The Accurate Reloading Forums

The Accurate Reloading Forums  THE ACCURATE RELOADING.COM FORUMS

THE ACCURATE RELOADING.COM FORUMS  Guns, Politics, Gunsmithing & Reloading

Guns, Politics, Gunsmithing & Reloading  Reloading

Reloading  Case Neck Trimming...

Case Neck Trimming...Go  | New  | Find  | Notify  | Tools  | Reply  |  |

| One of Us |

So I've learned that I'm going to have to trim the necks on my 400 Whelen brass. I have no experience with such a process, but I've read enough to understand how to do it(except for inside reaming). My question is whether I should use a inside the neck reamer or an outside neck trimmer. Also, a recommendation on what trimmer or reamer to buy would be great. I appreciate your help! Sent from my iPhone | ||

|

| one of us |

I think you are confusing it a touch. There is the inside reamer. The trimmer simply shortens the OAL. The turner works on the outside. I simply attach the reamer to my forester trimmer. It replaces the pilot. However it is designed for use in a fired case. If you have a donut on the inside I use a reamer. I use a neck turner to thin the neck to fit in a tight neck chamber. IE Bench rest. As usual just my $.02 Paul K | |||

|

| One of Us |

Sorry, yes I meant "turning". Been a long day and I'm beat. What has me confused is the fact that the Quality Cartridge 400 Whelen basic brass has a portion starting at the case mouth extending about 3/8" back that is .0025" thicker(wall thickness) than the rest of what will be the neck of the cartridge once sized. It's hard for me to explain, so I will post a pic of a 400 Whelen dummy round I made up. You can see how the front of the neck is a larger diameter the rear of the neck. Before sizing the basic brass, this thicker portion can only be seen from the inside. Once sized, you can see it on the outside and inside. Hence my dilemma to ream, or turn the neck. I'm just a novice to this whole situation.  So from the dark line pointed out on the neck to the case mouth, the diameter is .005" than the portion behind it. The front of the neck is .002" larger than the chamber reamer neck specification. Sent from my iPhone | |||

|

| one of us |

To use a reamer you will need to fireform the brass. When you first size the brass is the extra brass on the outside after the extractor pulls through it? If so turn the neck so that you remove the extra brass and just touch the front area. That ring happens a lot when people use factory cases to form wildcats. This might help http://www.6mmbr.com/neckturningbasics.html As usual just my $.02 Paul K | |||

|

| One of Us |

Templar, what say you to the suggestion that we engage in some more investigatory forensics before we rush to judgment and blow some big bucks ? 1. What leads you to the conclusion that you have learned that you need to neck turn ? 2. Is your brass new unfired ? 3. Do you have a micrometer ? A dial caliper ? 4. The neck OD should be 0.4300 inches *( 10.92 mm ). 5. Bullet diameter for the 400 Whelen should be .411. That's the groove diameter. 6. Case length should be 2.4940 inches *( 63.35 mm ). What I suggest is that you also measure the OD neck diameter of an unfired case, if available, and then the neck OD of one that you have loaded. I don't like the looks of the neck, crimp and wrinkles in your photo. The bullet probably could be a little deeper with more cannelure "buried". Looks like, too, that the roll crimp is a tad too deep judging from the "ring". Your crimping die may be set a bit too long. We need to separate the wheat from the chaff and establish if your are "bulging" your necks by too much crimping, too deep or your cases are over SAAMI spec. *( Your rifles leade, throat, bore is a separate issue left in abeyance for some future analysis ). I've been there, done that. I have some photos too embarrassing to post. They are really bad !!!!!! Case life and numbers of re-loadings can vary hugely, depending on several factors. Inevitably the case will stretch, the neck will grow longer and thin over time and repetition. I need to mention the potential for using a Lyman/Lee/Other special crimp die. It actually "squeezes" the neck in reducing diameter somewhat. To clarify a bit, there are roll crimps, taper crimps and the third I mentioned. FYI I have the Lee special crimp die and it works just fine as advertised. Reloading dies come in many forms and diversities. Some are 2 die sets, some are 3, some are 4 and with special crimp die, even a 5th step. Let us know ? We're interested. ___________________________________________ http://leeprecision.com/reload...s/factory-crimp-die/ Bummer!!!! The 400 Whelen isn't listed as commonly available. But I'll chase it more. | |||

|

| Administrator |

If you know the neck diameter of your chamber. Load a dummy with no powder, and measure the outside neck diameter with the bullet seated. If this is smaller than your chamber neck diameter, then you do not need to neck turn. If you do not know your chamber neck diameter. Load a dummy as above, and chamber it. If it chambers, again, you do not need to neck turn. If it won't, then I suggest you outside neck turn in stages, as you do not want to take too much brass off the neck than necessary. Sinclair International sells good neck turning tools, which we have been using for many years. Great products. | |||

|

| One of Us |

Check out Lee's Deluxe Case Trimmer. It's easy to set up and it trims, reams, and deburs all in one step. | |||

|

| One of Us |

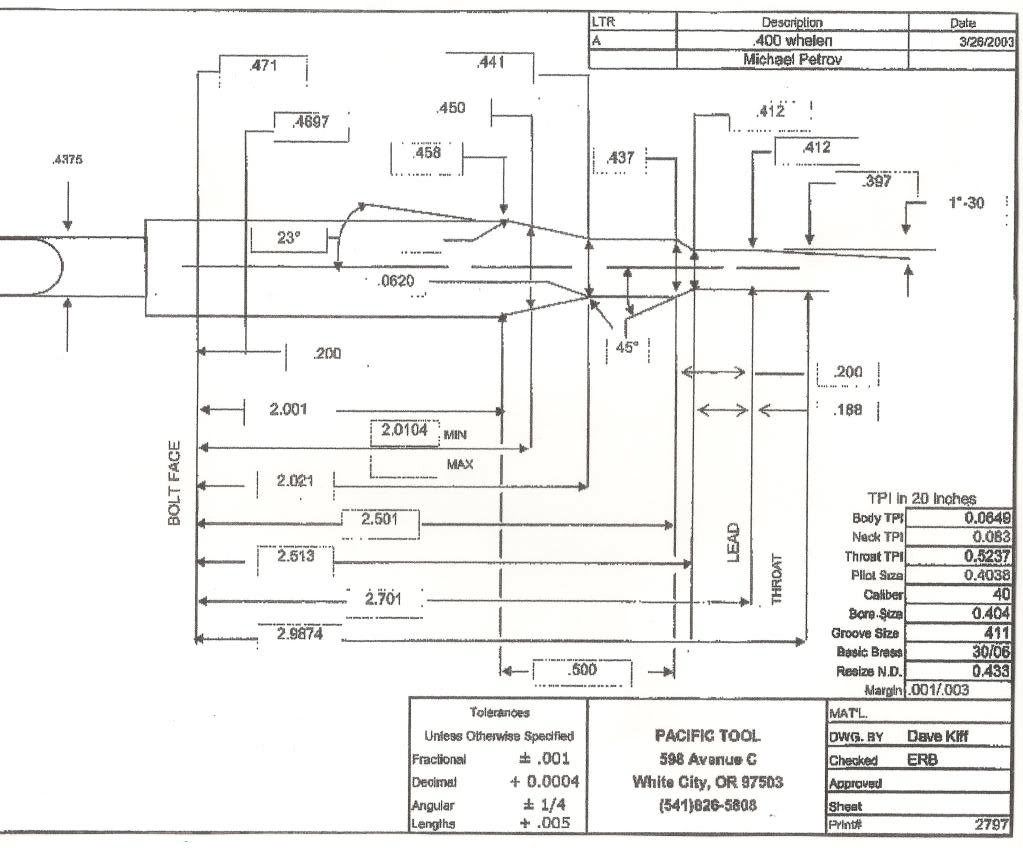

Paul, after sizing most of the "extra" brass is on the outside of the neck. There may be a slight amount inside the neck. Is it odd that the brass is thicker at the case mouth than it is towards the rear of the neck. A reverse taper if you will. I figured cylindrical brass should have a wall thickness that get thinner as you measure from the base to the case mouth, not all of a sudden get thicker for last 1/4" or so. The brass is brand new 400 Whelen cylindrical brass from QC. Wetibbe, 1. When the bullet is seated, WITHOUT a crimp or anything, the front of the neck(from the case mouth to the dark line) measures .439". The reamer print shows .437". Just behind the line and to the neck shoulder junction it measures .434"-.435" I'll post a pic of the reamer print below. The chamber neck tapers from .441" to .437". 2. I'm measuring with a micrometer and calipers. 3. Noted. What's the minimum amount of clearance I should have for the neck to release the bullet properly in the chamber. 4. Confirmed, bullets are .411". 5. Cases trimmed to 2.484". The crimp was just me playing with it. I've never used the built in crimping on a die. I've always used Lee factory crimp dies in the past. Saeed, I will check Sinclair's tools out. Thank you sir! THANK YOU for your responses!  Sent from my iPhone | |||

|

| one of us |

Crap I should have read closer. I was thinking the thicker part was closer to the shoulder. Guess I read what I wanted to read. I use cylinder brass and have never had that issue. I agree I think your bullet needs to be deeper when you crimp. A reamer requires a fired case. So as your brass is now you would need to turn the necks. Before my morning As usual just my $.02 Paul K | |||

|

| One of Us |

Thanks Paul. I did contact Quality Cartridge and they just told me that cylindrical brass is always thicker at the case and requires turning. I don't think the brass is right but I'll just live with it and turn the necks. Sent from my iPhone | |||

|

| one of us |

I guess it would be from the way they draw the brass. The case on the left is a Remington cylinder case. Middle I'm not sure any longer. The right is a Howell basic. You can for sure see the bottom of the 300 gr bullet but no build up of brass.  But neither say 400 Whelen. the Remington says 35 Whelen and the Howell says Howell Basic. As usual just my $.02 Paul K | |||

|

| One of Us |

Templar: Neck clearance: The big guy's, pros, say 0.003 inches is recommended. Some say 0.004. Some brave and adventurous bench rester's will use 0.001 - risk too high for me. Your circumstances: Dangerous. An interference fit. Case neck OD bigger than the chamber. Don't pull the trigger on those. Wiggle room: I suppose that if you are an incurable tinkerer like I am you can keep on messing with it and checking. * Make a cast of your chamber with Cerrosafe or some such. * Smoke a new case and chamber it. Look for scrub marks. * Load and crimp a round and chamber it to see if it will chamber. * Fire form a case with inert filler and check O.D. It should measure 0.001 inches less than your chamber. It will swell out to chamber size then shrink to 0.001 inches under that chamber size. There is more but it gets a bit trying. Facts of life are that various case manufacturers have different criteria, case thickness and metallurgy. In your example it does appear as though you got a lot of cases with highly questionable quality control. As you point out the neck is supposed to be tapered, the thinner at the neck end and thickening at the shoulder. Among the various options to remedy, there are several: * Measure every case neck for discrepancies. Check/ rotate to cross check if the 90% measurement is similar i.e. out of round/oval, or not. " Turn down the necks. *( There is a reason that there are so many tools available for that procedure !) * Contact Lee and see if they will special build a neck crimping die for your caliber. I think it was around $60 on top of the regular price. Phone their tech support and pick their brains. *( I find that "customer service" is generic, front, full of blather. However, tech support Guy's that I speak to often know their stuff. I am very impressed with their knowledge and expertise. Haven't had a bad one in a long time ). * Contact your case manufacturer and see if they will make restitution in some form for out of spec and unacceptable QA/QC. I can think of lots more to say but it gets too long winded. | |||

|

| One of Us |

What you're seeing is nothing more than the case sizer reducing the neck OD to a smaller diameter than the total diameter of the neck walls PLUS the OD of the bullet...ain't no thang ,Bro, it happens all the time when wildcatting AND actually in "normal" reloading MANY TIMES and that "oops" will "iron"/fill" out when the round is fired. It may happen every time you size, or not, depending on how close the neck sizing portion fits the ACTUAL OD of the sized case PLUS the bullet OD. One good reason to use bushing type sizers as you can fit the correct bushing so the case neck is sized only enough to hold the bullet firmly. I guarantee some of the wildcats I've built have MUCH worse bulges before finally getting everything to fit right. One thing I would suggest as part of your brass development procedures...Get a Sinclair Inc., catalogue, then order the cheapest Mod 1000 neck turner as already suggested(I also have the Forester hand held neck turner and a couple of other neck turners, and use them just as much and sometimes in combination) and the neck expander die, and the Case driver and #3 case holder, a #408 mandrel and a sizer button about 0.002 - 003" larger and the Sinclair or Hornady case comparator set. The larger button makes spinning the case much easier, and use Imperial Sizing Wax fir sizing, on the button and on the mandrel...AND a 1" mic and 6" dial caliper. These tools will help you build excellent, accurate ammo. You don't need them but I guarantee they will make the wildcatting AND standard case prep process easier more precise and safer. I use one or more or home made similar tools on a daily basis to develop ammo for wildcats AND standard caliber brass. Take your time as there is a learning and finalizing process. AS a matter of course I turn ALL MY BRASS...not more than 0.0005"(that 5 ten thousands, NOT 5 thousands) which means TWICE THAT 0.0005" OR 0.001"...that usually cleans up to ~75% which usually leaves about 0.0005" difference between the turned section and the unturned sections...but not ALWAYS...this ISN'T benchrest case fitting and is plenty good for this work.sd I turn case necks for UNIFORM BULLET RELEASE not to fit the chamber unless the chamber is "tight"...yours might be. I get the feeling you are fairly new to wildcatting and/or reloading so a visit to some of the small caliber forums might help as wildcatting is well developed on many of them and it might give you some more ideas and procedures to look at. There are also several excellent books on wildcatting...the 400 Whelan has been around a long time but you have to dig to get reliable info...and A.R. has many eager helpers readily available as you've already found out. All the basic procedures have been outlined already, and actually doing them takes less time than reading about it, and by doing an online/A.R. "case/wildcat prep" search a ton more info is available. Having the right tools helps and you can sell them in a NY second when you are through with them. Luck | |||

|

| One of Us |

Non: Great post. Thanks. However, he said his neck diameter exceeds his chamber diameter - mes pa? True ?? He will blow his gun to Kingdom come. I'm all ears and eager to learn so bring it on . | |||

|

| one of us |

Man I missed that one. Absolutely if the chamber is too tight to allow the case to chamber or even tight enough for no clearance the neck needs to be turned first. As usual just my $.02 Paul K | |||

|

| One of Us |

NON, I understand what your trying to say but the bulge is not caused by the seated bullet, in this case. That bullet is a 400gr Woodleigh and the base of it extends past the shoulder/neck junction. So this would not be the cause of the different neck diameters. The brass is simply thicker. But the bulge you describe can easily be seen in my 458 Lott rounds, 45-70 rounds, or any round with a long neck and short bullets. I do load for a few "amateur" wildcats: 6.5-06, 338-06, 338-06 AI, and 35 Whelen AI. Those are pretty easy to load for. No neck turning required. I wouldn't consider myself an expert reloader but I definately wouldn't say that I'm a novice. I've just never had a circumstance where I needed to turn case necks. I am currently looking at the Sinclair tool and the K&M tool. Anyone use the K&M? I do appreciate your recommendation for tools and equipment. I have a high quality set of micrometers and calipers that get re-certified bi-annually. Part of our ISO 9001 procedures. Wetibbe, I appreciate that you questioned my need to neck turn. I have gone out and blown money on uneccesary equipment in the past. Like the my Redding 6.5-06 form and trim die. Totally not needed, but it was my first wildcat and I thought I had to have it. Poor college kids must spend wisely... Sent from my iPhone | |||

|

one of us |

I use(d) to neck turn (Sinclair tools) all my rifle cases around 60-70 % of their circumference to even out neck thickness. One day, I ran comparison tests with un-,turned cases between several rifles of known accuracy and, guess what... I couldn't tell one group from an other ?!? Now this was done with sub-MOA hunting rifles but I wouldn't include tight custom match chambers or wildcat renecking, etc. in my conclusions. Just to add another grain of salt. Most everybody worries about neck thickening or case elongating... Would I surprise you by saying that, when your cases grow, brass is not only flowing to the neck, but rearwards also. After uniforming -i.e. bottoming out- my primer pockets to a same standard depth, I continued using the same little Sinclair too to clean out the primer pockets of deprimed cases. The day came when I was surprised that the Sinclair uniformer started cutting again in some cases : brass had flowed back in the primer pocket as well as toward the case neck, proof that case elongation happens in all directions ! André DRSS --------- 3 shots do not make a group, they show a point of aim or impact. 5 shots are a group. | |||

|

| One of Us |

He said his neck diameter is .002" larger than the chamber reamer neck specifications (presumably off the as built drawing), what are his actual chamber dimensions, suggest casting and measuring the chamber. | |||

|

| one of us |

To start with never use inside neck trimming unless your necking a case down, or dealing with bench rest no tolerance chambers. On such calibers as the 35 Whelen, and hunting chambers in general, as opposed to bench rest chambers, you should not outside or inside neck ream, but do trim to specs every reload but only then when necessary..Your over complicating the process, and creating problems... I out side neck ream my 6x45 as it has a bench rest chamber and I can actually get away with out resizeing the case, but I do resize it but its almost to little to measure and I must outside neck ream all cases formed from 223 cases to begin with or they will not even chamber.. If I were to neck a 30-06 case down to a 25-06 or a 308 to a 243 for instance, I would then inside neck ream to remove the edge formed from that process at the inside junction or the neck and shoulder, and you can feel that projection with a dental tool or ice pick. I know some folks inside neck ream all ammo for their factory guns..all they get is loose bullets and failed accuracy, and short brass life because you created a situation wherein your brass is overworked (over expanded)with each firing. Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Ray, I appreciate the post, but you missed the part where my 400 whelen brass with bullet seated has a neck diameter of .439 while my chamber has a neck diameter of .437. The cartridge will not fit in the chamber without neck turning. Now if I were to neck up 35 Whelen brass, all would be well. But I wanted some brass with the 400 Whelen head stamp. Sent from my iPhone | |||

|

| One of Us |

Templar, This is easy to figure out, take an unfired case and load it with 15gr of Bullseye or other fast pistol/shotgun powder and twist up about a quarter sheet of toilet/tissue paper and poke it into the case mouth with a pencil or similar quite firmly and fire it, then measure it and find your ACTUAL chamber dimensions. I have had to do this several times with differing wildcats I shoot, the most memorable being my 375 Weatherby, the chamber headspace is below SAAMI spec for the shoulder, not the belt and was difficult to diagnose. This will give you all the dimensions you need, even though the shoulder MAY not fireform 100%, the neck most certainly will. Hope this helps. Cheers. | |||

|

| One of Us |

The brass is too thick. QC has an explanation that doesn't make much sense, but that is the way it is. All of this was discussed in the 400 Whelen thread, if you can find it. I bought 300 rounds from Qc for myself and RIP. After turning 20 pcs. by hand, I sent the rest back for rework. When they finally came back, the neck was thinner but not perfect. They were usable but the cosmetics were slightly off. You will need a turner that will accommodate the diameter. I had to make a pilot to fit the 400. With some type of power attachment it won't wear you out, and you only have to do it once. Rusty (You can't fix stupid) Falls of Rough Ky University Our victory cry is FORK U! | |||

|

| one of us |

Templar, I understand what your saying, and your not wrong, but I do not understand why you would want such a tight chamber in a hunting rifle, especially a larger bore such as the 35 or 400 Whelen..Just my take as if it were mine, I would opt for more neck thickness, longer brass life, and put feed and function above accuracy within reason...I never use bench rest chambers on hunting rifles. Judging from your photograph, I would suggest you use a different or larger neck reamer an level that neck out to specs. Somethings haywire! Ray Atkinson Atkinson Hunting Adventures 10 Ward Lane, Filer, Idaho, 83328 208-731-4120 rayatkinsonhunting@gmail.com | |||

|

| One of Us |

Ray, I'll have to defer to someone more knowledgeable than I to say wether or not it is a tight chamber. You are correct and I absolutely agree that a tight chamber has no place for a big bore hunting rifle. I'll take a 4" group and 100% reliability over an unreliable sub-moa rifle anyday. I think it is just simply an issue with the Quality Cartridge brass. I made a couple of cases with the Howell Basic brass, no issues. I necked up 35 Whelen brass, no issues. Simply, if I want to have brass with the 400 Whelen head stamp, I will have to turn the necks. Unless we petition quality cartridge to make the brass "correctly". I talked to them again and I was told the neck area is left thick on purpose so you can use it for everything from 243 and up.(???). And you won't have a neck that is too thin if you neck it up. Has anyone ever necked up basic brass???? I think it's just a bogus excuse. Makes no sense to leave a 3/8" long doughnut at the case mouth. Sent from my iPhone | |||

|

| one of us |

I'm sorry I've taken Norma 280 Rem brass and necked it up to .416. Yes had to go slow and annealed along the way. No big issue just took time. Why would you want thicker neck even you necked down. The neck already gets thicker. I have to cry  As usual just my $.02 Paul K | |||

|

| one of us |

And they call themselves Quality Cartridge. Ha! | |||

|

| Powered by Social Strata |

| Please Wait. Your request is being processed... |

|

Visit our on-line store for AR Memorabilia