The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  First attempt at annealing brass using Tempilaq

First attempt at annealing brass using TempilaqGo  | New  | Find  | Notify  | Tools  | Reply  |  |

| one of us |

The only thing that I know for sure is that I don’t know anything. Well, at least when it comes to annealing brass. However, I gave it a shot tonight using some old brass pick-ups from the range. Equipment: -MAPP gas torch -Templiaq 600 degrees (probably should have went with 650 or 675 after doing more reading) -11 mm deep well socket on an electric drill  I used a much longer stripe of Tempilaq than I’ve seen most others use, but I wanted to get an idea of how much heat was being conducted to the base, if any. I think the socket worked well for protecting the case body. However, I am unsure about the Tempilaq use. It seemed to burn off relatively quickly, so I am not sure if I am using it correctly. I had a difficult time seeing it at all, to be perfectly honest. Perhaps it’s because I am using MAPP gas whereas most of the other sources I’ve read or videos I’ve seen are using propane torches. As you can see above, I arranged the cases from most heat to least amount of heat applied. Where should I have stopped? At any rate, I am open to advice, opinions, and ridicule. Fire away! | ||

|

| One of Us |

How does Tempilaq work? Does it turn black and stick or completely flake off when heated correctly? The one on the far left looks to my untrained eye like it did the right thing... | |||

|

| One of Us |

I've read it melts at temp. But I've never used it. On the other side, you need to paint a higher temp so you know you didn't overheat the brass. Or do it like I do. By eyeball and hope for the best. IMO, you need to put something in the bottom of your socket. I thought you needed more of the case visible than just 1/2 way down the shoulder. I'd get the bottom of the shoulder at least 1/8" above the socket. | |||

|

| One of Us |

I concur... | |||

|

| One of Us |

Here is how I set up my sockets. I need to see enough of the cartridge to watch for the colour change moving over the shoulder of the case. All set so the different sized cases have the neck and mouth at the same distance from the drill chuck.  Von Gruff. | |||

|

| one of us |

Thanks, everyone for the replies. So I think I will definitely make it so that I can see more of the shoulder. But what about the Tempilaq melting temperature? At what stage do you think the indicated temperature has been reached. If you know for sure, please tell us by using the cases above to explain (if applicable). | |||

|

| one of us |

Hey Kenati, You should use the Temp paint if you want to, but it is really over-complicating the process. My guess is 99% of people who Anneal get along fine without it due to a short learning curve. Best of luck to you. | |||

|

| one of us |

I agree, but the scientist in me wants objectivity. I'll experiment more. Mainly I was trying to void making the mistakes like those on YouTube who heat their brass to the surface temperature of the sun! | |||

|

| One of Us |

Kenati, I bought and tryed to use Tempilaq. Tempilaq is supposed to change color, But I could not see the temilaq change color with the torch flame and case is spinning or even if its not spinning. In other words it is way easyer to SEE the brass its self change to a dull red than to SEE the tempilaq color change while useing the torch flame Experiment with tempilaq if you can see the change with the flame brightness , and compare with the brass color change. I also used the 600 degree tempilaq. But I dont even use it when I annel now, I just watch the brass color | |||

|

| One of Us |

Kenati, I put my cases in the polisher for a while before annealing as I find it is easier to see the colour change that way. First you see the shine go from the brass then you see a slight rainbowing effect, and as this is suficient heat I stop there. I have my battery drill turniong as slow as it will go (about 3-4 turns per sec) and it gives me a good visual. Von Gruff. | |||

|

| One of Us |

Kenati ; More heat !. Here are Two of mine and Two Factory Lapua . I used 750 degree and a stop watch so as to determine correct times for caliber of cases being done , there by eliminating the necessity of using tempilaq which saved time and cleaning .  The critical time and temperature at which the grain structure reforms into something suitable for case necks is 662 degrees (F) for some 15 minutes. A higher temperature, say from 750 to 800 degrees, will do the same job in a few seconds. If brass is allowed to reach temperatures higher than this (regardless of the time), it will be made irretrievably and irrevocably too soft. Most screw up when trying to anneal by Color Glow ,inaccurate as hell . Brass will begin to glow a faint orange at about 950 degrees (F). Even if the heating is stopped at a couple of hundred degrees below this temperature, the damage has been done--it will be too soft. From this discussion we can see that there are four considerations concerning time and temperature: ( For what it's worth ) ... PRODUCT: TempilaqºG 750F/399ºC SUPPLIER/MANUFACTURER'S NAME: TEMPIL INC. ADDRESS: 2901 HAMILTON BLVD. SOUTH PLAINFIELD, NJ 07080 BUSINESS PHONE: 1-908-757-8300 | |||

|

| One of Us |

Well one thing you might try is putting the paint on around the case just below the shoulder, instead of lengthwise. It would be easier to see while spinning and when it changes your done. Just something to consider. Mike / Tx | |||

|

| one of us |

Nothing at all wrong with Experimenting and trying to learn as much about the process as you can. If you decide the Temp Paint is really a waste of time, or it is great, let us know. I remember the old fool "howl" making Annealing so complicated that I'm sure he discouraged a lot of folks from ever attempting it. He was presented with the "howl C.A.R.E.T. Award(howl Complicating Any Relatively Easy Task Award). I do understand about Over Heating and I sure want to STOP the Heat as quickly as possible, so I drop them in water, or tilt them over into water, depending on which way I'm doing it. I remember barsness and one of his buddies "claiming" they could Anneal with a Plumbers Candle. A buddy sent me the totally worthless article. | |||

|

| one of us |

Hey fellas- Thanks again for the responses. I did some more experimenting tonight and I think I feel a little better, but still not totally satisfied. Things that helped: -polishing cases first -switching to a 3/8" drive deep well socket (perfect protrusion for my test cases) -placing dot of Tempilaq further down out of the direct flame -stronger light from the side Things that didn't work well: -ring of Tempilaq around case... what a mess to clean up! -broad tip of my torch Still not satisfied with the precise moment the Templiaq indicates the given temp, I had a look at their FAQ section and read the following: Q. Does Tempilaq change color when it melts? A. The color is for identification purposes only. Melting is the indication that the temperature has been reached. Q. If color does not change, how do I differentiate between the “before” and “after” the melt points? A. The initial mark will appear chalky while the final (signaled) mark has higher glossiness and the shape will be visually different; it appears as wet and shiny. Lastly, I did the crush test using a pair of pliers on a couple of case necks that I intentionally overheated (to a glowing red) and then compared them to ones I thought were just about right. WHAT A DIFFERENCE! The overheated cases crushed like warm butter compared to the "just right" ones. Very subjective, but still very telling. Pretty interesting stuff. After 17 years of meticulous handloading, I can't belive I am just now adding another step to complicate things. haha | |||

|

| One of Us |

Hey don't feel bad, I have been at it a LOT longer than that, and have only tried it twice, and both times I decided screw it there was plenty of range brass out there to pick up. Well that ain't the case anymore, so I too am looking harder at making my cases last a bit longer. I am watching and learning right along with you, I've just had so much other stuff going on, this weekend will be my first round with it, and hopefully with everything you folks have given me it will be a shorter trip to success. Mike / Tx | |||

|

| One of Us |

Dropping cases into or tipping them over in Water WON'T HELP !. Other than protecting the now softened neck from denting if it hits something . People confuse annealing with quenching steel Totally different . Point is if you overheat the case DAMAGE IS DONE and water bathing WON'T CHANGE ANYTHING !. On every case I've ever done the neck turns blue then a faint silver It's Done at that point . Focus the tip of your torches on the Neck about centered seems right .I've held one in my hand while annealing the neck when correct temp. is reached ,It's hotter than I can hold onto . But NO WHERE NEAR any temperature that would endanger the case head . Read where Brass temp starts changing the structure . If any of you can hold onto a case at those temps! , Well Supermen have at it . Brass is an excellent conductor of heat. A flame applied at any point on a case for a short time will cause the rest of the case to heat very quickly. There are several temperatures at which brass is affected. Also, the time the brass remains at a given temperature will have an effect. Brass which has been "work hardened" (sometimes referred to as "cold worked") is unaffected by temperatures (Fahrenheit) up to 482 degrees (F) regardless of the time it is left at this temperature. At about 495 degrees (F) some changes in grain structure begins to occur, although the brass remains about as hard as before--it would take a laboratory analysis to see the changes that take place at this temperature. Don't understand why some people always want to reinvent the wheel ?. | |||

|

| One of Us |

I saw Von Gruff's set up he posted elsewhere and think that is a pretty tidy way to do it.. my route is to just hold the brass into a flame from a torch fueled by a propane tank, we use to fuel the stoves out camping with the Boy Scouts.. I use a pair of channel locks to hold the brass and put it in the flame for 10 seconds for a 223 case and 12 seconds for a 22.250 on up case... then throw it into a little metal decorative pail I picked up at Walmart for a $1.00... and let them air cool.. I am annealing every 4th shot.. between that and necksizing the brass with a Lee Collet Die and bumping the shoulder back with a Redding Body Die.. in a durability test on a 10 lot count of 223 brass, right now I am up to a pretty high usage count on them.. and they are still going strong.. I'll pass on posting how many times, since my buddy HC is here to pounce on any word I say.. but Von Gruff may desire to pass it on, if he recalls our exchange.. Annealing is a pretty simple process once you have it down pat, and yet yields phenomenal results in expanding brass life, especially if someone doesn't get a little overzealous on the velocity when handloading.. check out Lapua's web site and see how many reloads they claim to have on some of their brass! | |||

|

| One of Us |

is this your academic response, or did you actually try it to rule out that it doesn't work? I don't count John Barsness as an idiot. | |||

|

| new member |

I'm no expert, but I have studied this subject a lot and the overwhelming techniques are as follows: 1. If tempilac is used, put it on the inside of the neck 2. If not, heat necks in a dark room till a dull red then stop. 3. Focus the torch on the middle of the neck 4. Water is not needed for annealing, air dry is fine. 5. Do Not heat till glowing red! Take a look at this article it will help you 6mmbr Annealing | |||

|

| one of us |

You also think Down-Loading Blue Dot is brilliant. Obviously you have not tried Annealing a Case with a Candle or you would I'm not impressed with barsness and many MANY of us are not impressed with your attempt to be the guru of Blue Dot. It is just a matter of time. ----- Hey Doc, I put mine in the water to keep the Heat from getting to the Case Head. I do understand the Properties of Brass are the opposite of Steel when it comes to Softening and Hardening. | |||

|

| One of Us |

Hmmm, I thought this was a thread about annealing, not blue dot. | |||

|

| One of Us |

and yeah I tried it and yeah it works... but I see you declined to answer the question which proves my assumption.. .. your response WAS academic.. | |||

|

| One of Us |

You also think Down-Loading Blue Dot is brilliant. Obviously you have not tried Annealing a Case with a Candle or you would I'm not impressed with barsness and many MANY of us are not impressed with your attempt to be the guru of Blue Dot. It is just a matter of time. ----- [/QUOTE] This is sort of an interesting post by ANY forum member.. It seems we have someone in our midst that is just waiting for a fellow shooter to hurt himself, so he can prove a point..... Sounds sort of egotistical, sadistical and rather morbid doesn't it? He is waiting for someone to get hurt, so his point can be 'proven'? Some one seriously needs to get a life, or get back on his anti psychotic meds.. and Triplet Dad... since you are relatively new here, I'd like to just point out.. guess who uses the words BD in his threads the most? most of the requests I get any more for info come privately via PMs... so as not to evidently get the attention of our resident but mention my name and guess who is on his soapbox... | |||

|

| one of us |

Here is the problem for those of you who think this is a good idea and that also believe seafire "Annealed" a Case with a Candle But what about using a "Socket" as a Heat Sink? The problem is still the same. The Case is either Tapered from the Case Head forward, or the Flange on a Straight Case prevents the Socket from making intimate contact with the Case Walls. Therefore, the Socket does not act as a Heat Sink, simply a Holder. And since the person doing the Annealing with a Socket as a Holder can't "Feel" the Heat going to the Case Head, then they either do not actually Anneal the Case Neck, or they soften the Case Head to the point that it can be a Safety issue with normal Safe MAX Loads. Of course since seafire is totally clueless about Pressure, I feel sure none of that makes any sense to him. Nothing tricky about it. You just have to be smarter than a hammer which obviously seafire and barsness are not. By the way, that is the 4th totally stupid thing I've had folks send me articles about from barsness. So, as I said before - I'm not impressed. | |||

|

| one of us |

I get a fine annealing job just holding cases by the rim and spinning them in a propane torch flame until it starts to get uncomfortable. Your fingers will tell you when the temp is right with no risk of overheating. | |||

|

| One of Us |

What part of the above statement did some of you fail to read ?. I didn't make this up it came from a reputable metallurgist . It was also posted on 6mm bench rest but yet their also stupid ?. I guess according to some of you nonbelievers !!!. http://www.6mmbr.com/annealing.html | |||

|

| One of Us |

I'm no "expert" on annealing but have been doing it (successfully) for a long time. I first did the clueless "conventional wisdom" thing, of heating necks to a red glow. Soon realized that was much too hot. Now I tumble polish the cases first and heat the neck:shoulder junction with a fine tip propane flame until the body (just) below the shoulder shows a light blue blush and drop it in water. Done right, the necks will not lose their shiny surface appearance which shows they were not over heated. I can do this blue blush test in any lighted room and the annealed necks have sufficent hardness for good bullet tension. My rifle (only) annealing is done after each 5 or 6 cycles. My cases - .22-250, .243, .270, .30-06 - often live for 20-30 max load firings before I get a body split and that usually occurs during the FL sizing I do after each annealing. When one body in a box splits they all go by-by. I've done the finger burn thing, soon quit that. Found it a bit too varible in that with a really hot torch tip I could over heat the necks before my fingers said let go. The body blush seems pretty consistant no matter the torch or gas used. I'd like to play with TempleLac but have been too satisfed, and too cheap, to actually do it. | |||

|

| One of Us |

You know, that sounds right to me... | |||

|

| One of Us |

If you really want to try a method of annealing your brass that is as similar as possible to the methods used by premium brass manufacturers like Lapua, Norma, etc..you will want to discard any thoughts of flame annealing. Flame annealing is much too imprecise to reliably and evenly restore ductility to your necks. You will want to look into induction annealing. This method heats the neck (if the heating coil is fitted correctly) VERY fast and evenly. A company called Induction Innovations makes a tool called the mini-ductor, which will anneal case necks through and through and so precisely that you can anneal pistol brass with confidence that you will not affect the base. I have one. I use it. It works. I also have used the Ken Light double torch annealing machine which works quite well too, but I gave it to my son. The Mini-ductor is less expensive and works about as fast. It may work more effectively; the KL machine does not claim to be able to do pistol brass. If all you want to do is soften up the necks of the old standard (.30-06, .223 rem, etc..)cartridges a bit so as to get a bit more life from your cases and avoid cracking due to work hardening, it's NOT rocket science. You don't need anything more than a single propane torch and your hot little hands. You do not need a pan or bucket of water. You do not need Temp-L-lac, Temp-L-stick, or a dark room. All you need do is get a GOOD standard sized pencil type propane torch nozzle--adjust for the hottest flame and insert the case neck into the hottest part of the flame rotating it so as to cover all sides of the neck. The flame will be perpendicular to the axis of the case--coming at the side of the neck-- and you will be holding the case by the base in your fingers--yes, by your own lil digits. You can easily overheat a .30-o6 case while not burning your fingers using this method, so don't let some fool tell you that you don't get the case hot enough using it. The case will be too hot to hold by the base and you will have dropped it long before any damage could be done to the body or head. When the case neck begins to turn blue and the flame has formed an orange nimbus around the neck, your neck is about done. I say about because neck thickness and overall case size will affect how fast and how thoroughly your neck anneals. You will have to experiment. If you want this all handed to you on a silver platter--if you are the kind of person that need your hand held through every step--annealing is not for you--just ask for brass for Xmas. Those folks shooting the short fat cartridges so fashionable these days in target and varmint and bechrest events will find the induction method to be a lot better than ANY flame annealing. If the enemy is in range, so are you. - Infantry manual | |||

|

| One of Us |

It is amazing to me to be able to know so much and to be able to walk so humbly thru this world.... yeah, I admit to being Clueless to the things that YOU claim to be an expert on.... of course, you think everyone is clueless unless they agree with you and contribute to your ego inflation.. so what is your fan club up to? 3 guys now? by the way, is there any truth that you and Larry the Cable guy are related? I don't know why, but when I read your posts, he always comes to mind...because the first thoughts in my mind usually are.. " now I don't care who ya are, that thar is funny right thar!" by the way, now that it is early Feb, how many of those 1000 deer annual quota have you gotten so far this year? I think we were figuring you averaged 2-3 a day, so that should put you at about 60 to 90 so far this season? hopefully you didn't have to remove the harness off of anymore of them, before you sent them down to the butchers.. and remember, it is just a matter of time...  | |||

|

| one of us |

This is the response from my local dealer about the mini-ductor: "Mini is 498 and the mini 2's are 580. I have both in stock. I also have some demo mini's with full warranty I'll make you a good deal on. You can't tell they have been used." ToolTopia.com has them for $422. http://www.tooltopia.com/search.aspx?find=mini-ductor I know it has been discussed elsewhere, but at that rate, I will have to pass. I simply would not use the machine enough to justify its purchase... there are too many other toys I could buy with the $$$. HOWEVER, I would consider a DIY inductor. Check these babies out: http://www.youtube.com/watch?v...ws&NR=1&feature=fvwp http://www.youtube.com/watch?v=Hopa-oXh8cQ&NR=1 And this one??? I'm speechless. http://www.youtube.com/watch?v=aLwaPP9cxT4 P.S. Seafire and Hot Core: I think you guys are both very knowledgeable and we have learned a lot from the both of you, but do we need to drag this schoolyard fight into here too? | |||

|

| one of us |

OK, amamnn, I am intrigued, how EXACTLY do you use the tool. I was planning on buying the KL machine, I actually had gotten a quote and was just about to pull the trigger when my emplyment went away....I would love to know the process for something like the 'mini-ductor' | |||

|

| One of Us |

I have posted this link before. Click on the link and scroll down. This guy uses Tempilaq 650 and lets it air cool - no water. He paints the inside as shown. http://www.6mmbr.com/gunweek092.html | |||

|

| one of us |

I did not start it, simply responding to the fool. I do not need a sermon on what I should post or how I should post. If you do not like it, put me on IGNORE! | |||

|

One of Us |

http://www.youtube.com/watch?v=a_ohUknmaq4 http://www.thehighroad.org/sho...=gearheadpyro&page=2 ____________________________________ There are those who would misteach us that to stick in a rut is consistency - and a virtue, and that to climb out of the rut is inconsistency - and a vice. - Mark Twain | Chinese Proverb: When someone shares something of value with you and you benefit from it, you have a moral obligation to share it with others. ___________________________________ | |||

|

| one of us |

Thanks for the link Woods, I guess it's still a question of how long til you get it right for the specific cases you are annealing....seems like it would be more accurate than flame??? | |||

|

| new member |

Kenati, If you can find an easy way to build one of those let me know. I looked all over the net for basic instructions with no luck. | |||

|

| one of us |

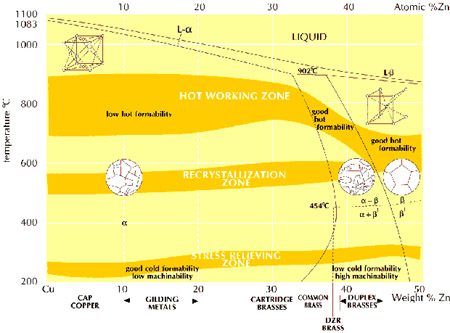

A few things to add. First a little engineering diagram about brass (temps in Celcius)  Second, I agree that induction heating would be far more precise; however, I think that the 80/20 rule applies: 80 % of the benefit can be achieved with 20% of the effort. It's one of the reasons that I suggest the use of Todd Kindler's annealing ring. It does two things: one, it heats evenly all around, and second, it burns the gas at a slightly lower temperature, so though it takes longer to anneal, it is also far more difficult to overheat. http://www.woodchuckden.com/catalog/catalog.pdf Finally, if you are going to put the Tempilaq inside the neck, use the 750-800 temperature level, rather than the 650. The 650 is to be used on the shoulder/body junction, to reflect the difference in temperature from the neck (where heat is applied) from the body (where the temperature is read). FWIW, Dutch. Life's too short to hunt with an ugly dog. | |||

|

| One of Us |

I've only been annealing for a year so I am certainly no expert. I start with clean cases, use my fingers to turn the case, heat w. a MAPP gas plumbing torch, and then drop them into a quench bath. So far it has worked well for me. I usually anneal standard cartridges (270/30-06) after 5 loadings, wsm, wssm, and RUM's usually 2 or 3 loadings. I've found about a 5 mississippi count works well. It's not to hard to know when you have overheated one either!!!!!!!!! | |||

|

| One of Us |

How about this new automated annealing machine from Bench-Source. http://www.bench-source.com/id81.html Not cheap but very adjustable and it looks cool. It debuted at the SHOT Show and won't be available until March. Kevin | |||

|

| Powered by Social Strata | Page 1 2 |

| Please Wait. Your request is being processed... |

|

The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  First attempt at annealing brass using Tempilaq

First attempt at annealing brass using Tempilaq

Visit our on-line store for AR Memorabilia