The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Redding bushing selection

Redding bushing selectionGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

Just bought a set of Redding Type S dies for my .264 Win Mag and wondering what bushing size I should try first? I have tons of brass and bullets, but no loaded rounds to measure. Any suggestions? | ||

|

| one of us |

If you had bullets and case neck gauge you could calculate it or just go the gun shop and measure the OD of a new round for a start. | |||

|

| one of us |

Reddings bushing range chart for your 264 win mag is .289"-.297" The maximum neck diameter is .298" of a loaded round. Most will never come close as this is the maximum. So to take a stab in the dark, a wild guess. Go with a .292" bushing. If you outside neck turning, go .290" Remember, just a guess. | |||

|

| One of Us |

Thanks for the advice. I will also see if I can get a measurement on some factory ammo. | |||

|

| One of Us |

Your reloading manual will have a cartridge diagram. The listed neck diameter will be a good starting place. If the enemy is in range, so are you. - Infantry manual | |||

|

| One of Us |

actually you need to figure in neck tension. measure the thickness of your brass and the bullet diameter and think about it for a second. two thicknesses of brass and 264 added together like .026 + 264 should make 290. so for .002 tension 288, or however thick your brass is. | |||

|

One of Us |

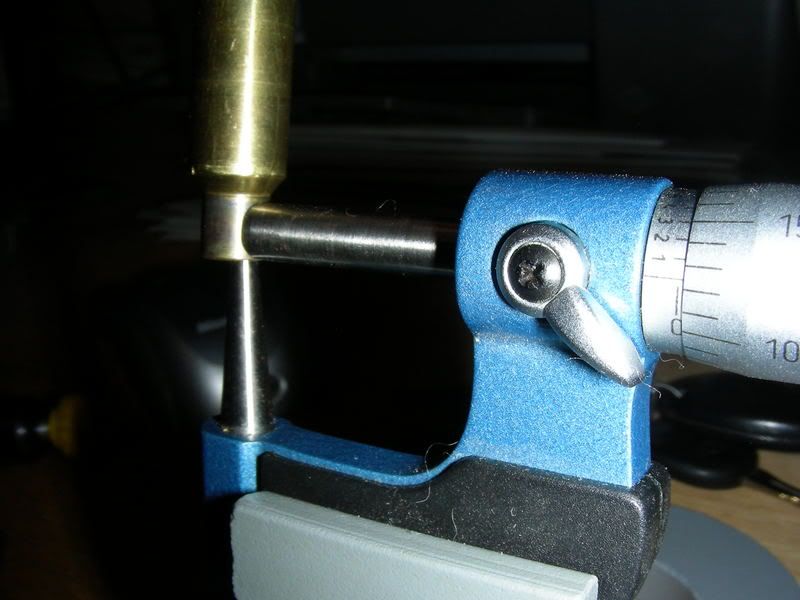

A measurement on factory brass may not be correct. The brass you have may have a different neck thickness. Like Lamar said, you need to measure the neck thickness of your brass. Do you have a ball micrometer  or a set of pin gauges    ?? ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

woods: I don't have either. I think it is time I pick up a ball micrometer. BTW, what is the difference between the full length Type S dies and the neck sizing Type S? Thanks Ian | |||

|

| One of Us |

The FL bushing die will FL size case and allow you to size neck to your choice of diameters. By using bushings. The neck die allows you to size the neck to your choice of diameters By using bushings but does not size the case. | |||

|

One of Us |

Make sure and get a ball micrometer and not just a regular Vernier micrometer. Also the Hollands micrometer stand makes measuring with one of these a lot easier - one hand to turn the dial one to hold the case. Otherwise is is trying to hold and turn the vernier with the same hand. I think Sinclair has some excellent tool for this also, but kinda pricey. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

I am thinking of ordering one of these. Would it be a better choice than a micrometer? Case neck gauge | |||

|

One of Us |

Looks like a great tool, however pricey at $125.00 and $10.00 for each caliber. Also you wouldn't be able to measure other things. Sometimes as a check I will run my micrometer out and use it as the ultimate measure for a bullet width or outside case measurement. Micrometers are generally more precise than calipers and I use it as a check on my calipers from time to time. However if you are measuring other things then a flat anvil rather than a ball anvil works better. Long Island Indicators is a great source of information if you want to look around. Since I already have a stand, if I were to buy another micrometer, it would have a interchangeable anvil from flat to ball. ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| One of Us |

IanD, Doing the same thing as you. I have a set of dies so I just seated 3 bullets in new Win brass and used my calipers to measure the outside neck dimension. 2 were .295 and one was .294. I think they recommed to order .003 smaller bushing, and maybe a couple withing a couple thousandths smaller/larger. I'll start with a .292 and .291 for my .264WM. David Edited to say: I sent one of the dummies with a $29 check to Lee for a custom Crimp die. | |||

|

| One of Us |

David, Unfortunately I only have the Type S dies, so ended up ordering a ball micrometer. | |||

|

| One of Us |

Good investment. Now you can qualify your brass. ________________________ "Every country has the government it deserves." - Joseph de Maistre | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia