The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Difficulty closing a neck sized cartridge?

Difficulty closing a neck sized cartridge?Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Hi All, I have neck resized once fired factory loaded Winchester cases in by BRNO .270W. I do have more difficulty closing the bolt on the final cam. Even on an empty case so it's not the seating depth. It’s not that I have to stand on it to close, just a little more effort. Is this a problem, should I shoot the loads and see what they do? Could it be a concentricity issue? Thanks for your advice in advance! Johan | ||

|

| one of us |

It is quite normal for neck sized brass to chamber with a bit more effort. You sized the neck, but the body of the case has not been sized. Depending on how much the brass contracted after firing, this makes for a pretty tight fit in the chamber. The effect will vary from brass type to brass type and from gun to gun. Eventually, you'll have to FL resize to be able to chamber the brass. Some rifles shoot well with tight fitting brass, others less so. You'll have to test whether your rifle prefers NS or FL sized brass. 99% of my reloading is done with "partial FL sizing" these days. I find this a nice compromise between (comparatively) easy chambering and long case life. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| one of us |

Do the fired but UNSIZED cases re-enter the chamber without resistance? Yes? Well, then you are obviously doing something in the loading process to swell some part of the case. If you are attempting to neck size with a "conventional" die, then you may be either swelling the shoulder in the sizing process or pulling the shoulder forward as the expander ball is pulled through the (unlubricated?) neck. In either event, it might (or might not) be improper lubrication which is causing your difficulties. | |||

|

| One of Us |

mho desrcribed the situation as it most probably is. Especially if the load is rather hot, the brass may swell to an extent, where it becomes hard to rechamber a fired case even into the very same gun. | |||

|

| one of us |

Have you checked the OAL of the case? Maybe it needs to be trimmed. | |||

|

| One of Us |

All cases trimmed to 2.530" As mentioned they once fired factory ammo | |||

|

| One of Us |

measure the C/L datum of the shoulder of a once fired-unsized case vs. a sized case to see if the shoulder has moved forwrd.  ________________________________________________ Maker of The Frankenstud Sling Keeper Proudly made in the USA Acepting all forms of payment | |||

|

| one of us |

Partial neck sizing, with a full length resizing die, can possibly increase the case headspace. The case gets "squeezed". Hope this helps. Kevin | |||

|

| One of Us |

Thanks for all the replies! Do you think there will be any pressure issues shooting these loads? Obviously I'll start at the bottom and work up and be on the lookout for excessive pressure Cheers Johan | |||

|

| One of Us |

No danger if the brass is only long to the shoulder. If a case is tight due to the neck being oversize, or pushing against the mouth that will be dangerous. The man that said to see how the fired brass fits was spot on. | |||

|

| one of us |

| |||

|

| One of Us |

If your powder charge was a sane choice there will be no problem shooting your loads. When using a FL die to neck size stay far enough up the body so you do not squeeze the body in and push the shoulder forward. | |||

|

| One of Us |

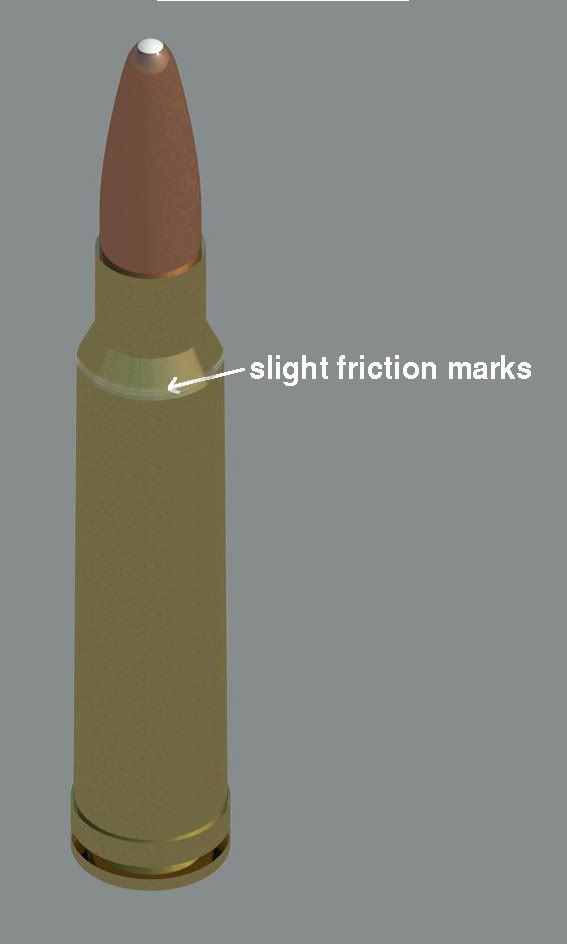

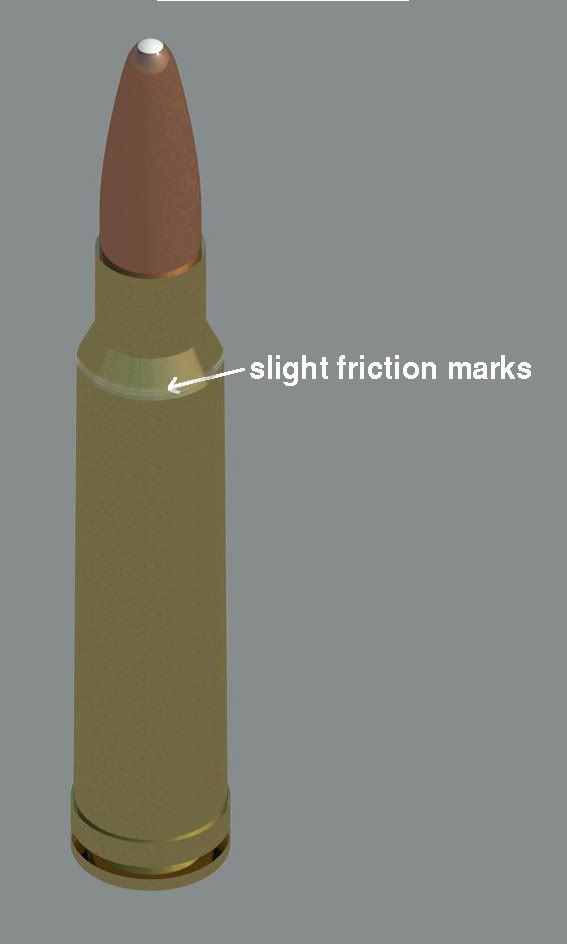

If your powder charge was a sane choice there will be no problem shooting your loads. When using a FL die to neck size stay far enough up the body so you do not squeeze the body in and push the shoulder forward.[/QUOTE] I think this is what happened. Had a close look last night. 1.Once Fired unsized brass chambered perfectly 2.Once Fired Neck sized empty brass was stiff 3.Once Fired Neck sized loaded ammo was obviously stiff as well. (all fired in this rifle) After I cycled a neck sized case a few times and inspected the case I could see a slight ring caused by friction on the shoulder just off the edge. [IMG:left]  [/IMG] [/IMG]My conclusion is that by using a full length die it "squeezed" the sides slightly and that increased the Head to shoulder distance a little. The increase can hardly be noticed or measured! | |||

|

| One of Us |

I think this is what happened. Had a close look last night. 1.Once Fired unsized brass chambered perfectly 2.Once Fired Neck sized empty brass was stiff 3.Once Fired Neck sized loaded ammo was obviously stiff as well. (all fired in this rifle) After I cycled a neck sized case a few times and inspected the case I could see a slight ring caused by friction on the shoulder just off the edge. [IMG:left]  [/IMG] [/IMG]I know this sketch is of my .338wm but only to indicate markings! My conclusion is that by using a full length die it "squeezed" the sides slightly and that increased the Head to shoulder distance a little. The increase can hardly be noticed or measured![/QUOTE] | |||

|

| one of us |

Get a headspace gauge, and you'll be able to quantify the problem. - mike ********************* The rifle is a noble weapon... It entices its bearer into primeval forests, into mountains and deserts untenanted by man. - Horace Kephart | |||

|

| one of us |

Johan: Your solution would appear fairly simple. While there is a slight mismatch of your resizing die and your chamber, you can probably solve the problem by turning the die down in the press until you are "paritially full-length sizing" as some people call it. When you have the die deep enough in the press, it will push the shoulder back just enough (without creating more headspace than is desirable) to allow the cartridge to seat in the chamber without significant resistance. The PFLS solution will also typically produce ammunition which is a bit more concentric than neck sizing (with a conventional die) since the entire cartridge is held in alignment with the axis of the reloading die rather than the neck-only being gripped by the die. It is possible that another sizing die from a different manufacturer would provide different results. | |||

|

| One of Us |

Don't know about in South Africa, but stateside here, that problem is instantly corrected by a little gizmo called a Body Die... in fact I neck size my rounds. and if the shoulder is a little hard to chamber, then they get bumped back with a body die... but in many other calibers I shoot, I use a larger bore's full length die for a body die... such as for a 243, I just use the full length 260 die, for a body die ( spindle removed of course) for my 6.5 x 57, instead of megabucks for a body die for that, since it is not a common caliber stateside here... I just use a 7 x 57 die instead... can even do that with loaded ammo as long as the case is lubed.. avoiding the need to disassemble, like I use to have to do... for your 270, just use an 06 die and adjust according since the 270 is just a hair longer in length... 3 mm I believe... | |||

|

| One of Us |

Could it be that your neck is too tight?. Lube the case mouth and champher the inside of the mouth. It looks like your case is bulging a scosh. | |||

|

| One of Us |

So Seafire, could I use a 375 H&H to bump shoulder of 300 H&H? Jim fur, feathers, & meat in the freezer "Pass it on to your kids" | |||

|

| One of Us |

I question "bumping the shoulder". The case has bulged a bit. I would try pulling the decapper from a 30/06 and trying to size things back. If that does it then find out why it bulged. Are you crimping, was the case mouth champhered etc. | |||

|

| One of Us |

Does it have to be a different size FL die. Can you bump the shoulder with the proper size die without the decapping/expander assembly? Say bump shoulder of 300 H&H case with a 300 H&H FL die w/o neck expander button? I have both FL dies & Lee neck dies Jim fur, feathers, & meat in the freezer "Pass it on to your kids" | |||

|

| One of Us |

If the case has not been loaded just FL resize it with the die set down enough to move the shoulder. If the round is loaded a lot of trim dies can be used as a body die. The best practice is to set the FL die right the first time you use it. | |||

|

| One of Us |

Sorry, haven't worked with either cartridge so I'd be talking out my fanny if I said I knew.. I certain would try it on a piece of brass to see what I got tho.. sorry, I work with the 308, 7 x 57 , 06 and Win Mag sized cases pretty much... | |||

|

| One of Us |

if it won't chamber and you have a bulged shoulder then you went too much.. adjust your die back up and resize it again.. it will straighten out that little snafu.. | |||

|

| one of us |

You will need to "Pull" the Bullet from the Case also,or you could create a bigger problem. | |||

|

| One of Us |

A 270 w should clear everything in a 30/06 die but the shoulder. | |||

|

| One of Us |

I've fired a starting load of the loads in question and no signs of pressure or anything out of the ordinary. The bolt opens normally and I've cycled a full mag without too much difficulty. the bolt closes a little harder than usual but if extend case life and get the accuracy I require I'll be happy. Have not shot for groups yet will do that next week and report back. Thank you for everyone's input. I'll look into the "shoulder bumping" at a later stage if necessary. Cheers Johan | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Difficulty closing a neck sized cartridge?

Difficulty closing a neck sized cartridge?

Visit our on-line store for AR Memorabilia