The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Nickel Cases?

Nickel Cases?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

Where can I find new nickel cases for 458 Win Mag, 458 Lott, and 375 H&H? I've searched the Internet with no luck. Maybe I'm not using the right search terms? I would also buy once-fired cases, and have found some on Gunbroker.com, but they are up for bid, vs. "buy now," and I would rather find a retail seller. Anyone know a source? LTC, USA, RET Benefactor Life Member, NRA Member, SCI & DSC Proud son of Texas A&M, Class of 1969 "A man's reach should exceed his grasp, or what's a heaven for?" Robert Browning | ||

|

| One of Us |

Most people don't reload nickel plated rifle brass because of problems with the plating. I've done some .38 and .357 but no rifle loads so I can't offer any input on nickel rifle brass. Macs Reloading and Ammo Depot don't seem to have them. You could call and see if they have a source for them. They may know who has them but available even if they don't carry them. macsreloading.com and ammodepot.com for phone numbers. A bad day at the range is better than a good day at work. | |||

|

| one of us |

Then wouldn't it be best to refrain from commenting on loading rifle brass if you've never done any of it? Sorry to be so brusque, but I hear the "internet wisdom" repeated ad nauseum about nickel plated brass. It works a bit differently from unplated brass, but reloads beautifully for someone who knows what they're doing. Sorry Nitro, I can't help you with an immediate source for the calibers you seek. | |||

|

| one of us |

Stonecreek: Agree; I've loaded a lot of nickel cases in 375 H&H & 458 Mag and never had a problem--or at least, no problem any different from loading brass cases. I personally think nickel feeds better and cleans up more easily. Back when Speer was making Nitrex ammo it was all loaded in nickel, and that's where I got most of my cases. Now I'd like to acquire some new nickel cases but can't seem to locate any source. Can anyone put me on the right track? LTC, USA, RET Benefactor Life Member, NRA Member, SCI & DSC Proud son of Texas A&M, Class of 1969 "A man's reach should exceed his grasp, or what's a heaven for?" Robert Browning | |||

|

| One of Us |

not sure, but i think federal has nickeled brass for those rounds | |||

|

One of Us |

Yup....reloading nickel brass is not a problem in my house.....I do it just like the regular stuff! BTW..... here's a link to Federal nickel plated loaded ammo.....Not sure if that helps.....spendy but a hell of a Cape Buffalo round! /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| one of us |

I sent Federal an email, asking for a source for unprimed nickel cases. We'll see. LTC, USA, RET Benefactor Life Member, NRA Member, SCI & DSC Proud son of Texas A&M, Class of 1969 "A man's reach should exceed his grasp, or what's a heaven for?" Robert Browning | |||

|

One of Us |

Run a WTB add in the classifieds....maybe someone has some for sale......a lot of big bore shooters here. /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| one of us |

Vapodog: Did that already, no luck. Guess I should bbt the ad-- LTC, USA, RET Benefactor Life Member, NRA Member, SCI & DSC Proud son of Texas A&M, Class of 1969 "A man's reach should exceed his grasp, or what's a heaven for?" Robert Browning | |||

|

| One of Us |

Stonecreek, Please enlighten us on the differences from plain brass on working and proper technique with nickel plated brass. ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ J. Lane Easter, DVM A born Texan has instilled in his system a mind-set of no retreat or no surrender. I wish everyone the world over had the dominating spirit that motivates Texans.– Billy Clayton, Speaker of the Texas House No state commands such fierce pride and loyalty. Lesser mortals are pitied for their misfortune in not being born in Texas.— Queen Elizabeth II on her visit to Texas in May, 1991. | |||

|

| one of us |

Nickeled brass can be quite successfully loaded with conventional dies using conventinional methods, but the plating tends to make the necks springier, so handle pressure on the press is harder; also, repeated sizings tend to abrade the nickel plating. I prefer using Collet Dies so that there is no sliding action to abrade the nickel (although billions of rounds of nickeled handgun brass has been successfully resized with "slide-in" dies.) Since the necks are springier, using collet-type dies may require honing down the mandrel a couple of one-thousandths to achieve the inside neck diameter you desire. I use exclusively nickeled cases in several rifles, among them a .30-06, and a .270, and I use predominantly nickeled cases in one .222 and one .22-250 (using nickeled cases in one gun and brass in another is a great way to keep the cases separated when you own and shoot two different guns of the same caliber.) I also have a varmint-barreled .243 in which I frequently shoot a batch of Federal Match .308 cases which I resized to .243 in a single stroke and without the loss of a single case. The only complaint I've ever had about nickeled cases was with a batch of Remington's which had a rough residue inside the case necks. I had to remove it with some steel wool wound on a spinner mandrel and powered with an electric drill. After they were cleaned up they were fine. I've heard of this same complaint (but not experienced it) on other lots of Remington nickeled cases, but not on other brands. | |||

|

| One of Us |

Thank you sir! That was very informative. As always you taught me something! ~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~~ J. Lane Easter, DVM A born Texan has instilled in his system a mind-set of no retreat or no surrender. I wish everyone the world over had the dominating spirit that motivates Texans.– Billy Clayton, Speaker of the Texas House No state commands such fierce pride and loyalty. Lesser mortals are pitied for their misfortune in not being born in Texas.— Queen Elizabeth II on her visit to Texas in May, 1991. | |||

|

| One of Us |

I've loaded Nickel Cases for my 338WM for years and never had a problem... Also no problem for the 45APC | |||

|

| One of Us |

I may have stated that wrong. I have reloaded nickel .38 and .357 brass. I do reload rifle just not nickel brass. A bad day at the range is better than a good day at work. | |||

|

| One of Us |

Good luck with Federal. Hpe you find wat you are looking for. A bad day at the range is better than a good day at work. | |||

|

one of us |

It took a lot more effort for me to trim the nickel brass, Winchester brand, in 30.06. I use a Wilson trimmer with the bushings. Pretty much gave myself epicondylitis. Curiously, the brass I trimmed right before the nickel .06 stuff was Federal regular .06 cases with no problems. It was like my cutter was instantly dulled. Ted Kennedy's car has killed more people than my guns | |||

|

| One of Us |

Doc, I loaded some up in a 22/250 and have damaged the cutter on my RCBS trimmer. $35 dollars later and a new cutter for the trimmer I've decided when these are done and they grow to long, in the bin they go. I find seating bullets more difficult than standard brass, now explained by the rough inside necks on some Rem nickel cases. (Mine are Rems). Whilst they feed brilliantly, stay clean etc, the bad points seem to outweigh the good. Therefore to my mind , more trouble than they are worth. | |||

|

| One of Us |

Back when Speer was making Nitrex ammo it was all loaded in nickel, and that's where I got most of my cases. Same for me, these Nitrex shot as well or better than any other factory load i've shot out of my Steyr 300 wm. I want to reproduce this load. It was speer nitrex 180 gran slams at 2950 fps. I've cleaned sized and trimed the origanal Nickel brass. I noticed the trimming was a little difficult with Nickel. reprimed with cci and going back with gran slams.COULD USE SOME INPUT WITH POWDER. WHERE SHOULD I START WITH BURN RATE. Any help with this load will be appreciated. Larry | |||

|

| One of Us |

Imperial Sizing Die Wax is slippery stuff. Ought to make resizin' 'em pretty easy. I reload .223 nickel now and then. Gonna do some tonight. | |||

|

| one of us |

Agree. And once you FINALLY get them Trimmed, then you need to Champfer and Deburr. The Trim/Deburr portion then exposes the "Edge" of the Plating and gives it a place to begin splitting. That "can be" followed by Flaking. In addition, I had "one" bad run of Plated 308Wins from Remington. They began Flaking at the Neck after the First Load was shot. Of course the only way to find it was to Ram the Plated Case into the Die. Then I took the Die apart and got it all cleaned, with no "apparent" scratching, so I was lucky in that regard. ----- As a side note, if you Reload Plated Cases and let them set for a year, they will "Tarnish" just like any other Case. The shiney brilliance is reduced to a dull matte patina. The only real advantage to Plated Cases I've seen, is locating "Pistol Cases" on the ground. And then only when they are shiney. Best of luck to you if you do use them, but they sure aren't worth the bother of trying to locate any. | |||

|

| one of us |

1. Ammunition/component manufacturers continue to produce nickel cases. 2. Distributors continue to stock them. 3. Resellers charge more for them. 4. It follows that reloaders must buy them, and are willing to pay more for them. 5. The market is sometimes "wrong", but since this situation has existed for many years, the market is likely "right" and nickel cases are somehow worth more than unplated cases. 6. It must follow that some reloaders (those who prefer to use plated cases) know something that other reloaders do not. 7. This logic will be lost on Hotcore. | |||

|

| One of Us |

Clean Dies Clean Cases and Boeshield T9 an I've never had an issue , as a matter of fact never stuck a nickel case . Sorry I can't say that about brass cases, because every once in a while Sheet happens !. I've never treated nickel cases any differently than brass and I'm still alive !. | |||

|

| One of Us |

I reload Nickel Cases for my 338WM and never had a problem... | |||

|

| One of Us |

I would have to guess that the reason that: 1. Ammunition/component manufacturers continue to produce nickel cases. 2. Distributors continue to stock them. 3. Resellers charge more for them. 4. It follows that reloaders must buy them, and are willing to pay more for them. 5. The market is sometimes "wrong", but since this situation has existed for many years, the market is likely "right" and nickel cases are somehow worth more than unplated cases. ...is that folks want them. Like you say, there is a market for them. This is true even though everything I have read states that using them is more trouble than it's worth. Some good info from Varmint Al who's background is in engineering:

| |||

|

| one of us |

This logic will be lost on stonecreek. | |||

|

One of Us |

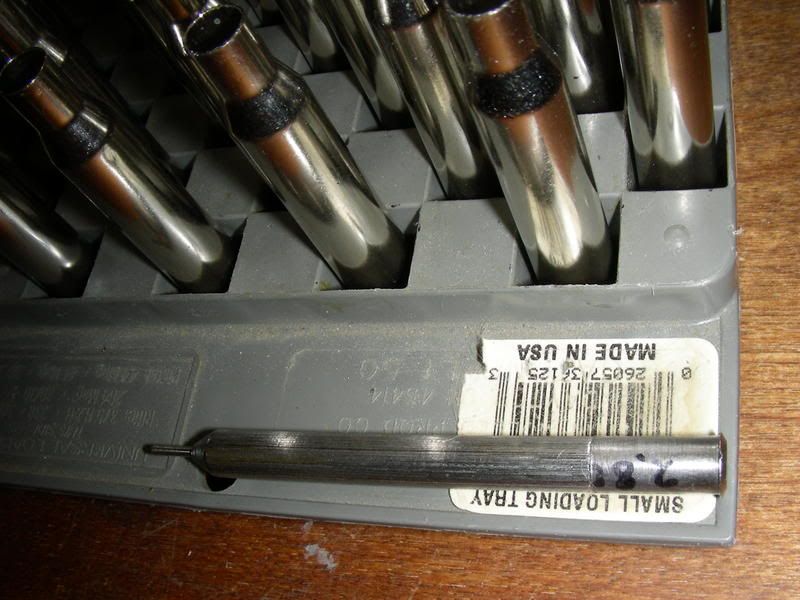

The last time I used nickle cases was on some 280 rem loads for a friend. I got a bag of 50 and decided to expand and uniform the neck by sizing with a Lee Collet mandrel   This probably did not have to be done, could have just loaded the bullets for fire forming, but imagine what the nickle case will do to your chamfer tool and to the inside of your die where the die starts to size the neck down. The outside of the neck mouth will wear on that die. This logic will be lost on everyone but me (but y'all are all wrong! ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

The Lee mandrel is not heat treated so it is easily devoured by the nickel cases. The nickel does not mar carbide expander though. My experience with it is to neck size in a bushing die so I can easily monitor the bushing. I have sized a lot of nickel cases that I got cheap as once fired brass. I would never buy it new for a rifle cartridge when I can get un-plated cases. I would never use it in a really expensive sizer die. | |||

|

| one of us |

As I said earlier, I've only encountered the rough inside neck surfaces on one particular lot of Remington nickeled brass, but clearly it shows up on other lots with enough frequency to be noted here. Removing it by spinning a little steel wool on a mandrel with a power drill negates the issue. Wait, what's that you say? Remington sometimes makes crummy, inconsistent brass? Nah, you're pullin' my leg! You don't think that the rough insides on some Remington nickeled cases is the result of some quality control issue, much like off-centered flash holes, short and long necks, and highly variable case weights in their non-nickeled brass? Could that be why some nickeled cases are as smooth as a baby's behind inside the necks? Like the Federal Match cases I've used, or some of the Winchester once-fired nickeled brass I've come across? And how could all of those billions of nickeled pistol cases that have been produced all of these years be so consistently smooth inside? A mystery worthy of Sherlock himself. | |||

|

| One of Us |

It is simple really----Reloaders use Nickel and Handloaders use Brass LOL!! For my use Nickel is junk ---- ever see anyone shooting a BR Match using Nickel??? Now in a high humidity environment nickel will not corrode nearly as fast as plain brass. It has a use but if you are loading for accuracy you are peeing into the wind | |||

|

| one of us |

Nice flicks Mr. Woods. Sure gets to the Problem much better than jawboning. By the way, I'm real glad none of your "Thingys" got destroyed, cause I'm sure there would have been a lot of | |||

|

| one of us |

This logic will be lost on stonecreek. | |||

|

| One of Us |

Before I found out about VA's site, I actually did this very thing. I had some factory Winchester .243 WSSM 95 grain XP2 ammo. The bullet is coated with some kind of black proprietary coating from Combined Technology. I pulled the bullets part way out to increase OAL to see if I could get better accuracy. The sides of the bullets were terribly scratched up. I checked the ID of some fired cases and noted how rough it was. I was thinking of saving and reloading all of the factory nickle cases I had. I bargained for 6 boxes of factory ammo when I bought the rifle. Then I read VA's take on nickle brass. It all went into the trash. | |||

|

| One of Us |

Well, I have to say that you all have my interest piqued about nickel coated brass again. I collected some 50pcs a number of years ago from a friend who was shooting some Speer Nitrex, I believe the brass was federal. Each and everyone had a loose primer pocket after 1 firing. No resistance on any, a few the primer would not stay in the pocket. I gave up on reloading nickel brass after that. I should not allow one experience to change my views, but sometimes, that is all it takes! I will look tonight and see if I can find some of those rounds. I believe a few of them are about still loaded. If I can find a couple I will take pictures. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

One of Us |

This had nothing to do with nickel! /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| One of Us |

Might not have. I have stopped using Federal brass. Side by side, same bullets, same charges, same rifle, Federal brass lasted 4 to 5 firings, then the primer pockets went loose. A few are still going. Winchester brass, not a single has been scrapped yet. Not that I am a huge fan of winchester... they just happened to be on hand. Nathaniel Myers Myers Arms LLC nathaniel@myersarms.com www.myersarms.com Follow us on Instagram and YouTube I buy Mauser actions, parts, micrometers, tools, calipers, etc. Specifically looking for pre-WWII Mauser tools. | |||

|

One of Us |

I can't say I've loaded thousands of rounds with Nickel brass but certainly a few hundred......and have never had a "nickels" worth of trouble from it! I have noticed in standard new brass some sharp edges at the case mouths which I remove by resizing and then ID chamfering.....and this IMO must be done to all new brass.....at least the stuff I buy. As to the stryations on the steel shanks photo'd above.....I'm not buying that .00005 thick nickel is the cause....(that's fifty millionths of an inch 1/60 th the thickness of a human hair) I do believe that I've seen increased neck splits with nickel cases inside three loadings but my total experience really does not confirm this. Nickel has some beneficial uses which include identification and resistance to tarnishing in leather bindings and also cleans easier than pure brass. I say if you want to reload nickel....go for it....it hasn't caused me any thouble.....so far.....let me find some wood to knock on now.... /////////////////////////////////////////////////////////////////////////// "Socialism is a philosophy of failure, the creed of ignorance, and the gospel of envy, its inherent virtue is the equal sharing of misery." Winston Churchill | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia