The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Annealing

AnnealingGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

I have been looking for a method of annealing brass but I can't seem to find it anywhere, just statements that it should be done from time to time. I have heard that you can get the brass too hot and ruin it. Can someone let me know how to do this properly? | ||

|

| one of us |

Mr.dog here is a link that covers the methods of annealing rifle brass. There are a lot of opinions on what is the correct way to anneal. I have used the pan, water, dark room method for many years and it has worked for me. http://www.6mmbr.com/annealing.html | |||

|

| One of Us |

Mr. Velocity, I thank you so much for the help. I am reading the web site now and it has more than enough of an explanation on annealing. I wish I could afford a machine like the guy in the video has. Thanks again. As always, the folks on this Forum came through and it is appreciated. Bill | |||

|

One of Us |

how about annealing cast bullets? anyone done that and could enlighten me on it? Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

I haven't done it, but these people have: http://castboolits.gunloads.co...&highlight=annealing ________________________ "Every country has the government it deserves." - Joseph de Maistre | |||

|

| one of us |

"proper" Hmmm. I rotate the brass in my finger tips neck in the flame of a propane tourch until dull red, drop into a bucket of water. Some folks use a temperature stick to indicate the temperature has risen to at least that temperature. Other folks will DIP the end of the cartridge into molten lead. (Most accurate temperature in my book) and then drop into a bucket of water to quench. Tim K (trk) Cat whisperer Chief of Smoke, Pulaski Coehorn Works & Winery | |||

|

One of Us |

Thanks Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

One of Us |

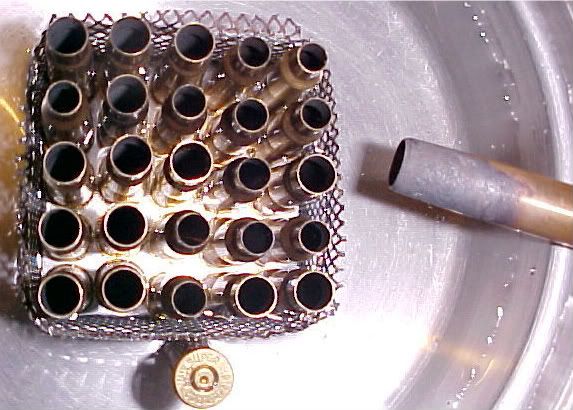

This is how I do it.  I stand all the cases in a basket in a pan of water with thier primers still in place. I then do the propane torch thing in a dark room untill I can see the dull red on the inside of the necks. When done I lift the cage out the water pan and drop the cases onto a towel and wipe off any water. The whole time I make sure no water gets inside the cases. Removing them quickly from the water pan keeps them warm to speed up drying. That's it - done! Ready to decap and resize and reload. Does it work? Check this out.  This case has been expanded from 311 to 425 in one go (with a tapered expander still in the case). Regards 303Guy | |||

|

| One of Us |

I will only say it's a very POOR PRACTICE to attempt annealing cases in the configuration shown 303 . Please don't take offense as I'm simply pointing out that annealing should be done properly so as not to OVER Anneal . Also heating should be done as evenly as possible around the neck and just down too the shoulder , 660 Degrees is target temp . Try using a temp stick or a pointing type infra red thermometer and see what Temp Red is !!. Standing in a pan of water is OK as it prevents case head or body overheating which is a NO NO !. A simpler way is to use a pipe large enough to slip your cases into yet only exposing the neck and barely the shoulder , when done tip the pipe , so the case goes into a bucket of water . All the water does is cushion cases to minimize neck dents as the brass is now soft . It does absolutely NOTHING for the annealing process it's self !. This subject has been covered so many times it resembles Water Gate !. Look in the Archives and you'll find several articles and methods many of the re loaders on this site use . | |||

|

| One of Us |

Two factory and two I did all Lapua !.  | |||

|

One of Us |

I remember that picture. How does overheating damage the case? I did manage to get a 'copper cloured' area on one neck but I did also take that one up beyound 'dull red' - I got careless! I will try the temperature stick - when I can find some. My idea with not tipping the cases into the water is to keep the interior dry. Makes life easier for me - no case drying! Regards 303Guy | |||

|

| one of us |

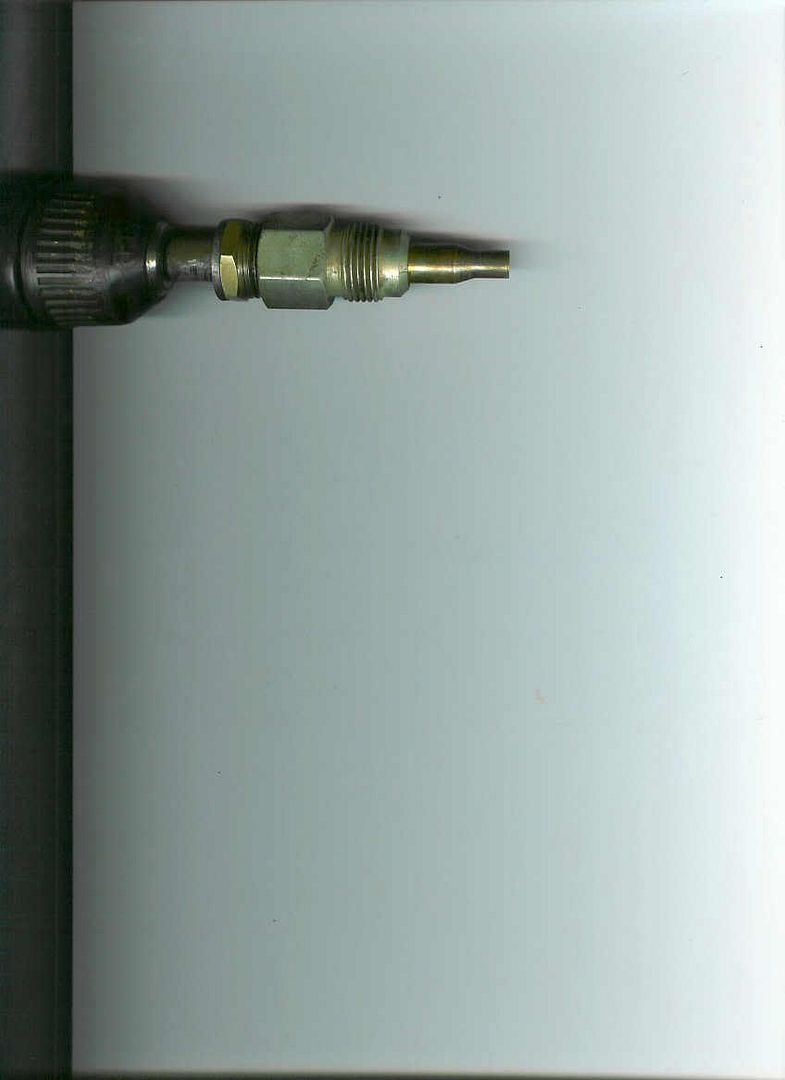

No offence intended but you should anneal cases 1 by 1; this is my method:  I slowly rotate the pipe while keeping the neck inside the flame during 7 seconds, then I let gently fall the case; no water. This way you exactly check the amount of heating for each case and you spread it on the whole surface of the neck. | |||

|

| one of us |

You can buy those temp stick crayons (good for a reference on temp). But you will probably find out its just easyer to see the brass turn dull red than trying to watch the temp stick mark I use a electric drill to spin the brass in the flame, with a holder chucked and the brass just drops in and dumps out into water  | |||

|

One of Us |

OK! I shall work on a new method. I'm sure I can combine the pipe, drill turning and not dumping into water. Thanks for all the ideas! But just a quick question - what happens if the case does not get heated evenly all round? Let's just say I anneal before each reload - logical for me as I fire a few of my loads then reload those cases and put them back in the mix - so on average, the cases should never get work hardened at all and should therefor remain evenly annealed. What I have been doing is heating the cases in the basket from the outside and following down each row then turning the whole thing 180 degrees and repeating from the other side. Each cycle heats two thirds of the neck to dull red. (The first one in each row takes longer to heat than the last, meaning that doing it this way is quite quick). Regards 303Guy | |||

|

One of Us |

Here's a pic of that 'copper' coloured heat stain. It's the 303 Brit in the pic. The other case is a 303-25 and is supposedly 'normal'.  Regards 303Guy | |||

|

| one of us |

James Kain: Here's what I do as to annealing cast lead bullets. I use them for my 375 H&H and follow the recipe that C.E. (Ed) Harris gave in the NRA publication, "cast bullets supplement no.1". Ed's method is, heat bullets made of straight wheel weights 2 hours @ 450' quench in water immediatly, and let cure for 17 days. this gives a BHN of 29. Size and gas check the bullets before heating, and then lube after the 17 days. This works very well, with no barrel leading at velocities of 2300fps. That load really brings the mail. Anything you can find written by Ed Harris, should be considered the highest authority on cast bullets of any form. Regards Jerry NRA Benefactor Life Member | |||

|

One of Us |

Regards 303Guy | |||

|

One of Us |

Thanks Jerry! I m going to look him up. Dose he share the same name or is the same guy as the actor? For I am unfamiliar with his work. Hey 303 we should hit up a chat and combine ideas. Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| one of us |

The use of water or not in annealing is controversial; after some reading, IMO, quenching in water seems to be much more an iron/steel affair, rather than brass; furthermore I've seen 2 annealing machines working trailers and none used water. I personally anneal once every 2/3 reloads. | |||

|

| one of us |

JamesKain: I am sure, it is not the same Ed Harris!! Although I am not familiar with it, there is apparently a "cast bullet club" somewhere in the USA, and Ed writes for them, according to a shooter I met at the range the other day. Callthe NRA, they have many articles and stories he has written. As to quenching brass in water, perhaps it is to keep the web from becoming overheated. I form a lot of 22 Remington Jet from 357 mag, and if the annealing process isn't performed correctly, the cases wrinkel during forming, and are a mess. I use the water method. Jerry NRA Benefactor Life Member | |||

|

| one of us |

Wildboar,in "The Norma Gunbugs Guide" 1967 , they recommend putting the case [without primer] in water about 3/4 of their height.Heat the case neck to cherry red and immediately tip the case into the water.This to prevent overheting the rest of the case. | |||

|

One of Us |

That's interesting. To give some idea of the conductivity of brass, try annealing the brass right down to the water level. Can't be done! I have proved to myself that standing the cases in water with primers still in that no overheating (or even just heating) can occur even near the water line. I still think that using water allows a margin of error ie makes it impossible to screw up and overheat the body. My big question is, what happens if I overheat the neck? Here they are saying heat to cherry red. That's hotter than I go. I go to dull red which is hard to see. I once 'dried' a bunch of cases I had flame heated and tipped into water, by placing them in an oven set on low. I forgot them in there overnight. There was no heat discolouration but when I fired on of them - a 223 - the whole case head expanded! I lost most of my Sako 303 Brit cases. Regards 303Guy | |||

|

| One of Us |

ed harris posts on the cast bullet association forum. annealing lead does the opposite of annealing brass. brass softens and lead alloys harden. they also do the opposite when hardening if you work brass it gets harder and lead alloys become softer. if you want to harden leadin the oven it should have some arsenic in it like .25% is enough. the water is used to stop the heating immediately and to keep it from migrating down to the web area and causing case failure. | |||

|

One of Us |

I was reading over the link someone posted about the subject. Man do they ever go in depth! I recommend jumping on the site and they explain all that you wonder in you last post and more....there were times where I!!! skipped over something, that alone should say something for over load on info at times. That in mind I think I should read and re read before I do anything Cheers Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

Thank You Wildboar : You were the one who used the pipe method . An excellent photo of proper annealing . I use a machine similar too Ken Lights annealing machine . Two torches at 170 degree with a revolving timed index plate with a knock out hole for dropping them into a pan of water . I simply use the water as a cushioning for the fall as it prevents neck dings . I load one case into the machine as it rotates , timer is variable for smaller cases .222 or .375 . Overheating a case is VERY BAD !. It's simply not the neck which gets to soft for bullet tension but the case body will heat by induction . Thus after firing can separate that or head separation sucks !. The way I see it if someones going to do it DO IT PROPERLY !. | |||

|

| One of Us |

I use a setup akin to Wildboars except i use two torches opposing each other,once i know how many seconds it takes to achieve the desired temp.,i just count off each case,nomally it takes about 6 seconds.Then dump into a bucket of water. | |||

|

One of Us |

I started a thread on making and/or buying a annealing machine. poke in and add your $0.02 Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| One of Us |

I did and my advise is worth $0.0025 dam Obuma inflation . However my links may be priceless only according to those who need them . | |||

|

| One of Us |

thanks guys for the info and the pictures. I have a pretty good idea what to do now and one hell of a lot more that when I started. You guys are the best! | |||

|

One of Us |

Thanks, been looking thought the links. Been busy so I haven't had a chance to respond. Disabled Vet(non-combat) - US Army NRA LIFE MEMBER Hunter, trapper, machinest, gamer, angler, and all around do it your selfer. Build my own CNC router from scratch. I installed the hight wrong. My hight moves but the rails blocks 3/4 of the hight..... | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia