The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Sobering Article

Sobering ArticleGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

I am an engineer, and while I am working while working on technical problems, I am used to a certain standard of rational thought. Gun magazines don't address us as engineers, but consumers, to buy, use, and think of guns as we are told. Most gun magazine articles have no useful information and if they have a comparative test, they often have out of control variables. The book " Rifle Accuracy Facts" by Vaughn writes, " Consequently, the only way that this is thing [accuracy for sporters] is going to get done is for someone to do it on an amateur basis (no pay).. [I] decided to take a shot at it." Forums on line are mostly lower in content than the gun magazines. Intelligence like I read on this forum is rare. | |||

|

| <Axel> |

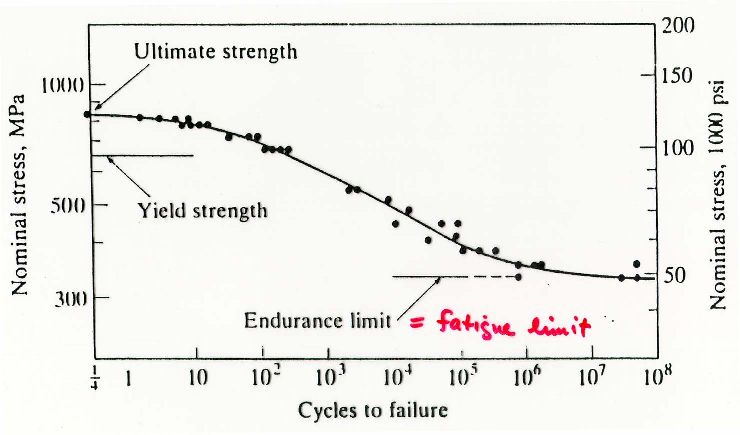

Clark, pressure IS THE MOST IMPORTANT parameter. Pressure determines the working forces and resulting stresses placed upon the action. Cumulative fatigue of metals DOES NOT begin at and above the YIELD point. You need to go back to your textbook and study ENDURANCE LIMIT. Cumulative fatigue initiates when the endurance limit is reached / surpassed! You will learn that the endurance limit of steel is FAR FAR below the YIELD POINT. What kind of enigneering consultant work do you do? EDIT - According to my calculations the shear stress on a M700 action generated by a 7mm Rem mag @ 83,000 psi chamber pressure is EDIT - Correct Shear Stress for this load is 1204 MPa - . I would wager that the action's cumulative fatigue life at that load, and assuming that the load is evenly carried by both bolt lugs, to be around 50 rounds or less till catastrophic failure! NO WAY NO HOW WOULD I SHOOT THOSE LOADS IN MY RIFLE!!!!!!!!!!!!!! Axel [ 04-17-2003, 19:48: Message edited by: Axel ] | ||

|

| <eldeguello> |

Well, this certainly is sobering, all right! But I suspect something is wrong here!! The modern bolt action will stay intact at pressures in excess of 100,000 PSI. The weak component of the system is the brass cartridge case. The figures I've seen indicate that brass begins to flow in the vicinity of 70,000 PSI, OR LESS, although of course, some alloys are stronger than others. I used to have trouble with certain loads in Norma brass, when both Win. and Rem. cases would handle the same loads without any signs of trouble at all. So, if brass, as a rule, begins to flow at 70 K PSI, HOW can a load develop the figures given by Jameson, in a brass case, and there not be "any signs of excessive pressures at all"? Obviously, if Jameson's pressure figures are correct, then his loads were SAFE IN HIS GUN, because they did not develop pressures high enough to damage ANY PART OF THE SYSTEM: the action, the cartridge case, or the shooter. I would say any load is safe, if it doesn't damage the weakest part of the system, the primer/cartridge case, REGARDLESS OF WHAT A PRESSURE-MEASURING DEVICE TELLS YOU!!! People who have experimented with steel cases have fired rounds developing over 100,000 PSI without injury to themselves or their rifles!! Yes, the pressure readings here were much higher than what we strive for, but no part of the system, including the shooter, was damaged in any way by the loads Jameson fired!! However, I would never RECOMMEND continuing to fire loads that develop the pressures Jameson gave, if they are actually correct!!! [ 04-14-2003, 23:25: Message edited by: eldeguello ] | ||

|

| one of us |

CUP vs. piezoelectric vs. strain gauges: All the gory statistical details coming up in the July issue of Varmint Hunter. Can you do pressure measurements at home that rival those of commercial testing organizations?? What systematic error is found in published piezoelectric data? Inquiring minds want to know... | |||

|

| one of us |

denton--- Don't keep us in suspense, tell us more. Thanks to all for the input, good stuff in this thread. Maybe I'm just impressed cause you guys are talking over my head. Keep it up anyway, I might learn something.---Shoot Safe---montdoug | |||

|

| one of us |

Axel, How much money have you got? | |||

|

| one of us |

The bottom line is that all three systems have a fair amount of random error in them, and, for that reason, don't do exceptionally well on individual cartridges. If you average 10 shots, any of the systems will put you within about 1,000 PSI, which is acceptable. With a little care, you can produce your own pressure measurements that are about as precise as published measurements, using equipment that costs less than a mid-priced rifle scope. The one data set that I have for cartridges simultaneously measured by the CUP and piezoelectric methods shows a strong systematic error in the piezoelectric data... fix that, and it improves the precision quite a bit. I'm about to start some tests on another low cost strain gauge system, that is just hitting the market. We'll see how that stacks up. | |||

|

| <Axel> |

Clark, why do you need to know how much money I have? Denton, you can reduce the error of your measurement instrumentation by calibration. Axel | ||

|

| one of us |

Axel, Have you forgotten your faith in Cumulative fatigue bolt lugs and offer to make a wager that a rifle can't take 50 rounds of needing a mallet to pound on the bolt handle open? | |||

|

| one of us |

quote:You claim to be an Engineer? Please tell me where you got your degree as I'd like to call them up and have them recind it! Ever heard of an S-N Curve? Look it up in your "text book" and get back to me. Find one for the material from which actions are commonly made. You'll find it has a finite life that begins well below its yield point. And it's on a logrithmic scale. Do you know what that means? What sort of "Engineer" are you, anyway? Some Civil-type that designs septic tanks or something? Sorry, but I can't let your idiotic statements stand. If you are, in fact, an Engineer then you are giving the profession a bad name by displaying such AssClownery. You haven't a freaking clue about the subject matter at hand. From your statement above, it's obvious you don't understand your one and only "text book" either. | |||

|

| <Axel> |

Clark, I am not sure what you are ranting about. It is completely possible a rifle could last longer than 50 rounds with that load and cartridge, BUT IT IS ALSO COMPLETELY POSSIBLE, AND EXPECTED I MIGHT ADD, THAT IT COULD FRACTURE EARLIER THAN 50 ROUNDS AS WELL. The life expectancy was determined based upon: 1.) An assumed Log S - Log N curve slope, which was based off of previous experience working with hardened 4140. 2.) A Y intercept equal to the ulitmate strength of 4140 at Rc 35. 3.) Use of a statistical failure population of 10% (B10) with a level confidence of 50%. By the way, catstrophic failure in this instance does not necessarily mean EXPLOSION. It DOES MEAN that the bolt lug has fractured though. JonA , you may be correct in that this guy is a Civil. That would explain many many things! Axel | ||

|

| <eldeguello> |

I'm sure there have been cases of rifle actions failing due to metal fatigue, perhaps caused by firing a lot of excessive loads. But I have never seen such a case documented anywhere!! I AM INTERESTED if this has actually happened, and if metal fatigue has been PROVEN to be the cause of the failure .... Am not talking about improperly made arms, such as low-numbered Springfields!! | ||

|

| <Axel> |

eldeguello, if you are that interested invest in a gun vise and remote firing system. Place a rifle in the vise, hook up the remote firing system and start shooting. Make sure that you enclose the firearm in a blast proof enclosure for safety reasons. Let us know how many of these 83,000 psi loads it takes to CRACK a bolt lug. Of course if you wish I can perform the test for you. Send me a PM and I will give you a quote for the cost of the testing. Modern bolt actions loaded to 60,000 psi in a H&H sized case should have a VERY long fatigue life. Understand however, that as Jon A said, fatigue life is a logarithmic scale. What that means is, a 10% increase in stress amounts to 1/2 the fatigue life. Remember these hot loads @ 83,000 represent approximately a 40% increase in operating stress to the action. This WILL dramatically reduce the actions fatigue life. Axel | ||

|

| one of us |

I really wish that I had the original info, but the following basic model may help structure the discussion: If you graph the probability of failure on semi-log (or is it log-log?) graph paper, with the applied "stress input" on the horizontal axis, and the number of "stress applications" required to cause 50% of test objects to fail on the vertical axis, you get a straight line graph in many cases. Applying that model, a huge number of mild "stress input" events (cartridge firings) are required to cause 50% of firearms to fail. However, even at low stress levels, you will eventually cause firearms to fail. It's just that the number is so huge that the probability of experiencing one in real life is extremely small. If you apply much larger stress events, such as 83,000 PSI cartridges, the number of events required to cause 50% of all firearms to fail becomes much, much smaller. So popping off a round at 83,000 PSI, and not getting a failure MEANS NOTHING. You have to test a lot of guns before you have tested enough to find out what the probability of failure is on any one stress event. If you have a large lump of uranium, you can plot the half-life (the time it takes 50%of the atoms to decay) very accurately, because you have a gazzillion atoms. If you have two atoms of uranium, there is no known way to predict when either of them will decay. It is the same with bursting firearms using overloads. One pass or fail means nothing. Just because you got away with it once or twice does not predict a secure future. The graph | |||

|

| one of us |

I believe it's "RESCEND", not "RECIND!" INQUIRING MINDS NEED TO KNOW. | |||

|

| one of us |

Ok, Axel, I have "Machineries Handbook" here and I am looking at metal fatigue. I see the S vs N curve. I see Goodman's formula: Sa= S[1-Sm/Su] I see Miner's rule: [Sum]n/N =1 is the cycle rule or damage fraction I see Low cycle vs High Cycle defined low cycle is in the elastic range [that must be our bolt lugs that do not change shape at 83 kpsi loads] It says that low to high cycle transition occurs at 10,000 to 100,000 cycles. Could you go through and example predicted number of cycles at 60 kpsi vs 83 kpsi on any bolt gun you have? Please? I would really like to learn how to calculate this. | |||

|

| one of us |

Jon A Those were not statements, but had question marks after them. It really is hard for me to imagine an elastic process having a cumulative effect on the molecular level, but I admit it must be going on. I have a degree in Electrical Engineering from the U of Washington in 1978. I have designed electronics all this time, but I have done some supervision [read pretend to understand] of vibration, shock, and thermal analysis, which is as close to this as I usually get paid for. I really would like to learn. Could you go through an example of the # of cycles difference between 60k and 83 kpsi loads in any bolt action? And welcome to the great Northwest. I am on Mercer Island's tough South end. [ 04-17-2003, 08:42: Message edited by: Clark ] | |||

|

| one of us |

sonofagun - "rescind" All - very interested in this discussion please don't hold anything back. BS (Sanitation, Specializing in Porcelin), University of Waikiki. PE (pseudo engineer) 1990. | |||

|

| <Axel> |

Clark, to answer your question. B10 life @ 83000 psi load ~ 50 firings B10 life @ 60,000 psi load ~ 2100 firings B10 means: That 10% of the tested samples will fail, while 90% will pass. Like I said this is an asssumed S-N curve. Axel | ||

|

| one of us |

Axel, Thanks for the response. I know how to get from the chamber pressure to the sheer forces in the bolt lugs, and the compression forces on the bolt lug mating surfaces. What I am stuck on is I have the yeild stength of the steel, with some assumtions about which steel and heat treat, but how do I get from there to plotting an S-N curve? I can't just assume any S-N curve I want, there must be a process. Do you know that process? | |||

|

| <Axel> |

Clark, The shear stresses for M700 action in the bolt lugs are: 83,000 psi load ~ 1204 MPa 60,000 psi load ~ 870 MPa The I mispoke in an earlier post and did not include the stress riser associated with the MINIMAL radius at the root of the bolt lug! The above stresses should be within 5% of correct. The proper way to generate a S-N curve is to actually test the component to failure. The test will be comprised of two populations of "identical" components. Each population tested at a different load to failure. For example. You could test two sets of M700 long actions with three actions in each set (total of 6 actions) Test three of the actions, one population, at a 83,000 psi chamber pressure until failure. Test three of the actions, second population, at a 60,000 psi chamber pressure until failure. Perform statistical analysis on the each population to determine it L10 life. This will provide you with two point on the Log S - Log N curve. With these two points you can calculate the equation for the line. That is about 75% of what must be done. I let you figure out the actual Life Equation. My life estimates are based upon torsional fatigue testing of hardened 4140 shafts. This provided me with the slope of the Log S - Log N curve. I made assumptions then as to the Y intercept. Basically, I assumed that the intercept was the Ultimate strength of the material. Axel | ||

|

| one of us |

Axel, Thanks for the response. I have been surfing the internet with Google for an hour reading. The world seems to be awash with Wohler /S-N Plots from 10,000 cycles to the Fatigue Limit. Not many at fewer cycles. They sorta kinda look like the yield strength slopes down to a million cycles at half the yield strength. More cycles are no worse. There seem to be allot of variables like surface finish, type of stress, residual stress, amplitude of the alternating stress, and type of steel. I have only one Rem 700 in storage, but lots of Mausers. I could measure headspace and get prepared to shoot 1,000 rounds of 8mm that destroy the brass. | |||

|

| <Axel> |

Clark, The reason that the S-N curves you see on the net start at 10,000 cycles and proceed to the Endurance limit, which is the correct term for the point at which fatigue no longer exists, is that the linearity of the S-N curve is lost below 10,000 cycles. By the way, ferrous alloys have an endurance limit, but aluminum doesn't. You may notice from my stress calculations that the peak shear stress in the bolt lug is practically equivalent to the ultimate strength of the material. That is why I said it may last far fewer than 50 firings! The fatigue characteristics can get pretty FUZZY when the stress is close to the ultimate strength of the material. If you want to determine the fatigue life of one of your Mausers that is ok with me. I WOULD STRONGLY RECOMMEND THAT YOU MOUNT THE RIFLE I A GUN VISE, FIRE IT REMOTELY, AND SHIELD THE WEAPON SO THAT ANY SHRAPNEL IS CONTAINED! Axel | ||

|

| <eldeguello> |

Axel, thanks for your offer. I have no doubt that what you say is true, concerning action failure. But I do see two practical difficulties with the test you propose: 1. How do you prevent cartridge case failure at 83,000 PSI, in which case, your action is going to be ruined by escaping gas long before you can fire it enough times to cause the receiver or bolt metal to fail due to metal fatigue? 2. How do you develop a load for the test that will produce just at 83,000 PSI in that particular gun so you can even conduct such a test? In all the years that handloaders have been loading and firing home-made ammo without the benefit of even chronographs, let alone pressure measuring equipment, I have heard of MANY blown-up rifles. But the only types of failures I recall that have caused damage were due to two causes: Bore obstructions, and brass cartridge-case failures. I am certainly not saying that there haven't been any failures of the kind you describe. But I do not recall having heard of documented cases of metal fatigue failures in any Mauser-type or Ruger single-shot actions made of modern materials. I am not an engineer, so cannot even carry on an informed discussion with you concerning the factors involved. However, I do recall once hearing that, according to many aeronautical engineers, it is impossible for a bumblebee to fly!! [ 04-18-2003, 18:26: Message edited by: eldeguello ] | ||

|

| <Axel> |

eldeguello, your contempt of engineering capabilities is evident with you last statement! I agree with you by the way, with regard to case failures with a load @ 83,000 psi! Steel cases would most likely be required to maintain case integrity during firing. As to loading to the exact 83,000 psi level you and I both know that is not truly possible. There will ALWAYS be a statistical distribution to the pressure. However, the test would be conducted with a 83,000 psi chamber pressure which was the mean peak pressure. So the standard deviation of the specific load would determine the minimum and maximum loads expected to be encountered during the testing. Perhaps, Clark with run the test with a mauser action and we will all learn something interesting! If Clark does conduct a test of this nature he had better utilize every safety precaution he can think of. Axel | ||

|

| one of us |

Axel, I have been overloading guns for a while. | |||

|

| <eldeguello> |

Axel, if you think I have contempt for engineers, you are wrong!! I freely admit that I cannot carry on an informed conversation with an engineer about the present topic!! As soon as calculus becomes involved, I am lost!! The only engineers I have doubts about are those who cooked up the latest .350 R. Mag. offering from Remington, with the vent. rib and sharks-fin front sight!! So if I understand you re: the bumble bee, it can fly, but has a very low glide ratio!! I don't even believe the bee is capable of auto-rotation. Is that correct?? [ 04-19-2003, 19:27: Message edited by: eldeguello ] | ||

|

| <Axel> |

eldeguello, the statement dealing with your "contempt" was meant in jest! That was the purpose of the " Axel | ||

|

| one of us |

OK guys, I'll try and explain things a bit better. First I want to clear this up--Axel seems to be implying that a statistical study needs to be done on anything ever built. This is not the case. The statistical studies have already been done for nearly any material you can think of. So, whatever you�re building, if you do the proper analysis you can accurately predict the failure of the part. That doesn't mean no testing on parts is ever required--it certainly is--but not to the degree he's implying. Think about what we'd have to do a Boeing. Build 1000 planes, fly them around and see how many break in half and fall out of the sky? "Well, that was a 50% failure rate. Let's change the design, build 1000 more and see how many of those fall out of the sky!" I'll try to outline how one would go about this: First, when analyzing the locking lugs/bolt for failure, PSI of chamber pressure does not directly equate to PSI of stress in the material. It may be close, way lower or way higher. The force acting on the bolt that you're interested in is bolt thrust. That's a force, not a pressure (although it is a result of chamber pressure of course). The subject of how to determine that is a large one. Let's forget that for now as the subject at hand is enough. But for say a 300 RUM, figure 5-6000 lbs of force. This force is acting on the bolt, putting the locking lugs in shear. From this you can calculate the shear stress of the locking lugs. It's simply the force divided by the area of the locking lugs (area of their bases, where they "attach" to the bolt body). As Axel mentioned, that's the easy part. The stress will not be evenly distributed across this area. There are stress concentrations on every bolt. These may double, triple, quadruple or even worse the stress you calculated above. There are some methods to estimate this by hand but it's pretty difficult to do on a bolt with a high degree of accuracy. The best method is a Finite Element Analysis. Here's an example of one I threw together over my lunch break one day awhile back: As you can see, the peak stresses are rather high! Once that has been determined, then you go to the S-N Curve. Here's a simple example:  As you can see, you can be quite a ways below the yield limit of the material and still have a failure in fewer than 1000 rounds! I've already put well over 1000 through my 300. Does that make more sense? [ 04-20-2003, 01:57: Message edited by: Jon A ] | |||

|

| one of us |

An interesting discussion. However, I think that the situation is much to do about nothing. I have never talked to a single person who had a rifle shear the lugs or blow up. I have read of some who had failures due to greatly overloaded ammo. I continue to believe that we loaded hot ammo for over half a century, and with careful working of loads there is no danger. If one examines loading data from 30 years ago, he will find many loads several grains above current load manuals loads. The velocity is much lower also in current manuals. I will continue to use hot loads in high velocity cartridges, such as the magnums and .270, and I am not worried in the slightest. Jerry [ 04-20-2003, 03:21: Message edited by: JerryM ] | |||

|

| one of us |

Sure gettin deep around here, think I'll go shootin. It's a wonder an ole fart like me hasn't blowed up all his rifles, what with not knowin any a them fancy formulas ner nothin. Lucky I guess.---Shoot Safe---montdoug | |||

|

| <Axel> |

JonA, excellent post! A picture is worth a thousand words, eh. Your S-N curve is not statistically significant. In my example I baked in a little Reliability Engineering and provided a recipe for a statistically significant S-N curve. Essentially, your S-N curve will predict double or triple the life of a R90 curve. Clark, you will notice that the curve JonA posted is stereotypical in that the curve is linear from 10,000 cycle to the endurance limit at 10,000,000 cycles. Linearity is lost below 10,000 cycles while the "curve" is horizontal above 10,000,000 cycles. Axel | ||

|

| one of us |

quote:PICKY PICKY! | |||

|

| one of us |

quote:Yes and no. I realize that you indicated that your FEA needs further work, but it sure looks curious the way it stands. What value for bolt thrust was used in that analysis? The peak indicated stresses are over the UTS; wouldn't that mean failure (or at least cracking) with one shot? Looks like that's a three lug bolt, too. I'd sure love to see a refined FEA of a Mauser bolt at typical chamber pressures. | |||

|

| one of us |

Jon A, What I am getting from your graph is that if I fire a proof load [1.5 X working pressure]in a bolt action and it survives, I believe I only know that I did not reach ultimate strength. But if I measure that rifle's head space before and after the proof load, and there is no change [yield not reached], to the extent your model is appropriate, I believer I can most likely have at least 2,000 rounds of standard load before failure. | |||

|

| <eldeguello> |

Axel: Thanks!! Jon A: Thanks for the graph and explanations!! | ||

|

| one of us |

Hey JerryM, Do not take this as a slam on you, because if that is the way you want to shoot your rifles, then by all means do so. But, the portion of Jerry's post below is the EXACT reason that unless I personally know the original owner and the Loads he shot, I've quit buying "used" fireams. quote:Jerry, best of luck to you. | |||

|

| one of us |

Hot Core I don't take anything here personal. It is a discussion, and we learn from one another sometimes. If loading hot loads such as I do and Jack O'Conner and others loaded for over half a century would shear the lugs or some sort of catastrophic failure, in 1000 rounds, then there would be wrecked rifles all over the landscape. It hasn't happened. All mine have lasted more than that, and I am sure they will last the rest of my life. The old signs of excessive pressure, including case life and expansion, and stiff bolt lift are as good today as ever. While I do not claim that velocity is an accurate indicator of pressure, there is a correlation. If one gets above average velocity with a certain load then the pressure is probably above average for some other rifles. Pressure results in velocity, and I do not worry about high pressure. I guess that means you won't be trying to buy my guns for a song. Have a good day. Jerry | |||

|

| one of us |

JerryM, I am sure you are right, and I put my face behind the bolt when I overload. But this thread has been an education for me about metal fatigue and I want to continue learning and possibly do some fatigue experiments. | |||

|

| Powered by Social Strata | Page 1 2 3 |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia