The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Question on pressure and bullets.

Question on pressure and bullets.Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| new member |

I was just reading the string on over pressure and other issues before I put up this post. Besides my initial thoughts< I saw another question. My initial thoughts were of chamber pressure. Some manuals list the pressures of loads especially max loads. My Hornady and Sierra manuals don't. I saw the comment on the difference in the bore surface are of the 68gn hornady and the 69gn smk. That gave me even more to think about. I can weigh powder and chrono speed, but don't have any way to measure pressure. As you all have mentioned, primer flatness is very subjective and varies with manufacturers. Hornady doesn't even list chamber pressure in their glossary. I try to use listed chamber pressure as an guide for experimental loads. Just another delimer to wonder about. | ||

|

| one of us |

Welcome to reloading. While you can add a strain gauge like Pressure Trace https://www.shootingsoftware.com/pressure.htm I "think" they really need a "known pressure load". Is this a factory load? Or simply a repeating check zero type of load I'm not sure. So I'm not sure if your can take the 55,000 read at face value or more a range of 53-57,000 but a good comparison to the load that reads 60,000 being in the 58-62,000 but for sure 5,000 more than the first load. Hopefully an experienced user will clarify. Anyway cheap compared to what my options were 30 years ago when I was doing serious wildcatting. As usual just my $.02 Paul K | |||

|

| new member |

Thanks for the link, but I already had that. I don't really want to measure pressure.I want to go to my load data to find it. Some of my load data sources list pressures and some don't. That's one of the main things that I want to know, Different sources list different max loads for the same set up. Just wondering why some sources don't consider chamber pressure to be important. I realize that everything from surface area and case fill to jump make a difference. A good example is my .223 Rem accuracy load for my mod 10 savage varmint is 75gn hpbt w/23.5gn Varget. Hornady lists this as max. Sierra doesn't list a 75 gn bthp, but they list a 69gn hpbt as 26.4gn Varget max and 80 gn hpbt as 25.3gn max. All of this makes me wonder what my real safety limits are. Just more to think about. By the way, Hodgdon lists the max as 25.0gn Varget @ 48400 cup. | |||

|

| one of us |

Haven't seen one. MY old Hornady vol II printed in 1973 Simply said that max load was either a full case or were they read .0005" head expansion. I would bet that even what a book shows as max has been "lawyered" now days. Also remember just because a load measured 48,000 in a nice pressure barrel doesn't mean you are at 48,000 in your barrel. If it concerns you play it safe and lean lower. I let my case,primer, velocity etc help me "guesstimate" when I'm approaching limits. I've also gotten more conservative as I've aged. Hope you find the data but not sure how it will really help you. As usual just my $.02 Paul K | |||

|

| new member |

Again, thanks for the $.02. I'm an engineer and I don't know the difference in 32 psi in a bald truck tire and a brand new tire. I would just like a safety margin that would seem to have been arrived at in a universal manner. It would seem that some data is more lawyered up than other. I hear that 5.56 barrels are rated at a higher pressure than a .223 because of the throat length. That would depend on the seating depth. I shoot mostly bolt guns on the bench. Savage told me and others that the mod. 10 .223 was rated for 5.56. I realize that it is all trial and error, but there have to be rules besides neck splits and flat primers. I play by the rules, but would like more standard rules for safety's sake. Just my 2p worth. | |||

|

| new member |

again thanks for the info, but as an engineer I don't know the difference in 32psi in a bald truck tire and a brand new tire. What I am trying to say is that there must be a way besides guesstimating loads by looking for signs that the limits have been exceeded and then back off. Don't take this wrong. I love to try new loads, but the more I learn, the scarier things I did in the past seem because of my ignorance then. When I started, there was no internet and the losd manual you had was the bible. Now you look at the "lawyered up" loads and have to wonder how I made it through the past. Just another 2p worth. | |||

|

| One of Us |

Please don't take this the wrong way, first of all. But you have mentioned prominently that you are an engineer. To me, this indicates a certain mindset, an attention to numbers, calculations, and perhaps a lot to theory and design that is perhaps a bit divorced from actual practice. As many of us, particularly the "curmudgeons" have experienced over time, there can be a certain tension between the engineering office and the old machinist or workman on the shop floor. The engineer will say, "Make this exactly according to the design that I have laid out." The old machinist will say something like, "That isn't going to work well; here are some small changes that my experience shows ought to work better..." Whereupon the engineer will say something like, "You are just an old uneducated person who works with your hands and gets dirty. What could you possibly know? I on the other hand have an education, and I am an engineer, and I "know" more than you. My design is just fine and the "numbers" bear this out. Do it my way." And of course the design doesn't work "as designed." Now there are probably several morals to this story. But do you believe that a good machinist can "feel" when his machine is cutting well? It's true. And there are a whole bunch of factors that go into this: Experience is one. Type and condition of materials, condition of cutting tool, depth and speed of cut etc. And then there are minute vibrations and sounds that he almost feels.. they're almost subliminal and would be missed by the casual observer. But they are real. And yes, there is a Machinery ' s Handbook with tons of numbers. But there is much more. A lot of this is what moves the process from being an entirely technical one, an exercise in "engineering," if you will, into being a bit of an art, a craft, something that isn't just done by the numbers but is actually "felt." A "who you are" as opposed to a "what you do." My thought here is simply that you should stop "being an engineer" about this. You shouldn't be asking for exact numbers. In this case there probably aren't any, and if there were they would probably be different in your case anyway. So learn what the signs of pressure are and how to use them: Flat or cratered primers are one. Case head expansion is another. A poster here says .0005", and I have also read that is .0015. A lot depends on brass hardness and this can vary. How many reloadings can the case withstand before the new primers seat too loosely? This takes a sense of feel developed over time. 6 or 8 is great,if the pocket goes loose on the second or third one, the load us too hot. Is brass extruding into the ejector hole or slot in the bolt face? Brass flows at north of 60000 psi somewhere. Another indication may be found on the chronograph. I believe that a given component combination can tend to work "best" at a certain powder charge level. This is usually shown by small extreme velocity spread. Adding powder often causes the ES to increase, indicating that the load is getting less "happy." Maybe more pressure than is good. Learn to use all these indicators together.. I think the term would be "gestalt." Add together, and add in some feeling, instinct, and a dash of "art," and you should be fine. But stop thinking like an engineer... and be happy. A good job is sometimes just a series of expertly fixed fark-ups. Let's see.... is it 20 years experience or is it 1 years experience 20 times? And I will have you know that I am not an old fart. I am a curmudgeon. A curmudgeon is an old fart with an extensive vocabulary and a really bad attitude. | |||

|

| one of us |

The rifle's action and barrel/chamber make up the pressure vessel. The vessel is sealed by the brass case. It is this seal which is the weakest link. A "safe" pressure varies with the strength of the case; the strength of the case varies with its thickness, hardness, and ductility. Most cases will withstand pressures which are not dangerous, per se, but are unsustainable in that the case will not maintain its head diameter (resulting in a loose primer pocket) for more than one or two firings. This is why handloaders rely on measuring case head expansion to determine if a load is running excessive pressures relative to a particular batch of brass cases. Most brass is standardized enough that its resistance to pressure is pretty much the same from lot to lot and also from brand to brand (within a particular caliber). Determining absolute pressure is relatively meaningless, especially since absolute pressure is (1) transient and (2) will vary with how much space one case takes up in the chamber as compared to another, and (3) is NEVER the same from one rifle to another. The pressures shown in handloading manuals were obtained in a particular rifle with components from the same lots of powder, primers, and cases. Varying any of these can and will result in very different pressures from those listed in the manual (just as the velocities you obtain are almost always different.) Bottom line: If primer pockets expand a detectable amount then pressures are unsustainable (and perhaps bordering on a dangerous case failure.) Back off until case heads no longer expand within several firings. By the way, this may mean using a different load with different cases, even if in the same rifle. | |||

|

| one of us |

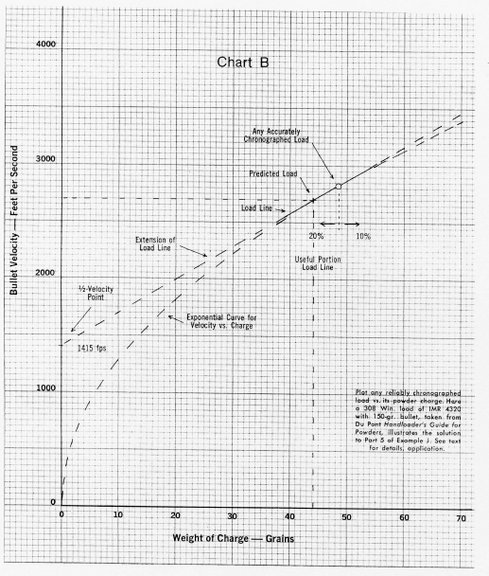

Just wanted to restate that the .0005" was posted in my Old Hornady manual as "their" stopping point. In the same manual that also state that on powders such as IMR they don't test every powder they list. Saying that IMR powders (as well as others "I assume") yield the same energy per grain so when plotted the various IMR powders for parallel lines and they used that data to develop some of their load data. Do new manual include this type of data as well?? I have no clue. By the way I hold and Engineering degree as well. As usual just my $.02 Paul K | |||

|

One of Us |

This, in short. | |||

|

| one of us |

AG Not a engineer, but a crusty old curmudgeon that's been repairing/building the engineers wet dreams for 40+ years. The creators of the manuals ARE using pressure testing equipment (and most of the "lawyer'ing up" is the result of better testing equipment). The testers use barrels/chambers that are at or just under SAAMI minimum spec, in all dimensions, so as to exaggerate the pressures along with a 20 shot string to look for statistical pressure spikes. The result is that with a standard production barrel/chamber that the "book max" will always produce levels that are safe in any rifle chambered for the same cartridge. As far as the .223/5.56 pressures go, 2 points, A) the throats of the chambers are cut different and B) the measurement point/method are also different. | |||

|

| new member |

Thanks for all the comments. I totally agree with most of them. As I was reading these I was also comparing target groups, chronos and spent brass from my latest quests. Being retired and 10 minutes from my gun club allows me to shoot several times a week as I want to. I really enjoy hand loading and the more I do the more I realize how much of an art it really is. As I stated, when I look back on past practices on my journey to now, I am amazed that I still have all my digits and health. I see youngsters now that are getting into reloading and see myself 50 years ago. I just feel that in this age of technology, there should be better guidelines for reloaders besides touchy/feely experience. I see kids that have gone to Bass pro Shop or elsewhere and bought a handi dandi reload kit and set out on their path to reloading. I realize there are no absolutes, but when different sources list different data that conflicts, I wonder. I guess I'm just in that curmudgeon place where my mind wanders over the past. | |||

|

| One of Us |

Yes, it is trial, error, and guesses, for handloaders who don't have pressure measuring equipment, which most don't. I no longer go for max loads, but when I did, I just used the primer pockets as gauges; if the primers seated firmly; keep using that load. If they got loose after that load, then back off. The appearance of the primer face is not important, if your brass is holding up. | |||

|

| one of us |

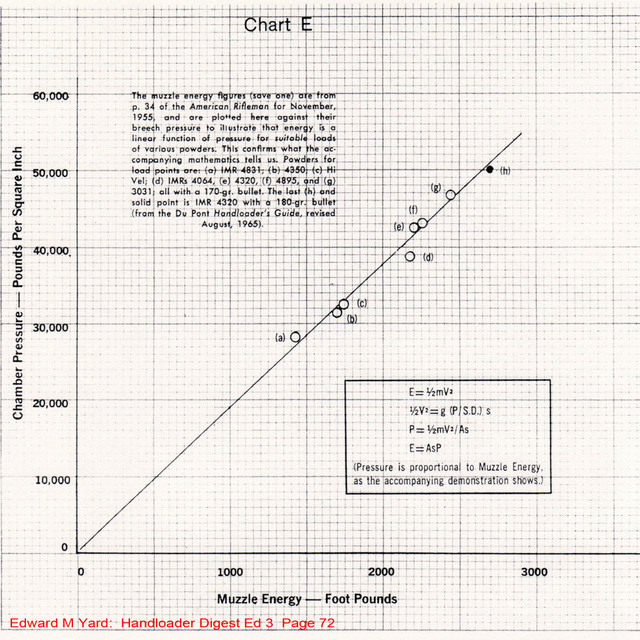

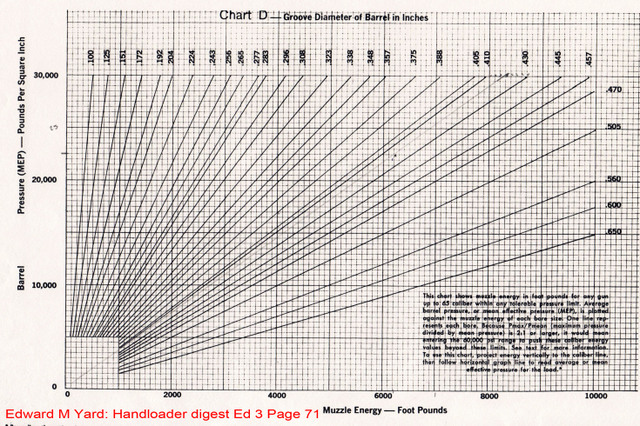

The chronograph is my best friend. By measuring velocity I can calculate muzzle energy. I can now compare my muzzle energy to the maximum allowable muzzle energy as per CIP for a cartridge. CIP lists both maximum chamber pressure and muzzle energy. If my loads ME is within the CIP limit I know I am safe. The reason for this assumption is based on the fact that there is a linear relationship between mean barrel pressure and muzzle energy based on caliber. Inside this ceiling as imposed by CIP I also know that Velocity per grain of propellant is virtually linear. So once I have a load I can predict with some accuracy that by adding or subtracting a grain of propellant from that load a predicted gain or loss of velocity can be expected.    | |||

|

One of Us |

Could this be summarised by the maxim, "You're not going to be the bloke who magically gets 3000 fps with a 180 grain bullet at safe pressures from your ought six"? | |||

|

| one of us |

How do you compensate for shot start pressure? | |||

|

| one of us |

Gerard: As far as i can see this method does not concern itself with SSP because it does not attempt to measure or calculate the angle of the rising slope nor the peak chamber pressure. It only represents a approximation of the mean barrel pressure curve which as we know actually falls below the actual barrel pressure curve. Corner points out that curves obtained by theory and experiment are "of a general nature" they are not absolute ! It also points out that whilst there is a mathematical relationship between MEP and muzzle energy none exists between peak chamber pressure and muzzle energy simply because there is no fixed mathematical relationship between muzzle energy and the ratio of peak chamber pressure to MEP. as it stands there is no accurate method to actually measure start pressure or the actual point of projectile release from the case mouth and most if not all of the ballistic programs arbitrarily or mathematically pick a start time for the onset of projectile displacement and start pressure. John Corner points out that in terms of gun design Peak pressure is not of concern. Its the pressure space curve after peak pressure has passed that is of importance. Using this method for conventional loads I am satisfied that as estimation it is aways conservative and as long as I'm below the CIP tested proof pressures and muzzle energies im reasonably safe. I have no desire to ruin very valuable collectable rifles with "cowboy ballistic gymnastics" | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Question on pressure and bullets.

Question on pressure and bullets.

Visit our on-line store for AR Memorabilia