of samples coming are supposed to have coated bullets that are also lubed. | |||

|

| One of Us |

Gents: I read this with interest as I want to begin coating bullets for my large bore double rifles in .500, .600, 12-bore, 8-bore, 4-bore. I have the projectiles cast and sized. So, how thick is the coating and will I be shooting an over sized bullet down my bore? I've emailed this morning two AK shooters who coat and want to get everyone's experiences. With old doubles, I'm not looking at accuracy but am looking at time cleaning lead out of the bores. For 50-yard rifles, I'm sure accuracy will be fine. Cheers, Cal _______________________________ Cal Pappas, Willow, Alaska www.CalPappas.com www.CalPappas.blogspot.com 1994 Zimbabwe 1997 Zimbabwe 1998 Zimbabwe 1999 Zimbabwe 1999 Namibia, Botswana, Zambia--vacation 2000 Australia 2002 South Africa 2003 South Africa 2003 Zimbabwe 2005 South Africa 2005 Zimbabwe 2006 Tanzania 2006 Zimbabwe--vacation 2007 Zimbabwe--vacation 2008 Zimbabwe 2012 Australia 2013 South Africa 2013 Zimbabwe 2013 Australia 2016 Zimbabwe 2017 Zimbabwe 2018 South Africa 2018 Zimbabwe--vacation 2019 South Africa 2019 Botswana 2019 Zimbabwe vacation 2021 South Africa 2021 South Africa (2nd hunt a month later) ______________________________ | |||

|

| One of Us |

You size them after they are coated; my caster guy loves that aspect cuz you can just load the hopper and let them swag; you dont have to watch to make sure the lube is right. I know you can thin the coating. Keep an eye on the thread, when we get it right, I'll tell you what I know. You know another way to avoid leading is the alloy you cast. Based on what you're saying, you probably have a hefty charge behind it and the heat is leaving lead behind. I use a specialty bullet in my 454 Casull firing a 340 grain bullet with 30 grains of 296 with all but zero leading. | |||

|

| One of Us |

I would not size them after coating; cast to size and then coat. The less than one mil of coating won't hurt anything. One of the main reasons to size is to apply the lube anyway. The paint eliminates that step; I experimented with this back in the 80s, as I said; some sort of moly paint, very thin. I don't have any left that I know of but I have forgot a lot since then. Don't confuse this with the "Moly Powder" coating that was the fad of the 1990s; that is just powdered moly, coated, or not, with carnuba wax. You tumbled the bullets in the powder; not for lead bullets. That crap I still have. | |||

|

| One of Us |

I have said this before, but I will offer it again. I see powder coated bullets as the answer to a non-existent problem. The trouble with commercial bullets typically is two-fold: 1) they are cast too hard and sized wrong. 2) they use a commercial wax-based lube that is too hard, and often falls out of the grooves. Look at a box of commercial hard cast bullets. My experience with them is the lube is so hard it can't melt and flow like it needs to, and the bullets are as hard as bois d'arc. If a bullet cannot slug up (obturate is the proper term) to fill the bore and the lube extrude out of the groove during that process, one is destined for leading at a minimum, and poor accuracy to boot. I see this plastic coating fad fading into the mist like the previously mentioned moly coating. As I said earlier, it fixes a problem that is only created by commercial casters that don't do what they should, which is offer a product that doesn't lead. It can be done... I do it all the time with my own cast. | |||

|

| One of Us |

For double rifles and big bore SS, I have used Teflon tape patched lead bullets with good results. Also, Corbins sells a dip coating you can use to coat your bullets with. they call it "Dip Lube". I don't know if it contains moly or not, but Bear Bullets sells moly coated pistol bullets too. Again, not the moly powder thing; that is a different animal. These are paint coatings. There are several spray on moly/coatings that you could experiment with; Brownells sells them and they go on very thin. | |||

|

| One of Us |

Oh, yeah, this is a solution to a non-existent problem. And the moly dip paint fad, preceded the moly powder thing by many years; the OP is just now trying to revive it's dead body. But, I say, continue to experiment; it is fun and harmless. | |||

|

| One of Us |

Believe me I agree with both of you. The lead bullets I buy barely lead the barrel; my caster has his own foundry and makes good bullets. What we're doing is seeing if it makes sense to try and provide an advantage which I dont see happening without the accuracy sacrifice so far. I'm playing along with it as a retired shooter who likes thinking outside of the box and am willing to do some shooting for him. He has myself and a few other of his top shot customers running tests with the same results, so far, as I am getting. My thread here is just searching for anybody else who is using coated bullets and what their experience is. One thing brought to mind is the Molly coated bullets which you dont hear anything about anymore; my hunch is this epoxy coated thing will likely do the same...fade away with time except for the caster who started this craze who cant bake a bullet worth a crap and the coating hides his serious,leading problem with his bullets. | |||

|

one of us |

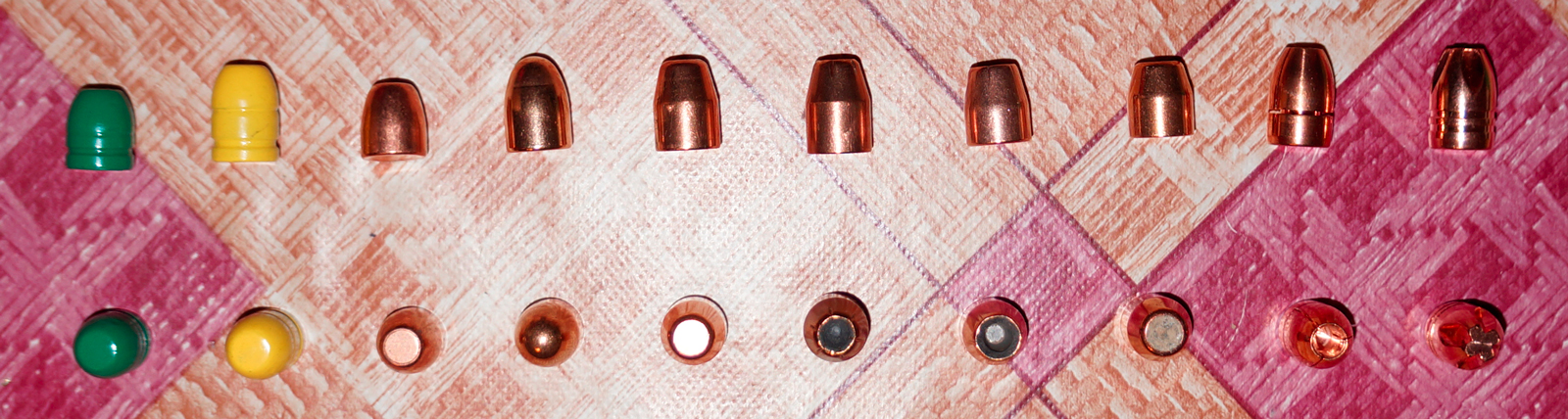

I shoot coated hard cast bullets (made by Ares company in Slovakia - http://www.ares-gunshop.sk/STR...RES-_-Bullets-/c-4/s) in .460 Rowland with great results. No barrel fouling.  Green is 200gr .451 bullet and yellow one is 250gr Jiri | |||

|

| One of Us |

OK but were they as accurate as the jacketed bullets? | |||

|

one of us |

PeeShooter: From my point of view, the load (powder, bullet, coal etc.) is more important. I can't find any real difference between that coated bullets vs. jacketed ones. But that are industrial made bullets, not home made painted cast bullets. But I didn't any exact measurements, like putting pistol to remote activated rest and shoot to target without influence of human factor. And really I don't care if my pistol shoot 1" group at 25 yards or 0.8". Without device I mentioned above, you can't really measure it at all. Jiri | |||

|

| One of Us |

Do you remember if your charge increased or decreased? | |||

|

| One of Us |

Epoxy? The stuff we used way back, was not epoxy. It was a single stage, thin, paint with moly in it. I would not use epoxy; it gets too hard and brittle, I think. This might be your problem. Use something more pliable. | |||

|

one of us |

PeeShooter: Only bullet with the same weight I can compare are 200gr (actually 203gr) Ares (coated one) and Sierra FPJ Match 200gr. It is in .460 Rowland, 5.5" barrel. Note that bullets have different lengths and cartridges have different COAL. Velocity is perfectly exact (average from 3 to 5 shots rounded to 1 fps) Ares 200gr, sized .451" Bullet length: 0.537" COAL: 1.220" Powder VVN 105: 15gr 1470 fps Sierra FPJ Match 200gr, sized .4515" Bullet length: 0.520" COAL: 1.205" Powder VVN 105: 15.5gr 1470 fps I never tried the same uncoated vs. coated bullet. Jiri | |||

|

| Administrator |

Cal, I suggest you try Molly spray coating. It will give you exactly what you want in less cleaning. The one I am using is a normal commercial spray. Much cheaper than the ones offered by bullet makers and so on, and works better actually. I clean my bullet with acetone before spraying them. | |||

|

| new member |

I think some posters meant to say 'enamel', not epoxy. | |||

|

one of us |

Saeed: If you lathe turn bullets and later put moly spray on them, do you turn them "undersized", or is the layer of moly negligible? Jiri | |||

|

| One of Us |

If you're asking me, I dont know. I'm just one of my bullet casters top shooters so he has me testing his bullets as he experiments. I have also ordered samples from other casters to compare. I do know that how my caster is doing this is to coat the bullets out of the mold then swag them as he would if he was applying a wax lubricant if that help answer your question. One problem you would experience with your method is that the coating thickness can vary as well he is thinning the coating as a part of trying to figure out how to get accuracy out of them. So if thinning is involved, your lathe work could be off very easily. Stay tuned for my ultimate findings. | |||

|

| One of Us |

Some say it's difficult to impossible to get the Molly coating out of your barrel. | |||

|

| new member |

Peashooter: For the sake of knowledge and input, you should contact Barnes Bullet Company on the subject of coatings used to enhance bullet performance. I contacted them for the very same reason. And, for discussion purposes, it was clearly noted that Barnes Company will no longer be offering their "XLC" coated line due to the introduction of their new "Triple Shock" bullet design(both products having a solid copper structure except for several incorporated design features). In short, they described their coated products as having very little gain over velocity or accuracy as a whole. The performance gains did not justify the added costs of manufacturing. For what ever its worth, Barnes technical staff could provide you the technical insight on past research endeavors. And, may provide alternatives to a solution to your endeavor. Drop them a line and see what they have to say! Joe Joseph Oldford O431441744521 | |||

|

| One of Us |

Wasn't Barns sold off and the previous owner is making the Hi-Tek coating? | |||

|

| new member |

Joseph Oldford O431441744521 | |||

|

| new member |

Joseph Oldford O431441744521 | |||

|

| Administrator |

Generally I keep the diameter of our bullets slightly under size. Example, for my own 375/404 I make the bullets to have a diameter of 0.3748. For some European rifles in .375 caliber, I have had to make bullets that of 0.3730 to shoot well. We basically custom taylor the diameter for the particular rifle. The only rifles we have had to make bullets for that required larger than caliber were Lee Enfield in 303 British. I have had some that were way overbore. For some we have made bullets that were 0.318!! But, adding the Molly spray does not any thickness that makes any difference whatsoever | |||

|

one of us |

Saeed: That is interesting. If you make for example one 375 bullet actually 0.3748 and other one 0.3730, the "bullet body" diameter is still the same or smaller too? If I want to make copper bullet for .460 Rowland pistol (longer .45 ACP with double energy), with what diameters should I start to develop it? Thanks for advice, Jiri | |||

|

| One of Us |

| |||

|

| One of Us |

Bayou Bullets in Louisana are excellent and a very good value. The bullets are Hi-Tek Heat set. No mess, on your hands or your barrel. No leading easy clean up and very accurate in size and weight. it is run by Michulek(sp) brother. A lot of 3 gun shooters use them. | |||

|

| One of Us |

I know all the advantages, which are great but they AREN'T accurate. The two targets just above your post is a side by side, everything exactly the same Hi-Tek coated bullets v. lead and wax. I have another company claiming to have accurate Hi-Tek coated bullets, I'm waiting for them to arrive and I will test shoot them and see if they perform better than the Hi-Tek bullets in the above targets. I have yet to find an accurate shooter that has anything good to say about the accuracy of coated bullets, no matter what the coating. | |||

|

| Administrator |

Jiri, It is not possible on our machine to make every bullet exactly the same diameter measured to 4 places of decimal. For example, each lot I make I keep within certain limits. Such 0.3746-0.3748. I suggest you might like to start with the standard diameter for that particular caliber, and worked from there. | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia